Research on asphalt concrete pavement deicing technology

Ma Hui Yang Ruochong Qian Shunzhi

(School of Transportation, Southeast University, Nanjing 210096, China)

?

Research on asphalt concrete pavement deicing technology

Ma Hui Yang Ruochong Qian Shunzhi

(School of Transportation, Southeast University, Nanjing 210096, China)

In order to reduce the cohesive force between pavement and ice, the approach of pavement surface coating with hydrophobic admixtures is investigated. The deicing effect of this approach is examined by the contact angle test and the shear test. The durability of the approach is examined by the accelerated abrasion test, and the skid resistance of the pavement with surface coating is examined by the British pendulum test and the surface texture depth test. In the contact angle test, the contact angle between hydrophobic admixture and water is 100.2°. In the shear test, the maximum shear stress is 0.06 MPa for the specimen coated with hydrophobic admixture, which is much lower than that of the specimen without hydrophobic admixture coating, 3.5 MPa. Furth-ermore, the ice and asphalt surface are completely separated for the coated specimen while not for the uncoated specimen. Based on the accelerated abrasion test, the residual hydro-phobic admixture in the veins of the pavement after abrasion still has a deicing effect. From the skid resistance tests, the British pendulum number (BPN) and the texture depth (TD) of the specimen coated with hydrophobic admixtures are larger than those of the standard requirements. The overall experi-mental observation indicates that the approach can effectively reduce close contact between asphalt pavement and ice; therefore, it can be a promising solution to road icing problems in winter.

deicing; hydrophobic admixture; surface coating; cohesive force; durability

With the second largest road network in the world, China is very vulnerable to snow and icy rain in winter which happens to be the high season for road traffic. The snow and ice on the road significantly impact the normal operation of vehicles, which causes heavy disruption to the national economy and people’s daily life. Over the last several decades, a significant amount of research have been conducted to explore convenient and efficient snow melting and deicing techniques to solve this problem. These techniques can be broadly divided into external and internal approaches.

External approaches include deicing by technologies such as scattering an ice-melting agent, surface coating and cleaning manually or by machinery, etc[1]. Scattering an ice-melting agent is an approach to reduce the melting point of ice; therefore, the ice can melt at a lower temperature. Chlorine salt is the main ice-melting agent due to its low cost. Although this approach has a high deicing efficiency, chlorine salt can also significantly corrode roads and bridges as well as pollute the soil and water in the long term[1-6]. The manual or machinery cleaning approach is commonly used for deicing; however, it has drawbacks such as a low cleanse rate and a high cost. More innovative deicing approaches such as microwave heating deicing have not been popularized because of their low deicing efficiency and immaturity[7-9].

An internal approach to deicing has functional pavements using different technologies, such as deicing by heating up the pavement, adding salinization material and granulated crumb rubber into the asphalt mixture[10]. Ice melting by heating mainly uses the heat produced by geotherm, gas, electric and solar energy. This method has a high rate of ice melting; nevertheless using this technology is energy intensive, costly and difficult to construct[10-16].Similar to the scattering ice-melting agent approach, ice melting by adding a salinization material into the asphalt mixture is to reduce freezing point of the ice on the pavement. The difficulty of this approach is to guarantee the pavement’s performance, such as high temperature stability, low-temperature crack resistance and water damage resistance[10,17]. The success of the last approach hinges on the uneven deformation characteristics of rubble particles. With the aid of the rubber particles’ larger deformation compared to the asphalt mixture, ice can be easily broken under the vehicle load. This approach can reduce road noise and improve the pavement’s performance including high temperature stability, low-temperature crack resistance and antiskid performance; nevertheless the deicing effect is not ideal and the smoothness of pavement will deteriorate over time[18].

As can be seen from the above literature reviews, extensive research has been conducted to solve deicing problems, yet various problems still need to be resolved. Therefore, this paper attempts to improve the efficiency of deicing technology via surface coating approach, resulting in safe and durable pavements.

1 Experimental Program

1.1 Materials

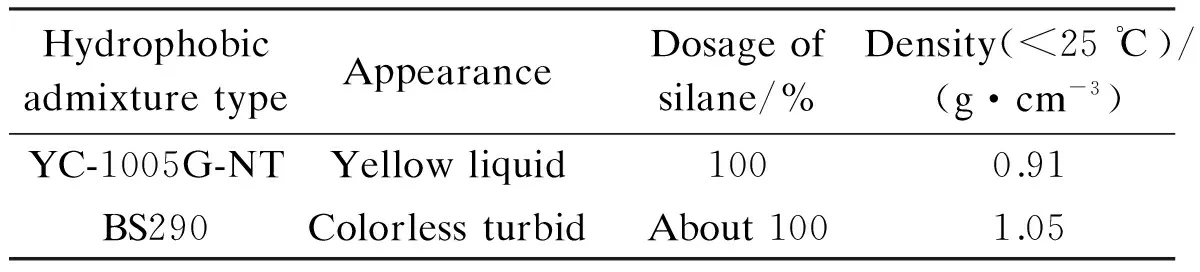

Two kinds of hydrophobic admixtures were used in this study, which include SILQUESTRYC-1005G-NT and SILRESRBS290. They are all liquid materials. YC-1005G-NT is a hydrophobic admixture based on organosilicon. It has a good hydrophobic ability, high penetrability and high adhesiveness. BS290 is a solventless silicone concentrate based on a mixture of silane and siloxane. The physical properties of hydrophobic admixtures are shown in Tab.1.

Tab.1 Physical properties of hydrophobic admixtures

1.2 Contact angle test

The contact angle test was used to illustrate the contact relationships of hydrophobic admixtures/water and hydrophobic admixtures/asphalt. First, hydrophobic admixtures and asphalt were coated on the glass boards, respectively. Then, distilled water was dripped onto the glass boards coated with hydrophobic admixtures and hydrophobic admixtures were dripped onto the glass boards coated with asphalt. The contact angles were measured by the admeasuring apparatus-CA-XP150.

1.3 Shear test

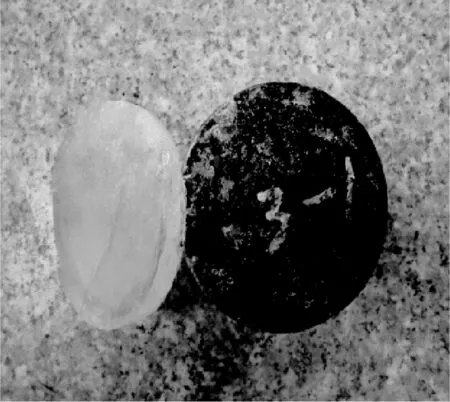

In order to study the change of cohesive force between the ice and pavement, which is coated and uncoated with hydrophobic admixtures, the shear test was conducted. To greatly simplify the research task, the surface of the Marshall specimen was adopted to represent the surface of the pavement in the experiment. The diameter and length of the Marshall specimen were 100 and 64 mm, respectively. The asphalt content was 5% in the mixture. First, hydrophobic admixtures were coated onto the top surface of Marshall specimens. There were three different dosages for each hydrophobic admixture, i.e., 0.3, 0.5 and 0.7 kg/m2, respectively. Secondly, the coated specimens were cured at room temperature for 10 h so that the hydrophobic admixtures could be absorbed completely by the Marshall specimen surface. The top surface of the Marshall specimen was lapped with a blown-sponge to form a reservoir to retain water, as shown in Fig.1(a). Afterwards, water was poured into the reservoir, which was then put into a refrigerator to form ice on the surface. At the same time, control specimens without coating were made following the same procedure for comparison.

After water on the surface of the specimens was frozen, the shear test was conducted with the universal testing machine (UTM), as shown in Fig.1(b). The test was conducted under a displacement control of 5 mm/min. In the test, the load and displacement data were continuously recorded; and the fracture surfaces of specimens were carefully

(a)

(b)

examined after the test. In order to prevent the ice melting, the temperature in the UTM chamber was set at -10 ℃ for one hour before the test. Due to the difficulty in mounting external LVDTs on the specimen, displacement data from the internal LVDT was used for this investigation.

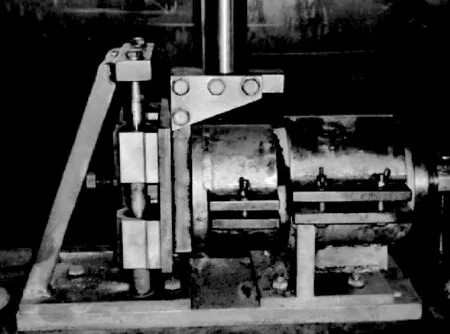

1.4 Accelerated abrasion test

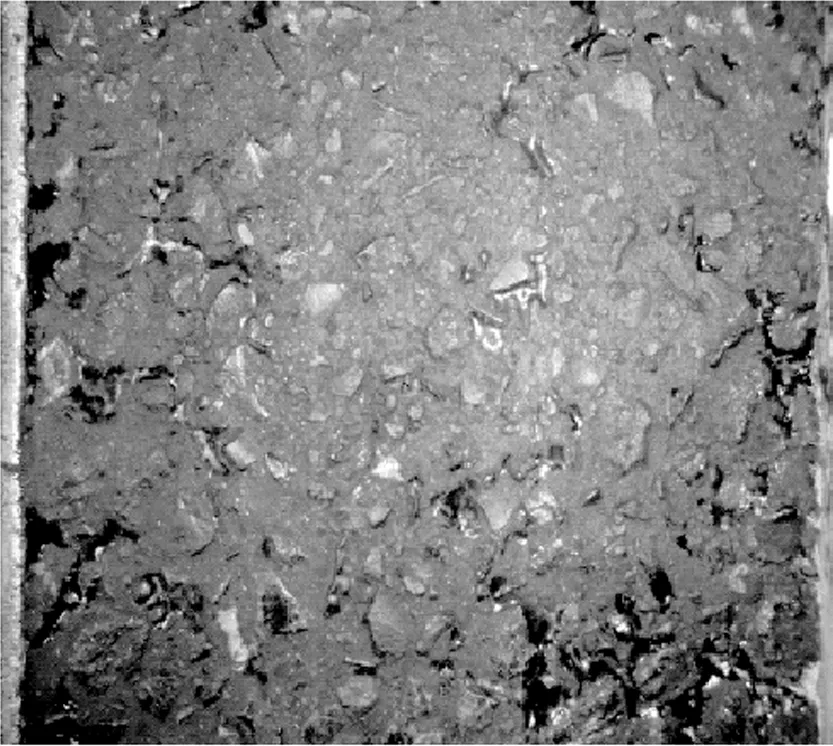

In order to study the durability of hydrophobic admixtures, which were coated on the top surface of pavement, an accelerated abrasion test was devised. First, the SMA-13 specimens were prepared with a size of 280 mm×140 mm×50 mm, as shown in Fig.2. Secondly, hydrophobic admixtures were coated onto the top surface of specimens three times with an interval of 15 min. The total dosage of the hydrophobic admixture for a specimen was 0.7 kg/m2. Finally, the coated specimens were cured at a temperature of 15 ℃ for 20 h so that the hydrophobic admixtures could solidify completely.

Fig.2 The specimen of accelerated abrasion test

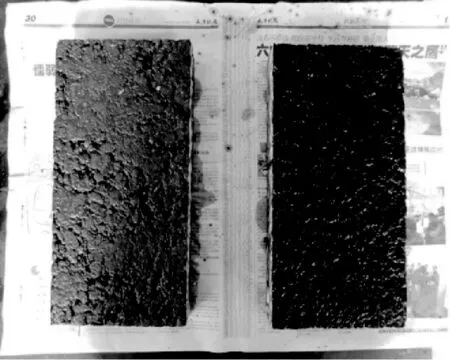

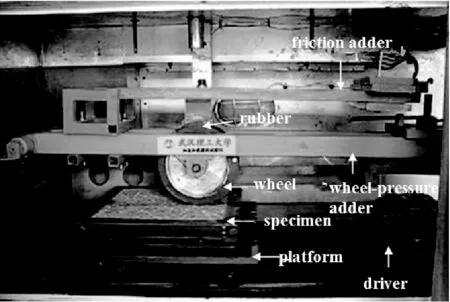

The accelerated abrasion test was conducted on an instrument modified from a rutting tester with friction provided by the additional loading frame, as shown in Fig.3. In order to imitate the interaction between the wheel and the road for two different scenarios, i.e. braking and driving wheel action, the friction stress levels were set to be 0.11 and 0.33 MPa, respectively, which were calculated by

τ=σnsinθ+kσn

(1)

whereσn=0.7 MPa is the pressure between the wheel and the pavement;kis the coefficient of rolling friction, under the condition of driving wheel action,k=0.13 to 0.22, and under the condition of braking wheel action,k=0.5 to 0.6; andθis the pavement profile grade (in this studyθ=3%). After abrasion, the top surface of the specimen was lapped with a blown-sponge to retain water (see Fig.4), which was then frozen in the refrigerator. Afterwards, the ice on the specimen was compressed 10 times by a rut board molding pendulum to simulate the action of wheel loads on an icy road, as shown in Fig.5. The compressive action on the ice-covered specimen was greatly amplified since the pressure of the rut board molding pendulum was 1.11 MPa, which is much larger than the normal pressure exerted by vehicle types. The fracture/damage forms of the ice on the specimens were checked carefully after compressing. Finally, a shear test was also conducted to reveal the deicing effect of residual hydrophobic admixtures after the accelerated abrasion test. The specimens for shear test were drilled from the specimens for the accelerated abrasion test once the test was finished. The diameter and length of shear test specimen were 100 and 50 mm, respectively.

Fig.3 Accelerated abrasion instrument

Fig.4 Specimen lapped with blown-sponge

Fig.5 Ice on surface of specimen compressed by rut board molding pendulum

1.5 Skid resistance test

In order to investigate the impact of hydrophobic admixtures on pavement skid resistance, BPN and TD of specimens were measured. First, the SMA-13 specimens were prepared with the size of 300 mm×300 mm×50 mm. Secondly, hydrophobic admixtures were coated onto the top surface of specimens with a dosage of 0.7 kg/m2. Then, BPN and TD were measured after the hydrophobic admixtures solidified completely. At the same time, control specimens without coating were tested for comparison.

2 Results and Discussion

2.1 Contact angle test

The bigger the contact angle, the better the hydrophobic properties of the surface of the specimen. Generally, when the contact angle is greater than 90°, the surface of the specimen has a hydrophobic property. In addition, if the contact angle is larger than 150°, the surface has super-lyophobic properties.

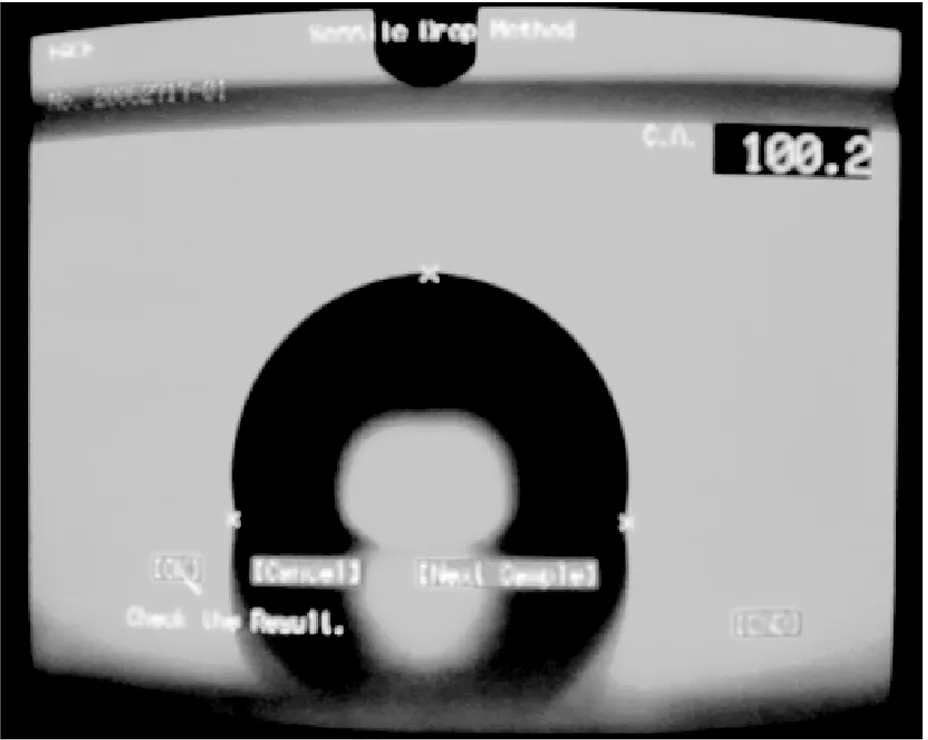

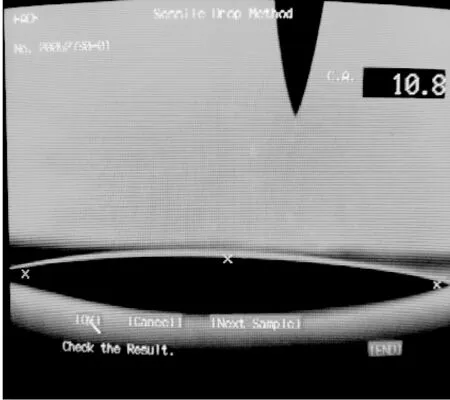

The contact angle between the hydrophobic admixture YC-1005G-NT and water is shown in Fig.6(a). The contact angle between YC-1005G-NT and water is 100.2°; while the contact angle between BS290 and water is 85.3°. It can be seen that the hydrophobic property of YC-1005G-NT is better than that of BS290. When hydrophobic admixtures are dripped on the surface of asphalt, the contact angles between asphalt and YC-1005G-NT/BS290 are 10.8° and 15.4°, respectively, as shown in Fig.6(b). The small contact angles between hydrophobic admixtures and asphalt suggest that the hydrophobic admixtures could bond with asphalt efficiently. Overall, hydrophobic admixtures have good hydrophilic properties, in particular YC-1005G-NT. Hydrophobic admixtures have small surface tension with asphalt, so they can permeate into asphalt concrete pavements and greatly extend its service life as a deicing material.

(a)

(b)

Fig.6 Contact angles of different interfaces. (a) YC-1005G-NT and water; (b) YC-1005G-NT and asphalt

2.2 Shear test

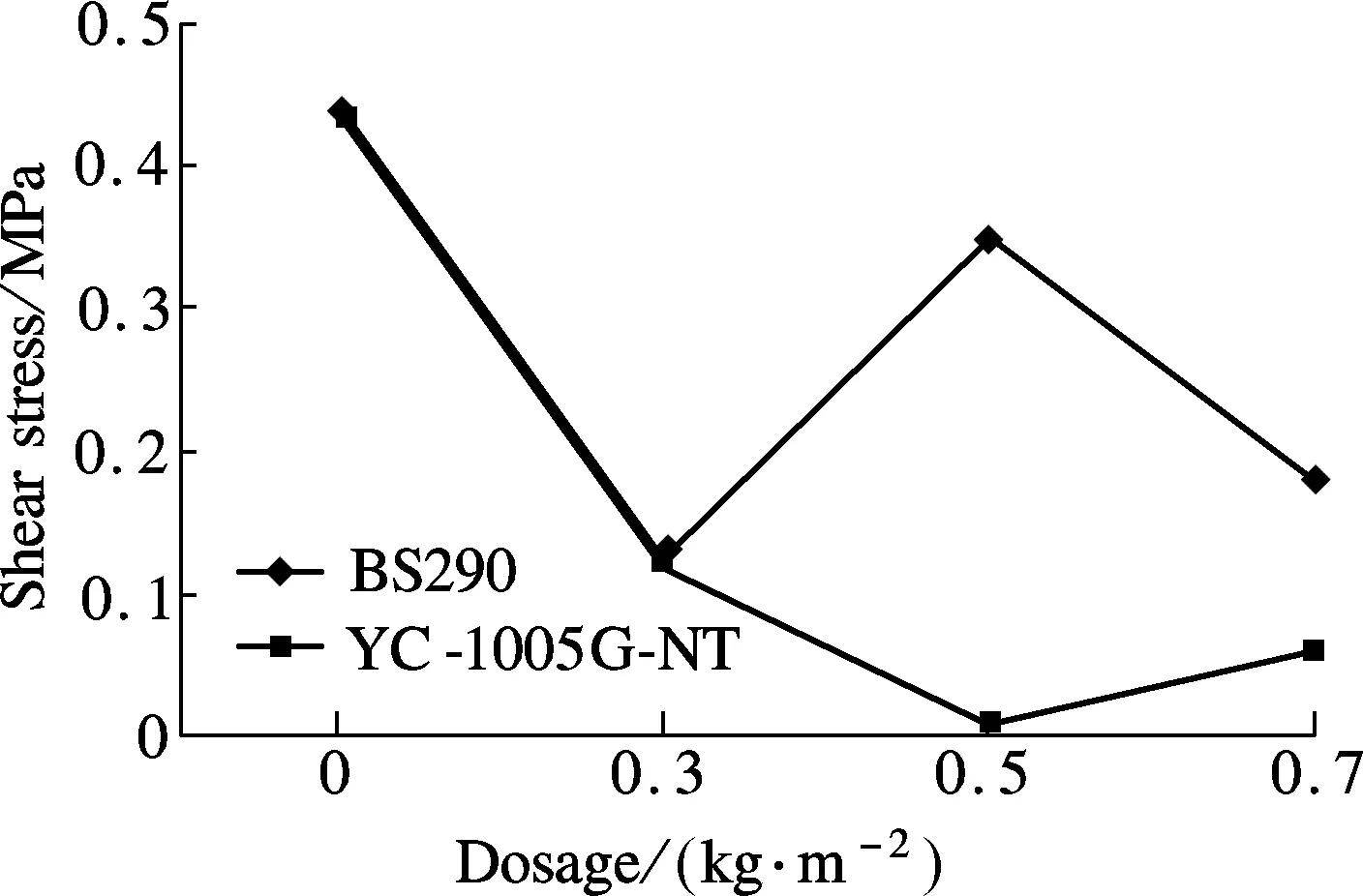

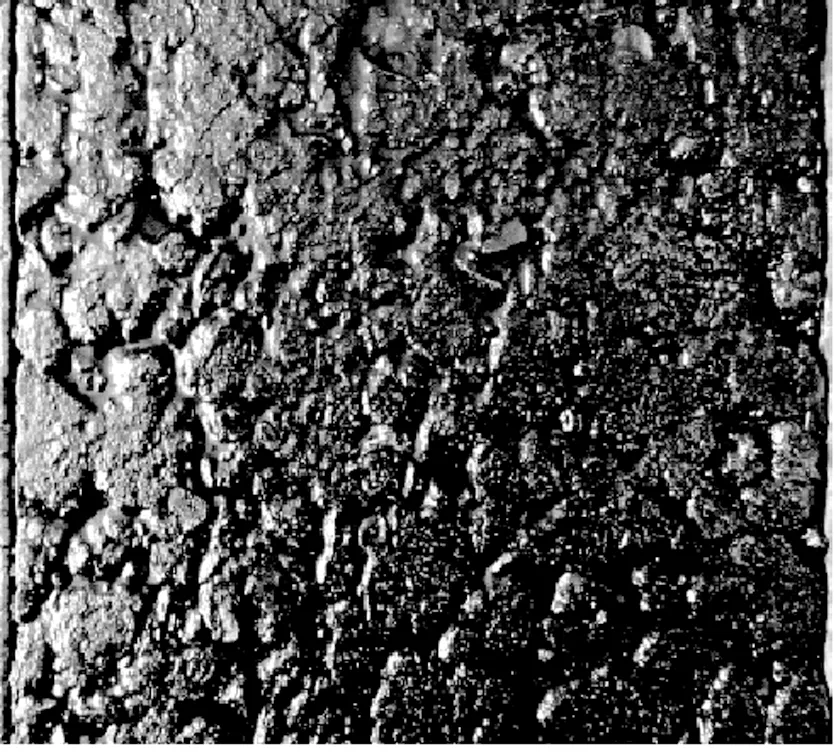

The test results corresponding to different dosage of hydrophobic admixtures are shown in Figs.7 to 9. It has been observed that hydrophobic admixtures are very effective in reducing the bond between the specimen surface and ice. Deicing effect of hydrophobic admixtures increases (shear strength decreases) when dosage increases. When the dosage increases to 0.7 kg/m2, the shear stress is 0.06 MPa for YC-1005G-NT. In all the shear samples coated with hydrophobic admixtures, ice has been completely sheared off along the interface, leaving the surface of specimen clear and intact, which is not the case for the specimens without surface coating. It can be clearly seen from Fig.7(a) that the surface of the specimen is largely bonded with the ice after the shear test.

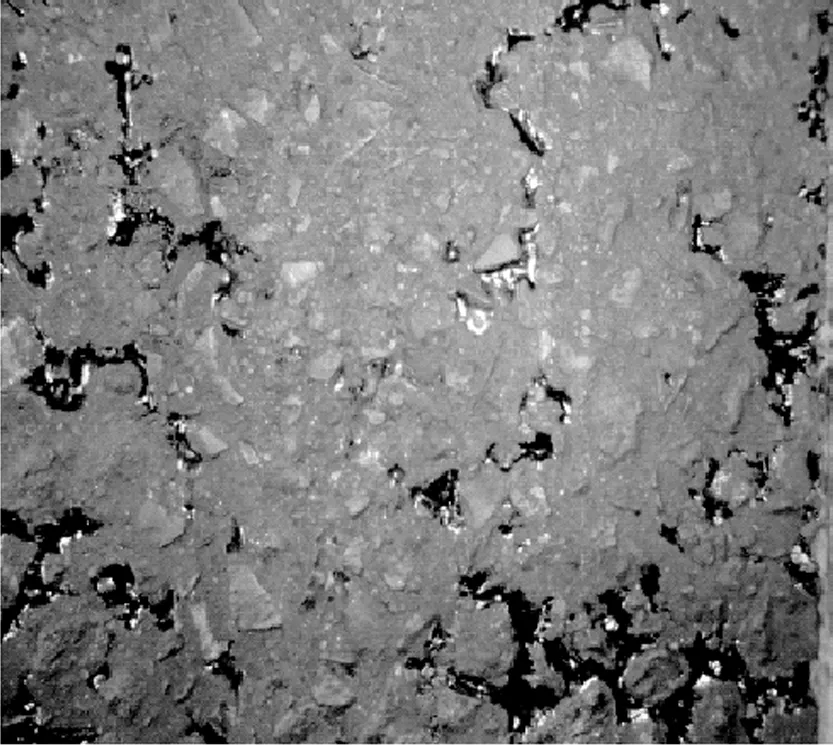

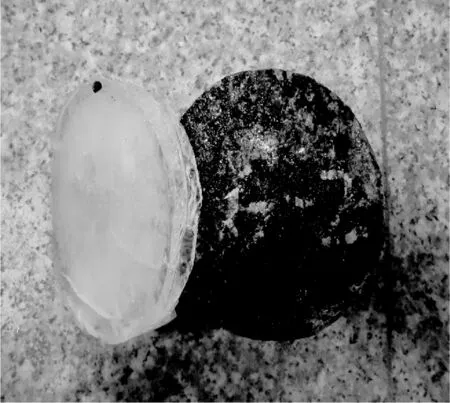

Compared with YC-1005G-NT, the shear test results of samples coated with BS290 suggest that the deicing effect of BS290 is less effective. As shown in Fig.9, when the dosage is 0.3 kg/m2, the deicing effect is similar to that of YC-1005G-NT. However, when the dosage increases to 0.5 and 0.7 kg/m2, the ice is not sheared off along the interface and there is some ice remaining on the surface of the Marshall specimen, as shown in Figs.8(c) and (d). The shear strength is minimal when the dosage is 0.3 kg/m2. The main reason for the seemingly unlikely increase in the shear load at higher dosage is that it becomes more difficult for the agent to be absorbed by the specimen with increasing dosage. Some hydrophobic admixture still remained in its liquid state on the surface of specimen when adding water on the top surface. Therefore, part of the hydrophobic admixture is diluted in water and has no effect on reducing the cohesive force. When dosages are 0.5 and 0.7 kg/m2, the shear planes are ice interiors, which suggests that their corresponding shear forces (see Fig.9) reflect more or less the shearing strength of ice.

(a)

(b)

(c)

(d)

Fig.7 Interface exposed after shear test for coating YC-1005G-NT at different dosages. (a) 0 kg/m2; (b) 0.3 kg/m2; (c) 0.5 kg/m2;(d) 0.7 kg/m2

(a)

(b)

(c)

(d)

Fig.8 Interface exposed after shear test for coating BS290 at different dosages. (a) 0 kg/m2; (b) 0.3 kg/m2; (c) 0.5 kg/m2;(d) 0.7 kg/m2

Fig.9 Relationship of shear force with dosage for coating hydrophobic admixtures

A brief sum up is made in this part. The shear stress corresponding to the dosage of 0.7 kg/m2is almost minimal for all coating admixtures, as shown in Fig.9. Among them, the shear stresses of the specimens coated with hydrophobic admixtures are much smaller compared with those of uncoated specimens. The shear planes of specimens coated with YC-1005G-NT are clear and intact according to Figs.7(b), (c) and (d). The test results indicate that YC-1005G-NT is better than BS290, and the optimal dosage of YC-1005G-NT is 0.7 kg/m2.

2.3 Accelerated abrasion test

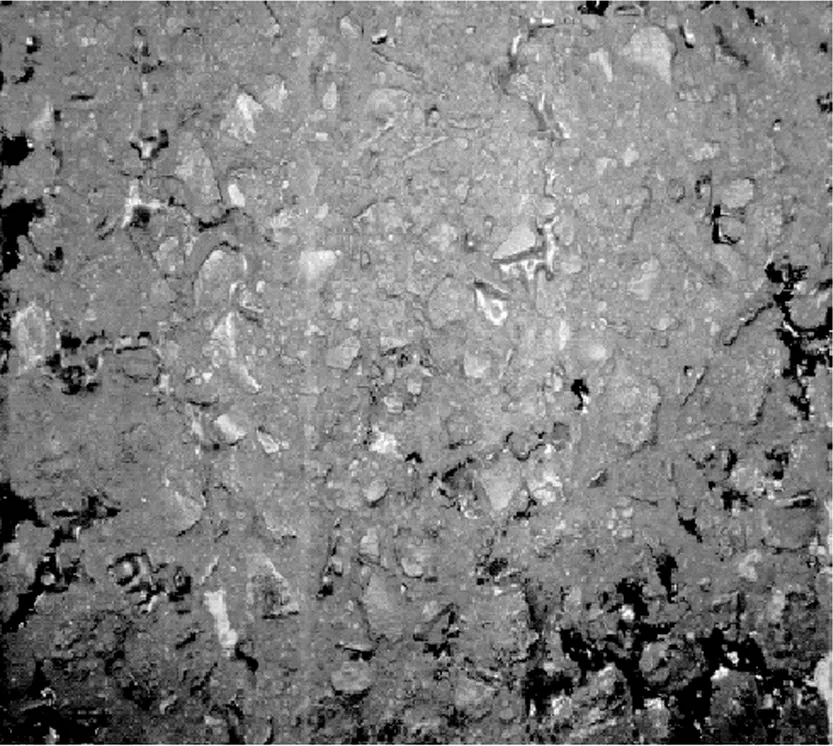

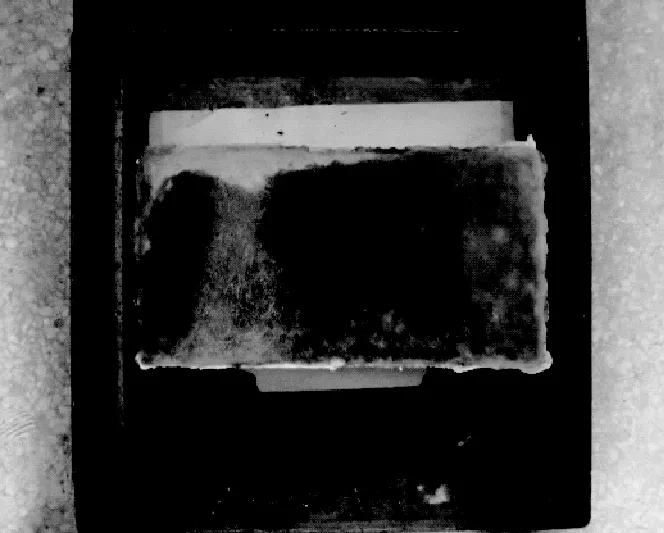

The results of the accelerated abrasion test are shown in Figs.10 to 12. The surface situations of specimens after the accelerated abrasion test with friction 0.11 MPa are shown in Fig.10. It can be clearly seen that there is a hydrophobic admixture membrane on the surface of each specimen. The membrane has been gradually abraded with the increase of the grinding times. However, the residual membrane is found in the veins of the specimen surface. Also, the residual hydrophobic admixture membrane has no change when the grinding times increase from 12 600 to 20 160. The abrasion occurs between the wheel and aggregate when the grinding times are more than 12 600, and the residual membrane can deice persistently. Observing the surface situations of the specimens after the accelerated abrasion test with the friction of 0.33 MPa, it is found that there is only a little residual membrane retained in the veins of the specimen surface when the grinding times are over 5 040. Actually, the friction used in this test is much greater than that in the actual situation.

(a)

(b)

(c)

(d)

Fig.10 Surface situation of specimen at different grinding times (σ=0.7 MPa,ζ=0.11 MPa). (a)N=0; (b)N=5 040; (c)N=12 600; (d)N=20 160

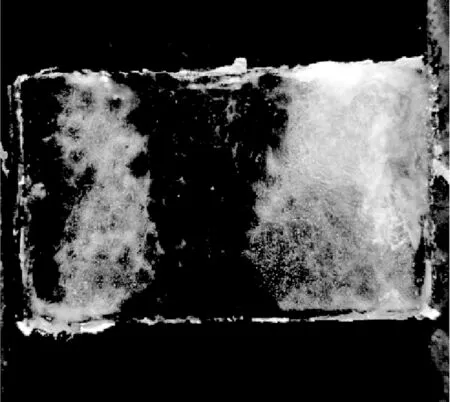

It can be seen from Fig.11(a) that ice on specimens without hydrophobic admixture almost suffers no damage after being laminated by the rut board molding instrument. By contrast, ice on specimens coated with the hydrophobic admixture is damaged completely, as shown in Fig.11(b). The hydrophobic admixture membrane decreases with the increase of the grinding times so that less ice is destroyed, as shown in Fig.12. The same trend is observed when the friction is added to 0.33 MPa.

(a)

(b)

Fig.11 Ice laminated by rut board molding instrument. (a) Without coating; (b) With coating

(b)

(c)

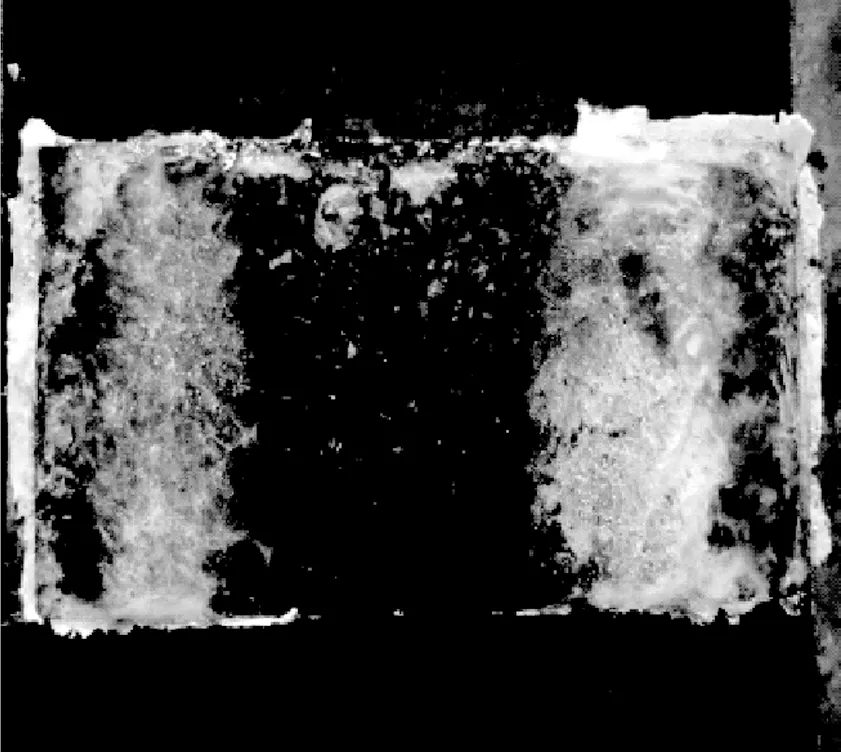

The shear test results corresponding to different grinding times are shown in Fig.13 and Fig.14. It is observed that ice has been completely sheared off along the interface, leaving the surface of specimen clear and intact when the grinding times are below 10 080. But when the grinding times are added to 20 160, the ice cannot shear off completely along the interface, and damage occurs internally in the ice, as shown in Fig.13(c). There is some residual ice on the interface after the shear test. From Fig.14, it can be clearly seen that shear stress increases with the increase of the grinding times. The shear stress for the case of YC-1005G-NT is smaller than that of BS290.

(a)

(b)

(c)

Fig.14 Relationship between shear stress and grinding times (ζ=0.11 MPa)

It indicates that when the hydrophobic admixture decreases, the deicing effect is reduced gradually. When the friction is 0.33 MPa, the deicing effect decreases rapidly.

Based on the above discussions, conclusions can be drawn that hydrophobic admixtures are effective at reducing the cohesive force between the pavement and ice, particularly for YC-1005G-NT. The residual hydrophobic admixture in the veins of pavement also still has the ability to deice after 20 160 times accelerated abrasion.

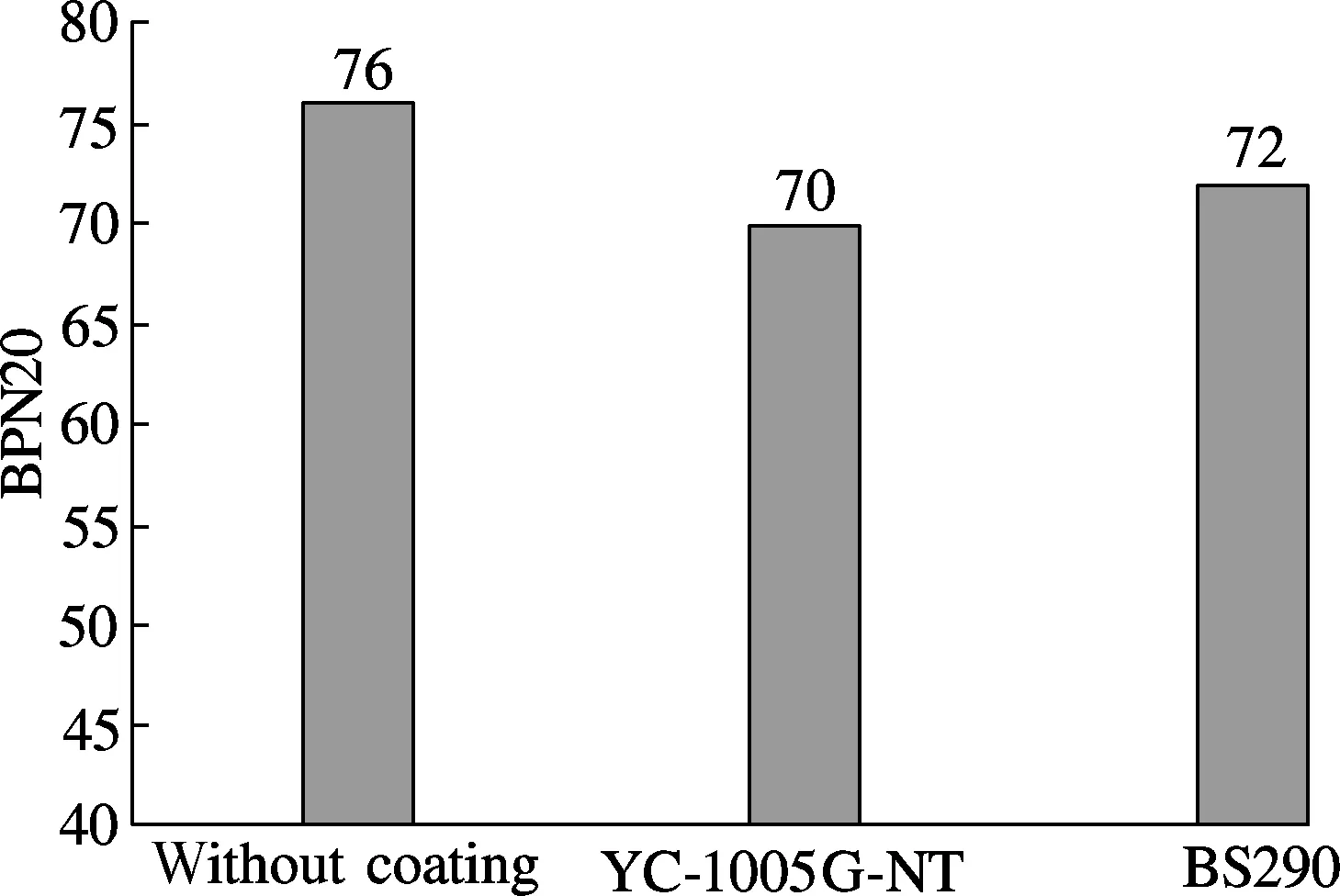

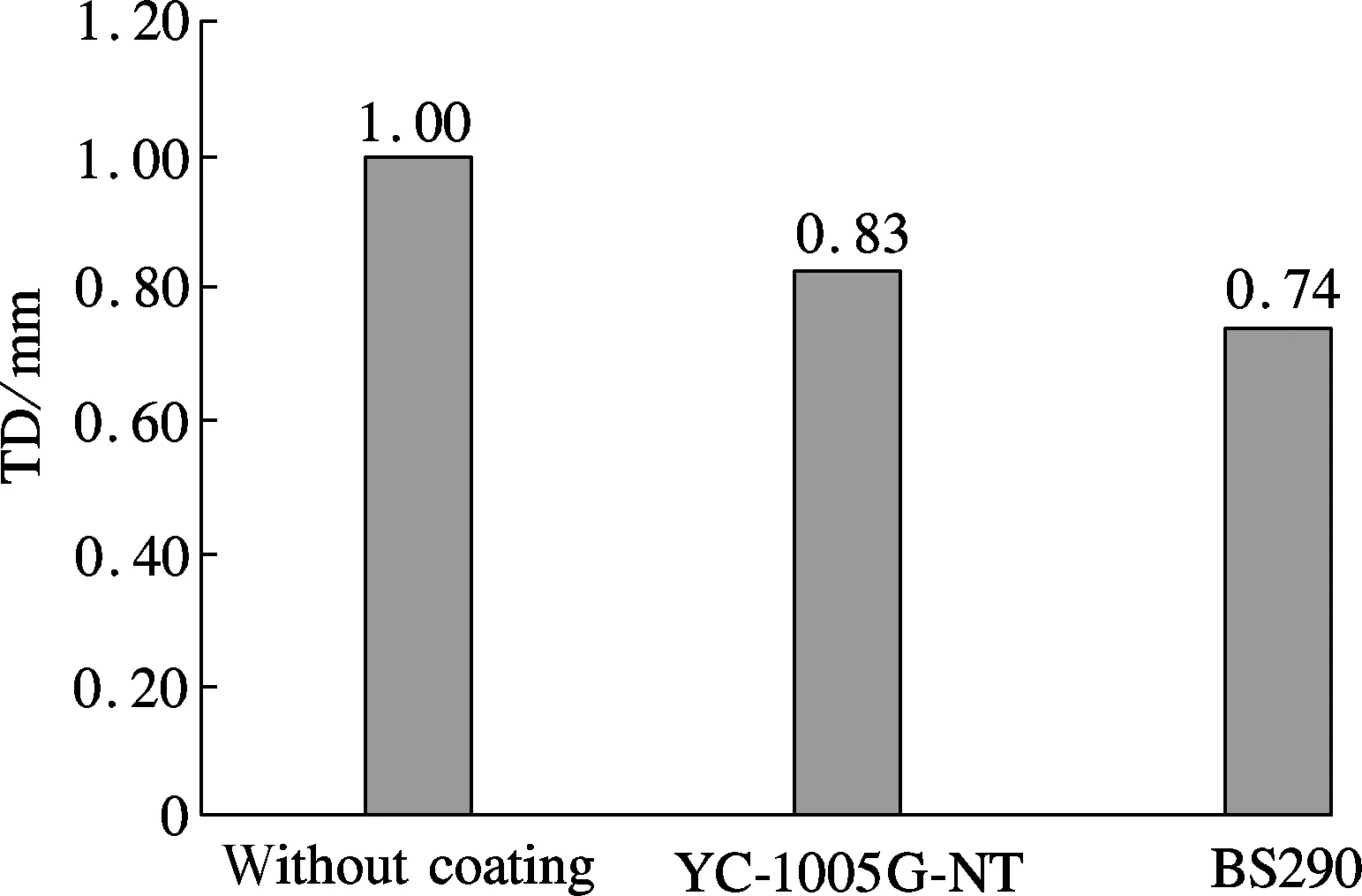

2.4 Skid resistance test

The impacts of hydrophobic admixtures on the skid resistance of pavements are shown in Fig.15 and Fig.16. The BPN and TD of highway pavements should be larger than 42 and 0.55 according to that of the standard, respectively. From Fig.15, it can be seen that when coated with hydrophobic admixtures, BPN decreases slightly compared to that of the specimen uncoated with hydrophobic admixtures, but it is still over 42. TDs of specimens with coating YC-1005G-NT and BS290 reduce from 1.00 to 0.83 and 0.74, respectively, which are greater than the required value of 0.55. So the deicing technology, coating hydrophobic admixture, can guarantee the required of skid resistance of pavement.

Fig.15 Variation of BPN of different hydrophobic admixtures

Fig.16 Variation of TD of different hydrophobic admixtures

3 Conclusions

Experimental results show that surface coating with hydrophobic admixture approach can greatly reduce the cohesive force between the pavement and ice. This method can also guarantee the required skid resistance. The accelerated abrasion test results indicate a certain durability of this deicing technology. Although further research on durability should be done, it certainly provides an alternative solution for the deicing problem faced by many countries. The following conclusions can be drawn:

1) The contact angles of hydrophobic admixtures/water and hydrophobic admixtures/asphalt are about 100° and 10°, respectively. It indicates that hydrophobic admixtures have good hydrophobic properties and they can soak on the surface of asphalt, so they can bond with asphalt very well.

2) Hydrophobic admixtures, in particular YC-1005G-NT, show a high potential for reducing the cohesive force between the pavement and ice. The cohesive stress can be reduced from 0.44 to 0.06 MPa when the dosage of the hydrophobic admixture is 0.7 kg/m2.

3) Because the residual hydrophobic admixtures in the veins of the pavement after the accelerated abrasion test still have the ability to reduce the cohesive force between the pavement and ice, the hydrophobic admixture coating approach has certain durability.

4) BPN and TD of specimens coated with hydrophobic admixture are all larger than the demand values of the standard. The deicing technology, coating hydrophobic admixture, can guarantee the required skid resistance of the pavement.

[1]Liu H Y, Hao P W. Technology and development trend of pavement deicing [J].RoadMachineryandConstructionMechanization, 2008, 25(11): 17-21. (in Chinese)

[2]Wang K J, Nelsen D E, Nixon W A. Damaging effects of deicing chemicals on concrete materials [J].Cement&ConcreteComposites, 2006, 28(2): 173-188.

[3]Yuan X Z, Zhu Y L, Li J. Effect of pavement deicing chloride salt on the soil properties [C]//ProceedingsofInternationalWorkshoponEnergyandEnvironmentintheDevelopmentofSustainableAsphaltPavements. Xi’an, China, 2010: 575-579.

[4]Green S M, Machin R, Cresser M S. Effect of long-term changes in soil chemistry induced by road salt applications on N-transformations in roadside soils [J].EnvironmentalPollution, 2008, 152(1): 20-31.

[5]Thunqvist E-L. Regional increase of mean chloride concentration in water due to the application of deicing salt [J].ScienceoftheTotalEnvironment, 2004, 325(1/2/3): 29-37.

[6]Ostendorf D W, Hinlein E S, Rotaru C, et al. Contamination of groundwater by outdoor highway deicing agent storage [J].JournalofHydrology, 2006, 326(1/2/3/4): 109-121.

[7]Tang X W, Jiao S J, Gao Z Y, et al. Study of 5.8 GHz magnetron in microwave deicing [J].JournalofElectromagneticWavesandApplications, 2008, 22(10): 1352-1360.

[8]Macelloni G, Ruisi R, Pampaloni P, et al. Microwave radiometry for detecting road ice [C]//ProceedingsofInternationalGeoscienceandRemoteSensingSymposium. Helsinki, Finland, 1999: 891-893.

[9]Macelloni G, Paloscia S, Pampaloni P, et al. Monitoring of melting refreezing cycles of snow with microwave radiometers: the microwave alpine snow melting experiment (MASMEx 2002—2003) [J].TransactionsonGeoscienceandRemoteSensing, 2005, 43(11): 2431-2442.

[10]Zhang H W, Han S, Liu H H. A summary of asphalt concrete pavement for deicing and snow melting technology [J].HeilongjiangJiaotongKeji, 2008, 169(3): 8-9. (in Chinese)

[11]Tang Z Q, Qian J S, Li Z Q, et al. Influential factors on deicing performance of electrically conductive concrete pavement [J].JournalofWuhanUniversityofTechnology:MaterialsScience, 2006, 21(2): 123-127.

[12]Sullivan C R, Petrenko V F, Mccurdy J D. Breaking the ice: deicing power transmission lines with high-frequency, high-voltage excitation [J].IndustryApplicationsMagazine, 2003, 9(5): 49-54.

[13]Yehia S, Tuan C Y. Conductive concrete overlay for bridge deck deicing [J].AciStructuralJournal, 1999, 96(3): 382-390.

[14]Tuan C Y. Roca Spur Bridge: the implementation of an innovative deicing technology [J].JournalofColdRegionsEngineering, 2008, 22(1): 1-15.

[15]Wang H J. Study of heat and mass transfer of hydronic snow melting process for pavement [D]. Tianjin: College of Mechanical Engineering, Tianjin University, 2007. (in Chinese)

[16]Wang H J, Zhao J, Chen Z H. Experimental investigation of ice and snow melting process on pavement utilizing geothermal tail water [J].EnergyConversionandManagement, 2008, 49(6): 1538-1546.

[17]Zhang L J. The study of salt antifreezing asphalt mixtures [D]. Xi’an: School of Materials Science and Engineering, Chang’an University, 2010. (in Chinese)

[18]Milani F, Takallou H B. De-icing characteristics of rubber concrete pavements [C]//ProceedingsofAsphaltRubber2009Conference. Nanjing, China, 2009: 989-994.

瀝青路面除冰雪技術研究

馬 輝 楊若沖 錢吮智

(東南大學交通學院, 南京 210096)

為降低路面和冰雪之間的黏結力,用有機硅憎水材料作為道路表面涂層.有機硅憎水涂層技術的除冰效果用接觸角實驗和剪切實驗來表征,其耐久性用加速加載磨耗實驗來評價,而其抗滑性能則用擺式摩擦法和鋪砂法來評價.接觸角實驗結果表明,有機硅憎水涂層材料與水的接觸角為100.2°,具有很好的憎水性能.其次, 通過剪切實驗可以得出: 在涂有有機硅憎水材料的情況下,冰層與試件表面的最大剪切應力僅為0.06 MPa,低于沒有進行表面涂層處理的最大剪切力3.5 MPa;剪切之后,冰層能夠很完整地從試件表面脫落.加速加載磨耗實驗表明,在經過一定時間的磨耗之后,殘留在瀝青路面構造深度里的有機硅涂層材料仍然具有除冰雪的效果.表面涂層后的道路表面的BPN值和構造深度值均有所降低,但是其仍然遠遠大于規范的要求,確保了安全性.研究表明,瀝青道路表面涂層技術能有效地降低瀝青路面與冰層的黏結,從而解決冬季道路結冰影響行車安全的問題.

除冰雪;有機硅憎水劑;表面涂層;黏結力;耐久性

U421.4

:Ma Hui, Yang Ruochong, Qian Shunzhi. Research on asphalt concrete pavement deicing technology[J].Journal of Southeast University (English Edition),2014,30(3):336-342.

10.3969/j.issn.1003-7985.2014.03.015

10.3969/j.issn.1003-7985.2014.03.015

Received 2013-12-19.

Biographies:Ma Hui (1987—), male, graduate; Qian Shunzhi (corresponding author), male, doctor, professor, zephyor@gmail.com.

Journal of Southeast University(English Edition)

2014年3期

Journal of Southeast University(English Edition)

2014年3期

- Journal of Southeast University(English Edition)的其它文章

- Observation and characterization of asphalt microstructure by atomic force microscopy

- Influence of different curing regimes on the microstructure and macro performance of UHPFRCC

- Evil-hunter: a novel web shell detection system based on scoring scheme

- Intelligibility evaluation of enhanced whisper in joint time-frequency domain

- Islamic traditional architecture environment overlapping the modern architecture design

- Hom-dimodules and FRT theorem of Hom type