高溫下IC10合金的動態(tài)再結(jié)晶特性研究

張宏建 溫衛(wèi)東 崔海濤

(南京航空航天大學(xué)能源與動力學(xué)院,南京,210016,中國)

INTRODUCTION

In recent years,ordered Ni3Al based intermetallic compounds have been intensively studied as the potential high temperature structural materials in the aerospace applications,e.g.,turbine engine components.Such materials have the features of high specific modules, high yield strength,fairly good ductility from room temperature to elevated temperature,high incipient melting temperature,excellent oxidation resistance,and high creep resistance over a wide range of temperatures.Alloy IC10is a newly developed Ni3Al based superalloy,which can be used as advanced aero-engine van materials at service temperature that is 1 373 K[1].

Extensive studies are made for the applications of alloy IC10. And various constitutive models are developed to describe the strain hardening behaviors at different temperatures and strain rates[2-6].But the studies about the recrystallization behaviors of alloy IC10 at elevated temperatures are still rare.

The evolution of the microstructure under high temperatures involves strain hardening,dynamic recovery, recrystallization, and grain growth,all of which are highly related to temperature and strain rate.In particular,recrystallization leads to the local elimination of a large number of dislocations and is generally associated with a decrease in the average grain size.Although state-variable based constitutive equations for materials undergoing hot work are successful in describing strain hardening and dynamic recovery,the limited work are performed in addressing dynamic recrystallization within a continuum framework.

In this paper,the recrystallization and the fracture behaviors of IC10 are investigated based on experiments,and a new phenomenological constitutive model is developed to describe the recrystallization behaviors.The effectiveness of the model is also verified by the extensive experiments on IC10.

1 EXPERIMENTAL PROCEDURES AND RESULTS

1.1 Experimental procedures

Ni3Al based alloy IC10,supplied by the AVIC1 Beijing Institute of Aeronautical Materials,is a directional solidification material in[001] orientation with itsnominal composition (in weight):0.07%—0.12%C,11.5%—12.5%Co, 6.5%—7.5%Cr, 5.6%—6.2%Al, 4.8%—5.2%W, 1.0%—2.0%Mo, 6.5%—7.5%Ta, 1.3%—1.7%Hf,0.01%—0.02% B,and Bal. Ni.The alloy is prepared by vacuum induction furnace and followed by casting to ingots.The column tensile specimens with dimension of H10 mm×50 mm are machined from the bars.

To investigate recrystallizational behaviors of IC10,tensile experiments are carried out at four different strain rates(10-2,10-3,5×10-4,and 10-4s-1)under the temperature of 900°C,which is attained with a high-intensity quartz lamp in a radiant-heating furnace(M TS653 furnace).All tests are conducted with M TS809 system,a computer-controlled,servo-hydraulic tensile torsion machine.All the specimens are strained to fracture and then cooled in the air to room temperature.The experimental data are gathered with the signal automatism gather system of M TS809.

To characterize fracture behaviors of IC10, the deformed specimens are observed by scanning electron microscopy(SEM)examinations on a JSM-5600LV SEM. The transmission electron microscopy(TEM)examinations are operated to describe the deformation mechanisms.For TEM examinations,slices parallel and vertical to the tensile axis are cut from specimens by spark erosion. The foils are prepared by using twin-jet electropolishing and examined on a JEM-2010 analytical transmission electron microscope.

1.2 Experimental results

The stress-strain(e-X)curves recorded at different strain rates(10-2,10-3,5×10-4,and 10-4s-1)under 900°C are shown in Fig.1.As shown in Fig.1,the flow stress is sensitive to the strain rate.But the stress-strain curve at every stain rate exhibits similar features: firstly the flow stress positively increases with the strain before the critical strain,and then the softening happens after the critical strain,which is the typical dynamic recrystallization curve.A close comparison among these curves at different strain rates reveals that the flow stress,the critical stress and the critical strain increase with strain rates.

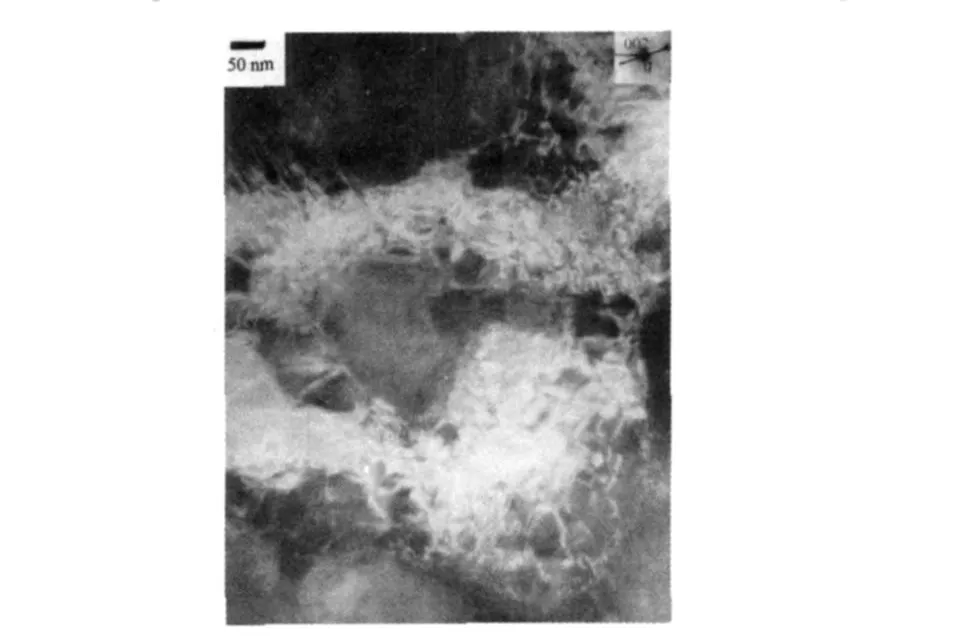

Fig.2 shows one of the typical bright-field images of dislocation structures in foils from specimens deformed to fracture at 900°C.As shown in Fig.2,the dislocations have a tendency to form either edge or screw segments on the cube plane so that almost regular square nets of dislocations can be observed.A great number of dislocation nets lead to the formation of the slipbands at phase boundaries.During the formation process, a lot of dislocations are annihilated,thus leading to the decrease of dislocation density and the softening effect of material.It is known that the dislocation greatly multiply in the process of deformation.And the multiplication can lead to the hardening effect of material.At the beginning of deformation,the multiplication rate is greater than the annihilation rate,and the hardening effect dominates.When the dislocation density achieves a critical value,the multiplication rate is equal to the annihilation rate,and the flow stress gets saturation.After that,the softening effect can colltrol the deformation if the multiplication rate is less than the annihilation rate.That is the mechanism of recrystallization behavior of metals.

Fig.2 Bright-field image

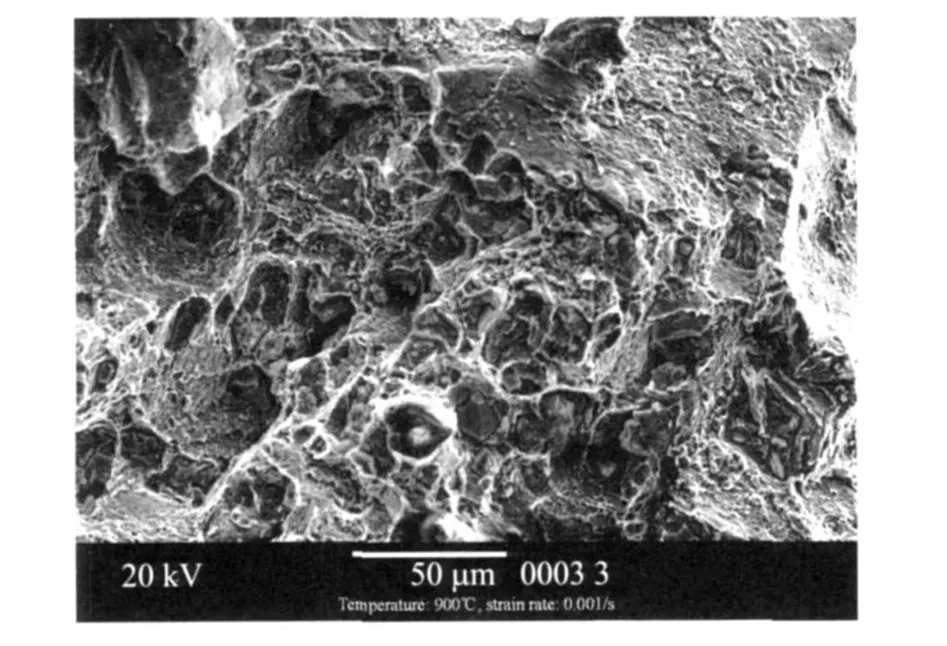

Fig.3 is one of the typical SEM images of fracture surface of alloy IC10 at 900°C,and shows that the fracture is the dimple fracture character mixed with a few of intergranular.

Fig.3 SEM image

2 DEVELOPMENT OF CONSTITUTIVE EQUATION

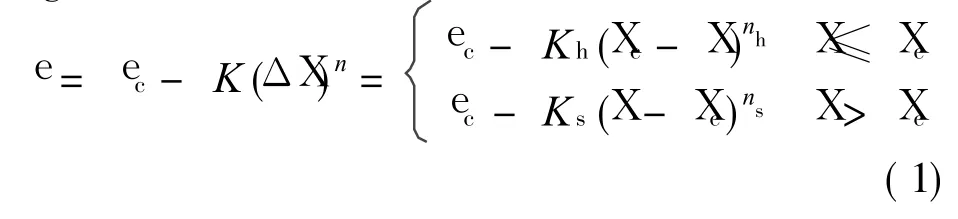

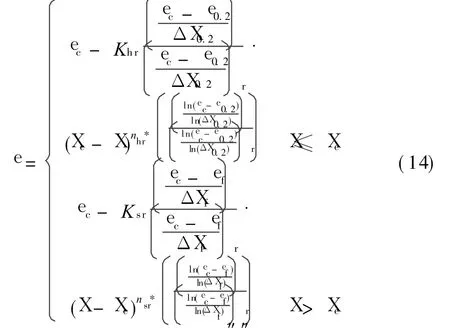

A new constitutive model is proposed for describing the recrystallization behaviors as following formulations

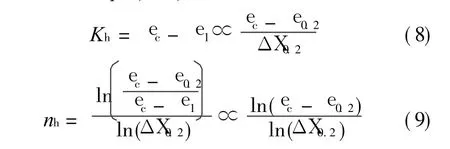

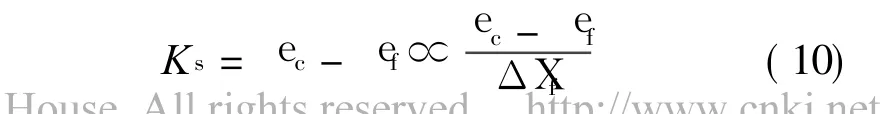

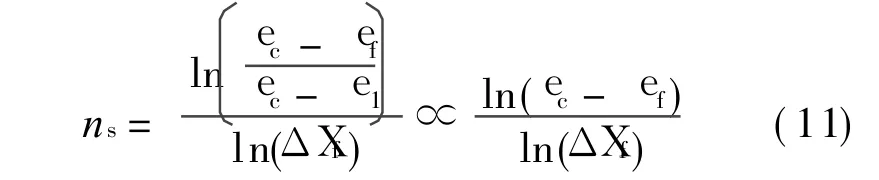

whereeis the stress,K(Kh,Ks)and n(nh,ns)are the parameters.The subscripts(h and s)refer to strain hardening part before the critical strainXc, and softening part after the critical strainXc,respectively.ecis the critical stress at the strain of Xc.ΔXis equal to|Xc-X|.

As seen from Eq.(1),the formulation e= ec- Kh(Xc-X)nhis used to describe the strain hardening part,and the equatione=ec-Ks(XXc)nsis the softening part.

Normally,the feature of the stress-strain curve is determined by the parameters(K andn), which are assumed to be constants at a decided experiment condition and vary with the mechanical properties,such as yield stress e0.2,critical stress/strain(ec/Xc),fracture stressef,and elongationXf.The variation rules are discussed in the following section.

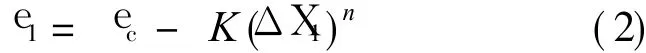

WhenXis equal to X1(X1is a random point in the curve),Eq.(1)follows that

From Eq.(2),we obtain

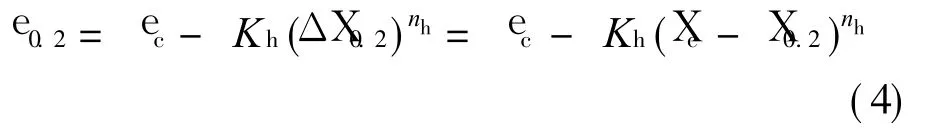

WhenXis equal toX0.2,the stress is the yield stresse0.2,we obtain

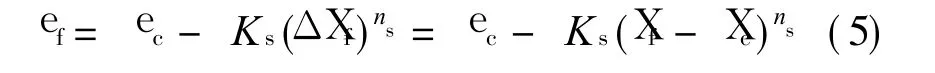

WhenXis equal toXf,the stress is the broken strength ef.Eq.(1)follows that

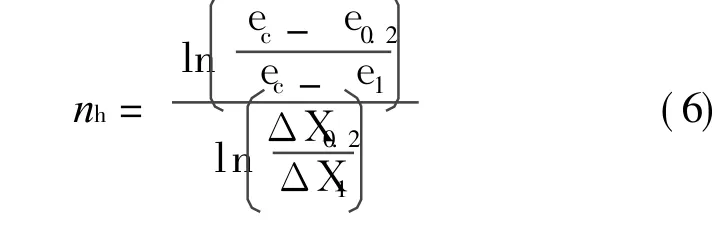

When X1is less thanXc,and let Eq.(4)divide Eq.(2),we obtain

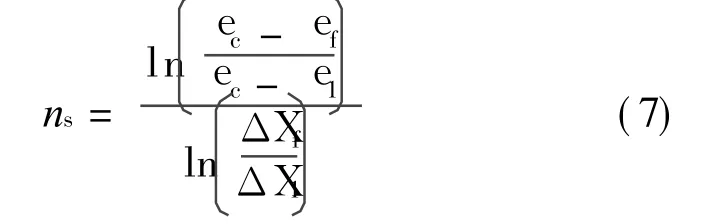

WhenX1is greater than Xc,and let Eq.(5) divide Eq.(2),we obtain

WhenΔX=ΔX1=1%,in order to describe the hardening part,the following equations are obtained from Eqs.(3,6).

AsΔX=ΔX1=1%,when describing the softening part,the following equations are obtained from Eqs.(3,7).

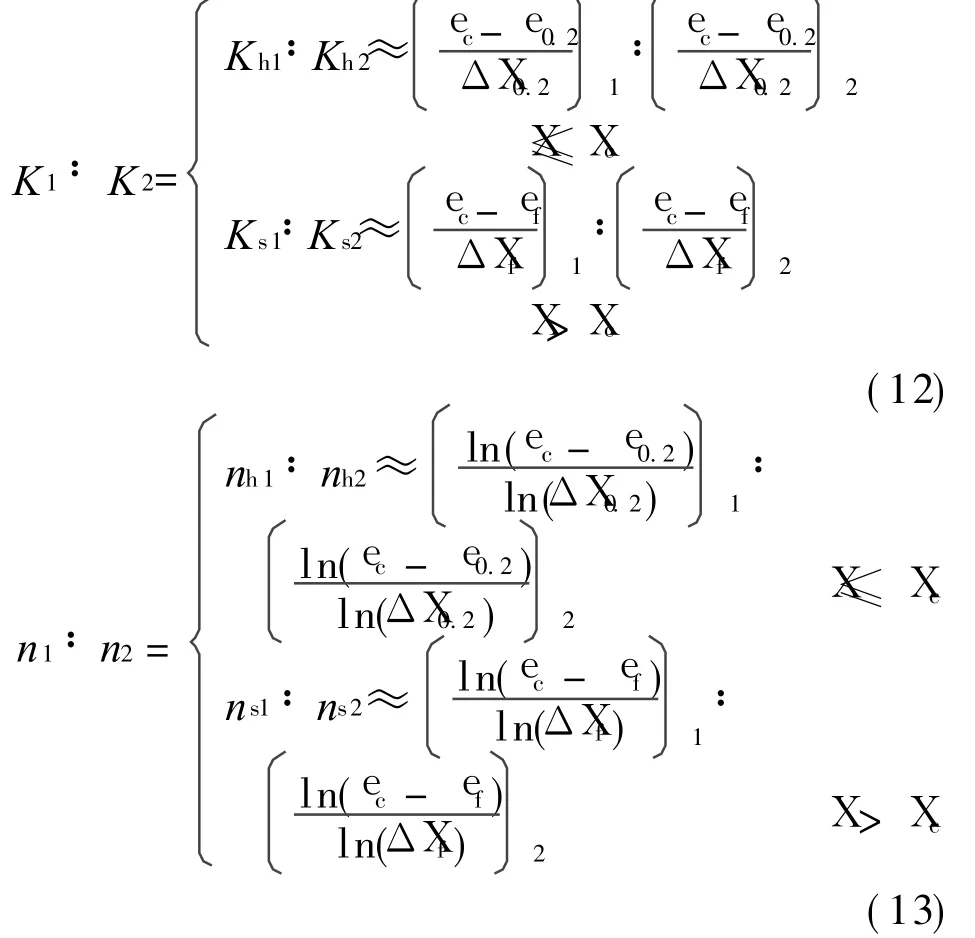

As seen in Eqs.(8-11),the variation of the parameters K and n at different conditions can be described by the mechanical properties,such as criticalstress ec, yield stress e0.2, fracture strength ef,ΔX0.2and ΔXf.The relationships between the parameters(K and n)and the mechanical properties follow that

The subscripts(1 and 2)in the two equations refer to the different experiment conditions.

Then,the constitutive equation can be obtained

The subscript letter″r″in the equation refers to the reference conditions.

3 APPLICATION,COMPARISONS AND DISCUSSION

In this section,the effectiveness of the newly developed model is verified by the extensive experiments on IC10.

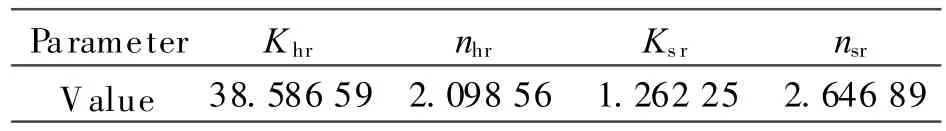

The reference stress-strain curve is the one measured at the condition of 900°C with strain rate= 10-2s-1.The parameters(K and n)are obtained by fitting the reference curve using Eq.(1).The fitted parameters are listed in Table 1.

Table1 Values of parameters K and n

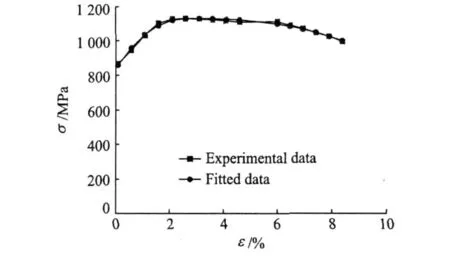

Fig.4 shows the comparison of the experimental and the fitted data,andillustrates that the model fits in the experimental data well.

Fig.4 Comparison of fitted and experimental data at 900°C with X·=10-2s-1

Then,the constitutive equations of IC10 follow that

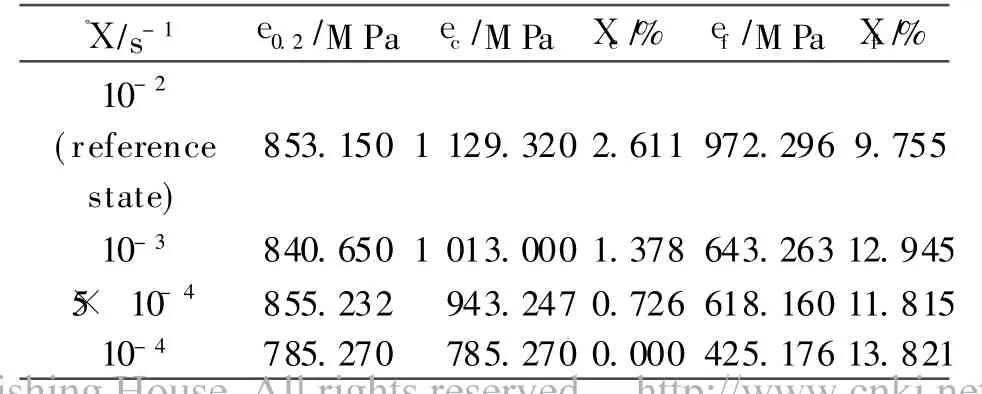

The values of the mechanical properties measured with the tensile experiments are listed in Table 2.

Table 2 Values of mechanical properties(measured by tensile experiments)

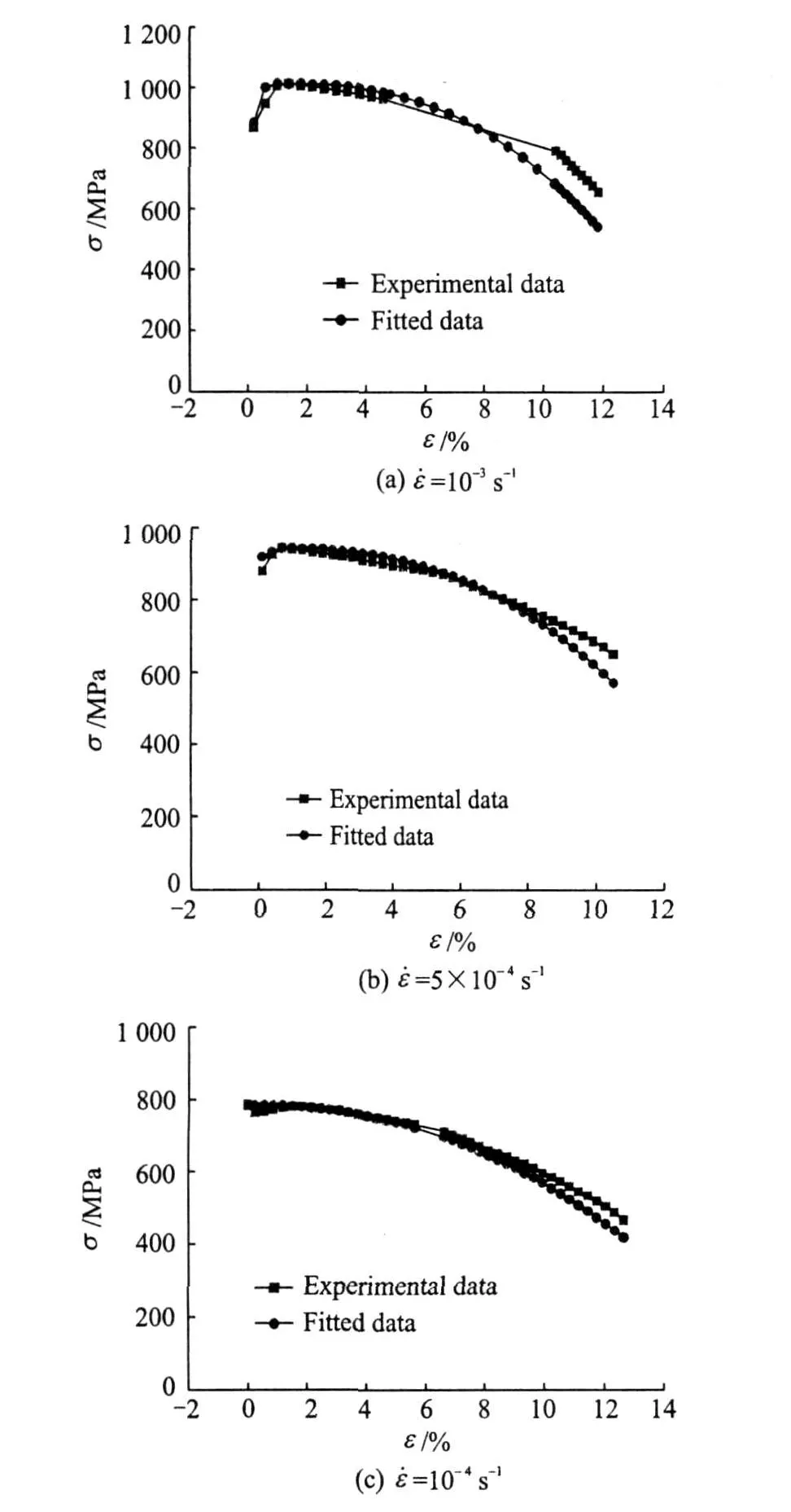

Fig.5 Comparison of predicted and experimental data at 900°C

The constitutive equation predicting a new curve can be obtained on the basis of the mechanical properties(listed in Table 2)and Eq.(15).

Fig.5 shows the comparisons between the data predicted by the new model and the experiment.The predicted data fit well with the experiment,which indicates that the new model is feasible to describe recrystallization behaviors of alloy IC10.

4 CONCLUSIONS

(1)Based on the tensile experiments,the flow behaviors of IC10 at 900°C are studied.Experiments show thatthe dynamic recrystallizationis the domination phenomena and the flow stress is sensitive to the strain rate.

(2)Based on the T EM and SEM experiments,the deformation and the fracture mechanisms are studied.Experiments show:the mechanism of recrystallization behavior is that the dislocations have a tendency to form almost regular square nets at phase boundaries;and the fracture mechanism is the dimple fracture mixed with a few of intergranular.

(3)A new model is developed and used to describe the recrystallization behaviors of alloy IC10.The predicted data fit well with the experiments.

[1] Zhao Xihong,HuangZhaohui,Tan Yongning,et al.New Ni3Al-Based directionally-solidified superalloy IC10[J]. Journal of Aeronautical Materials, 2006,26(3):20-24.(in Chinese)

[2] Zhang Hongjian,Wen Weidong,Cui Haitao,et al. Constitutive analysis of alloy IC10 at different temperatures[J]. Acta Aeronautica EtAstronautica Sinica,2008,29(2):499-504.(in Chinese)

[3] Zhang Hongjian,Wen Weidong,Cui Haitao.Behaviors of IC10 alloy over a wide range of strain rates and temperatures: experiments and modeling[J]. Materials Science&Engineering A,2009,504:99-103.

[4] Zhang Hongjian,Wen Weidong,Cui Haitao,et al. A study on flow behaviors of alloy IC10 over a wide range of temperatures and strain rates[C]//2008 TM S Annual M eeting&Exhibition on Materials for High Temperature Applications: Next Generation Superalloys and Beyond.San Francisco,California, USA:[s.n.],2009:219-226.

[5] Zhang Hongjian,Wen Weidong,Cui Haitao,et al. Modification of Z-A model and the prediction of the constitutive model[J].Journal of Aerospace Power, 2009,24(6):1311-1315.(in Chinese)

[6] Zhang Hongjian,Wen Weidong,Cui Haitao,et al. A modified Zerilli-Armstrong model for alloy IC10 over a wide range of temperatures and strain rates [J].Materials Science&Engineering A,2009,527: 328-333.

Transactions of Nanjing University of Aeronautics and Astronautics2011年1期

Transactions of Nanjing University of Aeronautics and Astronautics2011年1期

- Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- 拉壓、扭轉(zhuǎn)載荷下鑄鋁合金的億周疲勞性能研究

- 端墻形狀對蒸汽渦輪效率的影響

- 法國MBDA爆震和連續(xù)爆震波發(fā)動機(jī)的研發(fā)

- 使用液態(tài)化學(xué)循環(huán)的高熱效率動力研究

- FATIGUE LIFE PREDICTION METHOD FOR IMPACTED LAMINATES

- EXPERIMENTAL STUDY OF FORCED SHOCK TRAIN OSCILLATION IN ISOLATOR UNDER ASYMMETRIC INCOMING FLOW