Reliability Based Design Optimization of Aero-Engine Spindle Ball Bearings

YANG Jing(楊 靜), MENG De-biao(孟德彪), ZHANG Xiao-ling(張小玲), WANG Zhong-lai(汪忠來), XU Huan-wei(許煥衛)

School of Mechanical, Electronic, and Industrial Engineering, University of Electronic Science and Technology of China, Chengdu 611731, China

Reliability Based Design Optimization of Aero-Engine Spindle Ball Bearings

YANG Jing(楊 靜)*, MENG De-biao(孟德彪), ZHANG Xiao-ling(張小玲), WANG Zhong-lai(汪忠來), XU Huan-wei(許煥衛)

SchoolofMechanical,Electronic,andIndustrialEngineering,UniversityofElectronicScienceandTechnologyofChina,Chengdu611731,China

Aero-engine spindle ball bearings work in harsh conditions which are affected by relatively complex stresses. One of the key factors which affects bearing performance is its structure. In this paper, we used reliability based design optimization method to solve the structure design problem of aero-engine spindle ball bearings. Compared with the optimization design method, the value of equivalent dynamic load using reliability optimization design method was the least by MATLAB simulation. Also the design solutions show that the optimized structure possesses higher reliability than the original solution.

aero-enginespindleballbearing;complexstresses;reliabilitybaseddesignoptimization;structuredesign

Introduction

The spindle ball bearing is one of the key parts of aero-engine. Its performance affects the airplane’s safety and reliability. The researches on spindle ball bearing have been one of the focused areas in engineering design.

Liu and He[1]established the finite element model of rolling bearings and proposed its rated load and life model. Liu[2]gave an analysis method of structural vibration for the rolling bearings based on the mechanics model. Wangetal.[3]gave a bearing parts interaction model and a load distribution quasi dynamic model of high speed ball bearing to calculate the interaction force and torque. Chenetal.[4]proposed a method to calculate the rolling bearing load distribution and deformation based on MATLAB. Tangetal.[5]established a load distribution analysis model and summarized the effects of different structures and load parameters on the mechanical properties of ball bearings. Although many studies have been done, more researches on bearings are still needed. In this paper, we will give the optimization model of aero-engine spindle ball bearing and study its structure design optimization problem.

1 Aero-Engine Spindle Ball Bearing Optimization Model

1.1 Overview of optimization technology

The researches on optimization technology began in the early 1960s, which were mainly on the basis of the optimization principles[6]. With the development of computer technology, the optimization technique attacks more attentions[7-8]. Modern optimization technology can solve the design optimization problems effectively and provide ideal design solutions ultimately[9-10].

1.2 The general model of design and optimization

The mathematical model of design optimization is composed with design variablex, constraintsgn(x),hv(x), and objective functionf(x)[11]. Here, we give the optimization model as follows:

minf(x)

s.t.gn(x)≤0,

hv(x)=0,

(1)

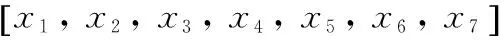

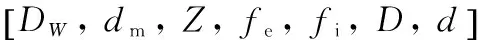

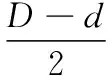

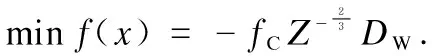

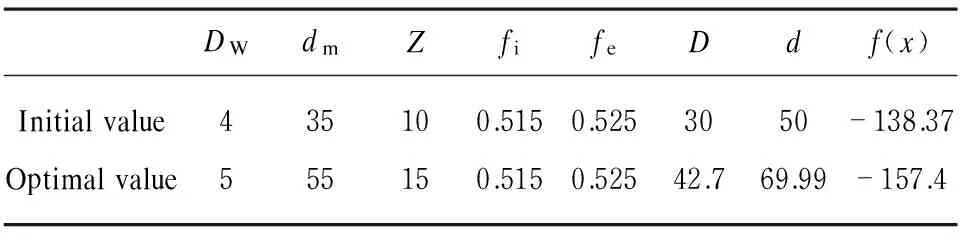

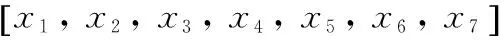

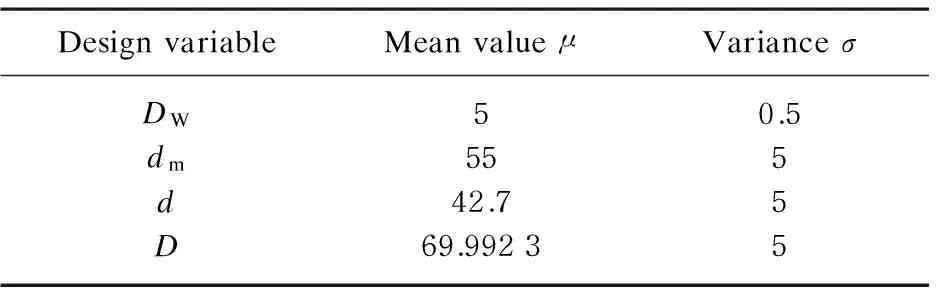

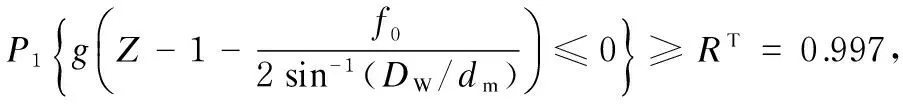

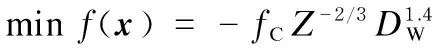

wherex∈n,u=1, 2, …,m,v=1, 2, …,p The design optimization solutions should satisfy the constraints. In the rolling bearing design optimization problem, the number of constraints and design variables are usually less than ten. Thus, this kind of optimization problems belongs to the category of small-scale optimization problems. 1.3 The establishment of rolling bearing optimization model In order to meet each performance index of bearings, we treat the bearing life as the objective function and consider structure parameters, such as the number of ball, as design variables[10]. The formula of rolling bearing life is (2) whereQCandQeare the rated dynamic load and the equivalent dynamic load, respectively. When the rolling element bearing load obey evenly distributed,Qeis a constant value, then the bearing life andQChave positive correlation. The formula of the equivalent dynamic load will be shown as follows. f(x)=fCZ-2/3DW, (3) wherefCis expressed as 1) Design variable Taking angular contact ball bearing as an example, the design variables areDW(mm),dm(mm),Z,fe, andfi. Here, we usexi,i=1, 2, …, 7 to denote design variables as: (4) 2) Constraints In the design optimization problem of spindle bearings, the design variablesDW,dm,Z,fe,fi,d, andDmust satisfy the following constraints. (1) The number of ball and diameter should meet the requirements of assembly angle[12]. (5) The corresponding constraint is (6) whereφ0is the maximum assembly angular,φ0=2.6 rad. (2) The selection of ball diameter should be consistent with the value range of experience. (7) whereKDminandKDmaxare the minimum and the maximum coefficients of sphere diameter, andKDmin=0.4,KDmax=0.45, respectively. Then there are two constraints as follows. (8) (9) (3) The flexibility of bearings is low when the ball group cannot fit to cage. Thus the difference of the ball diameter and the mean bearing diameter (D+d)/2 must be less than the specified value. There are two constraints as follows. (10) and (11) whereeis a constant,e=0.01. (4) The center circle diameter of ball should be greater than the mean bearing diameter. And the groove wall thickness of the outer ring should not be less thanεDW,ε=0.01, namely, (12) (5) The inner and outer radius of curvature should not be less than 0.515DW. Thus there are two constraints as follows. (13) and (14) (6) The optimization design model According to Eqs. (2)-(14), the design optimization model of spindle bearing is given in Eq. (15). (15) The initial values of spindle bearing optimization problem are shown in Table 1. The optimization process is conducted using MATLAB optimization toolbox. The optimal values are also shown in Table 1. Comparing the optimal solutions with initial solutions, there are two improvements as follows. (1) After optimization, the pitch circle diameter approximately equals the mean bearing diameter. (2) After optimization, the objective function value decreases by nearly 20. The optimal design solution has been improved. Table 1 The optimal value compared to the initial value In this section, we will solve the reliability design optimization problem of aero-engine spindle bearings. Here, we also treat the rated dynamic load as the objective function which is given in Eq. (3). 2.1 Design variables For the same bearing, Z,fe, andfiare usually treated as deterministic design variables, butDW,dm,d, andDare treated as random design variables. Then the design vector is as follows. (16) whereμis the mean value of random design variable. Assuming random design variables obey normal distribution, the mean value and variances are shown in Table 2. Table 2 The mean value and variance of random design 2.2 Reliability constraints We assume the target reliabilityR=0.997, then design variables need to satisfy the following probability constraints: P2{g(KDmin(D-d)-2DW)≤0}≥RT=0.997, 古代貨幣之所以會通過絲綢之路流到國外,是由中國與沿線各國的貿易決定的,這是一種經濟關系,是經濟規律在起作用。比如中國宋錢外流日本和東南亞地區,能夠長期在其國內起著主幣的流通職能,主要是由于當時的日本和東南亞各國經濟相對落后,國內貨幣體制落后或者沒有貨幣,或是由于當時東南亞各國鑄造技術落后,所制之錢質量低劣,容易磨損,不能勝任貨幣的職能。而宋朝的冶煉與鑄造技術先進,錢幣純度高,鑄造精美,正好彌補了日本和東南亞各國貨幣體制的缺陷,滿足了他們急需高品質貨幣的需求,加上中國當時的經濟影響力強,中國的銅錢在日本和東南亞諸國享有很高的信譽,因此被選為充當其國內貨幣進入流通就是順理成章的事。 (17) P6{εDW-g(0.5(D-dm-DW))≥0}≥RT=0.997, P7{g(0.515-fi)≤0}≥RT=0.997, P8{g(0.515-fe)≤0}≥RT=0.997. 2.3 Reliability optimization design model According to Eqs. (3), (16), and (17), the reliability optimization design model can be given in Eq. (18). P2{g(KDmin(D-d)-2DW)≤0}≥RT=0.997, (18) P6{εDW-g(0.5(D-dm-DW))≥0}≥RT=0.997, P7{g(0.515-fi)≤0}≥RT=0.997, P8{g(0.515-fe)≤0}≥RT=0.997. Here, the optimal solutions of deterministic optimization problem are used as the initial values. After reliability based design and optimization, we get the reliability optimal value and the optimal value, shown in Table 3. Comparing the reliability solutions with deterministic solutions, there are two improvements shown as follows. a) After reliability optimization, the objective function value is less than the value of deterministic optimization design. b) Reliability optimization design adds the reliability constraints, so the confidence is higher than the deterministic optimization design. Table 3 Reliability optimal value and optimal value comparison The parameters of bearings are important to the performance. We used deterministic design optimization and reliability based design optimization to solve the design problem of bearing respectively. The solutions show that reliability design solutions possess more safety and higher reliability. [1] Liu Z J, He S Q. The Rated Load and Life of Rolling Bearings[M]. Beijing: National Defence Industry Press, 1998.(in Chinese) [2] Liu C H. The Structure of the Rolling Bearing Vibration Problems[J].Bearing, 2002(21): 49-56. (in Chinese) [3] Wang L Q, Cui L, Zheng D Z,etal. Analysis on Dynamic Characteristics of Aero-Engine High-Speed Ball Bearings[J].ActaAeronauticaetAstronauticaSinica, 2007, 28(6): 1461-1467. (in Chinese) [4] Chen J J, Ren C Z, Xu Y S. Ball Bearing Contact Stress, Deformation and Load Distribution Calculation Based on the MATLAB[J].MechanicalResearchandApplication, 2004, 17(1): 59-60. (in Chinese) [5] Tang Y B, Gao G P, Luo G H. Research of Aero-Engine High-Speed Ball Beating[J].JournalofAerospacePower, 2006, 21(2): 354-356. (in Chinese) [6] Dong L L, Zhao Y P, Liang L Q,etal. Review on Theory and Approach of Mechanical Optimization Design[J].MachineTool&Hydraulics, 2010, 38(15): 114-119. (in Chinese) [7] Yang X W. The Study of Rolling Bearing Fatigue Life of Three Parameters Weibull Distrution[D]. Hefei: Hefei University of Technology, 2003. (in Chinese) [8] Wang K S. Machine Optimal Design[M]. Beijing: National Defence Industry Press, 2006: 1-4. (in Chinese) [9] Luo Z, Liu H Y, Tian H H,etal. Intelligent Optimization Design for Up-to-Date Machine Products and Its Application[J].JournalofNortheasternUniversity:NaturalScience, 2008, 29(7): 1004-1007. (in Chinese) [10] Dong K, Zhang G L, Chen W J. Introduction of Mechanical Optimization Design[J].ShandongWaterPolytechnicCollegeMagazine, 2009(2): 16-17. (in Chinese) [11] Xiao M. Analyzing and Rebuilding a Mathematical Model in Optimal Design[J].MachineTool&Hydraulics, 2004(9): 86-87. (in Chinese) [12] Luo J W. Deep Groove Ball Bearing Assembly Angle and Outer Ring Compression Deformation[J].Bearing, 1988(4): 8-11. 1672-5220(2014)06-0853-03 Received date: 2014- 08- 08 *Correspondence should be addressed to YANG Jing, E-mail: yj2808004035@163.com CLC number: V231 Document code: A

2 Aero-Engine spindle bearing reliability optimization design model

3 Conclusions

Journal of Donghua University(English Edition)

2014年6期

Journal of Donghua University(English Edition)

2014年6期

- Journal of Donghua University(English Edition)的其它文章

- Stress-Strength Structural Reliability Model with a Stochastic Strength Aging Deterioration Process

- Settlement Prediction of Dredger Fill with the Optimal Combination Model

- Condition-Based Maintenance Decision-Making for Equipment

- Identification of the Credit Guarantee Network of Steel Trade Enterprises in China

- Methods for Reliability Assessment under Irregular Time-Varying-Stress Degradation Testing

- Efficient Method for Accelerated Reliability Qualification Testing