基于顆粒縮放的小麥粉離散元參數標定

李永祥,李飛翔,徐雪萌,申長璞,孟坤鵬,陳 靜,常東濤

基于顆粒縮放的小麥粉離散元參數標定

李永祥1,李飛翔1,徐雪萌1※,申長璞1,孟坤鵬1,陳 靜1,常東濤2

(1. 河南工業大學機電工程學院,鄭州 450001;2. 河南金谷實業有限公司,鄭州 450001)

為獲得小麥粉離散元仿真精確的接觸參數,將不規則形狀的小麥粉簡化成軟質球形顆粒,利用顆粒接觸縮放原理和量綱分析進行顆粒縮放,將平均粒徑0.212 mm的小麥粉放大至1.2 mm,選擇“Hertz–Mindlin with JKR”接觸模型,利用休止角對接觸參數進行標定。首先通過Plackett-Burman 試驗篩選出對休止角影響顯著的參數:表面能JKR(Johnson Kendall Roberts)、小麥粉-小麥粉滾動摩擦系數、小麥粉-不銹鋼靜摩擦系數;然后根據Box-Behnken 試驗建立并優化休止角與顯著性參數的二階回歸模型,得到顯著性參數的最佳組合為JKR為0.157、小麥粉-小麥粉滾動摩擦系數為0.25、小麥粉-不銹鋼靜摩擦系數為0.58;最后用標定參數仿真所得休止角大小與真實試驗值進行對比,二者相對誤差為0.61%。結果表明標定所得的接觸參數可用于小麥粉放大顆粒的離散元仿真,為定量供送螺桿的設計提供參考。

農產品;顆粒尺寸;離散元;參數標定;休止角

0 引 言

自動包裝生產線上小麥粉的輸送與計量大多采用螺旋輸送裝置,螺旋輸送裝置的合理設計是提高小麥粉輸送效率及包裝精度的關鍵因素。利用離散元法(DEM,discrete element method)全面、系統研究粉體與螺桿間的相互作用機理及粉體流的運動狀態,可以優化螺桿參數,提高小麥粉包裝的速度及精度,同時也可以提高研發效率、降低研發成本。Gao等建立了螺旋集料裝置工作過程的離散元數值模型并進行仿真研究,獲得了螺旋集料裝置設計所需的最優參數,為螺旋集料裝置的結構改進提供了參考[1];Mazor等采用離散元(DEM)和有限元(FEM,finite element method)相結合的方法,通過分析粉末在給料區和壓實區的運動狀態,得出了粉體密度參數的變化趨勢曲線[2];Sun等通過對螺旋進料頭的離散元仿真,提出了不同摩擦系數下進料頭的曲線方程并得出計算輸送量的公式,對提高螺旋進料頭研發的效率具有一定意義[3]。離散元仿真所需參數眾多,一般通過直接測量和虛擬標定來進行獲得,在此研究領域,國內外學者基于JKR Cohesion模型對含濕物料的參數標定開展了大量研究[4-8],但對于小麥粉、淀粉等顆粒較小物料的離散元仿真及參數標定的相關研究還比較少。

小麥粉粒徑較小,螺旋輸送料筒內物料顆粒的數量達到上千萬甚至數十億,普通計算機能力有限而不能有效模擬,顆粒縮放法是目前較為可行的處理方式,已廣泛應用于工程研究中,該方法將原系統中顆粒放大,降低了模型中的離散單元數,使原物理模型問題能在合理有效的時間內解決。如任建莉等基于顆粒縮放理論,通過對垂直螺旋輸送中鑄鐵煤粉顆粒運動的離散元仿真,驗證了顆粒縮放法的準確性[9];Sakai等建立了粗粒模型并對其在流化床中進行數值模擬,得出了粗粒模型能較精確模擬原始粒子行為的結論[10];Weinhart等為表明對高度局部化系統中空間粗粒寬度及時間間隔選擇的重要性,以粗粒模型對筒倉進行了離散元仿真[11]。本研究利用縮放理論,以小麥粉休止角作為響應值,通過Plackett-Burman、最陡爬坡以及Box-Behnken試驗對放大顆粒的離散元仿真接觸參數進行標定,得到接觸參數的最佳組合,以期為小麥粉、淀粉等其他粉體的離散元模擬提供參考。

1 材料與方法

1.1 試驗材料獲取

原材料:鄭州海嘉食品有限公司生產的普通粉:含水率13.5%,蛋白質11.5%,灰分0.51%;將原材料通過70目的標準孔篩制得試驗所用小麥粉,其平均粒徑為0.212 mm。

1.2 顆粒縮放原理

1.2.1 量綱分析

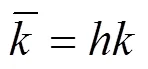

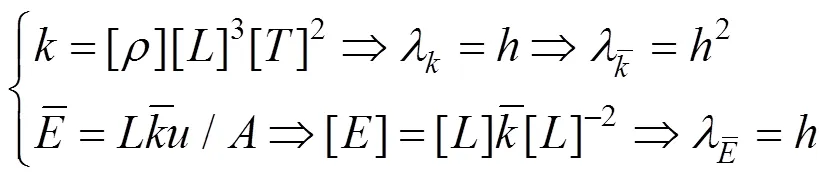

為使離散元能夠合理有效仿真,通過調整離散元仿真參數,使縮放粒子仿真結果盡可能表現出與原系統粒子相同的動態和靜態特性,以減小由于粒子縮放而造成的模擬誤差。Feng等采用簡單方法,建立了原系統物理模型和縮放模型之間單個物理量間的比例因子[12]。

式中為軸向力,N;為楊氏模量,Pa;為橫截面積,m2;為軸向位移,m。

式中為速度,m/s;為長度,m;為時間,s。

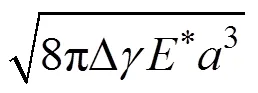

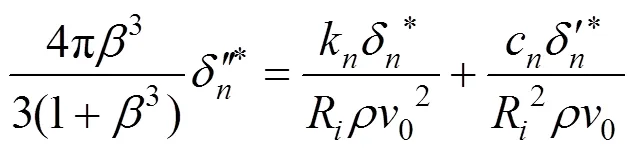

對于黏合彈性顆粒接觸模型來說,2個黏著彈性球間接觸力可表示為

由量綱分析結果可知,縮放模型密度保持不變,接觸剛度與顆粒尺寸成線性關系,不是固定常數,參數彈性模量的設置不是固定的原始數值,而是隨變徑縮放而被縮放,根據參數范圍,取其較大值。

1.2.2 縮放接觸原理

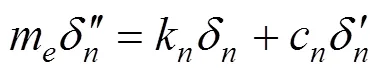

Stefan基于原始系統和縮放系統中相同的轉動動能,對線性彈性模型進行分析,根據牛頓運動定律,顆粒間法向重疊的微分方程可表示為[13]

式中m為有效質量,kg;k為顆粒剛度,N/m;c為阻尼系數,kg/s;δ為重疊量,m。

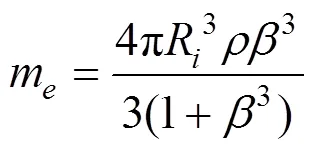

式中為顆粒密度,kg/m3;為顆粒粒度比,R為原系統顆粒半徑,m。

式中R為有效半徑,m;R為縮放系統顆粒半徑,m。

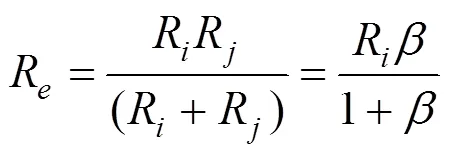

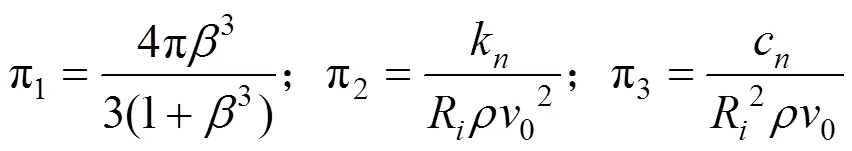

將(8)、(9)2式用無量綱量轉換。

式中*為無量綱數,δ為重疊量,m;為時間,s;0為速度,m/s。

代入(9)式可得

式中k為顆粒剛度,N/m;c為阻尼系數,kg/s。

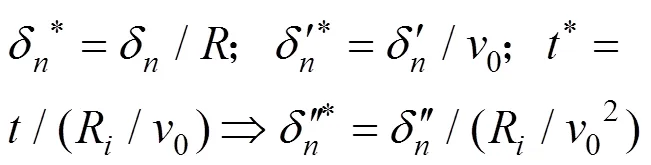

簡化可得

式(12)中系數可用以下無量綱數表示為

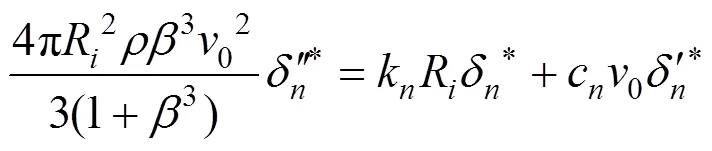

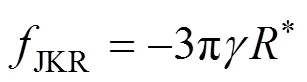

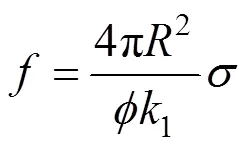

范德華力是細顆粒黏附的主要來源。在細顆粒離散元建模中,一般采用理論黏著彈性模型來表示范德華力[14]。對于JKR模型,將范德華力與顆粒半徑關聯:

式中為每單位接觸面積的表面能,J/m2。

Subhash等給出了具有隨機各向同性物料的硬質單分散球體系拉伸強度與顆粒間接觸力的關系[14]:

這表明顆粒間接觸力與縮放粒子半徑的平方成正比,隨著粒子半徑的增加,單對顆粒間接觸表面積也相對增加。由于粘附力與顆粒間接觸面積有關,而接觸面積與顆粒半徑的平方成比例,表明了粘附力與顆粒半徑二次方的比例關系。參數JKR設置中,JKR隨縮放比例變動,沒有特定的參考數值,根據其范圍,通過標定確定。為了盡量減小仿真誤差及獲得合理有效的仿真時間,縮放比例根據相關文獻[15-16],本文將小麥粉顆粒放大近6倍進行仿真模擬。

2 參數標定過程

2.1 物理模型

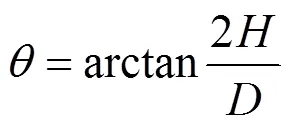

試驗參照GB/T 16913.5-1997國家標準,并結合已有文獻對休止角的相關研究[17-21],采用注入法測量小麥粉休止角,測量裝置如圖1所示,漏斗下口內徑為5 mm,錐度為60o,圓柱底盤直徑為80 mm,漏斗下端口距圓柱底盤上表面距離75 mm。測量時,將所制備的小麥粉緩慢倒入漏斗中,使用玻璃棒輕微攪動,防止小麥粉顆粒堵住漏斗出口,待圓柱底盤溢出一定數量的小麥粉后,停止向漏斗添加小麥粉,待顆粒堆積高度不再發生變化,用鋼尺測出底盤上小麥粉的堆積高度。根據公式(16)計算小麥粉休止角,重復5次取其平均值,測得小麥粉休止角為52.37o。

2.2 仿真模型

2.2.1 仿真參數

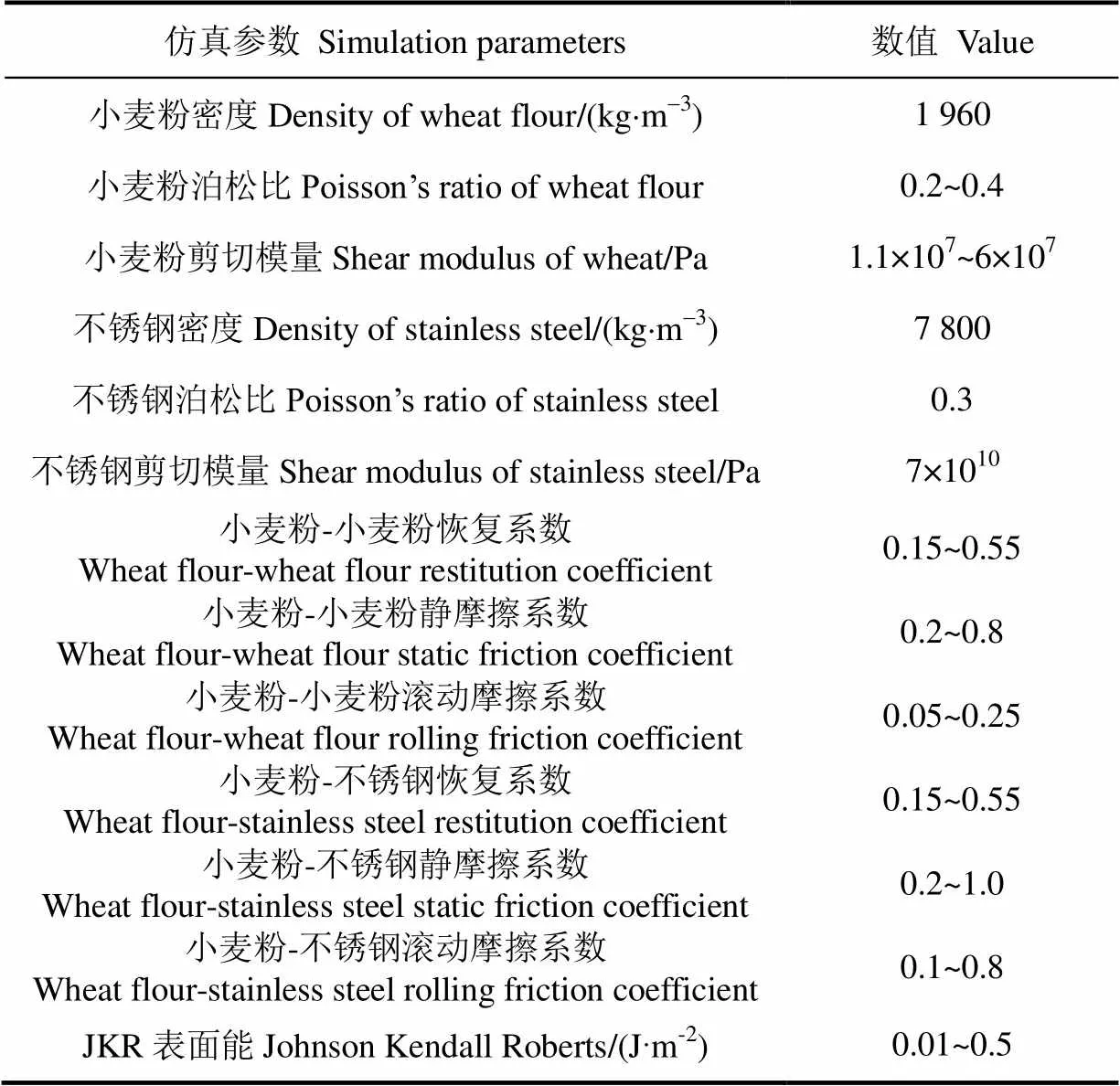

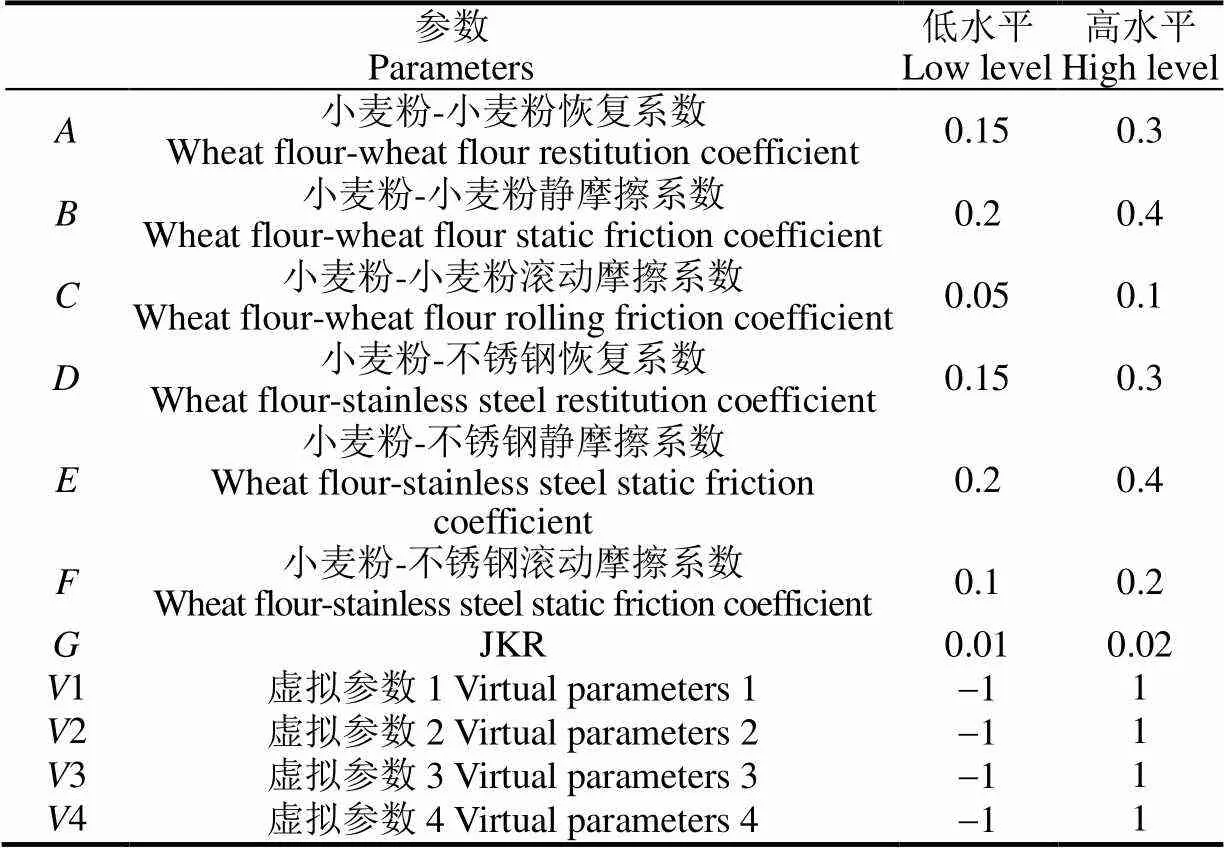

結合國內外文獻對粉體顆粒與不銹鋼離散元仿真參數的設置[22-25]及軟件內置 GEMM 數據庫,本研究中各仿真參數的變化范圍如表1所示。結合粉體仿真相關文獻[26-29]以及顆粒縮放理論規則,模擬所需小麥粉本征參數設定為:密度1 960 kg/m3、泊松比0.25、小麥粉剪切模量6.0′107Pa。材料的接觸參數隨材料密度、形狀、粒徑等不同變化較大,無法通過查閱物性手冊或文獻資料獲取,采用虛擬試驗進行標定。

2.2.2 仿真模型

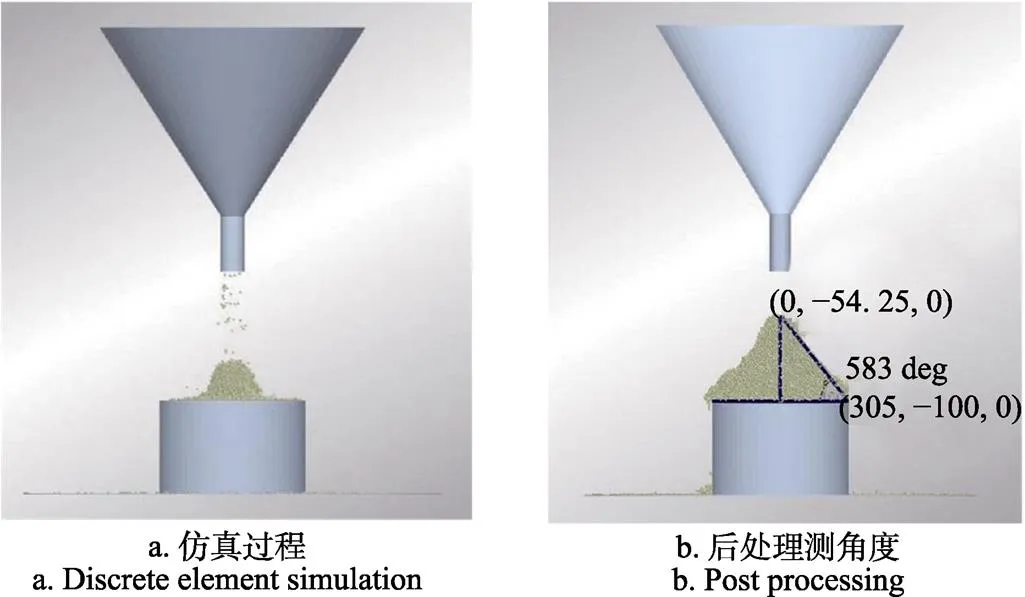

仿真參照GB/T11986-98《表面活性劑粉體和顆粒休止角的測量》標準,采用注入法,漏斗出口內徑為10 mm,接收圓柱底面直徑=100 mm,漏斗下端口距圓柱底盤上表面距離75 mm,放大顆粒粒徑設置為=1.2 mm,由于模擬條件及時間限制,仿真采用球形顆粒[30-32]。仿真模型如圖2所示,顆粒生成方式為Dynamic,生成速率設為2 000個/s,生成數量設為不限,仿真時間設為20 s,待圓柱底面接收的顆粒處于溢出狀態,將生成速率設為0個/s,繼續仿真,待漏斗中顆粒落完后,采用軟件后處理中記錄顆粒位置的功能,記錄顆粒堆積高度隨時間的變化趨勢,導出數據,找到處于相對靜止下的高度值,采用自帶的量角器工具,測量休止角。

表1 離散元仿真參數表

圖2 小麥粉顆粒堆積的模擬仿真

2.3 仿真參數的響應面設計

2.3.1 Plackett-Burman試驗

Plackett-Burman試驗通過考察目標響應與各因子間關系,比較各個因子2水平間的差異來確定因子顯著性。本文Plackett-Burman 設計以小麥粉休止角為響應值,對仿真接觸參數的顯著性進行篩選。低水平設定為最初原始水平,高水平設為低水平的2倍,試驗參數如表2所示。

表2 Plackett-Burman試驗參數列表

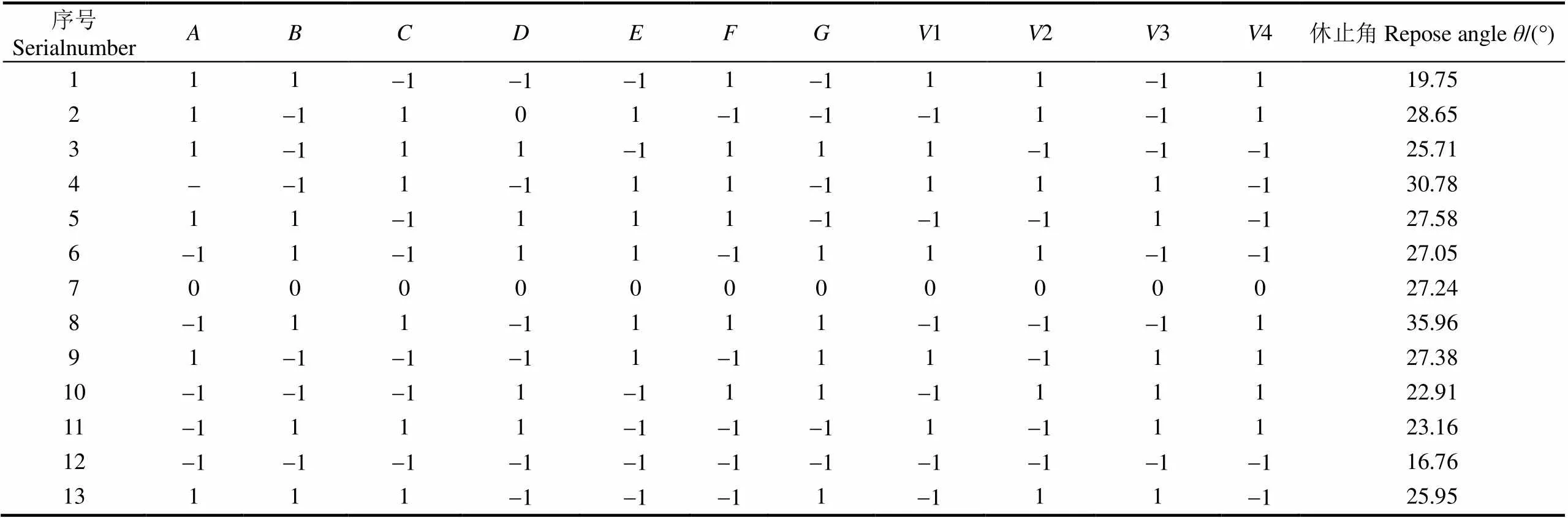

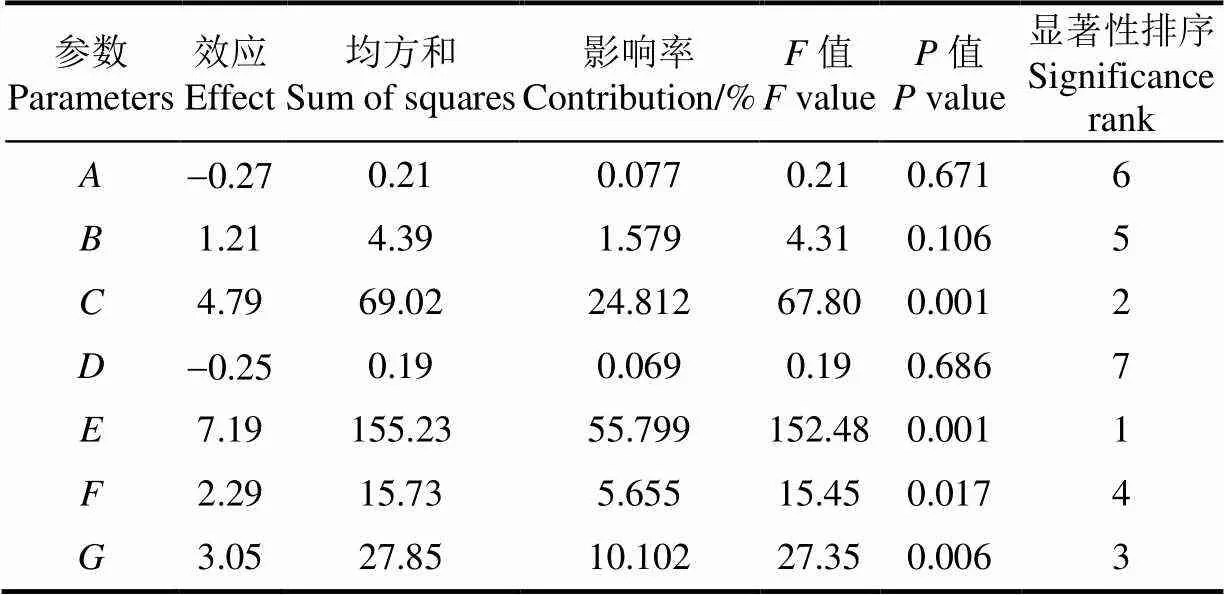

Plackett-Burman設計及結果如表3所示,利用Design Expert軟件對該結果進行方差分析,得到各個接觸參數的顯著性如表4所示。由表4可知,JKR、小麥粉-小麥粉滾動摩擦系數、小麥粉-不銹鋼靜摩擦系數的<0.01,對放大顆粒休止角的影響極其顯著;小麥粉-不銹鋼滾動摩擦系數的<0.05,對放大顆粒的休止角影響顯著;而其余參數>0.05,對放大顆粒的休止角影響極小。為方便后續試驗,在最陡爬坡以及 Box-Behnken 試驗中只考慮這3個影響極其顯著(<0.01)的參數。其余參數結合相關文獻[30-32]取值為(小麥粉-小麥粉恢復系數0.2、小麥粉-小麥粉靜摩擦系數0.6、小麥粉-不銹鋼恢復系數0.2、小麥粉-不銹鋼滾動摩擦系數0.25)來進行最陡爬坡以及響應面試驗設計。

表3 Plackett-Burman試驗設計及結果

表4 Plackett-Burman試驗參數顯著性分析

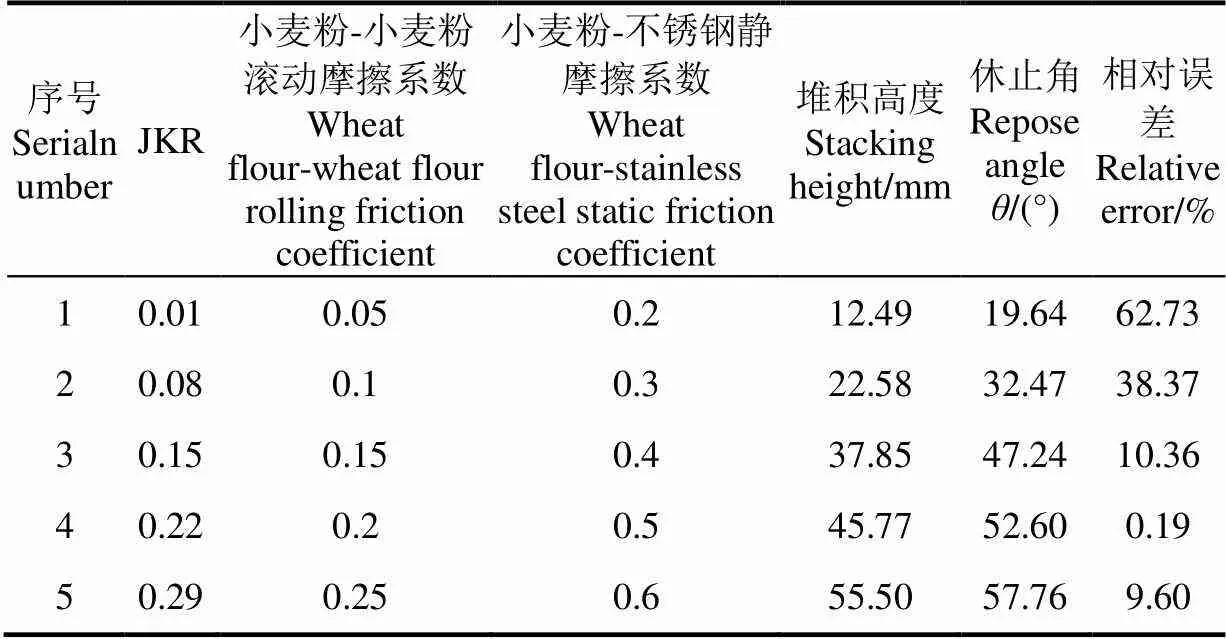

2.3.2 最陡爬坡試驗

Plackett-Burman 試驗后,根據篩選的顯著性參數,進行最陡爬坡試驗,以便能快速進入到最優值的附近區域。最陡爬坡試驗從PB試驗中心點開始,根據PB試驗所得的回歸系數來確定爬坡步長,為能盡快逼近最優值,爬坡步長通常取較大值。本爬坡試驗選定步長以及結果如表5所示。根據表5結果可知,在4號水平休止角相對誤差最小,由3號到5號水平相對誤差由大變小再變大,由此選取4號水平為中心點,3號、5號水平為低、高水平進行后續響應面設計。

表5 最陡爬坡試驗設計及結果

2.3.3 Box-Behnken試驗及回歸模型

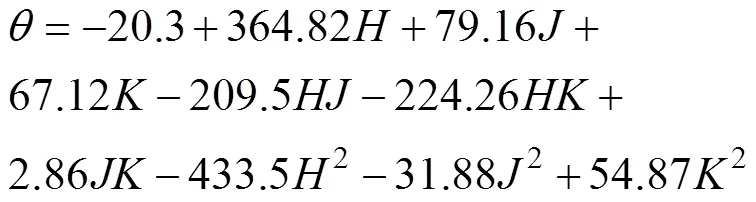

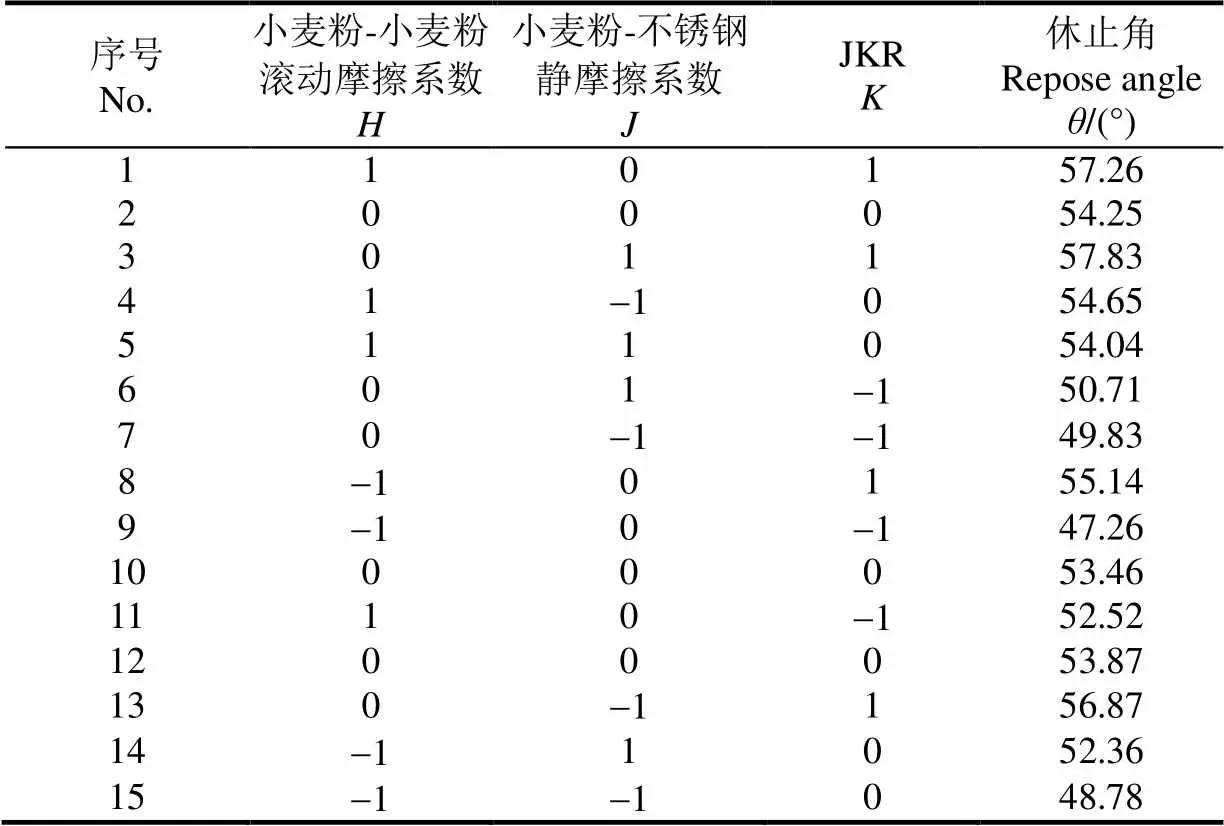

根據最陡爬坡試驗結果及響應面設計原理,選取顯著性參數的低、中、高3水平進行試驗設計,試驗選3個中心點對誤差進行評估。Box-Behnken試驗結果如表6所示,應用Design-Expert建立3個顯著性參數與休止角的二階回歸方程為

表6 Box-Behnken試驗設計及結果

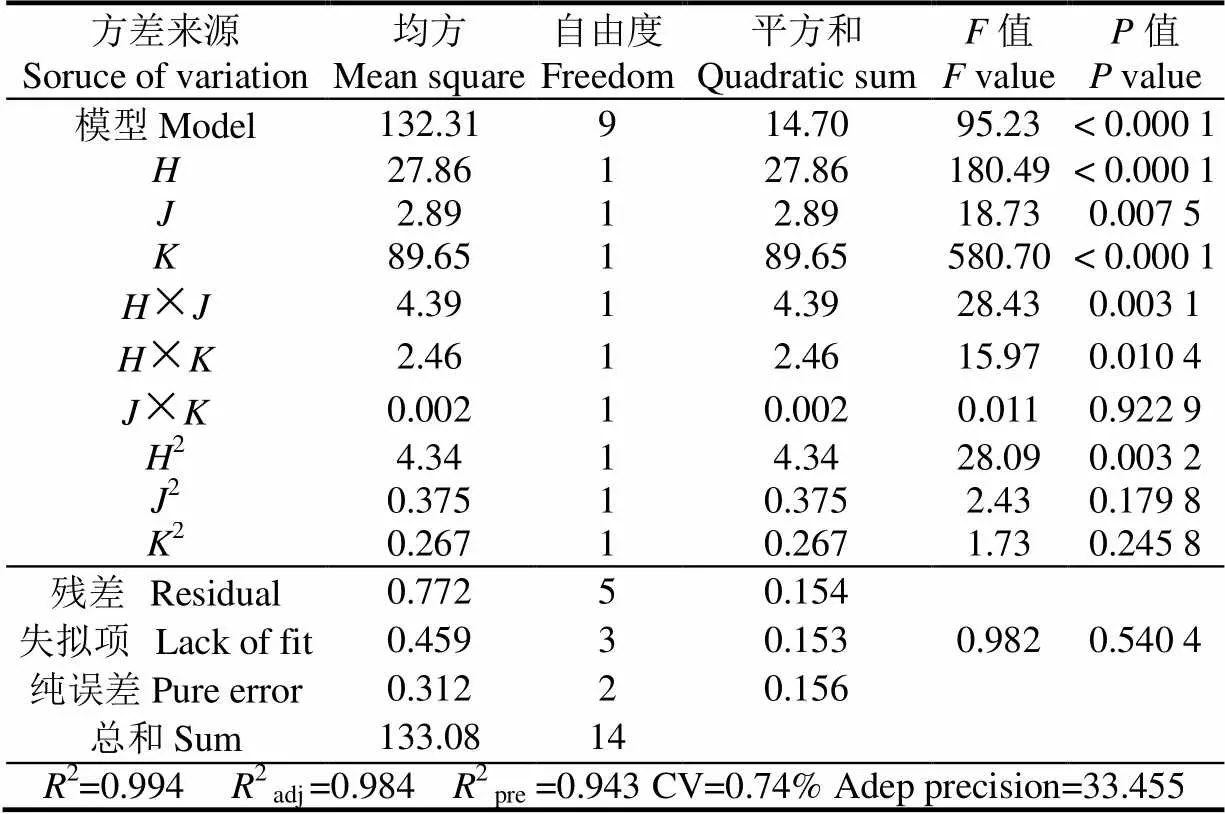

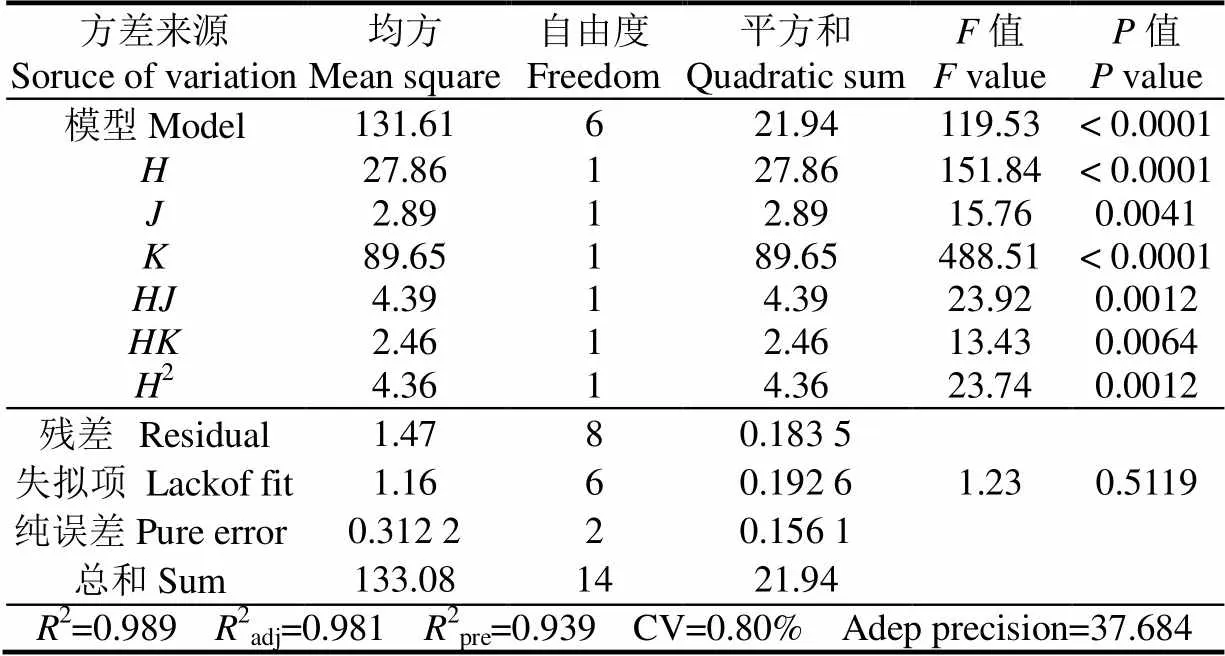

Box-Behnken試驗模型方差分析結果如表7所示,根據表7結果可知,該擬合模型<0.0001;JKR 表面能()、小麥粉顆粒間的滾動摩擦系數()、小麥粉-不銹鋼的靜摩擦系數()、JKR表面能-滾動摩擦系數(í)以及JKR表面能的二次項(2)值都<0.01;JKR表面能-靜摩擦系數(í)<0.05,說明各個參數對休止角的影響顯著,表明了回歸模型的有效性。失擬項=0.5405>0.05,表明模型良好,沒有彎曲失擬現象發生。試驗中變異系數CV=0.74%,說明試驗有較高的可靠性。決定系數2=0.994;校正決定系數2adj=0.984;預測決定系數2pre=0.943;三值都>0.9,表明模型能夠真實的反應實際情況。試驗精密度Adep Precision=33.455,說明模型具有良好的精確度。

表7 Box-Behnken試驗設計二次多項式模型方差分析

根據表7結果,在保證模型良好前提下,剔除對休止角影響不顯著的項(í、2、2),優化模型后的方差分析結果如表8所示,失擬項=0.511 9;變異系數CV=0.80%;決定系數2=0.989;校正決定系數2adj=0.981;預測決定系數2pre=0.939;試驗精密度Adep Precision=37.684。可知,模型擬合性,可靠性以及精確性良好,較優化前有了一定改善,優化后回歸方程為

表8 Box-Behnken試驗優化回歸模型方差分析

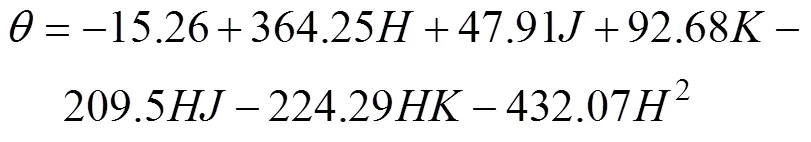

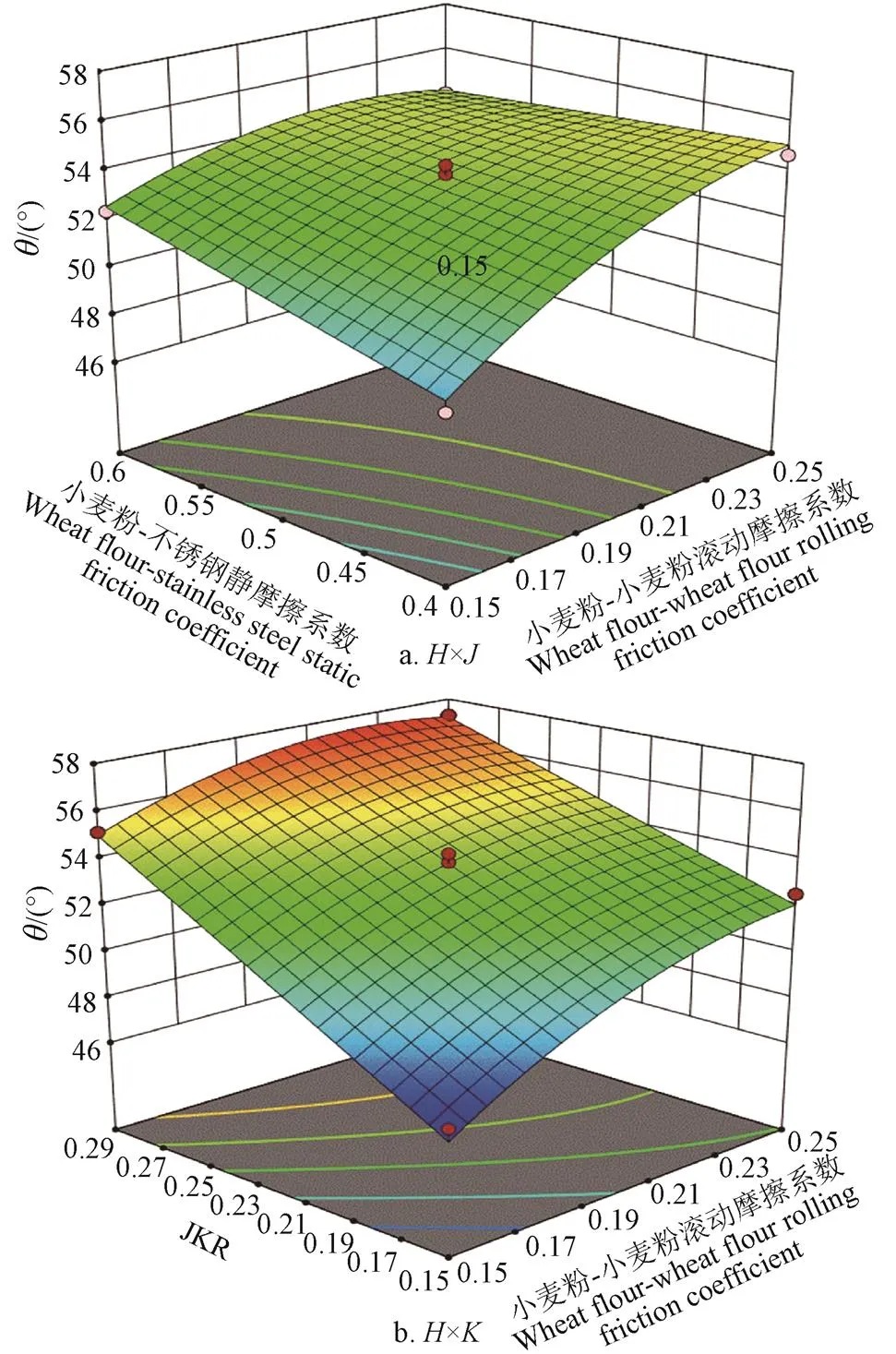

2.3.4 回歸模型交互效應分析

根據優化回歸模型方差分析結果,可知JKR表面能-滾動摩擦系數(í)以及JKR表面能-靜摩擦系數(í)的<0.01,這2個交互項對小麥粉休止角影響極其顯著。在小麥粉-不銹鋼靜摩擦系數()為0.22以及顆粒間滾動摩擦系數()為0.5的2種情況下,應用Design-Expert軟件對JKR表面能-滾動摩擦系數(í)以及JKR表面能-靜摩擦系數(í)交互作用的三維響應曲面進行繪制,如圖3所示,可以直觀的反應交互項對休止角的影響。由í曲面可知,相對于顆粒間滾動摩擦系數(),JKR表面能()的效應面曲線比較陡,表明其對休止角影響較為顯著。由í曲面可知,相對于JKR表面能(),小麥粉-不銹鋼靜摩擦系數()的效應面曲線比較陡,表明其對休止角影響較為顯著。

圖3 HJ與HK的交互效應圖

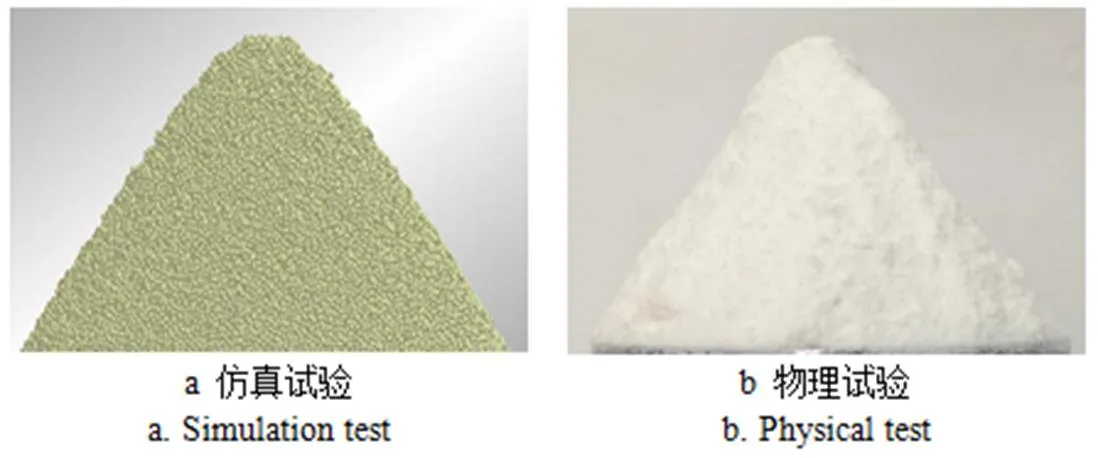

3 最佳參數組合的確定及仿真驗證

應用Design Expert 軟件以小麥粉實際休止角為目標,對優化后的回歸方程進行尋優求解可知,欲使仿真與試驗所得休止角誤差最小,則JKR表面能為0.157,小麥粉-小麥粉滾動摩擦系數為0.25,小麥粉-不銹鋼靜摩擦系數為0.58。用最佳參數組合進行休止角仿真試驗,仿真與物理試驗的對比如圖4所示。仿真試驗所得休止角為52.69o,與實際值52.37o的誤差為0.61%,表明仿真結果與真實試驗值無顯著性差異。

圖4 仿真試驗與物理試驗對比

4 結 論

1)采用顆粒縮放法將粒徑0.212 mm的小麥粉顆粒放大至1.2 mm,基于離散元中JKR模型對放大顆粒的接觸參數進行標定。由 Plackett-Burman 試驗篩選出對小麥粉放大顆粒休止角影響顯著的因素為表面能JKR、小麥粉-小麥粉滾動摩擦系數及小麥粉-不銹鋼靜摩擦系數。

2)根據Box-Behnken試驗結果,建立并優化3個顯著性參數與休止角間的二次回歸模型,根據優化模型方差分析的結果可知,除了3個顯著性參數(JKR表面能、小麥粉-小麥粉滾動靜摩擦系數及小麥粉-不銹鋼靜摩擦系數)的一次項外,交互項JKR表面能-滾動摩擦系數、JKR表面能-靜摩擦系數以及JKR表面能的二次項對小麥粉放大顆粒休止角影響也極其顯著。

3)以小麥粉實際休止角為目標,對回歸方程進行尋優求解,得到顯著性參數的最佳組合為小麥粉-小麥粉滾動摩擦系數為0.25、小麥粉-不銹鋼靜摩擦系數為0.58、表面能JKR為0.157,進行試驗對比,仿真所得休止角與實際所得休止角無顯著性差異(>0.05),表明應用響應面分析標定離散元仿真參數的可行性。

4)以試驗設計所得的最佳參數組合來進行休止仿真試驗,測得仿真試驗的休止角為52.69°,與試驗所測的小麥粉休止角52.37°,兩者誤差為0.61%,模擬值與試驗測試值無顯著差異。結果表明,基于顆粒縮放理論標定所得到的接觸參數可用于小麥粉離散元仿真。

[1] Gao K D, Xu W B, Zhang X, et al. Analysis of spiral aggregate device on the sump cleaning machine by discrete element method [J]. International Journal of Simulation Modelling (IJSIMM), 2018, 17(4): 643-656.

[2] Mazor A, Orefice L, Michrafy A, et al. A combined DEM & FEM approach for modelling roll compaction process[J]. Powder Technology, 2018, 337: 3-16.

[3] Sun Xiaoxia, Meng Wenjun, Yuan Yuan. Feeding head of relative rotary based on EDEM+ FLUENT[J]. Advances in Mech-an-ic-al Engineering, 2018, 10(7): 1-13.

[4] 羅帥,袁巧霞,楊龍元. 基于JKR粘結模型的蚯蚓糞基質離散元法參數標定[J]. 農業機械學報,2018,49(4):343-350. Luo Shuai, Yuan Qiaoxia, Yang Longyuan.Parameters calibration of vermicomposting nursery substrate with discrete element method based on JKR contact model [J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(4): 343-350. (in Chinese with English abstract)

[5] 袁全春,徐麗明,邢潔潔,等. 機施有機肥散體顆粒離散元模型參數標定[J]. 農業工程學報,2018,34(18): 21-27. Yuan Quanchun, Xu Liming, Xing Jiejie, et al. Parameter calibration of discrete element model of organic fertilizer particles for mechanical fertilization [J]. Transactions of the Chinese Society for Agricultural Engineering (Transactions of the CSAE), 2018, 34(18): 21-27. (in Chinese with English abstract)

[6] 王憲良,胡紅,王慶杰,等. 基于離散元的土壤模型參數標定方法[J]. 農業機械學報,2017,48(12): 78-85. Wang Xianliang, Hu Hong, Wang Qingjie, et al.Calibration method of soil contact characteristic parameters based on DEM theory [J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(12): 78-85. (in Chinese with English abstract)

[7] Alizadeh, Mohammadreza, Ghadiri, et al. A methodology for calibration of DEM input parameters in simulation of segregation of powder mixtures: a special focus on adhesion[J]. Powder Technology, 2018, 339: 789-800.

[8] Figueroa I, LI H, Mccarthy Joseph. Predicting the impact of adhesive forces on particle mixing and segregation[J]. Powder Technology, 2009, 195.3: 203-212.

[9] 任建莉,周龍海,韓龍,等. 基于顆粒縮放理論的垂直螺旋輸送離散模擬[J]. 過程工程學報,2017,17(5): 936-943.Ren Jianli, Zhou Longhai, Han Long, et al. Discrete simulation of vertical screw conveyor based on particle scaling theory [J]. Chinese Journal of Process Engineering, 2017, 17(5): 936-943. (in Chinese with English abstract)

[10] Sakai M, Takahashi H, Pain C, et al. Study on a large-scale discrete element model for fine particles in a fluidized bed[J]. Advanced Powder Technology, 2012, 23(5): 673-681.

[11] Weinhart T, Labra C, Luding S, et al. Influence of coarse-graining parameters on the analysis of DEM simulations of silo flow[J]. Powder Technology, 2016, 293: 138-148.

[12] Feng Y T, Owen D R J. Discrete element modelling of large scale particle systems-I: Exact scaling laws[J]. Computational Particle Mechanics, 2014, 1(2): 159-168.

[13] Radl S, Radeke C, Khinast J G, et al. Parcel-based approach for the simulation of gas-particle flows[C]. 8th International Conference on CFD in Oil & Gas, Metallurgical and Process Industries, Trondheim. 2011.

[14] Thakur SC, Ooi JY, Ahmadian H. Scaling of discrete element model parameters for cohesionless and cohesive solid[J]. Powder Technology, 2016, 293: 130-137.

[15] 周龍海. 垂直螺旋輸送的EDEM仿真與實驗研究[D]. 杭州: 浙江工業大學,2017. Zhou Longhai. EDEM Simulation and Experiment of Vertical Screw Conveyoring [D].Hangzhou: Zhejiang University of Technology, 2017. (in Chinese with English abstract)

[16] Sakai M, Abe M, Shigeto Y, et al. Verification and validation of a coarse grain model of the DEM in a bubbling fluidized bed[J]. Chemical Engineering Journal, 2014, 244: 33-43.

[17] 彭飛,王紅英,方芳,等. 基于注入截面法的顆粒飼料離散元模型參數標定[J]. 農業機械學報,2018,49(4): 140-147.

Peng Fei, Wang Hongying, Fang Fang, et al. Parameter calibration of discrete element model parameters for pellet feed based on injected section method [J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(4): 140-147. (in Chinese with English abstract)

[18] 劉凡一,張艦,李博,等. 基于堆積試驗的小麥離散元參數分析及標定[J]. 農業工程學報,2016,32(12): 247-253. Liu Fanyi, Zhang Jian, Li Bo, et al. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap [J]. Transactions of the Chinese Society for Agricultural Engineering (Transactions of the CSAE), 2016, 32(12): 247-253. (in Chinese with English abstract)

[19] 賀一鳴,向偉,吳明亮,等. 基于堆積試驗的壤土離散元參數的標定[J]. 湖南農業大學學報:自然科學版,2018,44(2): 216-220. He Yiming, Xiang Wei, Wu Mingliang, et al. Parameters calibration of loam soil for discrete element simulation based on the repose angle of particle heap[J]. Journal of Hunan Agricultural University: Natural Science Edition, 2018, 44(2): 216-220. (in Chinese with English abstract)

[20] 張銳,韓佃雷,吉巧麗,等. 離散元模擬中沙土參數標定方法研究[J]. 農業機械學報,2017,48(3): 49-56. Zhang Rui, Han Yulei, Ji Qiaoli, et al.Calibration methods of sandy soil parameters in simulation of discrete element method [J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(3): 49-56. (in Chinese with English abstract)

[21] 賈富國,韓燕龍,劉揚,等. 稻谷顆粒物料堆積角模擬預測方法[J]. 農業工程學報,2014,30(11): 254-260. Jia Fuguo, Han Yanlong, Liu Yang, et al. Simulation prediction method of repose angle for rice particle materials [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(11): 254-260. (in Chinese with English abstract)

[22] 張西良,張建,李萍萍,等. 粉體物料流動性仿真分析[J].農業機械學報,2008(8): 196-198.

[23] 郝友莉. 粉體包裝螺旋式密實輸送研究[D]. 無錫:江南大學,2017. Hao Youli. Research on Densifying Transportation of Spiral Powder Packaging Machine [D]. Wuxi:Jiangnan University, 2017. (in Chinese with English abstract)

[24] 張帥,單忠德,張杰. 基于離散元方法的型砂流動性仿真研究[J].鑄造技術,2016,37(2):288-291. Zhang Shuai, Shan Zhongde, Zhang Jie.Simulation of self-hardening resin sand mobility based on DEM [J]. Foundry Technology, 2016, 37(2): 288-291. (in Chinese with English abstract)

[25] 張建. 粉體定量加料器及應用研究[D]. 鎮江:江蘇大學,2008. Zhang Jian. Powder Dosing Devices and its Application [D]. Zhenjiang: Jiangsu University, 2008. (in Chinese with English abstract)

[26] 李明菲. 不同熱處理方式對小麥粉特性影響研究[D].鄭州: 河南工業大學,2016. Li Mingfei. Effect of Different Heat Treatment Methods on Wheat Flour Characteristics[D]. Zhengzhou: Henan University of Technology, 2016. (in Chinese with English abstract)

[27] 王崇崇. 粒度對小麥粉及面條品質特性的影響機理研究[D]. 鄭州: 河南工業大學, 2018. Wang Chongchong. Study on the Effects of Different Heat Treatment on Wheat Flour Characteristics [D]. Zhengzhou: Henan University of Technology, 2018. (in Chinese with English abstract)

[28] Chichti E. Multi-scale Approach for Understanding the Link between Triticum Aestivum Grain Texture and Milling Behaviour: Focus on the Endosperm Microstructure and Local Nano-mechanical Properties[D]. Montpellie: SupAgro, 2013.

[29] Kumar S, Saini C S. Study of various characteristics of composite flour prepared from the blend of wheat flour and gorgon nut flour[J]. International Journal of Agriculture, Environment and Biotechnology, 2016, 9(4): 679-689.

[30] 石林榕,趙武云,孫偉. 基于離散元的西北旱區農田土壤顆粒接觸模型和參數標定[J]. 農業工程學報,2017,33(21): 181-187.Shi Linwei, Zhao Wuyun, Sun Wei.Parameter calibration of soil particles contact model of farmland soil in northwest arid region based on discrete element method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(21): 181-187. (in Chinese with English abstract)

[31] Mio H, Akashi M, Shimosaka A, et al. Speed-up of computing time for numerical analysis of particle charging process by using discrete element method[J]. Chemical Engineering Science, 2009, 64(5): 1019-1026.

[32] Weinhart T, Hartkamp R, Thornton A R, et al. Coarse-grained local and objective continuum description of three-dimensional granular flows down an inclined surface[J]. Physics of Fluids, 2013, 25(7): 1-26.

Parameter calibration of wheat flour for discrete element method simulation based on particle scaling

Li Yongxiang1, Li Feixiang1, Xu Xuemeng1※, Shen Changpu1, Meng Kunpeng1, Chen Jing1, Chang Dongtao2

(1.,,450001,; 2..,450001)

In order to obtain the precise parameters for the wheat flour discrete element simulation, the actual repose angle of wheat flour was firstly measured by injection method. The experimental material was ordinary wheat flour, which average particle diameter is 0.212 mm and went through a 70-mesh standard sieve. Refer to GB 16913.5-1997, the inner diameter of the used funnel was 5 mm, the taper was 60°, and the cylindrical chassis was 80 mm in diameter. The result indicated the repose angle of the wheat flour was 52.37°, which was average value of five experiments. The irregular wheat flour was simplified into soft spherical particles, and then those particles with the size of 0.212 mm were enlarged to 1.2 mm for simulation thanks to the particle scaling and dimensional analysis, during those analyses, the3D modeling and simulation were finished by SolidWorks and EDEM software respectively. Considering the bonding characteristics between wheat flour particles, the “Hertz-Mindlin with JKR” contact model was selected to calibrate the contact parameters of wheat flour for discrete element simulation with the repose angle as a reference. Then, through the design-expert software, the parameters that have significant influence on the repose angle of wheat flour by Plackett-Burman test design are surface energy JKR, the rolling friction coefficient for wheat flour-wheat flour, the static friction coefficient for wheat flour-stainless steel. According to the significance parameters designed and screened by the Plackett-Burman test, the steepest ascent test was carried out so that it could be quickly close to the optimal value. The steepest ascent test was stared at the center of the Plackett-Burman test and the step size was determined by the regression coefficients obtained from the test. The Box-Behnken test was then carried out by selecting the low, medium and high levels of the significant parameters according to the results of steepest ascent test and the design principle of response surface, and then the three mediate points were selected to evaluate the errors. At last, the quadratic polynomial model for the repose angle and the significant parameters was successfully established and optimized by the Box-Behnken test. The analysis of variance (ANOVA) of the quadratic polynomial model showed that this model was significant and the lack-of-fit term was non-significant, which means the model can be applied to determine whether the parameters combination is the best. However, some terms in the quadratic polynomial model were non-significant. Therefore, a modified regression model was established by deleting those non-significant terms. The ANOVA of the modified model showed all of the terms were desirable, and the first-order term of those 3 significant parameters, the interactive term of the wheat flour-wheat flour static friction coefficient and JKR surface energy, and the interactive term of the wheat flour-wheat flour rolling friction coefficient and JKR surface energy had a significant effect on the repose angle. The best combination of the significant parameters could be achieved when the JKR value was 0.157, the rolling friction coefficient of wheat flour-wheat flour was 0.25, and the static friction coefficient of wheat flour-stainless steel was 0.58. Finally, the rest simulation test was carried out with the optimal combination of parameters obtained from the experiments, which showed that the repose angle of the simulation test was 52.69°, the error of the repose angle measured by the test was 0.61%, and there was no significant difference between the simulation results and the actual test values. In conclusion, the contact parameters obtained based on the particle scaling calibration can be used for wheat flour discrete element simulation which was shown by the experimental results.

agricultural products; particle size; discrete element method; calibration of parameters; repose angle

2019-03-15

2019-06-28

國家重點研發計劃項目(2018YFD0400704);河南省科技廳自然科學項目(182102110163)

李永祥,教授,博導,糧食機械及理論。Email:liyongxiang@haut.edu.cn

徐雪萌,副教授,主要從事糧油食品包裝工藝與裝備研究。Email:xuxuemeng7439@163.com

10.11975/j.issn.1002-6819.2019.16.035

O347.7; TP391.9

A

1002-6819(2019)-16-0320-08

李永祥,李飛翔,徐雪萌,申長璞,孟坤鵬,陳 靜,常東濤.基于顆粒縮放的小麥粉離散元參數標定[J]. 農業工程學報,2019,35(16):320-327. doi:10.11975/j.issn.1002-6819.2019.16.035 http://www.tcsae.org

Li Yongxiang, Li Feixiang, Xu Xuemeng, Shen Changpu, Meng Kunpeng, Chen Jing, Chang Dongtao. Parameter calibration of wheat flour for discrete element method simulation based on particle scaling[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(16): 320-327. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.16.035 http://www.tcsae.org