磺化腐殖酸型水煤漿分散劑的合成研究

李斌

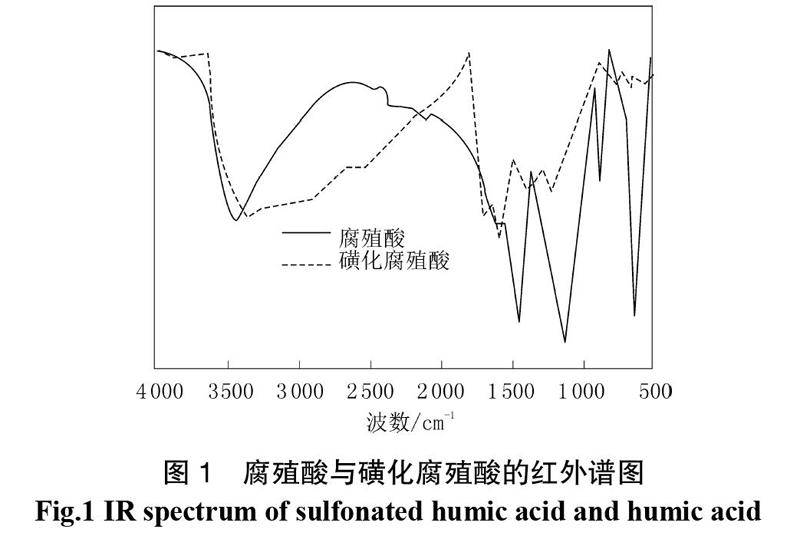

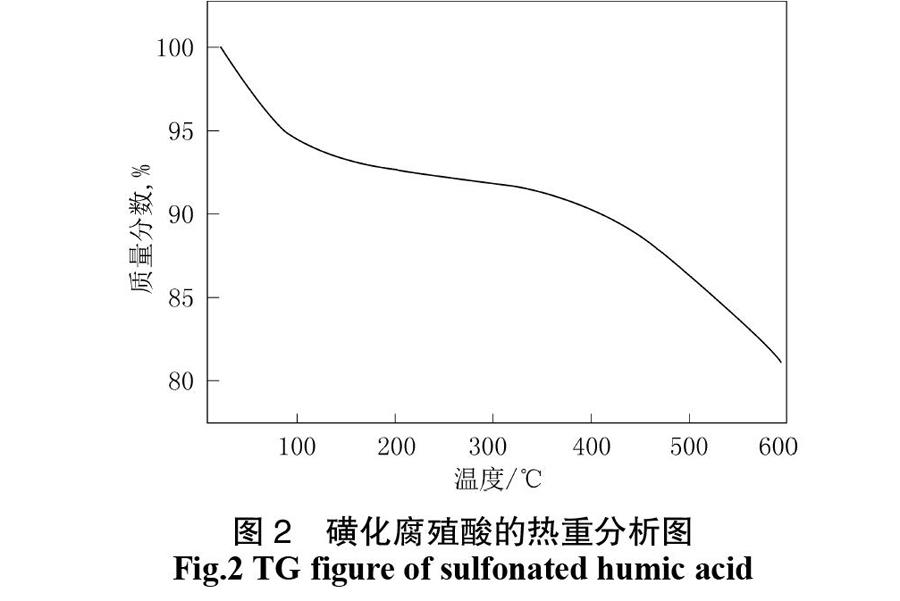

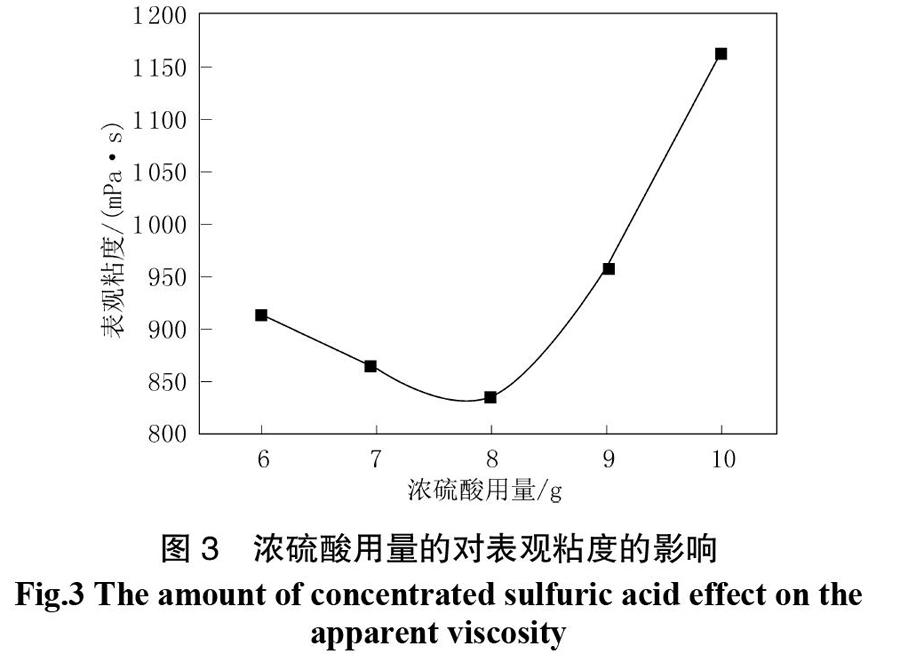

摘 要:采用腐殖酸為原料合成磺化腐殖酸型水煤漿分散劑,通過(guò)正交及單因素實(shí)驗(yàn),確定合成的最佳工藝條件為:腐殖酸與亞硫酸鈉的質(zhì)量比5:4;磺化時(shí)間4 h;溫度80 ℃;最佳濃硫酸用量為8 g。該條件下,對(duì)磺化腐殖酸系水煤漿分散劑進(jìn)行紅外、熱重表征,得知該分散劑具有磺化腐殖酸系水煤漿分散劑的優(yōu)點(diǎn):分散性好,合成成本低,穩(wěn)定性高。

關(guān) 鍵 詞:磺化;腐殖酸;水煤漿;分散劑;合成

中圖分類號(hào):TQ 53 文獻(xiàn)標(biāo)識(shí)碼: A 文章編號(hào): 1671-0460(2015)10-2338-03

Study on Synthesis of Sulfonated

Humic Acid Type Dispersant for Coal-water Slurry

LI Bin

(College of Chemical Engineering, Shaanxi Institute of Technology, Shaanxi Xian 710302, China)

Abstract: Using umic acid as raw material, sulfonated humic acid type dispersant for coal-water slurry was synthesized. By orthogonal and single-elemental experiments, the best synthesis condition was obtained as follows: mass ratio of humic acid and sodium sulfite 5:4, sulfonation time 4 h, temperature 80 ℃,doasge of concentrated sulfuric acid 8 g. The sulfonated humic acid type coal water slurry dispersant synthesized under above conditions was characterized by IR and TG. The results show that the dispersant for coal-water slurry has some remarkable advantages, such as good dispersibility, high stability and low synthesis cost.

Key words: Sulfonation; Humic acid; CWS; Dispersing agent; Synthesis

水煤漿是一種采用物理方法將煤液態(tài)化的新型燃料,由一定粒級(jí)的煤(約70%)、水(約30%)和少量添加劑制備而成,它保持了煤炭原有的物理特征[1,2],被稱為液態(tài)煤炭產(chǎn)品。我國(guó)水煤漿技術(shù)雖然取得了長(zhǎng)足的進(jìn)步[3],但許多地方尚需不斷完善,尤其在添加劑方面,這是影響水煤漿性能及價(jià)格的主要因素之一。只有針對(duì)不同煤種研制性能優(yōu)越、價(jià)廉的添加劑及配方,水煤漿技術(shù)才能得到廣泛的應(yīng)用和推廣[4,5]。

我國(guó)國(guó)產(chǎn)分散劑主要以萘系、木質(zhì)素系和腐殖酸系為主,萘系分散劑制漿存在著穩(wěn)定性差和成本較高的問(wèn)題[6],木質(zhì)素系和腐殖酸系分散劑則存在制漿黏度大[7],投加量多的問(wèn)題,而其他非離子分散劑和聚羧酸類分散劑雖高效但價(jià)格昂貴,制漿成本高[8]。因此,開(kāi)發(fā)適合多煤種制漿和性價(jià)比高的分散劑是今后開(kāi)發(fā)的重點(diǎn)。

本實(shí)驗(yàn)針對(duì)水煤漿的特征,以腐殖酸為原料,通過(guò)磺化反應(yīng)制得磺化腐殖酸型水煤漿分散劑,探究不同合成條件對(duì)水煤漿分散劑性能的影響,獲得最佳合成工藝參數(shù)。……