Modeling and simulation of muzzle flow field of railgun with metal vapor and arc

Yun Go , Yn-jie Ni , Zho-xin Wng , Ying-to Xu , Yong Jin ,*, Bo-ming Li ,b

a National Key Laboratory of Transient Physics, Nanjing University of Science and Technology, Nanjing 210094, Jiangsu, China

b China Academy of Ordnance,100089, Beijing, China

Keywords:Railgun Flow field Muzzle Plasma Simulation Al vapor

ABSTRACT During the electromagnetic railgun launching process, there will be a complex flow field with high temperature in the muzzle area because of the high-speed friction,transition and secondary arc-ignition.This paper models the muzzle area of railgun when the projectile is far away from the muzzle, and the dynamic simulation of the flow field with secondary arc in the muzzle area is carried out based on the magneto hydrodynamic equations. Meanwhile, a multi-component plasma transport model is used to analyze the muzzle arc plasma flow process of the mixed gas of Al vapor and the air. Furthermore, the pressure boundary conditions are fitted by the dynamic mesh simulation results.The current and voltage of the muzzle are obtained through the emission experiment of the railgun experimental prototype. We load the current data into the simulation model and the voltage of experiments and simulations are compared, which proves the accuracy of the simulation. Then the plasma temperature and the composition of Al vapor in the muzzle flow process are analyzed in-depth.

1. Introduction

Electromagnetic railgun is a new concept launching weapon with high controllability and super-high-speed launching capability.The projectile is accelerated quickly in bore by Lorentz force generated by high-energy pulse power supply discharge [1-3]. A projectile weight 3 g has been accelerated to 5.9 km/s by Marshall in 1977[4]. However, during the launching process of the electromagnetic railgun, the high-speed movement of armature in bore produces severe friction.With the transition phenomenon and the secondary arc after armature discharge[5-7],the muzzle flow field environment of electromagnetic railgun is complex, which is mainly reflected in the diversified ionic components, high temperature and speed. Weimier recorded the process of blast at muzzle and breech during the launching of railgun by the high speed photography and spectrophotometry [8]. The movement process and temperature of ion beam at muzzle and breech during the whole launching process were analyzed in detail,and the back flow phenomenon of high temperature gas in the launching process of electromagnetic railgun was put forward. Yong He suppressed the muzzle arc to a certain extent by improving the muzzle device [9]. Many scholars have also carried out experimental and theoretical research on muzzle voltage of electromagnetic railgun[10-12].However,for the numerical mechanism analysis of muzzle flow field, especially considering secondary arc and metal vapor,there are less specific works at present. Considering that the phenomenon of backflow of muzzle flow field and the high temperature characteristics of muzzle plasma may have great impacts on in-bore environment and projectile launching, it is necessary to conduct a research numerically of the muzzle flow field with metal vapor.

In this paper, a hydrodynamic model is established for the muzzle air region of railgun, and the dynamic simulation of the railgun muzzle flow field when the armature far away from the muzzle is conducted by FLUENT.This model is based on the theory of magneto hydrodynamics (MHD), and the plasma transport model is also considered. Then the research on numerical simulation and mechanism study of muzzle plasma flow field mixed with Al vapor is realized.In order to improve the accuracy of simulation,the pressure boundary conditions of plasma simulation model are obtained by aerodynamic simulation with projectile motion.Furthermore, the results of muzzle voltage and current are obtained through the experiment of the railgun prototype shown in Fig.1(In order to see the muzzle structure more intuitively,some of the original parts have been removed). With reference to the current setting potential boundary conditions, and the simulated voltage is in good agreement with the experimental voltage curve.In this paper, the process of plasma backflow at muzzle during launching is analyzed. In particular, the temperature of ions, the development of Al vapor mass fraction in muzzle area and the effect to the flow field in bore are discussed.

Fig.1. Muzzle photograph of railgun experimental prototype.

2. Model

2.1. Physical model

In this paper, we mainly study the plasma characteristics and movement process of the muzzle arc after the projectile is far away from the muzzle. At this time, the gas outside the muzzle moves into the bore mainly because of the pressure and density difference between inside and outside the bore. Therefore, the calculation region can be simplified to a part of the muzzle area. Fig. 2 is the simplified muzzle diagram of the railgun experimental prototype,in which the computational region of the model involved in this paper is indicated. And d is the distance between muzzle rails,which is 0.03 m.Because the plasma combustion model of cathode emission is adopted,half computational domain is used to simulate the flow characteristics of the whole muzzle area.Fig.3 shows the three-dimensional muzzle arc model mentioned in Fig.2.There are various boundary types in this model,where ABHG is the pressure boundary connecting the interior of the railgun. ABCD, BC1I1H are non-slip interfaces used to simulate the upper and lower rails,and ABCD is defined as the wall where the negative pole is located.HIJG is a non-slip interface for simulating inner bore wall. AGLF is a symmetrical surface,and the rest are air interfaces in contact with external air.A more intuitive classification of interfaces is shown in Fig. 3.

In the simulation of plasma flow of the railgun muzzle, a simplified calculation model is adopted as shown in Fig. 3. However,the muzzle flow field environment is very complex due to the high speed movement of the projectile, which makes it difficult to set boundary conditions for muzzle plasma simulation. In this paper, the aerodynamic simulation of the whole process of railgun launching is carried out by moving boundary and dynamic mesh laying method, and this simulation method has been proved to be accurate in this environment by previous work [13]. Through the analysis of the simulation results, the boundary conditions of the plasma model are set.

The assumptions are introduced here to simplify the heat transfer and flow of plasma:

1) The physical properties of the air in the arc ignition area are affected by the fluid temperature and other factors.

2) In this paper we ignore the interaction of arc and electrode,thus in the arc column area the plasma is electrically neutral.

3) In order to simplify the calculation and improve the computational efficiency, the magnetic conductivity of the arc is considered as constant. And within very short time after the start of backflow, the position of arc is set as a certain one.

4) The effect of metal particle friction and combustion can be ignored.

5) In the initial flow field of the arc model,an initial arc exists in the railgun [14].

Fig. 2. The computational region of simulation model.

Fig. 3. The model boundary setting.

2.2. Computational model

In the muzzle plasma model,the plasma flow field is affected by the electromagnetic field of the muzzle,which is mainly embodied in the volume force of Lorentz force on the ion motion and the combustion and radiation of the ion itself.Therefore,the flow field governing equations can be described as follows:

1) The momentum equation

2) The energy equation

3) The mass conservation

The source terms Siand STreflect the volume effect and thermal radiation of the plasma respectively. viis the velocity components in Cartesian coordinate system.μ is the viscosity coefficient,and λ is the thermal conductivity. In order to solve the equations, the Maxwell’s equations are introduced as follows:

4) The momentum source term

5) The energy source term

6) The electric field equation

7) The magnetic field equation

8) Ideal gas state equation:

Where J is the current density,B is the magnetic field intensity,φ is the electric potential, A is the magnetic vector potential. The plasma physical parameters are electrical conductivity σ, net emission coefficients εn, Boltzmann constant kB, and constant pressure specific heat capacity cP.Air is set as ideal state gas at low temperature (less than 2000 K), and as the temperature rises the physical parameters such as gas density are defined as the quantity determined by pressure and temperature. For multi-component fluids, besides solving the above equations, the mass fraction equation of each component in mixed plasma should also be considered.

9) Component transport equation

Where Jiis diffusive flux of component i, Yiis the mass fraction of component i,Riis the net yield of component i caused by chemical reaction, and Siis the increasing rate of component i due to other factors. Chemical reactions are not considered in this paper, and there are no other source terms in consideration. Therefore, Ri=Si= 0.

The above fluid equation is solved by FLUENT software, and its source term is realized by FLUENT. The electromagnetic field Eqs.(4)-(9) is realized by UDF code, thus the equation is closed. The second-order upwind mode is chosen to ensure the accuracy of the solver, and then the simulation is completed. Orthogonal structured grids are used in the model, and the mesh is refined to 0.00004 m at the arc root to avoid divergence.

2.3. Physical parameters of multicomponent plasma

According to the measurement results of Weimier, during the launching process of the railgun, the muzzle blast mainly includes Al ions, Cu ions, O2ions, OH-ions and so on [8]. Referring to the material of the device (the rails material is mainly copper,and the armature material is mainly aluminum) and the complexity of the model calculation, Al ion and air plasma are considered as the research objects for the time being.The number of equations can be greatly reduced by mixing diffusion method and considering two kinds of mixed gases. The diffusion coefficients of two gases are provided by Murphy et al. [15,16].

2.3.1. Transport coefficient of multicomponent plasmas

The parameters of mixed gases are obtained by linear interpolation. Yiis the mass fraction of component i, and Miis the molar mass of component i.

1) Density

2) Specific heat

3) Viscosity

4) Thermal conductivity

5) Electric conductivity

2.3.2. Physical parameters of plasma

The physical parameters of mixed gases are shown in Fig. 4[15,16].

3. Boundary condition

3.1. Experiments and results

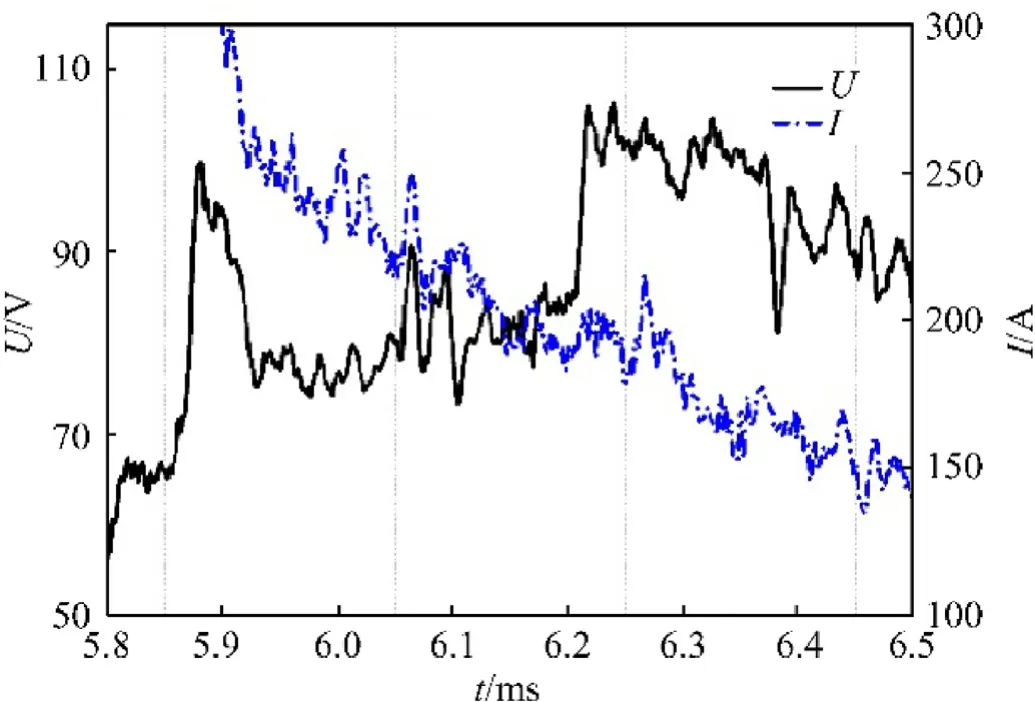

The boundary conditions of the plasma model are very important for an accurate simulation.Therefore,the launch experiment of the railgun experimental prototype has been carried out. The muzzle voltage and current are measured by high-voltage probe and Roche coil. Fig. 5 is the muzzle voltage curve during the launching process. It can be clearly observed that there is a rising and falling process after the muzzle time as shown in the figure.It is pointed out in literature[7]that there exists a secondary arc in the muzzle during the launching process of the railgun, and the arc exists after the armature comes out of the muzzle. Literature [9]suppresses muzzle arc by external trigger switch,and it can be seen from the test data that the action time of the switch corresponds to the voltage rise time after armature discharge. After comparative analysis, we can conclude that there exists muzzle arc after the muzzle time shown in Fig. 5.

The measured current is used as the boundary condition of current density.Fig.6 shows the arc voltage and the corresponding current curve.By fitting the current curve,the max value of current density at the arc root of the negative pole is set as function g(t).

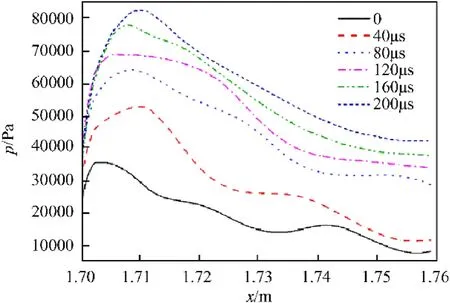

3.2. Simulation results of pressure boundary conditions

Because of the high-speed movement of the projectile (about 860 m/s) and the specific bore structure of the railgun, the flow field environment is very different from that of the artillery, etc.Therefore, the influence of complex fluid environment caused by the projectile motion must be considered in the dynamic simulation calculation of the muzzle plasma flow field. Because of the simple model adopted in this paper, the pressure boundary conditions are more difficult to define.

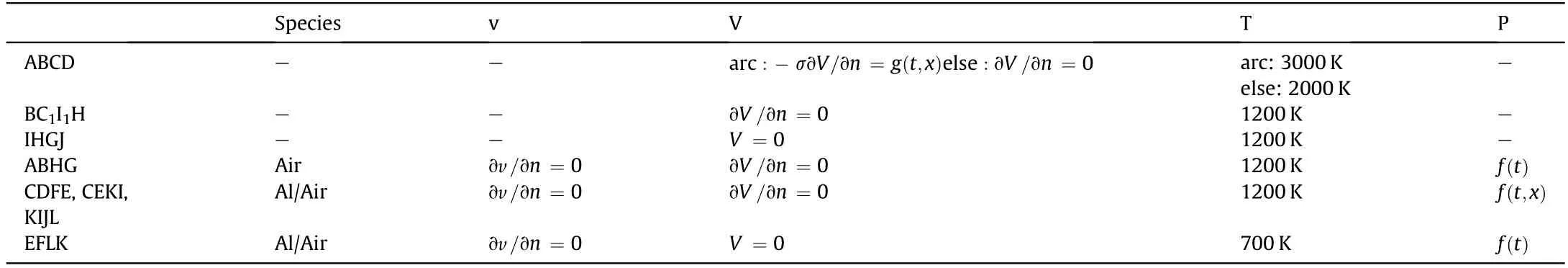

In this paper, the dynamic simulation of the whole launching process of railgun is carried out, and the pressure distribution of boundary CDEF is shown in Fig. 7. We find that the pressure distribution along the pressure boundary of the MHD model (CDEF,CEKI,and KIJL shown in Fig.3)varies with time in a certain period of time after the projectile exit.Therefore,these pressure boundary conditions are fitted to the function of both time and coordinate f(t,x) to simulate the impact of projectile motion. Similarly, the other two(ABHG and EFLK shown in Fig.3)gas pressure boundary conditions can also be fitted as the function of time f(t), and the specific boundary conditions are set as shown in Table 1.

The temperature of the armature is got from the result of armature Joule heating[17].As mentioned in the previous content,the maximum current density at the arc root is fitted as a function of time g(t). Therefore, the arc distribution in the arc root region obeys a parabolic distribution, which can be expressed as follows:

Fig. 4. The physical parameters of plasma (1 atm).

According to literature [18] and current value in this paper, the radius of arc root is 0.9 mm,thus the parameter b is set to 1.23×106[19].

4. Results and analysis

4.1. Temperature and potential distribution in initial state (t=0)

In this paper, because the arc shift and the high-speed movement of the projectile may affect the muzzle plasma flow field,we only simulates the dynamic arc in a short time (less than 200 μs).For convenience, the time with better data quality (5.95 ms-6.15 ms) in Fig. 6 were selected as the simulation duration.Based on this, the motion process and the characteristics of the railgun muzzle plasma are simulated.Fig.8 shows the temperature distribution of muzzle flow field in the initial state. It can be seen that the muzzle arc is contracted at the base of arc. At the same time, the temperature rises sharply and is much higher than 20000 K. In fact, the temperature here exceeds 26000 K in our simulation results.Ablative phenomena can easily occur when the high temperature is transferred through arc and rail. Moreover,temperature in most arc column region exceeds 6000 K and covers most part of the muzzle model area. In this, the muzzle arc has a significant impact on the energy and flow of the muzzle flow field.

In Table 1, the lower rail is set as the virtual anode, where the potential is zero.The air area in the direction of projectile motion is also set as the zero potential area. Fig. 9 shows the potential distribution of muzzle area in the initial state, where the potential shrinks rapidly near the cathode area and the gradient rises. The potential in the cathode region is less than-62 V,and the potential difference is slightly lower than the voltage measured in the experiment. Considering that the voltage measuring device does not directly measure arc voltage and has its own test error, this situation is acceptable. For convenience, the time now is set to 0,and then the model is simulated dynamically.

Fig. 5. Muzzle voltage curve.

Fig. 6. Voltage and corresponding current in the muzzle.

Fig. 7. Pressure distribution of aerodynamic simulation results.

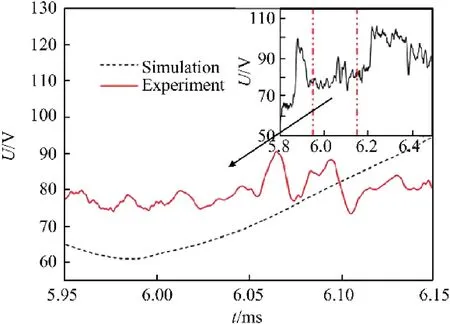

4.2. The arcing voltage

In this paper, the simulation voltage and experimental results are used as comparison items to judge the correctness of the simulation. Fig. 10 is the voltage curve in experiment and simulation. The two curves are consistent in magnitude, and the simulated values are slightly smaller than that of the experiment,which may be due to the fact that the high-voltage probe dose not measure the voltage of arc directly(as shown in Fig.2).The voltage curves of the simulation results are similar to those of the test results. Considering the test errors caused by the interference in the launching process, it can be considered that the simulation has a certain degree of correctness and credibility. From this point of view, measurement methods of the voltage and the current with higher accuracy and time resolution can play a great role in the study of the muzzle plasma flow field.

4.3. Moving process of muzzle arc

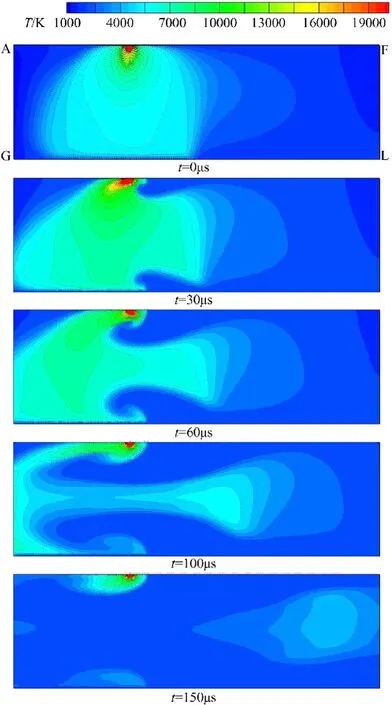

Compared with classical intermediate ballistics[20],there is no high temperature and high pressure propellant gas after projectile in electromagnetic railgun launching process. In addition, the velocity of the projectile is much higher than that of the sound.Considering that both muzzle and tail are connected externally,the inner bore of railgun is in a unique ultra-low pressure state. It is mainly reflected in the expansion wave and shock wave generated by projectile motion,as well as the ultra-low pressure environment in the inner bore and in the area after projectile. The high temperature plasma in railgun muzzle should have an outward expansion process[13],which is not described in detail here.Fig.11 show the dynamic change of the plasma temperature distribution in the muzzle area after the muzzle gas begins to flow back.Fig.11 when t=0 μs is the initial flow field.Because of the combustion and radiation of the arc, most of the muzzle area is in a high temperature environment above 6000 K. With the air shrinking in the muzzle area,the pressure is higher than that in the inner bore.Thus the external gas begins to move towards the inner bore of the railgun,which also causes the deformation of the muzzle arc.After 30 μs,the high temperature plasma gradually deflects into the bore.This process raises the gas temperature in bore to over 6000 K,which is much higher than the boiling point of metal materials commonly used in rail (such as copper: 2835 K, steel: 2633 K). At the same time, the cloud image shows that a part of the air mass with a maximum temperature of 3000 K will move toward the projectile. In Weimier’s experimental results [8], the temperature of metal vapor outside the bore ranges from 2600 K to 3700 K.The experimental results show that the arcing time should exceed 1 ms[9], which indicates that the muzzle arc moves towards the bore continuously and then the negative effects such as ablation will be brought to the bore.

4.4. The aluminum ion distribution

In the muzzle process of railgun launching, there are visible plasma light masses in the muzzle area after projectile out of the muzzle. These metal vapors eject from the railgun with the projectile motion, which are mainly produced by transition phenomena and friction between armature and rail.The main components of these plasma light masses are also determined by air,materials of the armature and the rail.In the definition of boundary conditions of this paper,the gas in the flow field outside the muzzle is mainly composed of Al vapor,while air only accounts for a small part(less than 3%).Fig.12 shows the mass fraction distribution of Al ions.At 30 μs, part of the metal vapor has moved to the arc position along with the backflow gas in the muzzle area. Because of the high velocity of gas flow in the muzzle flow field of railgun,the metal vapor has surrounded the arc root position at 60 μs and filled the whole muzzle space at 100 μs. With the continuation of the backflow movement, the metal vapor has moved into the bore at 150 μs.Compared with the temperature distribution in Fig. 11, the peaktemperature of the backflow Al metal vapor also exceeds 6000 K.It can be predicted that this part of Al metal vapor with high temperature and high velocity will rush into the inner bore rapidly.One part of plasma condenses and deposits as the temperature drops,the other part will continue to rush out of the gun breech in the ionic state to form the breech blast, which is also a plasma flow characteristic of the railgun.

Table 1 Boundary conditions.

Fig. 8. Temperature distribution of initial flow field.

Fig. 9. Potential distribution of initial flow field.

Fig.10. Comparison of simulation and test voltage curves.

Fig.11. Temperature distribution.

4.5. The internal backflow

Fig.12. Mass fraction of Al.

In order to make a more detailed analysis of the metal vapor mass backflow,the mass fraction and the temperature distribution on the inner bore boundary (ABGH in Fig. 3) at 150 μs are given.Fig.13 shows the mass fraction distribution of Al ions, where the mass fraction of most regions exceeds 0.5.It can be explained that metal vapor is the main component of the air mass moving towards the bore during the muzzle backflow process. Fig.14 is the corresponding temperature distribution. The temperature on the main body of the air mass is higher than 2000 K, and the peak value is about 4000 K.In the initial state,we define a very low temperature of 1200 K for the metal vapor in the boundary condition. It can be seen that there is a heating process of metal vapor under the influence of muzzle arc, which aggravates the movement of high temperature Al metal vapor towards the inner bore.

5. Conclusion

Fig.13. Mass fraction of Al at 150 μs.

Fig.14. Temperature distribution at 150 μs.

In this paper, a three-dimensional simulation model of metal vapor and arc in the muzzle flow field of electromagnetic railgun is established, aiming at the complex flow field of high-speed gas,secondary arc and metal vapor in the muzzle flow field during launching. The movement and influence of metal vapor in the muzzle flow field are considered through the component transport equation.The aerodynamic simulation results are analyzed,and the dynamic boundary conditions are set to simulate the flow field changes caused by the projectile movement in the muzzle area.At the same time, combined with the emission test results of prototype, the current is introduced into the plasma model and the voltage of simulation and experiment is compared.It is found that there is a certain consistency between the current and the experimental voltage.The conclusions are as follows:

1) By introducing metal vapor and setting dynamic boundary conditions according to aerodynamic simulation results, the combustion and deformation process of arc and the movement characteristics of metal vapor can be simulated.This method has certain accuracy compared with experiment.

2) There is a remarkable in-bore backflow process in the muzzle plasma,which mainly includes the movement of metal vapor in muzzle area and the migration of arc plasma to the bore.

3) In the backflow air mass,the main component is Al metal vapor,and the gas mass is heated by arc during the backflow process.The temperature of the gas mass is much higher than its boiling point,which will make some metal vapor move farther into the bore and eject out from the breech of the gun.

In conclusion, the muzzle arc has negative impacts on muzzle environment and bore interior, which are mainly reflected in the complexity of muzzle flow field environment and the rise of temperature,as well as the intensification of Al deposition in bore. An effective arc suppression method or muzzle structure is necessary to ensure high precision and high efficiency of railgun.At the same time, considering more components of the muzzle flame plasma can improve the accuracy of the calculation model, and it is necessary to better simulate the impact of high-speed projectile motion on the muzzle region plasma,which requires further study.

- Defence Technology的其它文章

- Novel approach for active vibration control of a flexible missile

- Performance study of jute-epoxy composites/sandwiches under normal ballistic impact

- Arbitrary-oriented target detection in large scene sar images

- Fast-armored target detection based on multi-scale representation and guided anchor

- Fragment spatial distribution of prismatic casing under internal explosive loading

- Experimental study of transient pressure wave in the behind armor blunt trauma induced by different rifle bullets