一種基于微泡沫鉆井液的廢水處理方案分析

劉傳馳 杜勝男 安健寧 等

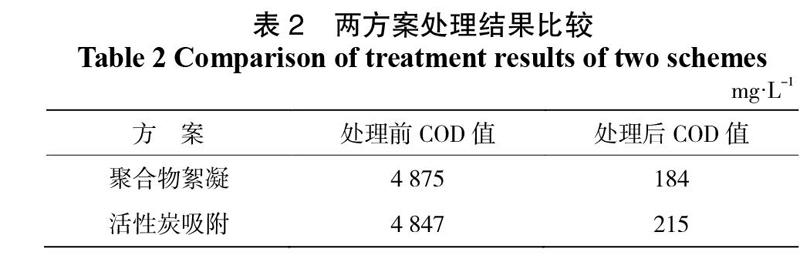

摘 要:采用微泡沫鉆井液進行鉆井過程中,會產生大量廢水。泡沫鉆井液廢水含有大量表面活性劑,化學需氧量(COD值)較高,直接排放會對環境造成極大的影響。簡要分析了表面活性劑對環境可能造成的影響,按照國家標準對廢水進行了檢測,依據實際情況,制定實驗并分析結果,通過消泡以及絮凝過程,除去廢液中大量的表面活性劑,并成功使COD值從4875降到184,證明方案切實有效。

關 鍵 詞:泡沫鉆井液廢水;表面活性劑;消泡;絮凝

中圖分類號:TE 357 文獻標識碼: A 文章編號: 1671-0460(2015)10-2294-03

Analysis on the Treatment Scheme of Micro Foam Drilling Fluid Wastewater

LIU Chuan-chi,DU Sheng-nan,AN Jian-ning,WANG Wei-qiang

(Liaoning Shihua University, Liaoning Fushun 113001,China)

Abstract:During drilling with the micro foam drilling fluid, a lot of waste water will be produced. Foam drilling fluid waste water contains a large amount of surface active agents and also has high chemical oxygen demand (COD) value, direct emission of which will cause a great impact on the environment. In this paper, the effect of surfactants on the environment was analyzed. The waste water was detected according to the national standard. Based on the actual situation, the experimental scheme was formulated, and the results were analyzed. The results show that, by defoaming and flocculation process, a large amount of surfactants can be removed from waste water, and the COD value can be decreased from 4875 to 184. The experiment results have proven that the scheme is practical and effective.

Keywords: Foam drilling fluid waste water; Surfactants; Defoaming; Flocculation

鉆井液,在石油鉆井工業中起著極其重要的作用,與此同時,廢棄鉆井液帶來的污染也是不容忽視的。廢棄的泡沫鉆井液中通常還含有膨潤土、聚合物、鉆屑、油類等多種雜質,均是無法自然降解的有害物質。隨著鉆井工業的發展,各種各樣的新型鉆井液正逐漸在復雜情況鉆井中起著越來越重要的作用。例如在“三低”以及裂縫油藏中發揮優勢的泡沫鉆井液。雖然目前我們已經通過調整泡沫直徑,研制出可循環使用的微泡沫鉆井液以盡量減少浪費,但是隨著油層雜質的摻入,我們也不得不在每次循環時加入新的起泡劑來保證泡沫的質量,以達到對鉆井的需求,這樣發展下去,發泡劑(即表面活性劑)在鉆井液廢液中的含量就會越來越多。這種添加劑嚴重超標的鉆井液如果直接排放,會對環境造成非常嚴重的污染。

目前最常用的鉆井液處理方法是掩埋,但是這樣處理,必然會使這些添加劑滲入泥土中,再經滲透作用匯入地下水源,所以采用這種方式無法從根本上杜絕污染。……