玻璃纖維針刺濾料耐高溫性能研究

趙振興 汪黎明

(青島大學 紡織學院,山東 青島266071)

0 Introduction

Glass fiber(GF)is a kind of inorganic fiber.It is one of the most high temperature resistant fibers,whose using temperature is 260℃ ~280℃.The main characteristics of glass fiber has a smooth surface and filtering less resistance,which is beneficial to dust off.In addition,the price of glass fibers are very cheap,and sources of materials extensive.Considering its excellent physical,chemical,the filtration performance and cost factors,glass fiber is the ideal filter material.

The more fine the diameter of glass fiber,the smaller the bending radius of the fracture,the more difficult to break,so the diameter of the glass fiber as fine as possible.In addition,the brittleness of glass fiber itself still not allowed to ignore.Usually,glass fiber and other high temperature resistant fibers(Kermel,P84,Aramid fiber,etc.)to make needled filter material,not only satisfied the requirement of filtering fine dust,can also be integrated fibers their advantages,improved the service life of composite filter material.It is a great development potential of the new type of filtration material[1-2].This experiment adopts Yilun,Aramid fiber and three different diameter of glass fibers to make composite filter material in the same fiber mixing ratio to test.

1 Experimental

1.1 Material preparation

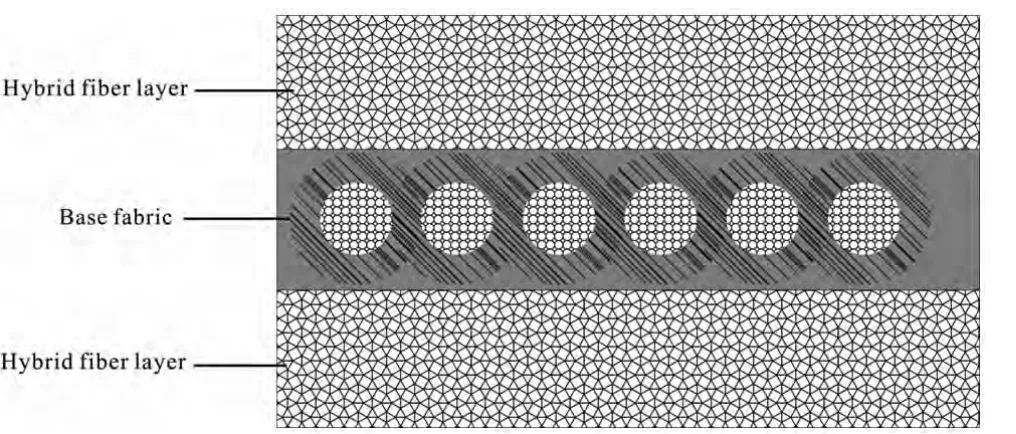

The Yilun is a polyimide fiber produced by Changchun HiPolyKing Co.,Ltd.,which is the first domestic industrialized production of polyimide fiber.It has many aspects of good performance,such as excellent thermal stability and electrical insulation,radiation resistance,chemical resistance and so on.Its limit oxygen index>38%can be applied in harsh environment of high temperature[3].Aramid fiber(PMIA)is the earliest development of high temperature resistant fiber in the world.It has good flame resistance,limit oxygen index of 29%and better high temperature resistant performance,so it is an ideal material to high temperature filtration used[4].According to certain proportion,Yilun ,Aramid fiber and glass fiber are mixed as surface and glass fiber fabric as base cloth,then composite filter material can be made through needle punching technology in this experiment.It can be seen from the Fig.1 that the glass fiber composite filter material structure has three layers.

Fig.1 Glass fiber composite filter material structure diagram

The composite filter materials used in the following table∶

Tab.1 Test sample listings

1.2 High temperature resistant performance test

1.2.1 Mechanical properties

Filter material of heat-resisting breaking force is defined as the filter material placed under a specific temperature after a certain period of time(usually 24h)in warp and weft of breaking force and elongation at break[5].The force of filter material is characterized by breaking force,the greater the value,the longer the service life of filter bag.Elongation at break,characterization of filter material tension toughness and elasticity, this value too big or too small will have an impact on the use of filter bag.It should not have too big change in the actual process of using of filter bag.Breaking force of the filter material depends on the force of the base fabric and needle-punched fiber,as well as the process parameters in the manufacturing process of filter material,such as needling density, needling force,post-processing,etc[6].

The change of filter material mechanical properties can be characterized by breaking strength retention and breaking elongation rate,de-fined as the filter material of breaking force and elongation at break after the test divided by breaking force and elongation at break before the test, respectively.

The test standard is GB/T 7689.5 2001 Reinforcements-Test method for woven fabrics Part 5∶Determination of tensile breaking force and elongation at break for glass fiber.According to this standard,breaking force F0and elongation at break E0in warp and weft can be tested for the original sample.The other samples were placed the high temperature oven by 160℃,200℃,240℃and 280℃for 24h,tested breaking force Fiand elongation at break Eiafter being cooled.

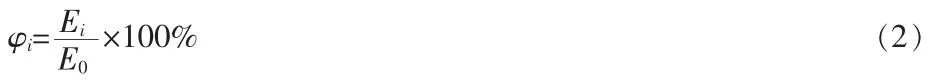

According to the equation to calculate breaking strength retention λi∶

F0is the initial breaking force of flter material.Fiis the breaking force after high temperature treatment,i equal to 160℃,200℃,240℃and 280℃.

According to the equation to calculate breaking elongation rate φi∶

E0is the initial elongation at break of flter material.Eiis the elongation at break after high temperature treatment,i equal to 160℃,200℃,240℃and 280℃.

1.2.2 Permeability

Permeability is the performance of the air through the fabric,use vertical airflow through the sample speed to characterize in the prescribed test area,pressure drop and time conditions.The permeabilities of filter material are different due to the structure of filter material and the size of the density,which is an indicator on drag force characteristics of clean filter material[7].

Three samples placed in the oven,respectively,by 160℃,200℃, 240℃and 280℃high temperature treatment for 24 h,then removed the sample under standard atmospheric conditions for 24 h.According to the standard of GB/T 5453-1997 textiles-determination of the permeability of fabrics to air to test[8].

2 Results and discussion

2.1 The influence of high temperature on the filter material mechanics performance

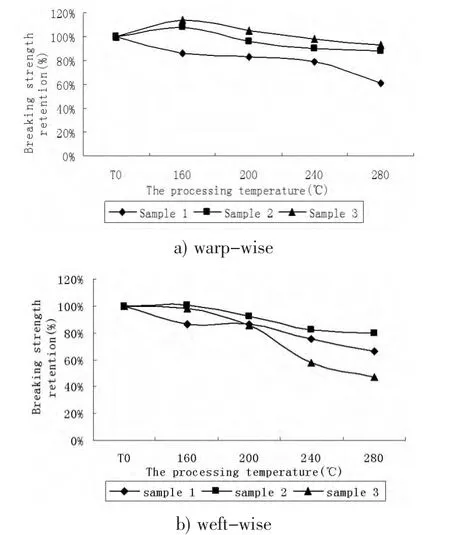

The choice of the test temperature with reference to filter material the range of temperature in practical work,respectively is 160℃,200℃, 200℃ and 280℃.Fig.2 is the changes of the filter material mechanical properties under the different processing temperatures,of which T0 representative at room temperature(23℃)test.

Fig.2 The influence of different processing temperatures on breaking strength retention of filter material

The Fig.2 shows that with the increase of processing temperatures, the warp-wise breaking force of sample 1 is on the decline,in 240℃drop quickly,breaking strength retention by 280℃treatment was 61.25%.Sample 2 at different temperatures treatment for 24 h,warp-wise breaking force has the rising slightly and then downward trend,the breaking strength retention kept as high as 87.73%by 280℃treatment.The warpwise breaking force change trend of sample 3 as well as sample 2,compared with sample 2 fall more slowly,by 280℃for 24 h the breaking strength remained at 93.06%.This suggests that the finer diameter of glass fiber,the better breaking strength retention.

With the change of different processing temperatures,three samples of weft-wise breaking force is falling.The change of sample 1 and sample 2 is moderate.Sample 3 by 280℃treatment weft-wise breaking force stay at a rate of 47.09%,have a bigger change.Compared with warp-wise breaking strength retention,three samples weft-wise strength retention rate of change is bigger.The difference show that in the process of needling in weft great damage to the fiber,the strength of entanglement between fiber declined.Therefore,it is very essential to optimize the production process.

Fig.3 The influence of different processing temperatures on breaking elongation rate of filter material

Fig.3 reflects sample 1 and sample 2 of warp-wise elongation at break were appeared drop and rise and fall trend along with the change of processing temperatures.Elongation at break of sample 3 is gently downward trend,elongation at break by 280℃ treatment remained at 84.83%.Sample 1 and sample 2 of weft-wise breaking elongation rate change is smooth,sample 3 of weft-wise breaking elongation rate lead in slow decline,by 200℃for 24 h falling faster.This change with the impact of the needling process has a certain relationship.

2.2 The influence of high temperature on the filter material permeability

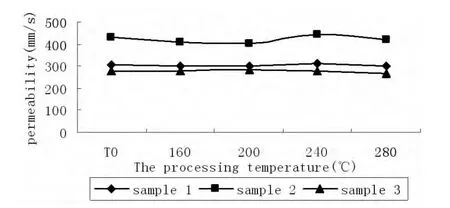

Fig.4 The influence of different processing temperatures on the filter material permeability

Fig.4 shows that three samples permeabilities are not too big change by 160℃,200℃,240℃and 280℃high temperature treatment for 24 h.Their permeabilities are within the scope stipulated by the deviation[9].Three different diameter of glass fibers used in different samples,the main components of sample 3 is 4 microns in diameter glass fiber,the figure shows that its permeability is relatively low,but has reached the filter material permeability standard stipulated by the country[10],which demonstrates higher filtering precision of finer glass fiber composite filter material,less affected by temperature.

3 Conclusions

(1)Three kinds of composite made of different diameter of glass fiber filter material warp-wise breaking force have varying degrees of decline by 160℃,200℃,240℃and 280℃high temperature treatment for 24 h.Breaking force of 4 microns in diameter glass fiber composite filter material has good retention in warp,the warp-wise breaking force remained at 93.06%by 280℃for 24 h.

(2)Compared with warp-wise breaking strength retention,three samples weft-wise strength retention rate of change is obvious,because of the process of needle-punching for weft-wise fiber damage is bigger.

(3)Three kinds of glass fiber composite filter material permeability are no obvious fluctuation by high temperature treatment,which suggests that the influence of the processing temperature on filter material permeability is lesser and to ensure that the filter material under the condition of high temperature to maintain good filtering effect.

[1]Wu Xiaomei,Zhao Dongbo.Development of Needled Fiberglass Mat for Filtration [J].Journal of Glass Fiber,2009(3)∶1-3.

[2]Zhu Ping.research on Multilayer fiberglass combination mat by needle bonding [J].Journal of Glass Fiber,2006(3)∶1-7.

[3]Yang Junjie.Sun Fei.Zhang Guohui.Pang Yuanyuan.Ding Mengxian.Yang Cheng.The properties and applications of Yilun polyimide short fiber[J].Hi-Tech Fiber&Application,2012,37(3)∶57-60.

[4]Lin Yuanzhang.Zhu Juanchao.Kurt Wyss.Wang Qiqi.Meta-aramid fiber and its application in the field of high temperature filtration[C]//National Symposium on Baghouse Dust Removing Technique,2007-2009(14)∶415-421.

[5]Sun Xi.Technology and application of bag filter[M].Beijing∶China Machine Press,2004.

[6]Liu Jingxian.Mao Ning.Chang Deqiang.Lei Pengcan.Sun Xi.The influence of temperature on the PPS needled felt filter material research [C]//2008(Shenyang) International Academic Symposium on Safety Science and Technology.2008∶317-321.

[7]Chen Longshu.Tao Hui.baghouse dust removing technique handbook[M].Beijing∶China Machine Press,2010.

[8]China textile science and technology development.GB/T 5453-1997 Textilesdetermination of the permeability of fabrics to air[S].Beijing∶China Standards Press, 1997.

[9]State administration of production safety supervision and management.GB/T 6719-2009 The bag filter technical requirements [S].Beijing∶China Standards Press,2009.

[10]China building materials association.GB/T 25041-2010 Glass fiber filter material[S].Beijing∶China Standards Press,2010.