等高齒對數螺旋錐齒輪加工仿真

李 麗,閆 歡

內蒙古科技大學機械工程學院,包頭 014010

1.Introduction

High-tooth logarithmic spiral bevel gear is a new kind of gear with some advantages such as smooth transmission and higher carrying capacity.It is suitable for large-scale machinery and transportation.However,since the engagement theory and the tooth surface shapes of high-tooth logarithmic spiral bevel gear are more complicated,it is relatively difficult to improve the quality both in the design and in the manufacturing sectors because the huge computational analysis is required[1].Currently,in china there are fewer universities to study on engagement theory,deriving the tooth surface equation and test equipment development and other aspects of special spiral bevel gears.In these respects,Xi’an Jiaotong University has a solid strength.Until now we have not find the relevant literature about engagement theory processing and detection technology of high-tooth logarithmic spiral bevel gear.Based on Siemens UG CAM,one could complete the NC code generation by creating tools,geometry and procedures,and calculate the tool path of high-tooth logarithmic spiral bevel gear[2-3].All of these provide a reliable basis for hightooth logarithmic spiral bevel gear.

2.Virtual processing technology and milling principle of high-tooth logarithmic spiral bevel gear

Processing has diverse ways,such as casting and cutting.The cutting method is a commonly used method.Starting from the processing principle,it could be divided into generation method and copy method.The suitable processing method of high-tooth logarithmic spiral bevel gear is copy method.The principle is that the tooth profile is processed directly by using tools.Those tools have the same shape with the tooth profile shape,common tools such as a diskshaped cutter.In milling cutting simulation of hightooth logarithmic spiral bevel gear,it is difficult to establish an accurate simulation model to reflect the tool and wheel blank space and sports relationships.Error is inevitable when the factor error is considered such as how to milling cutter and the relationship between the movements of the gear blank mathematical modeling.Due to this difficulty,the following de-scribes the creative model and simulation processing.

3.Machining simulation of high-tooth logarithmic spiral bevel gear

In the process,the main coordinates of tool path was stored in some data structure,such a process is called the tool path simulation[4].In big wheel of high-tooth logarithmic spiral bevel gear,for example,combine CNC with high-tooth logarithmic spiral bevel gear processing,we could use Siemens UG CAM functions to complete the creation of the tool,the tool path generation and generate NC programs[5-8].

3.1.Create a gear blank and mills

As shown in Figure 1,it is simple to establish the blank model of high-tooth logarithmic spiral bevel gear.

Figure 1.The blank model of high-tooth logarithmic spiral bevel gear

For the tool path simulation,especially for milling gear teeth combined with the model and the actual situation of the gear blank,the selection of milling process is the primary means of gears.

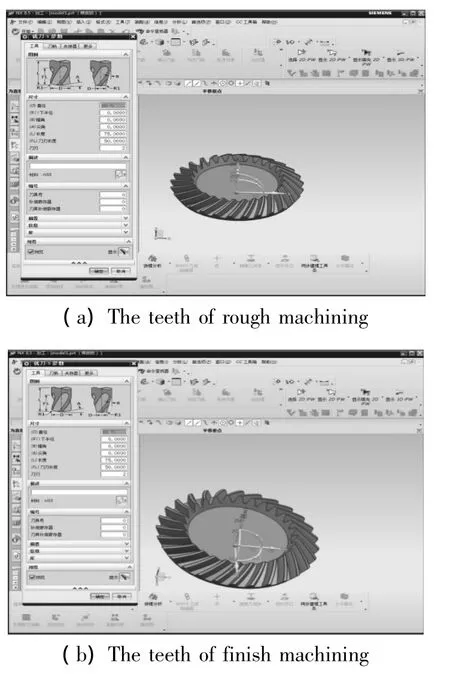

3.2.Tooth machining

The tooth is successive processed according to a tool path by mills.In this step,user could establish a good working tool and a method to process the first tooth.The other teeth could be fully obtained by copy process.If one chooses a diameter d=4 mm end mill to rough machining,finish machining teeth of hightooth logarithmic spiral bevel gear is fixed with a diameter d=4 mm,2 cutting edges of the round nose cutter processing could be presented,as shown in Figure 2(a),(b).

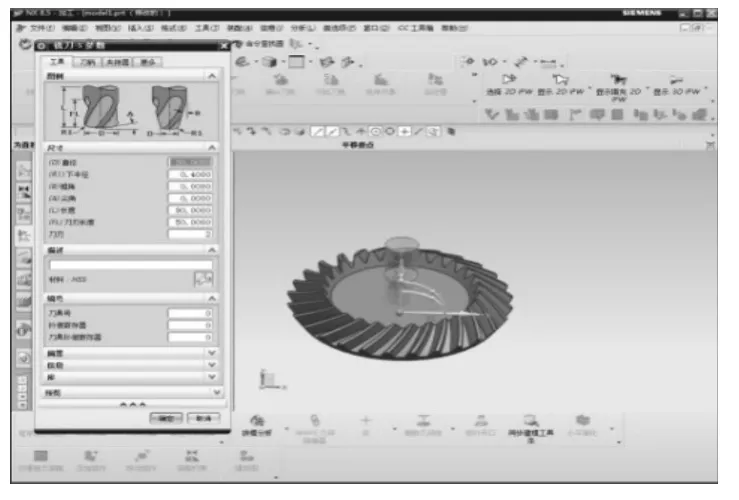

3.3.Bore machining of gear

Bore machining will choose cavity milling to finish during rough machining,the machining tool,the tool path geometry and setting are shown in Figure 3.After the cavity milling,user might need to have a deep machining,then the plane milling will be the final step to finish the whole bore machining of gear.

Figure 2.Tooth machining

Figure 3.Bore machining and tool information

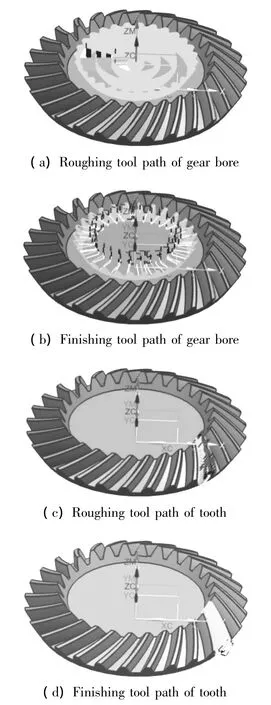

4.Tool path generation and verification

Cutter location data files and the tool running position are the important basis for tool path generation process.In this process,the dominant factor could be determined whether there have been cut and processed by a reasonable tool,advance and retreat knife,and take the knife route choice through the tool route to find if the selected milling tool with a surface to be machined could interfere with the collision of the tool,and it could verify the tool path by a knife rail confirmation.

In UG,by choosing a tools,processing methods and clicking the right mouse button and selecting a good choice“generate”command,one could get tool path of each machining of high-tooth logarithmic spiral bevel gear,as shown in Figure 4(a)~(d).

Figure 4.Tool path generateion

In UG,in the operating process Navigator,right-click on the operation of the program-the tool path-confirmation command,one could select the authentication method for tool path verification.Last tool path verification can be shown if user needs to modify the results.

5.Conclusion

The NC program of DMU50ECOLINE could be successfully obtained by UGPOST.The NC program is adopted by machining center.According to the designed process cards,knives and gear blanks installed on the machine,user could achieve that hightooth logarithmic spiral bevel gear can be machined through simulation debugging on the machine.Timeconsuming of the detection and diagnosis could be reduced.The consumption of resources on the processing equipment will be reduced as well.All of these has a strong operational and stability characteristic.

[1] Ju Hai-jun.The processing method of logarithmic spiral bevel gear[D].Baotou:Inner Mongolia University of Science and Technology,2009.

[2] Deng Xiao-zhong,Guo Jian-song.Suitable for China’s national conditions such as bevel gear manufacturing technology[J].Modern Components,2011(9):57-58.

[3] Qing Chun.NC program and machining process simulation based on UG[D].Hohhot:Inner Mongolia University of Technology,2007.

[4] Zhang Yong.Research and realization of the method of numerical control code auto generation and simulation[D].Qinhuangdao:Yan Shan University,2007.

[5] Zhu Xiao-lu.HANDBOOK OF GEAR DESIGN[M].Beijing:Chemical Industry Press,2004.

[6] Yu Wen-tao.The entire CNC machining methods and software of epicycloids gear[D].Chongqing:Chongqing University of Technology,2009.

[7] Rong Qing-he.Research on CNCmachining Simulation of spiral bevel gear[D].Shenyang:Shenyang University of Technology,2011.

[8] Wern-Kueir Jehng.Computer solid modeling technologies applied to develop and form mathematical parametric tooth profiles of bevel gear and skew gear sets[J].Journal of Materials Processing Technology,2002,122:160-172.