弧形齒滾扎式殘膜回收機的設計及參數優化

謝建華,張鳳賢,陳學庚,韓英杰,唐 煒

?

弧形齒滾扎式殘膜回收機的設計及參數優化

謝建華1,張鳳賢1,陳學庚2※,韓英杰1,唐 煒1

(1. 新疆農業大學機電工程學院,烏魯木齊 830052; 2. 石河子大學機械電氣工程學院,石河子 832000)

針對現有殘膜回收機具存在殘膜撿拾機構復雜、可靠性差、邊膜回收率及卸膜率低等問題,從工作部件受力、撿拾機構運動軌跡的角度對起膜鏟、殘膜撿拾機構、卸膜機構等關鍵部件進行了研究,設計了一種弧形齒滾扎式殘膜回收機。為探明拾膜釘齒扎膜過程中釘齒、地膜和土壤的形變、受力情況,從而指導機具的設計,運用ANSYS軟件對弧形齒滾扎式撿拾機構撿拾地膜過程進行非線性有限元動力學仿真分析,仿真結果顯示:在撿拾地膜過程中,釘齒末端變形最大,根部應力最大;地膜最大變形發生在與釘齒末端接觸位置;土壤受到釘齒擾動變形量小。運用Box-Benhnken的中心組合方法,以機具行進速度、邊膜鏟鏟翼與鏟柄夾角、釘齒入土深度為試驗因素,起邊膜率、殘膜撿拾率、卸膜率為試驗指標,進行三因素三水平二次回歸試驗,建立了響應面回歸模型,分析了各因素對試驗指標的顯著性并對因素進行了綜合優化。確定最優試驗參數為:機具行進速度為4.0 km/h、邊膜鏟鏟翼與鏟柄夾角為90°和釘齒入土深度為55 mm。在該條件下進行田間試驗,得到起邊膜率為93.5%、殘膜撿拾率為87.4%、卸膜率為87.1%,與優化理論值相對誤差均小于4個百分點,研究結果為殘膜回收機具結構設計及工作參數選擇提供理論基礎和技術參考。

機械化;設計;優化;拾膜機構;卸膜機構;仿真分析;響應面試驗

0 引 言

地膜覆蓋技術的應用給中國的農業生產帶來了可觀的經濟效益,同時也帶來了一系列的污染問題[1-4]。由于殘膜回收不徹底導致土壤滲透性差,常年的積累使土壤結構遭到破壞,嚴重影響中國農業經濟的可持續發展[5-7]。為解決地膜污染問題,中國農機研究人員研制了多種殘膜回收機具,包括釘齒式、伸縮桿齒式、夾持式、彈齒式等幾十種[8-10],但普遍存在結構復雜、可靠性差以及殘膜回收率低等系列問題[11-13]。2015年前,中國多數地區農業種植使用厚度不超過0.008 mm的聚乙烯地膜,由于地膜覆膜種植年限長,且回收率低等系列問題,大量的殘膜滯留在土壤耕作層內,總量已達440.85 kg/hm2,其中,掩埋于地表以下的邊膜占所鋪設地膜比例達到7%~16%[14]。邊膜與土壤發生板結黏連,回收時易與地表膜撕裂,導致邊膜回收困難[15]。為解決邊膜撿拾及脫卸問題,國內研究者分別對其回收機構進行了研究。康建明等[16]針對邊膜存在的問題,設計了一種起膜鏟,并進行了起膜鏟起膜機理的試驗分析,但存在邊膜漏撿,膜、土分離差等問題。馬少輝等[17]研制了一種結合后續其他機構回收殘膜的邊膜回收機,當機具作業農田土壤含水率過大時,土壤與邊膜黏連,膜、土難以分離,導致卷膜輥易漏撿,邊膜回收率低等問題。李辰等[18]設計了一種鏈齒式耕層殘膜回收機,對機具撿拾機構進行了設計,主要存在殘膜撿拾彈齒刮帶地膜,卸膜困難,同時回收后的膜、土分離差等問題。王旭峰等[19]設計了一種包含起膜拋送、鏈齒輸送、自動脫膜的拋膜鏈齒輸送式殘膜回收機,主要針對目前起膜裝置出現的殘膜纏繞工作部件、卸膜難等問題進行分析,該機具存在殘膜含雜率高,回收率低等問題。

將掩埋于板結土壤下的邊膜起出,翻至地表,利用撿拾機構回收邊膜是提高殘膜撿拾率的有效途徑。目前殘膜回收機具的研究主要集中在地表膜撿拾方面,對邊膜撿拾和卸膜部分的研究存在不足[20]。如何破碎板結土壤實現膜、土分離,起出邊膜并將撿拾的地膜完全卸入膜箱是繼續提高殘膜回收率的主要途徑。針對以上問題,本團隊設計了一種弧形齒滾扎式殘膜回收機[21],通過分析起邊膜裝置、殘膜撿拾機構、卸膜機構的功能及結構要求,確定各部分結構參數;借助響應面試驗分析機具工作參數對起邊膜率、殘膜撿拾率、卸膜率的影響;建立回歸方程,求取最優因素組合,為提高弧形齒滾扎式殘膜回收機的殘膜最終回收率奠定理論和試驗基礎[22]。

1 機具整體結構及工作原理

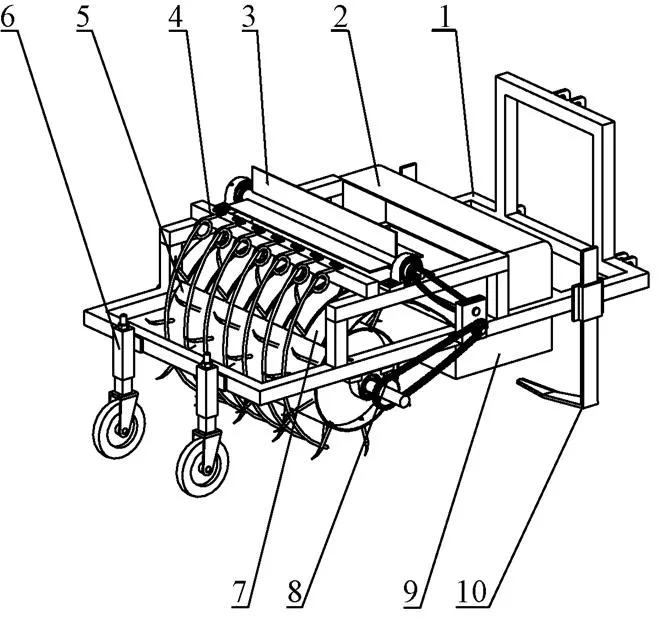

如圖1所示,弧形齒滾扎式殘膜回收機主要由機架、邊膜鏟、傳動系統、弧形齒滾扎式撿拾機構、卸膜機構、集膜箱等組成。弧形齒滾扎式殘膜回收機工作時由拖拉機牽引機具,在前進過程中,邊膜鏟與板結土壤接觸擠壓破碎板結土壤,同時將邊膜起出,后部的弧形齒滾扎式殘膜撿拾機構將中間地表膜與邊膜一起扎起。未被扎起的殘膜被摟膜彈齒摟起,再次被旋轉的釘齒扎起。隨著滾筒的滾動,釘齒帶著殘膜經過卸膜導板,殘膜與卸膜導板摩擦接觸刮掉地膜。刮板式脫膜輥轉動,進而將堆積在卸膜導板上的地膜刮入集膜箱,完成殘膜回收。

1.機架 2.集膜箱擋風罩 3.刮板式脫膜輥 4.摟膜彈齒 5.拾膜機構 6.限深輪 7.卸膜導板 8.鏈輪 9.集膜箱 10.邊膜鏟

1.Frame 2.Windshield of collecting film box 3.Scraper type stripping roller 4.Vibrator tooth for film picking 5.Pick-up residual film mechanism 6.Depth wheel 7.Unloading film guide plate 8.Sprocket 9.Collecting film box 10.Edge film shovel

圖1 弧形齒滾扎式殘膜回收機結構示意圖

Fig.1 Structure diagram of arc tooth and rolling bundle type plastic film residue collector

2 關鍵部件設計

2.1 邊膜鏟的設計

由于邊膜掩埋于板結土壤下,回收時易與地表膜撕裂,導致邊膜回收困難[23]。對比圓盤、開溝器、雙翼鏟的碎土、起膜效果發現雙翼鏟碎土作業效果最佳,但是其對邊膜抬升和起出效果不理想。因此,根據雙翼鏟的結構改進設計出了邊膜鏟,邊膜鏟的結構及受力如圖2所示。為了破碎邊膜位置的板結土壤,減少邊膜的破損并完整的起出邊膜,同時考慮減少膜下土壤擾動,減小土壤阻力,避免將土壤翻耕到地膜上,翻起的地膜由鏟翼前端將邊膜抬升一定角度以便撿拾機構回收邊膜。所以,邊膜鏟鏟翼與鏟柄夾角及鏟翼與水平面夾角的選擇尤為重要。

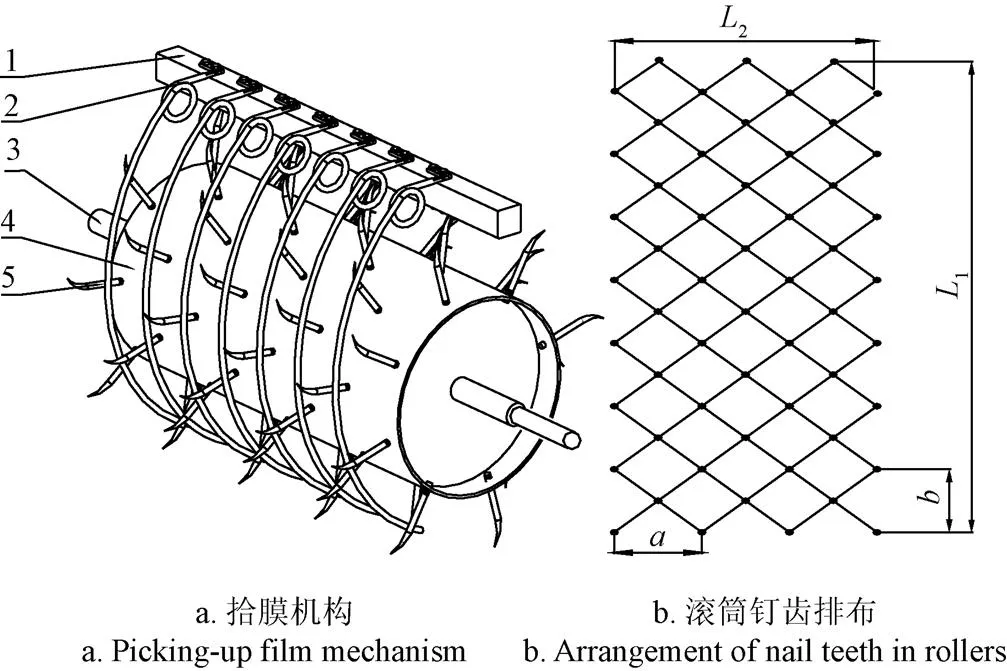

邊膜鏟水平方向(前進方向)平衡方程為

式中為土壤摩擦系數,取值為0.21

1.鏟柄 2 鏟翼 3.鏟尖

1.Shovel handle 2.Shovel wing 3.Shovel tip

注:為邊膜鏟受到的拉力,N;01為邊膜鏟鏟翼和鏟尖上表面受到土壤的正壓力,N;為邊膜鏟鏟翼切土阻力(=,N;為邊膜鏟鏟翼的刃寬,mm;為單位刃寬上的刃切阻力,N;0、1為土壤與邊膜鏟鏟翼的摩擦力,N;為鏟翼與鏟柄夾角,(°);為鏟翼與水平面夾角,(°);為鏟尖與水平面夾角,(°);為鏟翼后傾角,(°)。

Note:is the pull force on edge film shovel, N;0and1are the positive pressures of the soil on the wing and upper surface of the tip of the edge film shovel, N;is the blade cutting resistance of the edge film shovel wine (,N;is the wing width of edge film shovel, mm;is the cutting resistance on unit blade width, N;01are the frictions between soil and edge film shovel wing, N;is the angle between the shovel wing and the shovel handle, (°);is the angle between shovel wing and the ground, (°);is the angle between shovel tip and horizontal plane, (°);is the caster angle of the shovel wine, (°).

圖2 邊膜鏟結構及受力分析

Fig.2 Structure and force analysis of edge film shovel

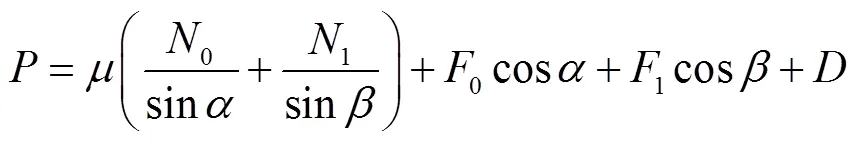

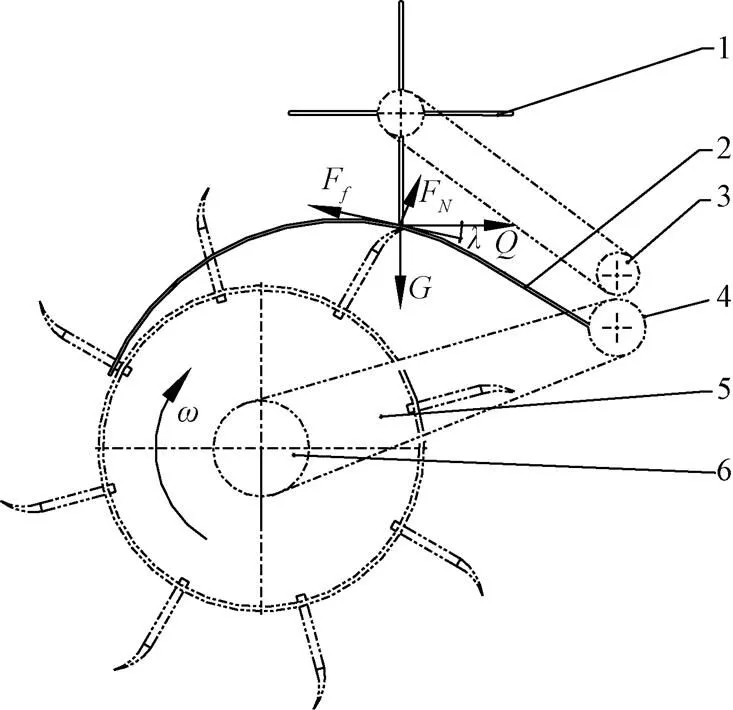

2.2 弧形齒滾扎式拾膜機構的設計

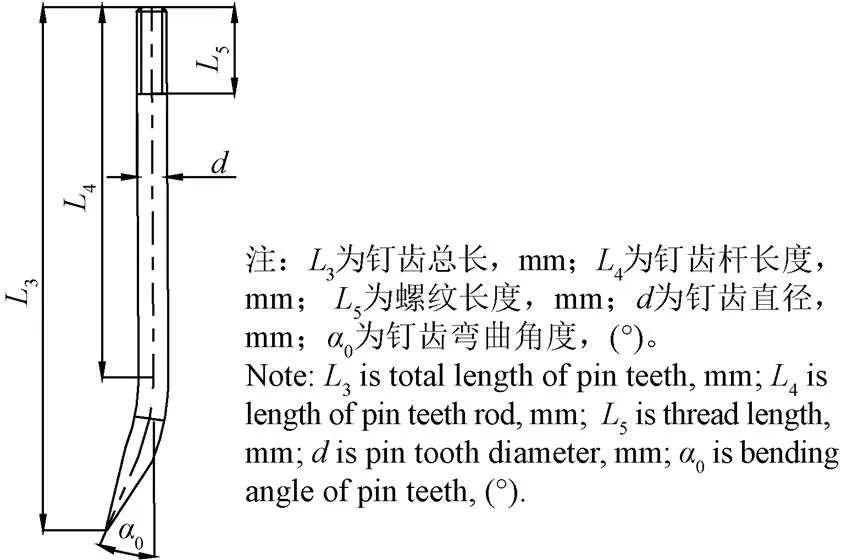

拾膜機構是機具關鍵部件之一[24-25],該機構的可靠性和作業效果決定了機具工作的性能。為了解決地頭地膜被板結土壤覆蓋導致釘齒無法自動上膜和拾膜釘齒作業過程中漏撿問題,在拾膜滾筒外后側增加一排彈齒,構成弧形齒滾扎式拾膜機構,其結構如圖3a所示,主要由主軸、滾筒、釘齒、摟膜彈齒等組成。拾膜滾筒運動一周工作面積為1×2,相鄰兩釘齒橫向距離為,縱向距離為,釘齒排布如圖3b所示[26]。根據新疆白蘿卜種植模式和避免機具總體質量過大,同時考慮避免機具漏撿殘膜等因素,機具作業幅寬為800 mm,滾筒半徑為350 mm,釘齒采用交錯法排列于滾筒上。由于撿拾殘膜采用扎膜方式,同時考慮減小釘齒入土阻力,對比圓頭直桿齒、尖頭直桿齒和帶弧度尖頭齒,選用帶有彎度的尖頭釘齒,具體結構如圖4所示。并且,為了方便更換釘齒,將釘齒根部做成螺紋,安裝于焊接在滾筒上的螺母內。

圖4中釘齒總長3取值為137mm,釘齒桿長度4取值為90mm,螺紋長度5為25mm,釘齒直徑取值為16mm,釘齒彎曲角度o取值為10°。

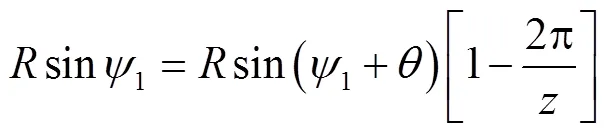

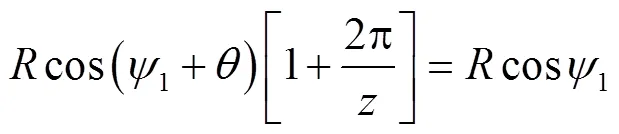

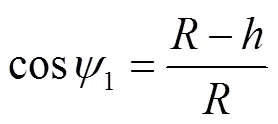

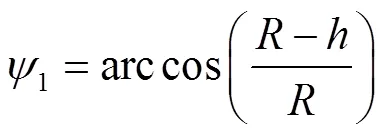

拖拉機帶動機具工作時,撿拾滾筒與土壤相互作用產生自身的圓周運動。釘齒撿拾地膜過程可以分為扎膜和挑膜過程,釘齒隨滾筒轉動深入土壤撿拾地膜,釘齒入土過程中主要承受土壤的阻力,拾膜機構的運動速度影響機具的拾膜效果。當釘齒入土速度過快時,沖擊力較大,釘齒容易發生變形,同時由于殘地膜力學性能下降,釘齒運動過快會將地膜貫穿撕成條狀,導致殘膜無法撿拾;當拾膜釘齒入土速度較慢時,地膜無法被釘齒挑起,導致殘膜漏撿嚴重。為確定滾筒上釘齒較為合理的布置參數,同時探明釘齒的運動規律避免釘齒對地膜的二次損傷,提高殘膜撿拾率,對釘齒拾膜過程進行分析[27-28]。弧形齒滾扎式殘膜撿拾機構在拾膜過程中釘齒滾筒與地面的相對運動可以看作齒條與齒輪的嚙合運動[29]。為減少殘膜漏撿,任意一釘齒離開土壤時,其相鄰的下一個釘齒應進入土壤開始扎膜,拾膜釘齒運動軌跡如圖5a所示。

1.彈齒固定梁 2.摟膜彈齒 3.主軸 4.滾筒 5.釘齒

1.Spring teeth fixing beam 2.Cuddle film spring teeth 3.Spindle 4. Rollers 5. Nail teeth

注:1為滾筒軸向距離,mm;2滾筒周向展開距離,mm;為周向相鄰釘齒距離,mm;為軸向相鄰釘齒距離,mm

Note:1is the axial distance of rollers, mm;2is the circumferential spreading distance of rollers, mm;is the distance of circumferential adjacent nail teeth, mm;is the distance of axial adjacent nail teeth, mm.

圖3 拾膜機構及釘齒排布結構示意圖

Fig.3 Structure diagram of picking-up film mechanism and nail teeth arrangement

圖4 釘齒結構

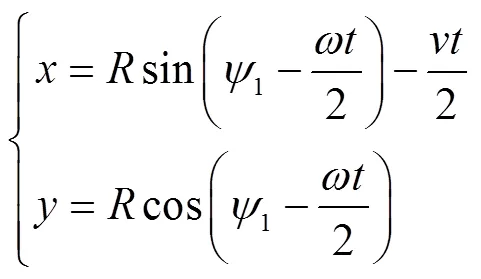

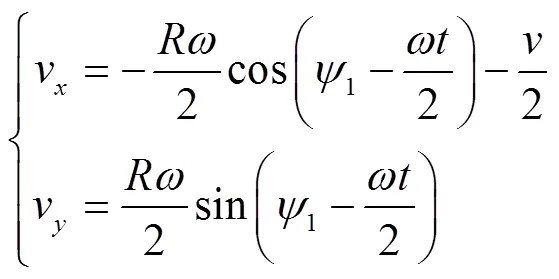

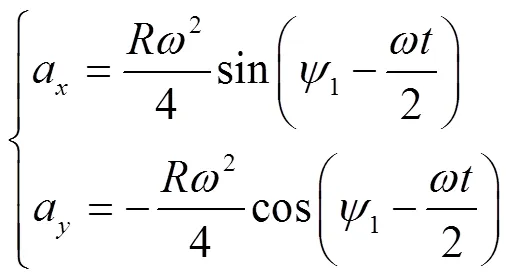

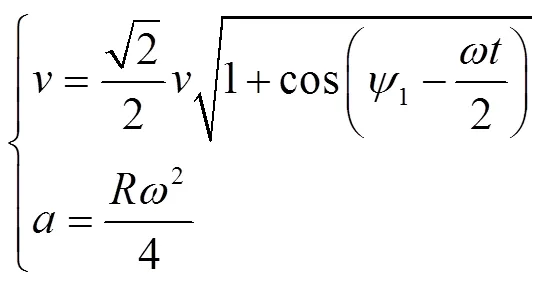

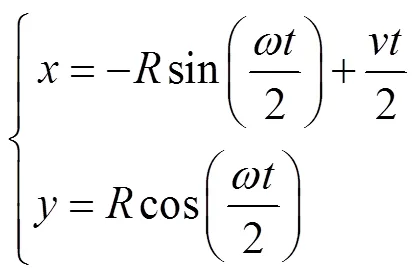

釘齒處于點時,與軸夾角為1,此時為拾膜起始位置,機具工作/2時,釘齒繞軸心轉動/2到達1點,滾筒作業距離為/2。釘齒入土扎膜軌跡方程為

注:為時間,s;為滾筒旋轉角速度,rad·s-1;為機具行進速度,m·s-1;1為初始相位角,(°);為釘齒入土深度,mm;1為周向相鄰釘齒夾角,(°);為釘齒末端至滾筒中心距離,mm。

Note:is the time, s;is the rotation angular velocity of the rollers, rad·s-1;is the machine advancing velocity, m·s-1;1is the preliminary phase angle, (°);is the penetration depth of nail teeth, mm;1is the angle of circumferential adjacent nail teeth, (°);is the distance from end of nail teeth to center of rollers, mm.

圖5 拾膜機構的運動分析

Fig.5 Motion analysis of picking-up film mechanism

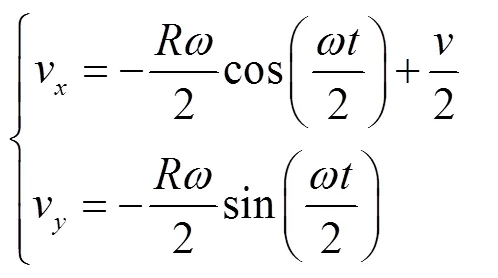

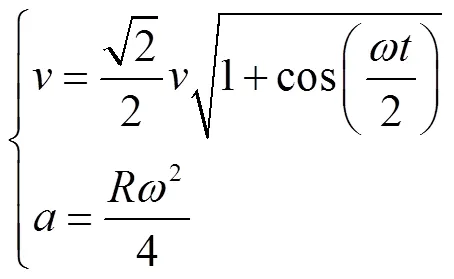

對時間進行一階、二階求導得到釘齒末端的速度及加速度為

則釘齒末端運動的速度及加速度

釘齒入土完成扎膜,滾筒繼續作業,釘齒末端由1點運動到2點完成挑膜,其運動軌跡為

對時間進行一階、二階求導得到釘齒末端的速度及加速度為

則釘齒末端運動的速度及加速度

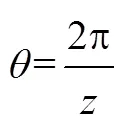

由圖5可知

為了保證撿拾機構不漏撿,則釘齒末端所處點水平位移與豎直位移應為

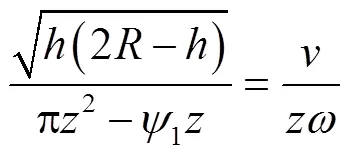

將式(9)和式(10)帶入式(8),求得

由式(11)得

整理得

由以上分析可知,只有當釘齒末端至滾筒中心距離、釘齒入土深度、同一圓周上釘齒總數、滾筒旋轉角速度滿足以上關系時,殘膜拾膜機構作業軌跡如圖5a所示,實現連續撿膜。

根據秋后殘膜回收機具作業要求,機具行進速度為2.4~4.8 km/h,釘齒末端距離滾筒回收機中心旋轉半徑為480 mm,釘齒入土深度為50 mm,通過對釘齒運動軌跡分析,滿足式(12)、式(13)的要求,滾筒旋轉角速度為1.39~2.78 rad/s,得到釘齒滾筒周向齒數為8個。考慮防止漏撿且便于卸膜,取軸向間距為200 mm,所以拾膜滾筒釘齒數量為64個。

2.3 卸膜機構的設計

為了脫卸拾膜釘齒撿拾的地膜,針對弧形齒滾扎式拾膜機構的結構特點,參考文獻“鏈條導軌式地膜回收機”的卸膜裝置[30],其運用環形導軌脫卸殘膜,殘膜在重力和卸膜葉輪的作用下被送進集膜箱,設計了一種刮膜導板式卸膜機構。卸膜機構主要由卸膜導板和刮板式脫膜輥組成,其結構及位置關系如圖6所示,卸膜導板由弧形鋼板和尼龍膠板鉚合組成。

1.刮板式脫膜輥 2.卸膜導板 3.換向齒輪 4.傳動鏈條 5.拾膜機構 6.鏈輪

1.Scraper stripping roller 2. Unloading film guide plate 3.Commutation gears 4.Driving chain 5.Picking-up film mechanism 6.Sprocket

注:為地膜自身重力,N;F為卸膜導板的支撐力,N;為刮板式脫膜輥的作用力,N;F為地膜與卸膜導板之間的摩擦力,N;為地膜所受力與卸膜導板之間的夾角,(°)。

Note:is the gravity of plastic film, N;Fis the supporting force of unloading film guide plate, N;is the force of scraper stripping roller, N;Fis the friction between plastic film and unloading film guide plate, N;is the angle between the force acting on the plastic film and the unloading film guide plate, (°).

圖6 卸膜過程中殘膜受力分析

Fig.6 Force analysis of plastic film residue during unloading film process

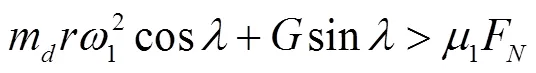

機具工作時,隨弧形齒滾扎式拾膜機構的滾動,通過鏈傳動經換向齒輪帶動刮板式脫膜輥轉動,當拾膜釘齒撿拾殘膜運動到與卸膜導板接觸位置,卸膜導板鉚合的尼龍膠板從釘齒根部到釘齒末端將地膜捋下,卸在卸膜導板上,再由刮板式脫膜輥將地膜刮進集膜箱。為了盡可能的將殘膜刮進集膜箱[31-32],相鄰兩釘齒離開卸膜導板至少被卸膜刮板刮捋2次,選取滾筒與刮板式脫膜輥速比為1:4。

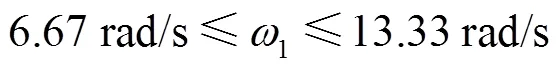

殘膜的受力簡圖如圖6所示,在卸膜過程中,由于地膜與卸膜導板、刮板式脫膜輥的靜電吸附等力太小,可忽略不計[33]。卸膜過程中,刮板式脫膜輥與卸膜導板相對運動時,地膜受力平衡條件為

式中m為卸膜導板堆積的殘膜質量,g;1為地膜的瞬時加速度,m/s2;為刮板式脫膜輥瞬時旋轉半徑,mm;1為刮板式脫膜輥的角速度,rad/s;1為卸膜導板與地膜之間的摩擦系數。

則地膜被刮板式脫膜輥從刮膜導板上刮下卸進集膜箱須滿足受力為

在卸膜過程中,盡量避免刮板式脫膜輥將地膜拉扯斷裂及撕裂,所以刮板式脫膜輥對地膜的作用力應當小于地膜的抗拉強度,即

由式(15)和(16)可知

刮板式脫膜輥的瞬時角速度取值范圍

式中為卸膜導板上堆積殘膜的截面面積,mm2;[]為地膜的許用拉應力,Pa。

3 弧形齒滾扎式殘膜撿拾機構的仿真分析

撿拾機構是弧形齒滾扎式殘膜回收機的關鍵部件,其結構強度和可靠性直接影響機具性能;同時在機具實際作業過程中無法直接觀測到拾膜釘齒扎膜以及釘齒、地膜和土壤的形變情況。依據殘膜力學性能,對拾膜機構進行非線性有限元動力學仿真分析,通過建立拾膜機構、地膜-土壤的有限元復合模型,觀測地膜和土壤受到拾膜釘齒作用后,拾膜釘齒、地膜、土壤具體變形及應力情況,增加機具的可靠性和確定拾膜機構的結構(包括釘齒形狀及尺寸),從而指導整機的加工制造。

機具在實際作業過程中,由于土壤阻力和作物殘茬作用,容易造成釘齒損壞變形,導致機具可靠性降低。依據地膜力學特性,通過構建殘膜撿拾機構、土壤、地膜的復合模型,運用ANSYS Workbench對殘膜撿拾機構撿拾地膜過程進行非線性動力學分析,對釘齒撿拾地膜進行仿真,獲得釘齒、地膜、土壤的變形及受力情況,有限元復合模型如圖7所示。考慮到殘膜撿拾機構結構的對稱性,且整體建模耗費計算資源過大,所以在仿真軟件中將殘膜撿拾機構的撿拾地膜過程簡化成單個釘齒繞滾筒中心端點旋轉,單個釘齒所作用土壤-地膜復合模型大小為500 mm×300 mm×100 mm,地膜厚度取0.010 mm。

1.殘膜撿拾機構 2.地膜 3.土壤

1.Plastic film residue picking mechanism 2.Plastic film 3. Soil

圖7 殘膜撿拾機構有限元復合模型

Fig.7 Finite element compound model of plastic film residue picking mechanism

3.1 參數設置

釘齒材料為熱處理過的45鋼,硬度值為HRC55密度為7 850 kg/m3,彈性模量為2.10×1011Pa,泊松比為0.31。地膜的密度為0.92×103kg/m3,彈性模量為0.6×106Pa,泊松比為0.34。土壤的密度為2 600 kg/m3,黏聚力為2 200 Pa,內摩擦角22°,體積模量1 756 Pa,剪切模量為5 858 Pa,含水率為22%[34]。由于地膜厚度較小,所以采用Shell181殼體單元,其余部件使用Solid164實體單元。

根據平作種植模式及拾膜機構的分析,機具行進速度為4.0 km/h,計算拾膜滾筒旋轉角速度為3.8 rad/s,釘齒從入土扎膜到出土挑膜作用時間為0.3 s,設定釘齒入土深度為55 mm,釘齒與地膜采用Separation接觸方式,而地膜和土壤采用Rough接觸方式,土壤四周施加固定約束。

3.2 仿真結果分析

通過ANSYS Workbench對撿拾機構撿拾地膜過程進行分析,釘齒的變形和應力情況如圖8所示。

圖8 釘齒的變形、應力分析

在釘齒入土扎膜、挑膜過程中,釘齒末端變形最大,釘齒根部應力最大,最大變形量為6.30 mm,最大應力為1.08×105Pa。由于地膜受到釘齒作用產生變形吸附包裹釘齒,隨釘齒一起向前運動,導致地膜在釘齒末端與地膜接觸位置發生較大變形。同時地膜和板結覆土粘結,在入土拾膜過程中,部分土壤會隨地膜一起向前運動一段距離,導致其變形擾動較大。

4 田間試驗

4.1 試驗條件

為得到弧形齒滾扎式殘膜回收機最優作業參數組合,進行田間試驗。2018年7月試驗在石河子市145團科神農業裝備科技開發有限公司試驗地進行。試驗田根據新疆白蘿卜平作種植模式鋪設厚度為0.010 mm的地膜,幅寬800 mm,邊膜寬度為80 mm,覆膜時間為2018年4月-2018年7月,自然板結。土壤緊實度為41 kg/cm2,含水率為16.7%~22.1%。樣機田間試驗如圖9所示,機具由約翰迪爾404牽引機具作業。

圖9 田間試驗

4.2 試驗因素確定

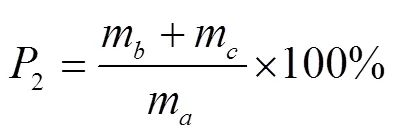

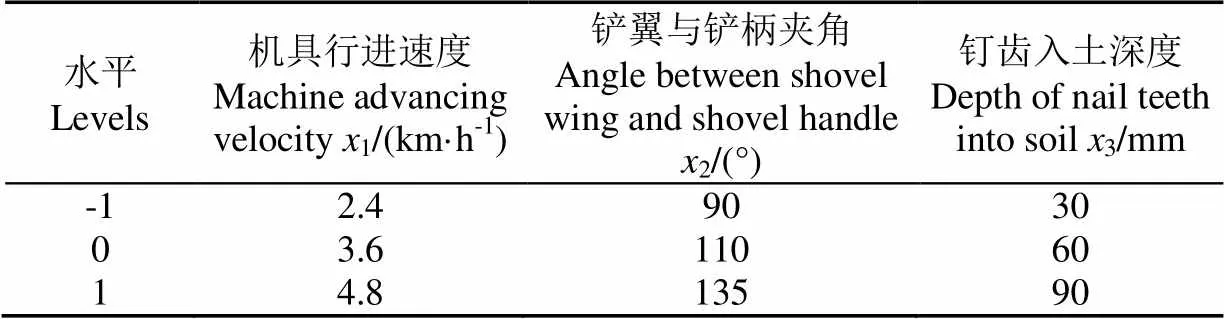

通過前期機具的單因素試驗,依據弧形齒滾扎式殘膜回收機結構及工作原理,選取影響機具回收率的3個主要因素為:機具行進速度1、邊膜鏟鏟翼與鏟柄夾角2和釘齒入土深度3。根據新疆秋后殘膜回收機工作要求,試驗將機具行進速度設定為2.4~4.8 km/h,邊膜鏟翼與鏟柄夾角設定范圍為90°~135°,釘齒入土深度設定范圍為30~90 mm之間。

4.3 試驗指標確定

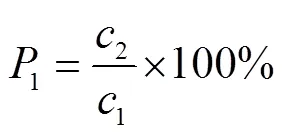

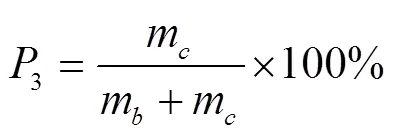

在殘膜回收過程中邊膜的起出有利于殘膜的撿拾,而撿拾膜率和卸膜率直接反映機具工作性能和工作效果。故試驗指標為起邊膜率1、殘膜撿拾率2、卸膜率3,分別表示為

式中1為當年所鋪設邊膜質量,g;2為起膜裝置工作后翻起邊膜質量,g;m為當年每組試驗鋪設地膜的質量,g;m為被釘齒撿拾回收但未被卸入集膜箱殘膜質量,g;m為被卸入集膜箱殘膜的質量,g。

4.4 試驗方案

在試驗地里隨機選取長17個機具行進有效長度為20 m的測試區,每個測試區內隨機選取長200 mm,寬80 mm的邊膜監測點,然后機具進行回收作業。每次試驗結束后將各組檢測點翻起的邊膜、殘膜撿拾機構撿拾的殘膜和被卸入集膜箱的殘膜進行人工收集標記,回收的殘膜洗凈曬干后由FA2014N電子天平稱其質量分別為c、m、m,利用式(18)、(19)、(20)計算起邊膜率、殘膜撿拾率、卸膜率。

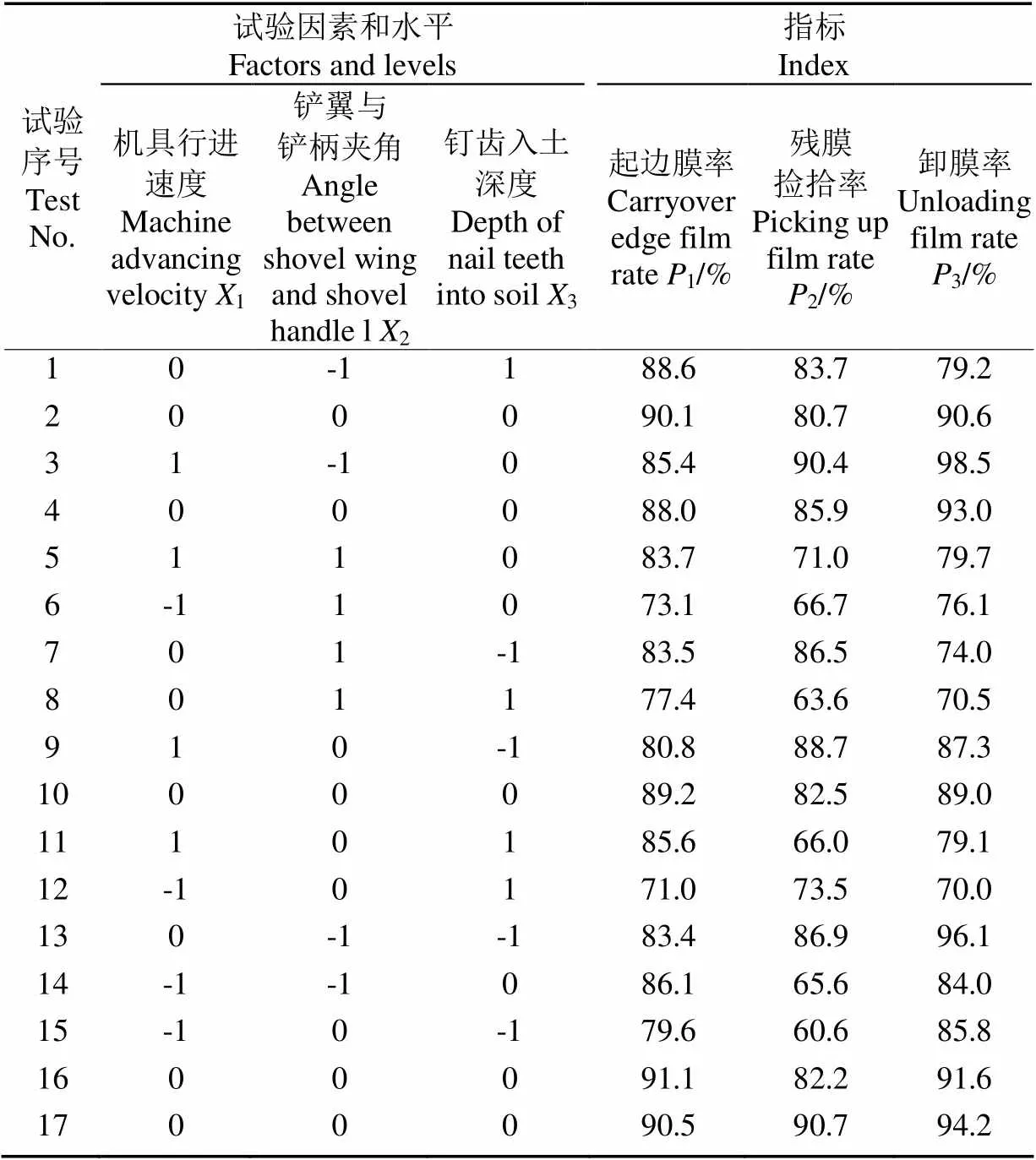

殘膜回收過程中存在很多非線性因素影響機具的試驗指標,一般需要選用二次或高次的模型逼近響應,本次試驗選取響應面來建立模型[35]。試驗利用Box-Benhnken試驗設計方法,選取自變量為機具行進速度、邊膜鏟翼與鏟柄夾角、釘齒入土深度。各因素水平如表1所示,試驗結果如表2所示。

表1 試驗因素與水平

表2 試驗方案與結果

5 試驗結果分析及優化

5.1 回歸模型的建立與檢驗

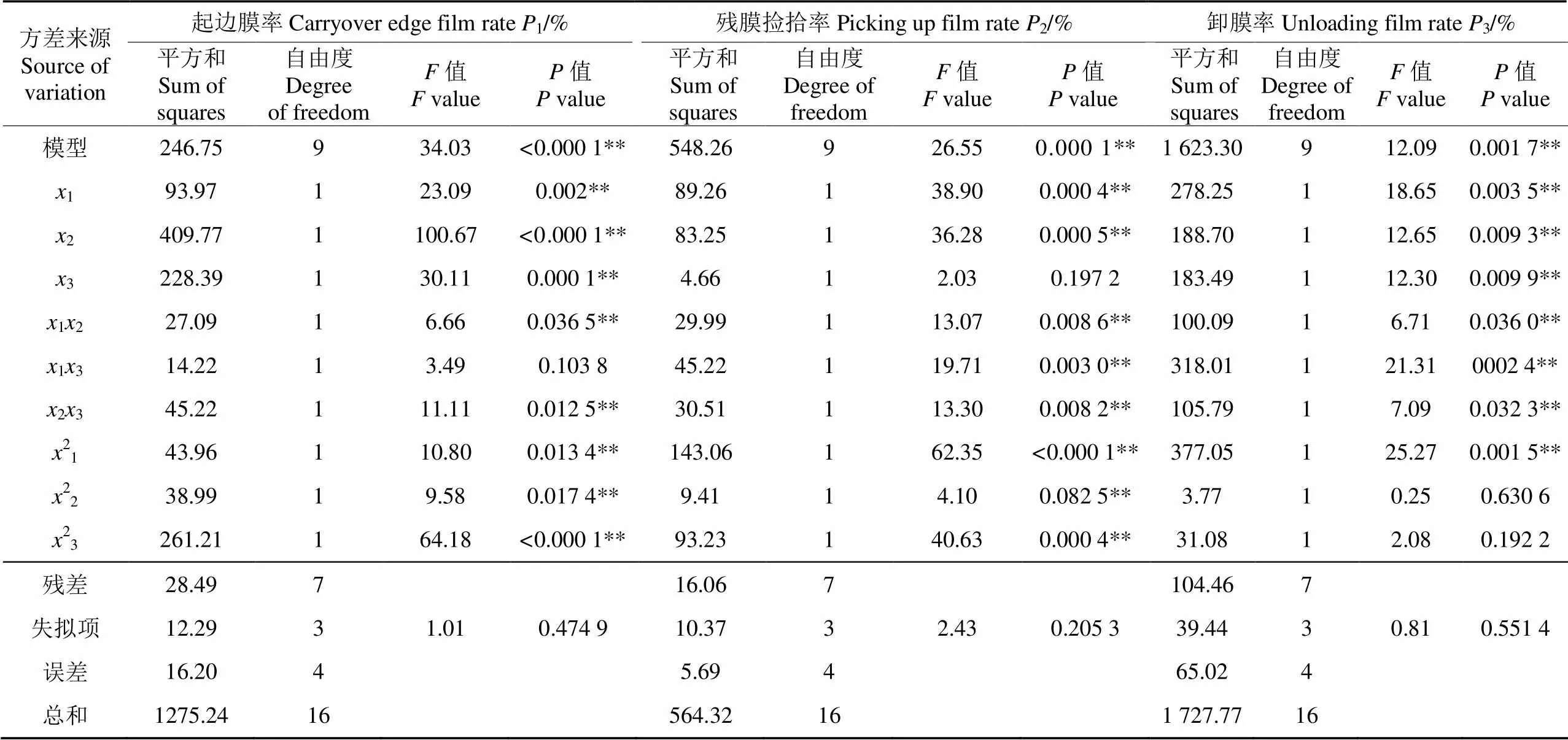

使用Design-Expert軟件對表2進行數據分析處理,結果如表3所示。根據表3中起邊膜率、殘膜撿拾率和卸膜率的值和失擬值,說明起邊膜率、殘膜撿拾率和卸膜率的回歸模型與實際情況擬合精度很高,田間試驗具有很好的實際研究意義。

表3 試驗分析結果

注:<0.01為極顯著(**),<0.05為顯著(*)。

Note:<0.01: highly significant (**),<0.05: significant (*).

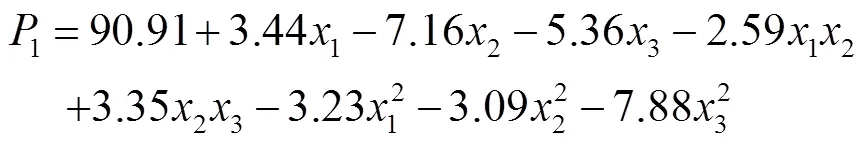

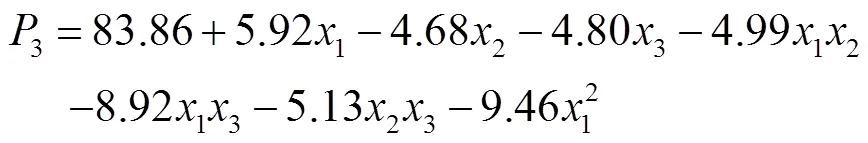

觀察表3二次項212223和121323顯著性,說明所選的3個因素與起邊膜率、殘膜撿拾率、卸膜率之間存在二次非線性關系和交互作用。建立起邊膜率1、殘膜撿拾率2、卸膜率3對機具行進速度1、邊膜鏟鏟翼與鏟柄夾角2、釘齒入土深度33個自變量的響應面二次多項式回歸模型。

通過上述分析,將不顯著因素剔除得到各因素的回歸方程

式中1為機具行進速度,km/h;2為邊膜鏟鏟翼與鏟柄夾角,(°);3為釘齒入土深度,mm。

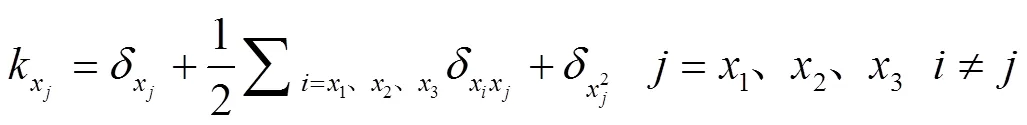

5.2 影響因素對性能效應影響分析

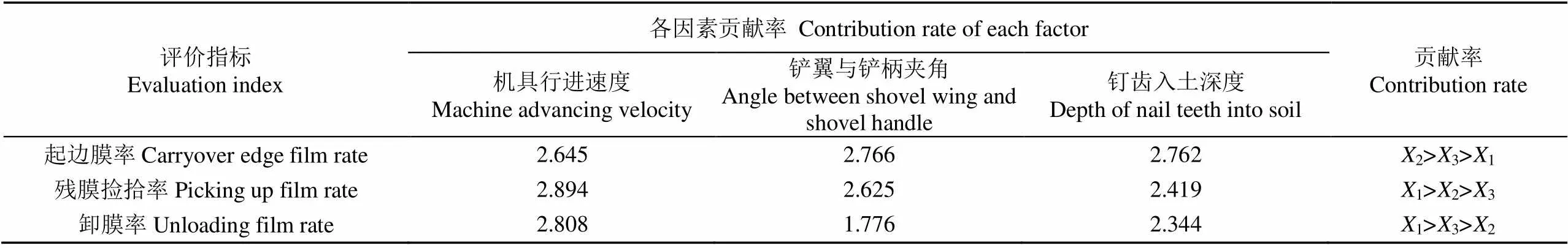

各單因素對模型的影響程度可以由貢獻率值的大小來體現[22],值越大,單因素對模型的影響越大,其計算式為(24)和(25),各因素對邊膜起膜率貢獻率為:邊膜鏟鏟翼與鏟柄之間的夾角>釘齒入土深度>機具行進速度;各因素對殘膜撿拾率貢獻率大小為:機具行進速度>邊膜鏟鏟翼與鏟柄之間的夾角>釘齒入土深度;各因素對卸膜率貢獻率為:機具行進速度>釘齒入土深度>邊膜鏟鏟翼與鏟柄之間的夾角;分析結果如表4所示。

表4 各影響因素貢獻率分析

5.3 各交互因素對性能影響規律分析

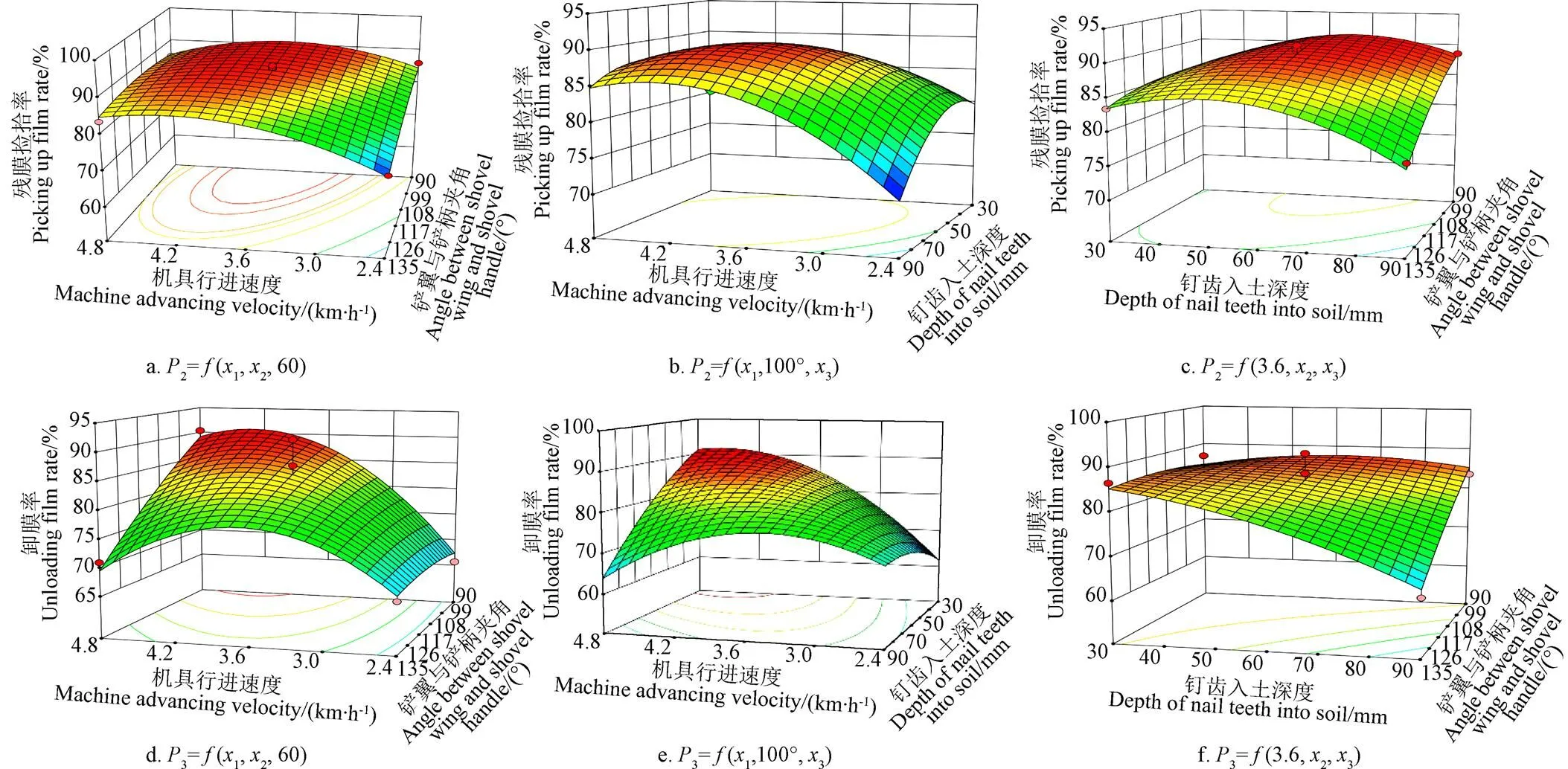

機具回收殘膜時,主要通過檢測機具的殘膜撿拾率和卸膜率判定機具總體殘膜撿拾率,所以本文使用Design-Expert軟件繪制響應面圖,對影響殘膜撿拾率和卸膜率的機具行進速度、邊膜鏟鏟翼與鏟柄之間的夾角和釘齒入土深度進行分析,如圖10所示。

圖10 交互因素對殘膜撿拾率、卸膜率的影響

1)因素交互作用對殘膜撿拾率的影響

各因素交互作用對殘膜撿拾率影響的響應面曲線如圖10a~10c所示。圖10a為釘齒入土深度位于中心水平(60 mm)時,機具行進速度與邊膜鏟鏟翼與鏟柄夾角交互作用對殘膜撿拾率2的響應面圖,由圖10a可知機具行進速度和邊膜鏟鏟柄與鏟翼夾角交互影響,殘膜撿拾率先增大后減小。殘膜撿拾率隨著機具行進速度增大先增大后減小,隨著邊膜鏟鏟翼與鏟柄夾角減小而增大,機具行進速度對殘膜撿拾率的影響更顯著;圖10b為邊膜鏟翼與鏟柄夾角為中心水平(110°)時,機具行進速度與釘齒入土深度交互作用對殘膜撿拾率2的響應面圖,由圖10b可知機具行進速度與釘齒入土深度交互作用,殘膜撿拾率先增大后減小。殘膜撿拾率隨機具行進速度的增加先增大后減小,隨釘齒入土深度的增加先增大后減小,機具行進速度對殘膜撿拾率的影響更顯著;圖10c為機具行進速度為中心水平(3.6 km/h)時,邊膜鏟鏟翼與鏟柄夾角和釘齒入土深度交互作用對殘膜撿拾率2的響應面圖,由圖10c可知釘齒入土深度和邊膜鏟鏟柄與鏟翼夾角交互影響,殘膜撿拾率先增大后減小。殘膜撿拾率隨釘齒入土深度的增大先增大后減小,隨邊膜鏟鏟柄與鏟翼夾角的減小而增大。邊膜鏟鏟翼與鏟柄夾角對殘膜撿拾率的影響更顯著。

從各因素對響應值2響應圖10a~10c可知,因素影響響應面變化規律與模型(22)及回歸方程方差分析結果一致,影響總體的大致趨勢為機具行進速度越大、邊膜鏟鏟翼與鏟柄夾角越小、釘齒入土深度越大則殘膜撿拾率越高。分析其主要原因為:機具行進速度越快,同一圓周上相鄰釘齒運動重疊度越高,可以避免漏撿殘膜;邊膜鏟與鏟柄夾角越小,邊膜鏟在起邊膜過程中將邊膜翻至地表時翻帶的土壤越少,越有利于釘齒撿拾;釘齒入土深度越深,釘齒鉤撿殘膜的時間越長,但入土深度也不易過深,因為過深土壤對釘齒阻力太大,容易損傷釘齒,給卸膜帶來困難。

2)因素交互作用對卸膜率的影響

各因素交互作用對卸膜率影響的響應面曲線如圖10d-10f所示。圖10d為釘齒入土深度位于中心水平(60 mm)時,機具行進速度與邊膜鏟鏟翼與鏟柄夾角交互作用對卸膜率3的響應面圖,由圖10d可知機具行進速度與邊膜鏟鏟柄夾角交互作用卸膜率先增大后趨于穩定。卸膜率隨機具行進速度增大先增大后減小,隨邊膜鏟鏟翼與鏟柄夾角減小而增加,機具行進速度對卸膜率影響更顯著;圖10e為邊膜鏟翼與鏟柄夾角為中心水平(110°)時,機具行進速度與釘齒入土深度交互作用對卸膜率3的響應面圖,由圖10e可知機具行進速度與釘齒入土深度交互作用卸膜率增大。卸膜率隨機具行進速度的增大先增大后減小,隨釘齒入土深度的增大先增大后穩定,機具行進速度對卸膜率的影響更顯著;圖10f為機具行進速度為中心水平(3.6 km/h)時,邊膜鏟鏟翼與鏟柄夾角和釘齒入土深度交互作用對卸膜率3的響應面圖,由圖10f可知邊膜鏟鏟翼與鏟柄夾角和釘齒入土深度交互作用殘膜撿拾率先增大后減小,卸膜率隨著釘齒入土深度的增大而減小,隨邊膜鏟鏟柄與鏟翼夾角的減小而增大。釘齒入土深度對卸膜率的影響更顯著。

從各因素對響應值3響應圖10d-10f可知,因素影響響應面變化規律與模型(23)及回歸方程方差分析結果一致,影響總體的大致趨勢為機具行進速度越高、釘齒入土深度越小、邊膜鏟鏟翼與鏟柄夾角越小則卸膜率越高。分析其主要原因為:機具行進速度越高滾筒運動越快通過傳動機構帶動刮板式脫膜輥運動越快,單位時間內卸膜導板和刮板式脫膜輥剮蹭殘膜次數越多越有利于卸膜。釘齒入土深度越淺,被撿拾的殘膜位于釘齒越上端,越有利于卸膜導板的剮蹭越有利于卸膜。邊膜鏟鏟翼與鏟柄夾角越小,翻帶土壤越少,防止過度土壤堆積在已撿拾地膜,避免撿拾的地膜過重,導致無法被卸載。

5.4 參數優化及試驗驗證

起出邊膜、撿拾地膜和卸膜都是機具作業的重要環節,起邊膜率、殘膜撿拾率和卸膜率都是反映機具回收殘膜的重要指標,所以要求其值越高越好。考慮邊膜起出、地膜撿拾和地膜脫卸是本機具工作過程的前后連續的3個階段,3個試驗指標對機具整體殘膜回收率影響均等[36],故起邊膜率、殘膜撿拾率、卸膜率各占1/3權重。應用Design-Expert軟件的尋優功能,對起邊膜率、殘膜撿拾率、卸膜率影響因素進行尋優,得到最優參數為:機具行進速度4.0 km/h、邊膜鏟鏟翼與鏟柄夾角90°、釘齒入土深度55 mm時,起邊膜率為97%、殘膜撿拾率為90%、卸膜率為91%。

為驗證優化后影響因素的效果,采用機具行進速度為4.0 km/h、邊膜鏟鏟翼與鏟柄夾角為90°和釘齒入土深度為55 mm的優化參數值,在石河子市145團科神農業裝備科技開發有限公司試驗地進行試驗,試驗重復3次,依據式(18)、(19)和(20)進行計算,得到起邊膜率93.5%、殘膜撿拾率為87.4%和卸膜率87.1%。與起邊膜率97%、殘膜撿拾率90%、卸膜率91%的理論值相比,相對誤差均小于4個百分點,所以參數優化模型可靠。

6 結 論

1)針對現有殘膜回收機具存在可靠性差、邊膜回收率低、卸膜困難等問題,設計一種弧形齒滾扎式殘膜回收機具。主要包括邊膜鏟、摟膜弧齒滾扎撿拾機構、卸膜機構、集膜箱等組成,通過對邊膜鏟受力、拾膜機構運動軌跡及卸膜機構的設計分析,確定各組成部分結構參數。

2)采用Box-Benhnken中心組合試驗方法對機具行進速度、邊膜鏟鏟翼與鏟柄夾角、釘齒入土深度對起邊膜率、殘膜撿拾率、卸膜率的影響進行分析,建立了以起邊膜率、殘膜撿拾率、卸膜率為響應指標的回歸方程。通過對響應曲面和因素交互作用對模型的影響得出了起邊膜率、殘膜撿拾率、卸膜率與機具行進速度、邊膜鏟鏟翼與鏟柄夾角、釘齒入土深度之間的變化規律。各因素對起邊膜率的影響大小為:邊膜鏟鏟翼與鏟柄夾角>釘齒入土深度>機具行進速度;各因素對殘膜撿拾率的影響大小為:機具行進速度>邊膜鏟鏟翼與鏟柄夾角>釘齒入土深度;各因素對卸膜率的影響大小為:機具行進速度>釘齒入土深度>邊膜鏟鏟翼與鏟柄夾角。

3)對起邊膜率、殘膜撿拾率、卸膜率的回歸方程進行優化求解,最佳參數為:機具行進速度為4.0 km/h、邊膜鏟鏟翼與鏟柄夾角為90°和釘齒入土深度為55 mm。在該條件下進行田間試驗,試驗結果為起邊膜率93.5%,殘膜撿拾率為87.4%,卸膜率87.1%。各理論優化值與試驗值均較吻合,相對誤差均小于4個百分點,所以參數優化模型可靠。

[1] 謝建華,侯書林,付宇,等. 殘膜回收機彈齒式拾膜機構運動分析與試驗[J]. 農業機械學報,2013,44(增刊1):94-99.

Xie Jianhua, Hou Shulin, Fu Yu, et al. Motion analysis and experiment on spring-tooth mulching plastic film collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(Supp.1): 94-99. (in Chinese with English abstract)

[2] 畢繼業,王秀芬,朱道林. 地膜覆蓋對農作物產量的影響[J]. 農業工程學報,2008,24(11):172-175.

Bi Jiye, Wang Xiufen, Zhu Daolin. Effect of plastic-film mulch on crop yield[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(11): 172-175. (in Chinese with English abstract)

[3] 侯書林,胡三媛,孔建銘,等. 國內殘膜回收機研究的現狀[J]. 農業工程學報,2002,18(3):186-190.

Hou Shulin, Hu Sanyuan, Kong Jianming, et al. Present situation of research on plastic film residue collector in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(3): 186-190. (in Chinese with English abstract)

[4] 王頻. 殘膜污染治理的對策和措施[J]. 農業工程學報,1998,14(3):190-193.

Wang Pin. Measures to reduce the pollution of residual of mulching plastic film in farmland[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1998, 14(3): 190-193. (in Chinese with English abstract)

[5] 劉艷霞. 中國農村地膜殘留污染現狀及治理對策思考[D].咸陽:西北農林科技大學,2014.

Liu Yanxia. Reflections on the pollution status and control countermeasures of plastic film residuals in Chinese rura areas[D]. Xianyang: Northwest A&F University, 2014. (in Chinese with English abstract)

[6] 肖軍,趙景波. 農田塑料地膜污染及防治[J]. 四川環境,2005,24(1):102-105.

Xiao Jun, Zhao Jingbo. Farmland plastic film pollution and its countermeasures[J]. Sichuan Environment, 2005, 24(1): 102-105. (in Chinese with English abstract)

[7] 張東興. 農用殘膜的回收問題[J]. 中國農業大學學報,1998,3(6):103-106.

Zhang Dongxing. Study on collection of used plastic film in fields[J]. Journal of China Agricultural University, 1998, 3(6): 103-106. (in Chinese with English abstract)

[8] 李斌,王吉奎,胡凱,等. 殘膜回收機順向脫膜機理分析與試驗[J]. 農業工程學報,2012,28(21):23-28.

Li Bin, Wang Jikui, Hu Kai, et al. Analysis and test of forward film removing mechanism for polythene film collector[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2012, 28(21): 23-28.(in Chinese with English abstract)

[9] 陳發,史建新,王學農,等. 弧型齒殘膜撿拾滾筒撿膜的機理[J]. 農業機械學報,2006,37(6):36-41.

Chen Fa, Shi Jianxin, Wang Xuenong, et al. Study on collecting principle of arc-type tooth roller for collectig plastic residue[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(6): 36-41. (in Chinese with English abstract)

[10] 張新超,畢新勝,王志歡,等. 釘齒滾筒式殘膜回收機關鍵部件的設計與研究[J]. 農機化研究,2017,39(10):72-76.

Zhang Xinchao, Bi Xinsheng, Wang Zhihuan, et al. The design of key-parts of spiked tooth plastic film residue recovery[J]. Journal of Agricultural Mechanization Research, 2017, 39(10): 72-76. (in Chinese with English abstract)

[11] 謝建華,侯書林,劉英超. 殘膜清理回收機具的研究現狀及存在的問題[J]. 中國農機化,2012(5):41-44.

Xie Jianhua, Hou Shulin, Liu Yingchao. Research status and trends of plastic film residue collectors[J]. Chinese Agricultural Mechanization, 2012(5): 41-44. (in Chinese with English abstract)

[12] 張佳喜,王學農,張麗,等. 農田地膜拉伸性能變化對纏繞式回收的影響[J]. 農業工程學報,2015,31(20):41-47.

Zhang Jiaxi, Wang Xuenong, Zhang Li, et al. Effects of mechanical tensile properties of plastic film on plastic recycling method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(20): 41-47. (in Chinese with English abstract)

[13] 孫興凍,陳玉龍,羅昕,等. 針對秋后立稈模式的殘膜回收機的設計[J]. 農機化研究,2015,37(9):73-76.

Sun Xingdong, ChenYulong, Luo Xin, et al. Design and resarch of plastic film residue collector used on vertical stem after autumn[J]. Journal of Agricultural Mechanization Research, 2015, 37(9): 73-76. (in Chinese with English abstract)

[14] 張佳喜,張麗,劉旋峰,等. 不同邊膜鏟起膜性能分析及其起膜率對比試驗[J]. 農業工程學報,2017,33(4):10-15.

Zhang Jiaxi, Zhang Li, Liu Xuanfeng, et al. Mechanical analysis and conterast experiment on collecting residual plastic film with different side-film shovels[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(4): 10-15. (in Chinese with English abstract)

[15] 王吉奎,付威,王衛兵,等. SMS-1500型秸稈粉碎與殘膜回收機的設計[J]. 農業工程學報,2011,27(7):168-172.

Wang Jikui, Fu Wei, Wang Weibing, et al. Design of SMS-1500 type straw chopping and plastic film residue collecting machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(7): 168-172. (in Chinese with English abstract)

[16] 康建明,王士國,顏利民,等. 殘膜回收機起膜鏟設計與試驗[J]. 農業機械學報,2016,47(增刊1):143-148.

Kang Jianming, Wang Shiguo, Yan Limin, et al. Design and experimet of loose shovel installed on plastic film collecting machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(Supp.1): 143-148. (in Chinese with English abstract)

[17] 馬少輝,張學軍. 邊膜殘膜回收機的設計與試驗[J]. 農業工程,2012,2(1):73-75.

Ma Shaohui, Zhang Xuejun. Design and experiment of side of used plastic film collector machine[J]. Agricultural Engineering, 2012, 2(1): 73-75. (in Chinese with English abstract)

[18] 李辰,白圣賀,靳偉. 鏈齒式耕層殘膜回收機撿拾機構設計與試驗[J]. 農機化研究,2019,41(4):107-111.

Li Chen, Bai Shenghe, Jin Wei. Design and experiment on picking mechanism of chain tooth type plough residue film reclaiming machine[J]. Journal of Agricultural Mechanization Research, 2019, 41(4): 107-111. (in Chinese with English abstract)

[19] 王旭峰,胡燦,魯兵,等. 拋膜鏈齒輸送式殘膜回收機設計與試驗[J]. 農業機械學報,2018,49(3):122-129.

Wang Xunfeng, Hu Can, Lu Bing, et al. Design and experiment of sprocket conveying residual film recycling machine of casting film[J]. Transactions of the Chinese Society For Agricultural Machinery, 2018, 49(3): 122-129. (in Chinese with English abstract)

[20] 楊麗,劉佳,張東興. 棉花苗期地膜回收機設計與試驗[J].農業機械學報,2010,41(增刊1):73-77.

Yang Li, Liu Jia, Zhang Dongxing. Design and experiment of plastic film collector for cotton fields during seedling period[J]. Transactions of the Chinese Society For Agricultural Machinery, 2010, 41(Supp.1): 73-77. (in Chinese with English abstract)

[21] 張學軍. 殘膜分離與輸送裝置的研究[D]. 長春:吉林大學,2007.

Zhang Xuejun. Study on Separation and Transport Device for Device for Remnant Plastic Film[D]. Changchun: Jilin University, 2007. (in Chinese with English abstract)

[22] 段文獻,王吉奎,李陽,等. 夾指鏈式殘膜回收裝置的設計及試驗[J]. 農業工程學報,2016,32(19):35-42.

Duan Wenxian, Wang Jikui, Li Yang, et al. Design and test of clamping finger-chain type device for recycling agricultural plastic film[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(19): 35-42. (in Chinese with English abstract)

[23] 謝建華,張鳳賢,段威林. 圓盤碎土過程分析及試驗[J].機械設計與制造,2018(7):218-221.

Xie Jianhua, Zhang Fengxian, Duan Weilin.Analysis and experiment of the disc crushing soil process[J].Machinery Design & Manufacture, 2018(7): 218-221. (in Chinese with English abstract)

[24] 劉英超,謝建華,侯書林,等. 一種直稈作物苗期殘膜回收機構設計[J]. 農機化研究,2013,35(5):81-84,91.

Liu Yingchao, Xie Jianhua, Hou Shulin, et al. Plastic film recycling mechanism design of the straight rod crops in the seeding stage[J]. Journal of Agricultural Mechanization Research, 2013, 35(5): 81-84, 91. (in Chinese with English abstract)

[25] 楊松梅,顏利民,莫毅松,等. 隨動式殘膜撿拾裝置設計與試驗[J]. 農業機械學報,2018,49(12):109-115,164.

Yang Songmei, Yan Limin, Mo Yisong, et al. Design and experiment on collecting device for profile modeling residual plastic film collector[J]. Transactions of the Chinese Society For Agricultural Machinery, 2018, 49(12): 109-115,164. (in Chinese with English abstract)

[26] 楊業龍. 圓盤扎輥式殘膜回收機碎土及撿拾機理研究[D].烏魯木齊:新疆農業大學,2016.

Yang Yelong. Research on Breaking Soil and Collecting Mechanism of the Disc Roller Type Residual Film Recycling Machine[D]. Urumqi: Xinjiang Agricultural University, 2016. (in Chinese with English abstract)

[27] 張新超. 釘齒滾筒殘膜回收機的設計與研究[D]. 石河子:石河子大學,2017.

Zhag Xinchao. The Design and Research of Spiked Tooth Plastic Film Residue Recovery[D]. Shihezi: Shihezi University, 2017. (in Chinese with English abstract)

[28] 謝建華,陳學庚,孫超偉. 桿齒式殘膜回收機卸膜過程分析及高速攝像試驗[J]. 農業工程學報,2017,33(10):17-24.

Xie Jianhua, Chen Xuegeng, Sun Chaowei. Unloading film process analysis and high-speed photography experiment of pole-tooth residual plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(10): 17-24. (in Chinese with English abstract)

[29] 王海新. 釘齒式殘膜撿拾機的優化及試驗研究[D]. 烏魯木齊:新疆農業大學,2016.

Wang Haixin. Optimization and Experimental Study of Nail Tooth Plastic Film Residue Collector[D]. Urumqi: Xinjiang Agricultural University, 2016. (in Chinese with English abstract)

[30] 呂釗欽,張磊,張廣玲,等. 鏈條導軌式地膜回收機的設計與試驗[J]. 農業工程學報,2015,31(18):48-54.

Lü Zhaoqin, Zhang Lei, Zhang Guangling, et al. Design and test of chain guide rail-type plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(18): 48-54. (in Chinese with English abstract)

[31] 劉旋峰,石鑫,郭兆峰,等. 滾筒式殘膜回收機的性能試驗研究[J]. 農業工程學報,2017,33(16):26-31.

Liu Xuanfeng, Shi Xin, Guo Zhaofeng, et al. Performance test on roller type residual film recycling machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(16): 26-31. (in Chinese with English abstract)

[32] Witter S H. World-wide use of plastic in horticultural produc-tion[J]. Hort Technol, 1993, 3(1): 6-19.

[33] 嚴偉,胡志超,吳努,等. 鏟篩式殘膜回收機輸膜機構參數優化與試驗[J]. 農業工程學報,2017,33(1):17-24.

Yan Wei, Hu Zhichao, Wu Nu, et al. Parameter optimization and experiment of film transmission mechanism of spade screen recovery machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(1): 17-24. (in Chinese with English abstract)

[34] 楊菊. 基于擴展有限元法和離散元法的土壤:耕具接觸研究[D]. 昆明:昆明理工大學,2014.

Yang Ju. Analysis of Soil-Tool Interaction Using Extended Finite element Method and Discrete Element Method[D]. Kunming: Kunming University of Science and Technology. 2014. (in Chinese with English abstract)

[35] 明道緒. 高級生物統計[M]. 北京:中國農業出版社,2006.

[36] 孫岳,簡建明,田玉泰,等. 殘膜回收機旋轉式起膜裝置起膜機理分析與試驗[J]. 農業機械學報,2018,49(增刊1):304-310.

Sun Yue, Jian Jianming, Tian Yutai, et al. Analysis and experiment of filming mechanism of rotary film-lifting device of residual film recycling machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Supp.1): 304-310. (in Chinese with English abstract)

Design and parameter optimization of arc tooth and rolling bundle type plastic film residue collector

Xie Jianhua1, Zhang Fengxian1, Chen Xuegeng2※, Han Yingjie1, Tang Wei1

(1.,,830052,; 2.,,832000,)

The application of plastic film mulching technology has brought considerable economic benefits to China's agricultural production, but also caused a series of pollution problems. Due to the incomplete recovery and cumulative accumulation of plastic film residuals over years, the soil permeability to water and the soil structure are poor, seriously affecting the sustainable development of China’s agricultural economy. The main cause of such soil pollution is that the polyethylene film used in agricultural production in most areas of China is thin, the film covering time is long, and the recovery rate is low, and as such a large number of residual films remains in the soil tillage layer. Among them, the proportion of the buried edge film under the surface is 7% - 16%. The edge film is bound to the soil, which is easy to tear with the surface film when recycling, which leads to the difficulty of the recovery of the edge film. Researchers of agricultural machinery in China have developed a variety of plastic film residue collectors, including nail-tooth, telescopic rod-tooth, clip the hold type, spring-tooth and so on. However, there are many problems, such as complex structure, poor reliability and low recovery rate. At the same time, the research of the plastic film residue collector mainly focuses on the surface film pickup, while the research on the side film pickup and unloading is insufficient. Aiming at the problems of the existing plastic film residue collector, an arc tooth and rolling bundle type plastic film residue collector was designed in this study. According to the force of its work piece and the analysis of the motion track of the pickup mechanism, the key components such as the pickup shovel, the picking-up film mechanism and the unloading film mechanism were researched. In order to simulate the deformation and stress of nail teeth, plastic film and soil in the process of film-picking nail teeth fixing was used to guide the design of collector. Nonlinear finite element dynamics simulation analysis of film picking process of arc tooth and rolling bundle picking-up mechanism was done by use of ANSYS software. The simulation results showed that in the process of picking up plastic film, the end of nail teeth had the largest deformation. The maximum deformation of plastic film occurred at the contact position with the end of nail teeth. The deformation of soil disturbed by nail teeth was small. Using Box-Benhnken's central combination method, three-factor and three-level quadratic regression tests were carried out for the influence of the machine advancing velocity, the angle between the shovel wing and the shovel handle, and the depth of the nail teeth into the soil. Response surface regression model was established based on the carryover edge film rate, picking up film rate and unloading film rate, and the influence trend of each factor on the test index was analyzed. In order to improve the recovery rate of residual film residue, the influencing factors were optimized comprehensively. The experimental results showed that the significant factors affecting the rate of rimming film were as follows: the angle between the shovel wing and the shovel handle > the depth of the nail teeth into the soil > the machine advancing velocity. The significant factors affecting picking up film rate were as follows: the machine advancing velocity > the angle between the shovel wing and the shovel handle > the depth of the nail teeth into the soil. The significant factors affecting unloading film rate were as follows: the machine advancing velocity > the depth of the nail teeth into the soil > the angle between the shovel wing and the shovel handle. Finally, the optimum parameters were determined as follows: the machine advancing velocity was 4 km/h, the angle between the shovel wing and the shovel handle was 90°, and the depth of the nail teeth into the soil was 55 mm. Field experiments were conducted under these conditions and the following data were obtained, the carryover edge film rate was 93.5%, the picking up film rate was 87.4% and the unloading film rate was 87.1%, and the error between the experimental results and the optimized theoretical values was less than 4 percentage point. This research results provide theoretical basis and technical reference for structural design and working parameters selection of plastic film residue collector.

mechanization; design; optimization; picking up film mechanism; unloading film mechanism; simulation analysis; response surface experiments

2018-12-19

2019-05-15

國家自然科學基金資助項目(51665057);公益性行業(農業)科研專項(201503105);新疆自治區區域協同創新專項(2019E0202);中國農業大學-新疆農業大學聯合基金項目(2017TC009)

謝建華,副教授,博士,主要從事農業機械裝備設計與研究。Email:xjh199032@163.com

陳學庚,中國工程院院士,主要從事棉花生產機械化和殘膜污染治理研究。Email:chenxg130@sina.com

10.11975/j.issn.1002-6819.2019.11.004

S223.5

A

1002-6819(2019)-11-0026-12

謝建華,張鳳賢,陳學庚,韓英杰,唐 煒. 弧形齒滾扎式殘膜回收機的設計及參數優化[J]. 農業工程學報,2019,35(11):26-37. doi:10.11975/j.issn.1002-6819.2019.11.004 http://www.tcsae.org

Xie Jianhua, Zhang Fengxian, Chen Xuegeng, Han Yingjie, Tang Wei. Design and parameter optimization of arc tooth and rolling bundle type plastic film residue collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(11): 26-37. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.11.004 http://www.tcsae.org