SAGD采出液高溫密閉脫水工業化試驗初步認識

蔣旭 宋傳陽 張侃毅 等

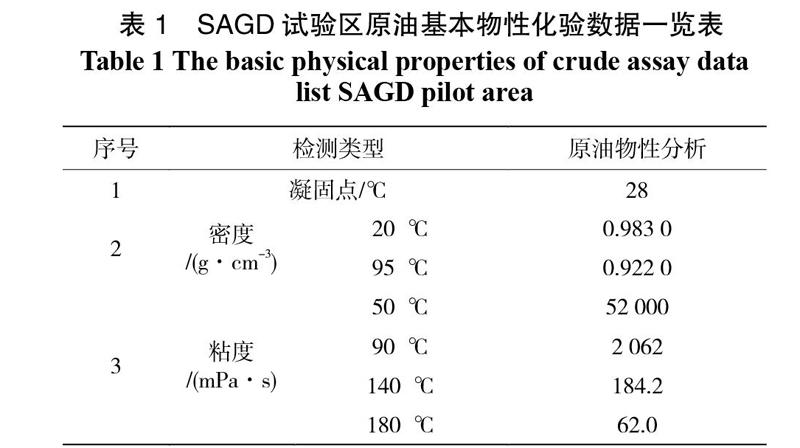

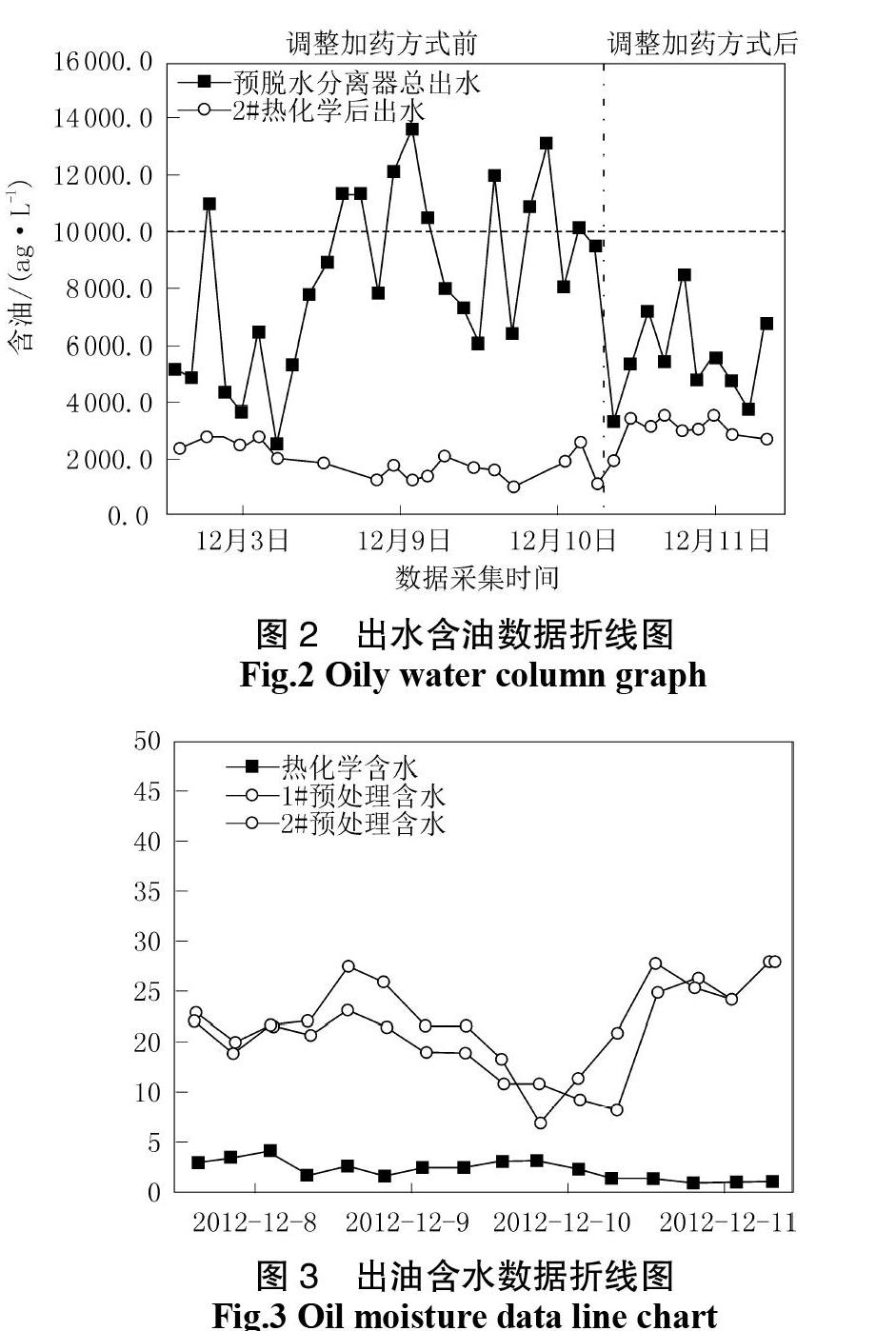

摘 要:隨著新疆風城超稠油規模開發,SAGD開發方式被廣泛用于油田生產,該部分采出液進入常規稠油處理站后,造成原油脫水困難,并導致出水指標惡化,給油水處理系統的平穩運行造成很大沖擊。為解決SAGD采出液油水處理難題,CPE新疆設計院通過大量室內研究和動態模擬試驗,初步確定了“氣液分離、高效預脫水、高溫正向破乳”的SAGD采出液高溫密閉處理流程,輔以“預脫水劑、正向破乳劑”的藥劑體系,以確保SAGD采出液在低粘度、高密度差的最佳工況下實現油水高效分離。根據風城油田30×104 t/a 規模SAGD采出液處理站建站初期現場試驗情況,通過試驗數據分析,對室內研究結果進行工業化驗證,同時為該站生產運行提供數據支持。

關 鍵 詞:超稠油;SAGD采出液;高溫密閉脫水;耐溫破乳劑

中圖分類號:TE 624 文獻標識碼: A 文章編號: 1671-0460(2015)10-2403-03

Study on Industrial Test of High Temperature Closed Dehydration

of SAGD Produced Liquid From Xinjiang Oilfield

JIANG Xv,SONG Chuan-yang,ZHANG Kan-yi,LIU Jing-yu

(China Petroleum Engineering Co., Ltd. Xinjiang institute,Xinjiang Karamay 834000,China)

Abstract: With scale development of Fengcheng super heavy oil in Xinjiang Oilfield, SAGD development mode has been widely used in oilfield production. In the production, part of the produced fluid is piped to the 1st heavy oil treatment station, which can result in the difficulty of crude oil dehydration in the station to make the sedimentation tank effluent index worse, to cause great impact on the smooth operation of water treatment system. In order to solve the water treatment problems, through experimental research and dynamic simulation, Xinjiang institute initially established a high temperature sealed dehydration process of "gas-liquid separation, efficient pre-dehydration and high temperature demulsification", supplemented by "pre-dehydrating agent and demulsifier" the agent system. The process can ensure efficient separation of oil and water in SAGD produced fluid under optimum conditions. In this paper, based on field test of 30×104 t/a SAGD produced liquid treatment station, through test data analysis, industrial test of the process was carried out.

Key words: Super heavy oil; SAGD produced fluid ; High temperature sealed dehydration; Demulsifier

1 項目背景

新疆風城油田SAGD開發區采出液具有溫度高、攜汽量大、攜砂嚴重、油水密度差小、乳化類型復雜等特點。隨著風城超稠油規模開發,SAGD開發方式被廣泛用于油田生產。該部分采出液進入常規稠油處理站后,在一段沉降罐迅速產生油水過渡帶,造成原油脫水困難;同時導致出水指標惡化,一段沉降罐出口采出水含油超過20 000 mg/L、懸浮物含量超過3 000 mg/L,遠超《油氣集輸設計規范》特、超稠油采出水含油含量小于4 000 mg/L的指標,給處理站油水處理系統的平穩運行造成很大沖擊[1]。

為解決SAGD采出液油水處理難題,CPE新疆設計院通過大量室內研究和動態模擬試驗,初步確定了SAGD采出液高溫密閉脫水工藝,并完成了配套脫水設備和耐溫藥劑的研發,建成了國內首座SAGD采出液高溫密閉處理站,規模為30×104 t/a。……