馬里尼奇橋,什科茨揚溶洞公園,斯洛文尼亞

工程設計:維克托·馬爾凱利,羅克·姆拉卡爾/龐廷工程顧問有限公司Engineers:Viktor Markelj,Rok Mlakar/Ponting Ltd.

?

馬里尼奇橋,什科茨揚溶洞公園,斯洛文尼亞

Marini? Bridge,?kocjan Caves Park,Slovenia,2010

工程設計:維克托·馬爾凱利,羅克·姆拉卡爾/龐廷工程顧問有限公司Engineers:Viktor Markelj,Rok Mlakar/Ponting Ltd.

1 峽谷中的步行橋/the Marini? bridge across the gorge

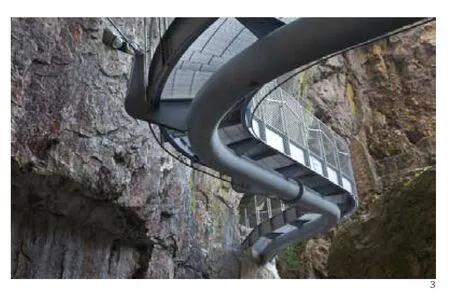

2.3從下往上看橋底/Upward views

在什科茨揚溶洞公園的西部有一座著名的步行橋。在原先的橋梁被一次毀滅性的洪水沖垮后,這座新的構筑物延續了舊橋的功能,連接了兩處高差為4.5m的懸崖,在瑞卡大峽谷上架設了一條安全的通路。設計的任務一方面是要解決如何在敏感的自然環境中加入一個輕質結構的問題,另一方面也探討了這個空中步道如何能夠吸引游客,并給人們帶來生動有趣的體驗。

這座步行橋被設計成一個曲線形的、纖細而近乎透明的鋼結構:一個30m長的筒形主梁支撐著數個橫向的肋和方格網構成的甲板。該構造的結構設計和形態都契合了場地獨特而苛刻的要求和限制:通過彎曲橋身貼近巖壁,該橋避免了落石的侵擾;通過巖石錨固的支撐方式,橋梁具有了穩固的結構。步行橋的輕盈性和有機的形態都極好地融入了周圍脆弱的自然環境,安靜謙虛地伏在聯合國教科文組織的保護遺產之下。

橋梁的主要承重結構是一條457.1mm/20mm的鋼質筒形梁,該梁由三段預制的節段組成,通過圓形鋼板和預應力螺栓連接起來。在主梁上,每隔2.25m安裝一條T型鋼質橫梁:這些橫梁由10~25mm厚的鋼板制成,直接焊接在主梁上,支撐著橋面甲板。在縱向上,橫梁被400mm/10mm的鋼箍帶連接起來,從而增強整個橋梁的強度,為橋面方格構架提供支撐,鋼箍帶也扮演了邊梁的角色。

橋梁的承重結構都由S355結構鋼制成,而橋面、欄桿和其他構件則由不銹鋼預制而成。支撐節點包括兩端錨固在巖石中的錨點和兩條附加的M28彈性拉桿。拉桿一端鉸接在特制的加強橫梁上,另一端通過13m深的耐久預應力地錨鉸接錨固在南側的巖壁上,順著拉桿的形態深入堅固的巖石中。南側巖壁上的錨固工程是由專業的攀巖者完成的。

整個橋梁包含三段獨立的結構,每段重約3.5t,都在工房中通過了力學測試。這些節段在建造時被運送到溶洞上方的高地上,并從那里被移動吊車吊裝下降107m,進入了預定的位置。(張裕翔 譯)

項目信息/Credits and Data

長度/Length:30.0m

跨距/Span:27.0m

高差/Height Difference:4.50m

寬度及凈寬/Width and Clear Width:1.50m,1.25m扶手高度/Railings Height:1.10~1.38m

甲板面積/Deck Area:45m2

結構重量/Structure Weight:11,300kg

總造價/Overall Cost:€298,800

攝影/Photos:Ponting Ltd.

評論

王向榮:馬里尼奇橋順應復雜的地貌,曲折蜿蜒在巖石峭壁之間,跨越在險峻的峽谷之上,引導游客進入洞穴。橋梁采用工業材料,與自然山體形成對比與反差,但輕型的結構和通透的形體又弱化了橋梁的體量,使得橋梁完全能被自然峽谷環境所接納。步行在橋梁之上如同一次探險,這強化了峽谷的險峻和山洞的深邃。

Comments

WANG Xiangrong:Winding through rocks and cliffs and spanning over steep gorges,Marinic Bridge is constructed along complex landforms to lead visitors into a cave.Industrial materials stand in stark contrast to nature hills,but light structures and transparent shapes which reduce bridge weight merge in the natural environment of the gorges.The adventurous walking on the bridge adds unusual experience to the gorges.

竇平平:馬里尼奇橋的價值遠遠超過了從一點到另一點的連接作用。它創造了置身于溝壑峽谷之中的難得機會,并將這一段穿越抵達的經歷變得驚險刺激。橋身的曲線應對和呼應了洞穴形態的天然野性。沿著這蜿蜒又纖細的步道行走,人們得以體驗峽谷雕塑般的側影變幻。這個奇妙又大膽的構想因結構設計的巧妙而得以實現,我們看到步行橋與粗獷又清脆的周邊環境細膩地融合在一起。粗壯的管狀梁置于半透明的鋼格網橋面之下,營造了一種事實上非常平滑和安全,但感受上扣人心弦的行走經歷,如同走在獨木橋上一般。僅有的兩個拉桿將建造對巖石的損害降至最低,同時也增加了這個自然環境中的人工物的輕盈感。

DOU Pingping:Marinic bridge offers much more than just a connection from A to B.It creates an unparalleled opportunity for being inside the gulley gorges and turns traversing into an exhilarating,breath-taking experience.The curvy line of the bridge reflects and echoes the wildness of the cave.Maneuvering carefully along the sinuous and slender walkway,one perceives the sculptural silhouette changes.Marrying bold whimsy to ingenious structural design,the bridge integrates sensitively with the rough yet crisp surroundings.By putting the strong tubular beam underneath the translucent decking,it creates a smooth and safe,yet perceptually thrilling experience that is similar to walking on a single-plank bridge.The only two tie bars minimize construction damage to the rocks,while at the same time contributing to the lightness of the artificial work in the natural environment.

A new bridge has been realized in the eastern part of ?kocjan Caves Park,replacing the old structures destroyed by a devastating flood and overtaking a 4.50m height difference between the extremities,in order to assure a safe passage over the wild Reka River Gorge.The aim was to conceive a lightweight structure to fit into the sensitive natural gorge environment and in the meantime to provide visitors an attractive walkway,offering a vivid cave experience.

The bridge has been designed as a curved,slender and almost transparent steel structure:a 30m long sinuous tubular beam supports several transversal ribs and a grid decking.The structural design and the shape of the bridge meet the peculiar conditions given by the characteristic natural environment:thanks to its curvature towards the cave entrance,the path avoids falling debris and thanks to the rock-anchoring stable support conditions are provided.Its lightness and organic shape suits well with the fragile natural environment,laying under the UNESCO protection.

The main bearing structure is a steel tube 457.1mm/20mm,consisting of three separate manufactured sections,connected over round steel plates and pre-stressed bolts.T-shaped steel cross-beams are positioned every 2.25m:they are made of 10~25mm thick plates,directly welded onto the main tube,supporting the bridge deck.The cross-beams are longitudinally connected via 400mm/10mm steel band,which increases the overall bridge rigidity,supports the bridge deck lattice and serves as outer beam.

Bridge bearing structure is made of structural steel S355,while bridge deck,railings and other equipment are manufactured of prefabricated stainless steel elements

The bridge is supported by both end anchors fixed into the ground rock and by two additional elastic M 28 tie bars assuring overall bridge stability.The tie bars are hinge-connected to the bridge over specially designed and strengthened cross beams and hinge-anchored into the south cave wall by two permanent,prestressed,13.0m deep,ground anchors,following the tie bar geometry into the firm rock wall.The anchoring works in the south rock wall have been performed by professional climbers.

The structure consisted of three separate sections weighting up to 3.5t each,and it was checked and test-mounted in the workshop.It was transported separately together to the plateau just over the bridge location and then and placed into its final position,107m beneath,using a mobile crane.