Characteristics of dynamic strain and strength of frozen silt under long-term dynamic loading

ShuPing Zhao , Wei Ma , GuiDe Jiao ,2, XiaoXiao Chang

1. State Key Laboratory of Frozen Soil Engineering, Cold and Arid Regions Environmental and Engineering Research Institute,Chinese Academy of Sciences, Lanzhou, Gansu 730000, China

2. Civil and Engineering Department, Lanzhou University, Lanzhou, Gansu 730000, China

Characteristics of dynamic strain and strength of frozen silt under long-term dynamic loading

ShuPing Zhao1*, Wei Ma1, GuiDe Jiao1,2, XiaoXiao Chang1

1. State Key Laboratory of Frozen Soil Engineering, Cold and Arid Regions Environmental and Engineering Research Institute,Chinese Academy of Sciences, Lanzhou, Gansu 730000, China

2. Civil and Engineering Department, Lanzhou University, Lanzhou, Gansu 730000, China

The dynamic strain and strength of frozen silt under long-term dynamic loading are studied based on creep tests. Three groups of tests are performed (Groups I, II, and III). The initial deviator stresses of Groups I and II are same and the dynamic stress amplitude of Group II is twice as that of Group I. The minimum value of dynamic stress in Group III is near zero and its dynamic stress amplitude is larger than those of Groups I and II. In tests of all three groups there are similar change trends of accumulative strain,but with different values. The accumulative strain curves consist of three stages, namely, the initial stage, the steady stage, and the gradual flow stage. In the tests of Groups I and II, during the initial stage with vibration times less than 50 loops the strain amplitude decreased with the increase of vibration times and then basically remained constant, fluctuating in a very small range. For the tests of Group III, during the initial and steady stages the strain amplitude decreased with the increase of vibration times, and then increased rapidly in the gradual flow stage. The dynamic strength of frozen silt decreases and trends to terminal dynamic strength as the vibration times of loading increase.

frozen silt; long-term dynamic loading; accumulative strain; strain amplitude; residual strain; dynamic strength

1. Introduction

Frozen soil is distributed widely in China and has special and complex characteristics. Study of the dynamic stability of frozen soil subgrade under traffic loading is very important, with the current increase of roadway construction in the cold regions, especially high-speed railways and highways (Cheng and He, 2001). The stress caused by traffic loading is a kind of small-amplitude dynamic compression stress, and a kind of long-term cyclic stress which results in accumulative strain (Chenet al.,2006). Many scholars have studied the accumulative strain and dynamic strength properties of certain special soils,including soft clay and loess, under traffic dynamic loading(Cao and Cai, 1996; Sunet al., 2003; Yu and Huang, 2003;Bian and Chen, 2005; Chen and Bian, 2006; Liu and Chen,2007; Zhanget al., 2007). Permafrost itself has strong rheological properties, that is, the deformation of frozen soil will develop with over extended time; that could exacerbate uneven settlement of the frozen subgrade and lead to the damage of subgrade (Wuet al., 2002).

A large crack appeared on the road shoulder at the Not-Frozen-Spring section of the Qinghai-Tibet Railway in the spring of 2007, which hinders the operation of the railway. This is an example that demonstrates its necessity to study the dynamic characteristics of frozen soil under traffic loading. At present, research on frozen soil dynamics is limited and mainly focused on the dynamic parameters of fro-zen soil (e.g., shear modulus, damping ratio, and Poisson’s ratio) under different conditions of temperature, water content, loading stress amplitude, and vibration frequency(Vinsonet al., 1983; Heet al., 1993; Xuet al., 1998; Wuet al., 2003; Zhaoet al., 2003; Linget al., 2009). A few scholars have carried out experiments on dynamic strength and dynamic creep (Zhuet al., 1998; Wanget al., 2005). However, in the above researches great amplitude dynamic loading is exerted on the soil samples to simulate earthquake loading, but research on the characteristics of frozen soil under traffic loading is very sparse (Zhuet al., 2007). For these reasons, the strain and dynamic strength properties of frozen silt under long-term dynamic loading with different amplitudes are studied here.

2. Experimental design

2.1. Samples preparation

The material used in this investigation is silt from a borehole in Shandong Province. The soil particle distribution curve is shown in Figure 1. All specimens used remolded soil. The raw soil was air dried, ground, and sifted out, and distilled water was added to the soil (grain diameter less than 2 mm) to make the water content 19.58% by weight. After storage overnight to allow for moisture equilibration, the moist soil was carefully compacted into a special mold. A specially designed compactor was used to uniformly tamp the silt-water mixture in three layers. The samples were compacted to a dry density of 1.73 g/cm3. The mold containing the specimens was then placed in a freezing cabinet and quickly frozen in a closed system (without additional moisture) with a boundary temperature lower than -30 °C.After freezing for more than 48 h, the specimens were ejected from the mold and the ends were carefully trimmed flat and parallel on a lathe in a cold-room. The nominal size of the specimens after trimming was 61.8 mm in diameter by 125 mm long. Each specimen was sealed with a piece of rubber membrane and two resinous end caps. Before testing,all specimens were tempered at the -10 °C testing temperature for at least 24 hours.

Figure 1 Grain distribution curve of the test soil

2.2. Test conditions

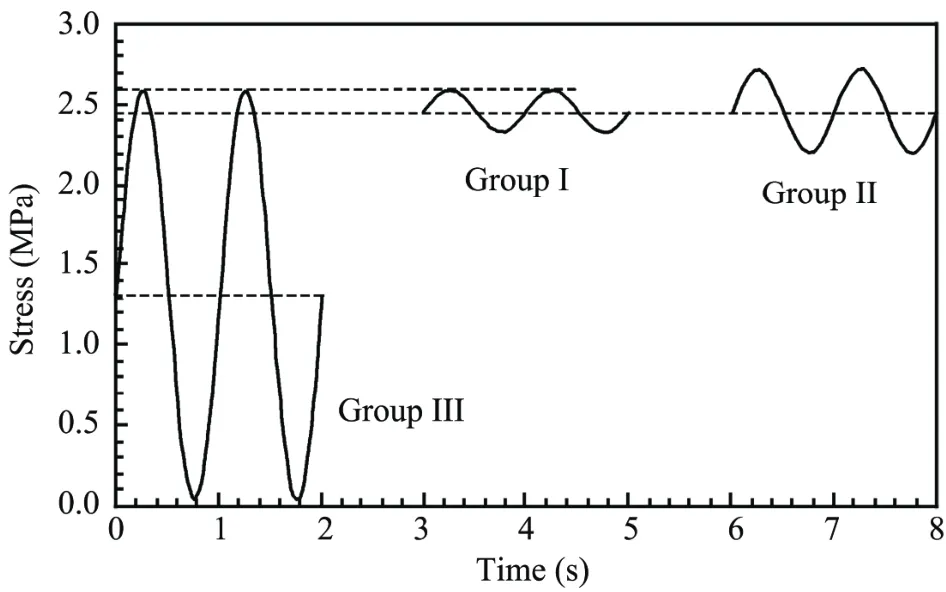

All tests were performed on a mechanical test system(MTS-810) made in America with a temperature-controlled cabinet, which maintained the desired test temperature. During the tests, the stress and strain were recorded with a data logger. The dynamic stress in actual subgrade contributed by the traffic loading is a type of compressive, long-term,low-frequency stress (Chenet al., 2006). To simulate this condition, constant stress amplitude dynamic loading with sine wave was applied, as shown in Equation(1)and Figure 2:

whereP0is the initial deviator stress,P1is the dynamic stress amplitude,fis the vibration frequency, andtis time.

Figure 2 Dynamic stress of three Groups of tests

Three groups of tests were performed. Each group consisted of four tests, A, B, C, and D. For each test in each group, the values ofP0andP1were different while the value ofP1/P0was the same. The values ofP1/P0for Groups I, II,and III were 5.3%, 10.6%, and 97.8%, respectively. For tests of Groups I and II, the correspondingP0was the same, while the value ofP1of Group II was twice as that of Group I. TheP1value of Group III was obviously larger than that of Groups I and II. The test temperature was -10 °C and the frequency of dynamic loading was 1 Hz. The details of the test conditions are shown in Table 1.

3. Test results and analysis

3.1. Accumulative strain

In actual subgrade under traffic loading, subgrade destruction or significant deformation may not appear in a short term. Therefore, the accumulative strain should be analyzed under dynamic loading. The accumulative strain is defined as the largest compressive strain under each dynamic loading cycle (Wang, 2003). This is accomplished by extracting the strain maximum under each load cycle and then mapping out the change curves of accumulative strain with load vibration times.

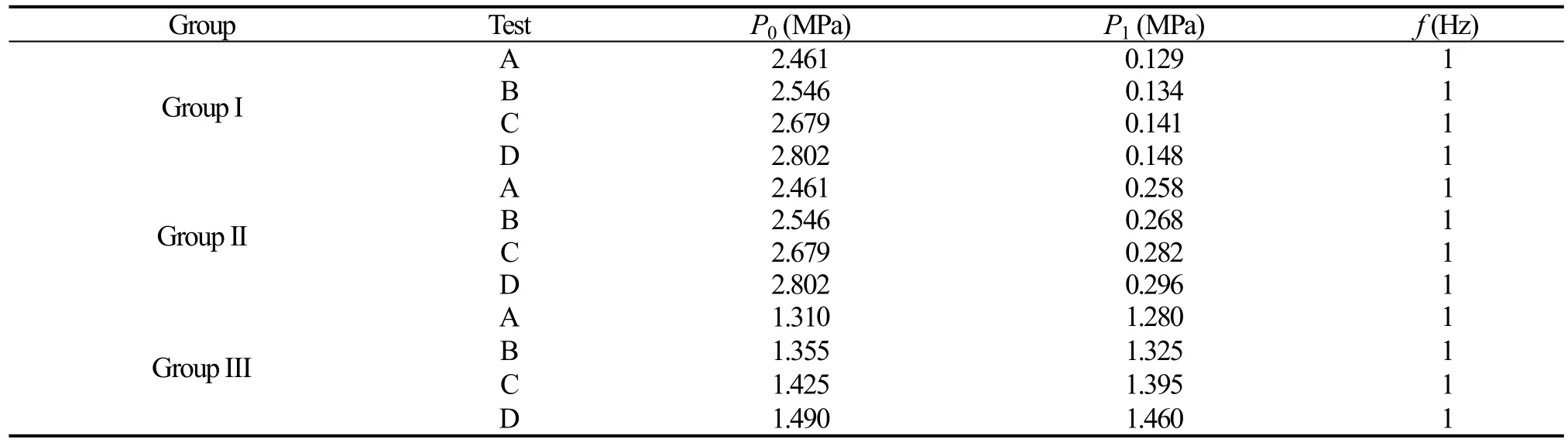

Table 1 Details of the test conditions

3.1.1 Influence of deviator stress on accumulative strain

Figure 3 shows the accumulative strain change curves of frozen silt with the load vibration times under dynamic loading with different initial deviator stresses. The accumulative strain curves reflect three stages, namely, the initial stage, the steady stage, and the gradual flow stage. In the initial stage the accumulative strain increases quickly; in the steady stage the accumulative strain develops with constant speed; in the gradual flow stage the accumulative strain increases rapidly.In the steady stage and gradual flow stage, during the same lengths of loading time, the larger the initial deviator stress is,the greater the accumulative strain is. Moreover, the difference becomes increasingly obvious as the load time is extended.

Figure 3 Accumulative strain of frozen silt vs. the vibration times of dynamic loading

3.1.2 Influence of dynamic stress amplitude on accumulative strain

Figure 4 presents the accumulative strain change curves of frozen silt along with the vibration times under dynamic loading with different amplitudes. For the tests of Groups I and II, the initial creep stage is very short and the values of accumulative strain are very similar. The steady creep stage is relatively longer and the accumulative strain of Group II is significantly greater than that of Group I. In the gradual flow stage, the accumulative strain of Group II is also greater than that of Group I. This proves that the roadbed will be sub-jected to more strain and will be more easily destroyed with worse road conditions and higher vehicle speeds, regardless of the type of vehicle.

The accumulative strain of Group III was less than that of Groups I and II during the initial stage and steady stage;however, due to its higher strain rate during the steady stage and consequently a considerable strain increment, after a much shorter steady stage Group III moved into the gradual flow stage quickly where the strain became larger than that of Groups I and II. The possible reason for this is that in the initial stage the soil had certain elasticity; in addition, the unloading time for the soil recovers from strain of the Group III test was longer than that of Groups I and II, so the accumulative strain was commensurately smaller. However, a fatigue effect will occur when the loading time is extended,and the internal structure of the soil will change greatly under dynamic loading with larger amplitude, so the strain will increase rapidly.

Figure 4 Comparison of accumulative strain of frozen silt under dynamic loadings with different stress amplitudes

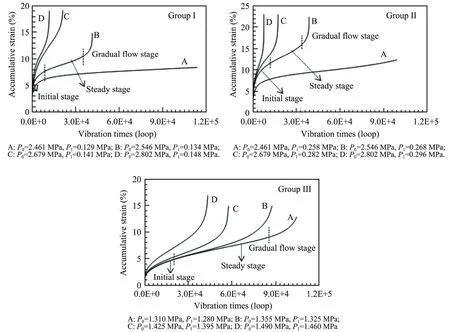

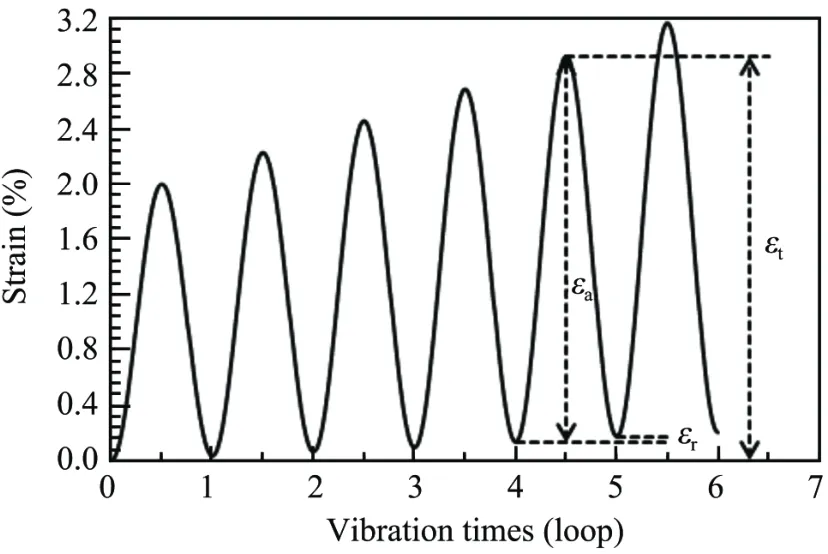

3.2. Strain amplitude and residual strain

The overall accumulative strain curve of frozen soil is shown in Figure 5. The accumulative strainεtincludes the strain amplitudeεaand the residual strainεr. The development of accumulative strain contributes to the change of strain amplitude and residual strain. The strain amplitudeεais defined as the difference between the initial strain and the maximum strain in each cycle of dynamic loading. The residual strainεrrefers to the difference between the strain incurred in the sample before and after one cycle of dynamic loading. The change of strain amplitude contributes to the rheological properties of frozen soil, when the stress amplitude is constant. The residual strain embodies the plastic properties of frozen soil because the strain cannot restore to its original minimum value after one cycle of dynamic loading (Wang, 2003).

3.2.1 Strain amplitude

Figure 6 shows the strain amplitude curve of frozen silt vs. load vibration times under all of the test conditions.

For the tests of Groups I and II, in the initial stage with vibration times less than 50 loops, the strain amplitude decreased with increase of vibration times; then the strain amplitude basically remained constant, fluctuating in a very small range. The size of the initial deviator stress barely affected change of strain amplitude, and the constant change ranges of it were, respectively, from 0.007% to 0.022% and from 0.015% to 0.036%. It can be seen that the strain amplitude of Group II was slightly greater than that of Group I.

Figure 5 Accumulative strain vs. vibration times of loading

For the tests of Group III, in the initial stage with vibration times less than 130 loops, the strain amplitude also decreased with the increase of vibration times. In the steady creep stage the strain amplitude tended to decrease and the change rate was less. At the gradual flow stage the strain amplitude increased obviously with the increase of vibration times. The size of the initial deviator stress had a great influence on the change of strain amplitude. The greater the initial deviator stress, the greater the strain amplitude. The change range of strain amplitude in steady creep stage was 0.26%-0.47%. It is obvious that the strain amplitude of Group III was one magnitude greater than that of Groups I and II.

Figure 6 Strain amplitude vs. vibration times of dynamic loading

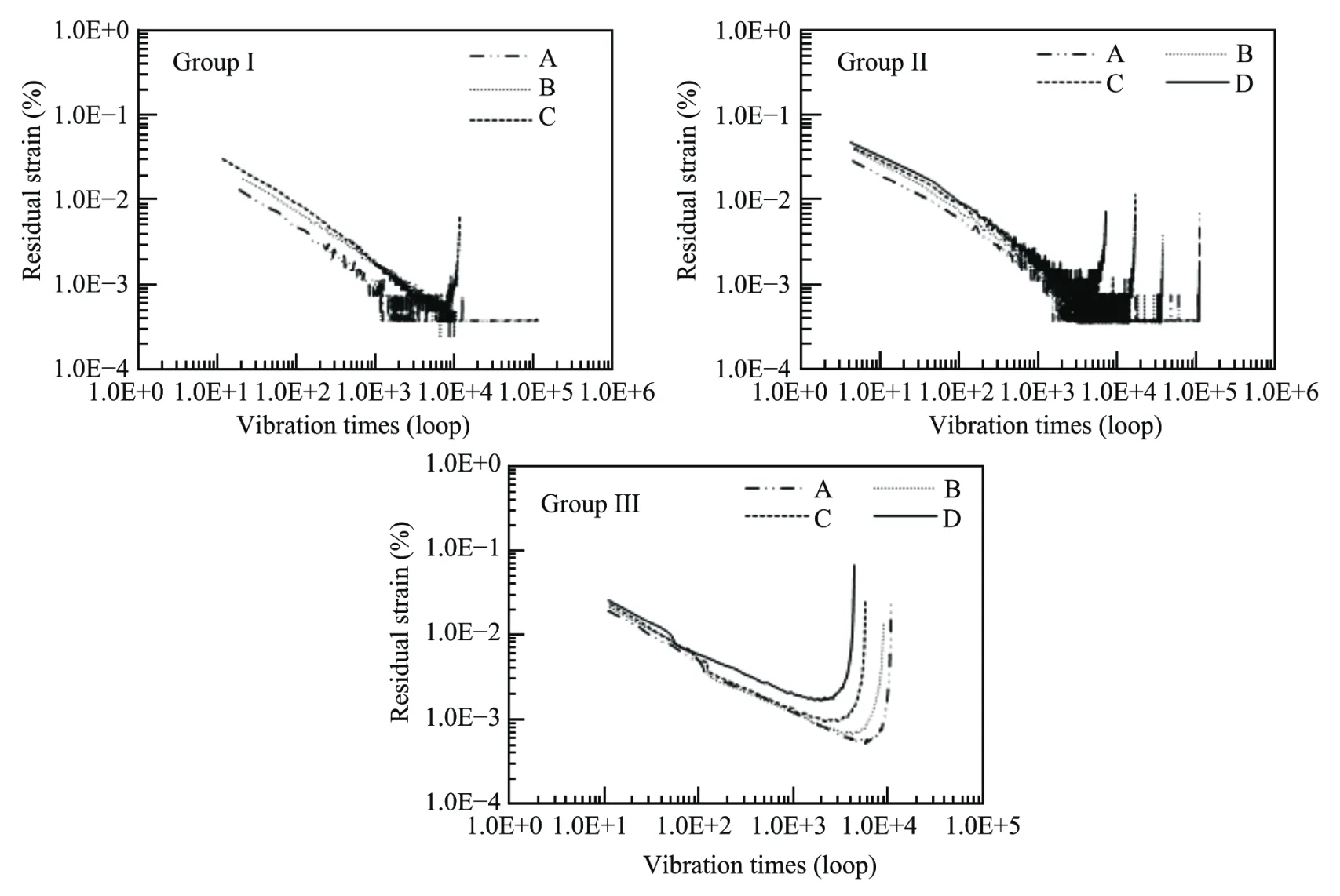

3.2.2 Residual strain

Figure 7 shows the residual strain of frozen silt vs. vibration times under all of the test conditions. In the initial stage the residual strain decreased with the increase of the vibration times; after achieving the minimum value it then increased with the increase of vibration times. When dynamic loading was applied to the samples, the soil was gradually pressed dense and the plastic properties become less obvious,so the irrecoverable strain decreased gradually until damage became apparent and failure strain began to occur. Then the irrecoverable strain increased rapidly.

As to the minimum value of residual strain, that of Group III was the largest, and that of Group II was slightly larger than that of Group I. In tests of same group, the larger the stress amplitude of the dynamic loading is, the larger the residual strain is.

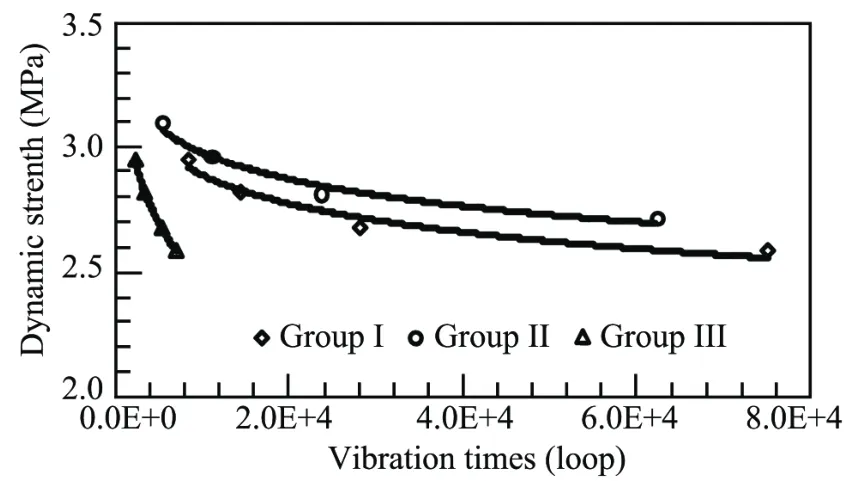

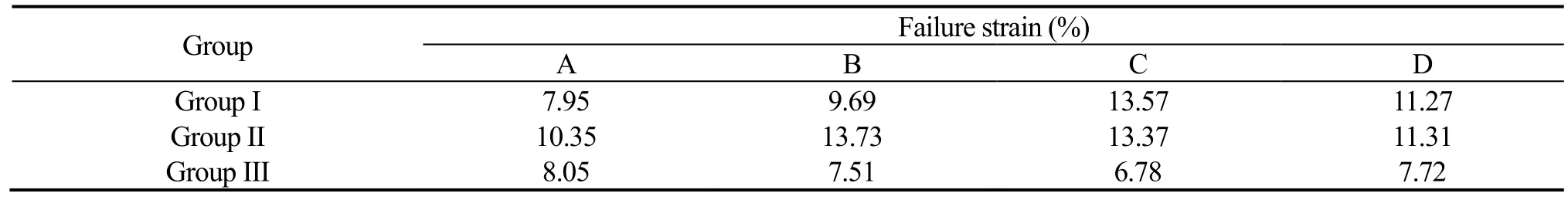

3.3. The dynamic strength

The dynamic strength of soil corresponds to the dynamic stress that will cause the strain of the soil to reach a certain failure standard (Xie, 1988). Here the dynamic stress represents the sum of the initial deviator stress and the dynamic stress amplitude (P0+P1). Because of the rheological properties of frozen soil, the strain will increase continually, even if the loading is kept constant. As for frozen soil under long-term dynamic loading, two factors, namely, the cyclic fatigue effect and the rheological property of the frozen soil,will cause the internal structure of the soil to change and reach final instability or failure. The failure standard selected here is the point where the accumulative strain curves change from the steady stage to the gradual flow stage. The corresponding vibration times and strain are named as "failure vibration times" and "failure strain", respectively.

The dynamic strength of frozen soil is shown in Figure 8.It can be seen that the dynamic strength weakens with the increase of vibration times of cyclic loading.

The following functional relations can be used to indicate the attenuation trend:

wherePdis dynamic strength (MPa),Nfis failure vibration times (loop), andk(MPa) andN0(loop) are fitting coefficients. The values ofkandN0are shown in Table 2.

Figure 7 Residual strain vs. vibrating times of loading

Figure 8 Dynamic strength of frozen silt

Figure 8 also indicates that the dynamic strength weakens with the increase of the vibration times of dynamic loading,and the attenuation rate lessens. Finally, the dynamic strength will trend to a constant value, which is named as"terminal dynamic strength". Taking vibration times of 105loops as the standard, the terminal dynamic strength of frozen soil can be estimated by Equation(2). The terminal dynamic strengths of Groups I, II, and III were thus 2.53 MPa,2.64 MPa, and 2 MPa, respectively.

The failure strain of frozen silt is shown in Table 3. The change ranges of failure strain of Groups I, II, and III were 7.95%-13.57%, 10.35%-13.73%, and 6.78%-8.05%, respectively. It is obvious that the failure strain of Group III was the smallest and that of Group II was slightly larger than Group I.

Table 2 The fit coefficients of Equation (2)

Table 3 The failure strain of frozen soil

4. Conclusions

Three groups of tests were performed on frozen silt under long-term dynamic loading (Groups I, II, and III). The dynamic stress amplitude of Group II was twice as large as that of Group I. The minimum value of the Group III dynamic stress was near zero, and its dynamic stress amplitude was larger than that of Groups I and II. Based on these test results, the following conclusions are drawn.

(1) The accumulative strain curves consist of three stages,namely, the initial stage, the steady stage, and the gradual flow stage. In the initial stage the accumulative strain increases quickly; in the steady stage the accumulative strain develops with constant speed; in the gradual flow stage the accumulative strain increases rapidly. In the steady stage and gradual flow stage, during the same length of loading time,the larger the initial deviator stress is, the greater the accumulative strain is. Moreover, the difference becomes increasingly obvious as the load time extends.

(2) The accumulative strain of Group III was less than that of Groups I and II during the initial stage and steady stage; however, due to its higher strain rate during the steady stage and consequently a considerable strain increment, after a much shorter steady stage Group III moved into the gradual flow stage quickly when the strain became larger than that of Groups I and II.

(3) In all the tests of Groups I and II, in the initial stage with vibration times less than 50 loops, the strain amplitude decreased with the increase of vibration times; then the strain amplitude basically remained constant, fluctuating in a very small range. In the tests of Group III, in the initial and steady stages the strain amplitude decreased with the increase of vibration times, and increased rapidly in the gradual flow stage. The value of strain amplitude of Group II was slightly greater than that of Group I. The strain amplitude of Group III was one magnitude greater than that of Groups I and II.

(4) In the initial stage, the residual strain decreased with the increase of vibration times; after achieving the minimum value, it then increased with the increase of vibration times.

(5) The dynamic strength of frozen silt decreases and trends to terminal dynamic strength with increasing vibration times of loading. The terminal dynamic strengths of Groups I, II, and III were thus 2.53 MPa, 2.64 MPa, and 2 MPa, respectively.

This project is supported by the National Natural Science Foundation of China (Nos. 40971046, 41023003) and the Project from the State Key Laboratory of Frozen Soil Engineering of China (No. 09SF102003).

Bian XC, Chen YM, 2005. Dynamic analyses of track and ground coupled system with high-speed train loads. Chinese Journal of Theoretical and Applied Mechanics, 37(4): 477-484.

Cao XW, Cai Y, 1996. A model test study of the dynamic performance of subgrade. Journal of Southwest Jiaotong University, 31(1): 36-41.

Chen YM, Bian XC, 2006. Vibration and settlements generated by high-speed traffics. Proceeding of the 7th National Conference on Soil Dynamics. Tsinghua University Publishing Company, Beijing. 3-13.

Chen YM, Bian XC, Wang CJ, 2006. Dynamic responses of ground induced by high-speed train operations. Proceeding of the 7th National Conference on Soil Dynamics. Tsinghua University Publishing Company, Beijing. 350-359.

Cheng GD, He P, 2001. Linerity engineering in permafrost areas. Journal of Glaciology and Geocryology, 23(3): 213-217.

He P, Zhu YL, Zhang JY, Shen ZY, Yu QH, 1993. Dynamic elastic modulus and dynamic strength of saturated frozen silt. Journal of Glaciology and Geocryology, 15(1): 170-174.

Ling XZ, Zhu ZY, Zhang F, Chen SJ, Wang LN, Gao X, Lu QR, 2009. Dynamic elastic modulus of frozen soil from the embankment of Beiluhe Basin along the Qinghai-Tibet Railway. Cold Regions Science and Technology, 57(1): 7-12.

Liu XZ, Chen GX, 2007. The research progress on the dynamic characteristic of roadbed soil under traffic loading. Proceeding of the 10th National Conference on Soil Mechanics and Geotechnical Engineering. Chongqing University Publishing Company, Chongqing. 3: 656-663.

Sun CX, Liang B, Yang Q, 2003. Test and analysis for the dynamic stress responses of the Qin-shen Railway’s subgrade. Journal of Lanzhou Railway University, 22(4): 110-112.

Vinson TS, Wilson CR, Bolander P, 1983. Dynamic properties of naturally frozen silt. Proceeding of Fourth International Conference on Permafrost, Alaska, USA. National Academies Press, Washington D.C.1315-1320.

Wang LM, 2003. Loess Dynamics. Earthquake Publishing Company, Beijing. 47-84.

Wang LX, Ling XZ, Xu XY, Gu QY, Hu QL, 2005. Comparison of dynamic and static triaxial test on frozen silty clay of Qinghai-Tibet railway. Chinese Journal of Geotechnical Engineering, 27(2): 202-205.

Wu QB, Liu YZ, Shi B, Zhang JM, Tong CJ, 2002. A review of recent frozen soil engineering in permafrost regions along Qinghai-Tibet Highway,China. Journal of Engineering Geology, 10(1): 55-61.

Wu ZJ, Wang LM, Ma W, Cheng JJ, Feng WJ, 2003. Laboratory study on dynamics parameters of frozen soil under seismic dynamic loading.Northwestern Seismological Journal, 25(3): 210-214.

Xie DY, 1988. Soil Dynamics. Xi’an Jiaotong University Publishing Company, Xi’an. 46-76.

Xu XY, Zhong CL, Chen YM, 1998. Research on dynamic characters of frozen soil and determination of its parameters. Chinese Journal of Geotechnical Engineering, 20(5): 77-81.

Yu M, Huang XQ, 2003. The analysis on the influence of soft soil mobility to the roadbed deformation of express highway. Guangxi Communication Science & Technology, 28(5): 63-65.

Zhang JM, Lan MT, Wang LM, Zhang G, 2007. Soil dynamics and geotechnical seismological engineering. Proceeding of the 10th National Conference on Soil Mechanics and Geotechnical Engineering. Chongqing University Publishing Company, Chongqing. 1: 100-113.

Zhao SP, Zhu YL, He P, Wang DY, 2003. Testing study on dynamic mechanics parameters of frozen soil. Chinese Journal of Rock Mechanics and Engineering, 22(supp. 2): 2677-2681.

Zhu YL, He P, Zhang JY, Wang JC, 1998. The triaxial creep model of frozen soil under dynamic loading. Progress in Natural Science, 8(1): 60-62.

Zhu ZY, Ling XZ, Hu QL, Yu Y, Zhou ZY, 2007. Experimental study on dynamic strain rate of frozen soil from railway embankment of Qinghai-Tibet railway in China. Chinese Journal of Geotechnical Engineering,29(10): 1472-1476.

10.3724/SP.J.1226.2011.00478

*Correspondence to: Dr. ShuPing Zhao, Associate professor of Cold and Arid Regions Environmental and Engineering Research Institute, Chinese Academy of Sciences. No. 320, West Donggang Road, Lanzhou, Gansu 730000, China. Tel: +86-931-4967424;Email: shuping@lzb.ac.cn

21 May 2011 Accepted: 29 August 2011

Sciences in Cold and Arid Regions2011年6期

Sciences in Cold and Arid Regions2011年6期

- Sciences in Cold and Arid Regions的其它文章

- Analysis on the temporal-spatial distribution character and effect factors of PM10 in the hinterland of Taklimakan Desert and surrounding area

- Variability of atmospheric freezing level height derived from radiosonde data in China during 1958-2005 and its impact to cryosphere changes

- Impacts of snow cover and frozen soil in the Tibetan Plateau on summer precipitation in China

- Incident analyses of frost heaving failure of municipal underground gas pipelines in cold regions of northern China

- Simulation and analysis of river runoff in typical cold regions

- Climatic changes have led to significant expansion of endorheic lakes in Xizang (Tibet) since 1995