Tunnel Projects for Menghua Railway:The Longest Heavy Haul Railway in China

HAN Xingjun

(Mengxi-Huazhong Railway Co.,Ltd.,Beijing 100073,China)

Tunnel Projects for Menghua Railway:The Longest Heavy Haul Railway in China

HAN Xingjun

(Mengxi-Huazhong Railway Co.,Ltd.,Beijing 100073,China)

1 Engineering significance

The Menghua Railway from west Inner Mongolia to Central China is a major infrastructure for coal transportation in the 12th Five-Year Plan of China. The railway starts from Haolebaoji South Station and ends at Ji′an Railway Station of Beijing-Kowloon Railway, via Inner Mongolia, Shaanxi, Shanxi, Henan, Hubei, Hunan and Jiangxi, passing through 7 provinces and 17 municipalities, with a total length of 1 814.5 km and a design speed of 120 km/h. The Menghua Railway is Grade Ⅰ heavy haul national railway and the longest heavy haul railway built in one time in China, with the planned annual capacity of more than 200 million tons.

Connecting the energy golden triangle in Shanxi-Gansu-Ningxia region and the Hubei-Hunan-Jiangxi region in Central China, the Menghua Railway is the new national strategic transport corridor for "north-to-south coal transport", and is also an important part of large-capacity and efficient coal transportation system and national comprehensive transportation system, connecting multiple coal transportation lines, combining transportation spots and networks and integrating railway and waterway transport.

Along the Menghua Railway, there are many major transportation nodes with good accessibility, large accumulation effect, strong market radiation, and significant overall effect of roadway network backbone. The Menghua Railway is a convenient corridor connecting Central China and Eurasia, and the rear corridor for "the Belt and Road". Along the conjoint region in Central and Western China, the Menghua Railway crosses Northwest China, North China, Central China and other regions, and provides multiple interest points for the regions alongside, with a high degree of strategic fit, and large room and great potential to materialize external benefits.

2 Overview of tunnel projects and typical tunnels

2.1 Overview of tunnel projects

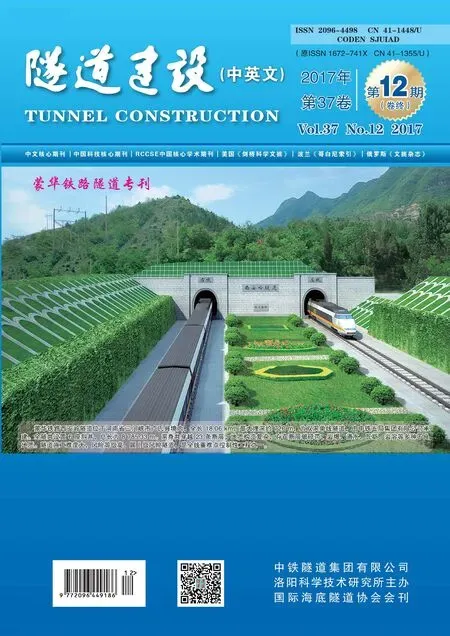

There are 228 tunnels along the Menghua Railway with a total length of 529 km (469 km for the left tunnel), accounting for 25% of the total length of the Railway. Among the tunnels, 63 tunnels are constructed in loess with a total length of 146 km. There are 10 tunnels with length longer than 10 km, among which the 22.7 km Yaoshan Tunnel is the longest. The tunnel cross section is mainly in the form of single line and double lines, and dovetail or three lines for several tunnels. The net cross-sectional area is 31.38 m2(Fig. 1) for a single-line tunnel and 63.98 m2for a double-line tunnel (Fig. 2). The ballastless track is adopted for tunnels or tunnel groups longer than 1 km, so as to reduce the need for maintenance and repair during operation. The ballasted track is employed for tunnels shorter than 1 km, with the clearance area meeting the requirements of large maintenance equipment.

The tunnels pass through various formations from the Archeozoic to the Cenozoic, namely, the North China, Qinqi, Yangtze and South China formations. Some tunnels are constructed in new loess, silty sand layer, soft rock, water-bearing Tertiary sand layer, large-scale faulted and fractured zones, karst, gassy coal seam, expansive soil, gypsum karst breccia, soft soil, and strata with high temperature, harmful gas, and high in-situ stress.

Fig.1 Crosssectionofasingle-linetunnel(unit:mm)Fig.2 Crosssectionofadouble-linetunnel(unit:mm)

2.2 Typical tunnels

2.2.1 The Baicheng Tunnel

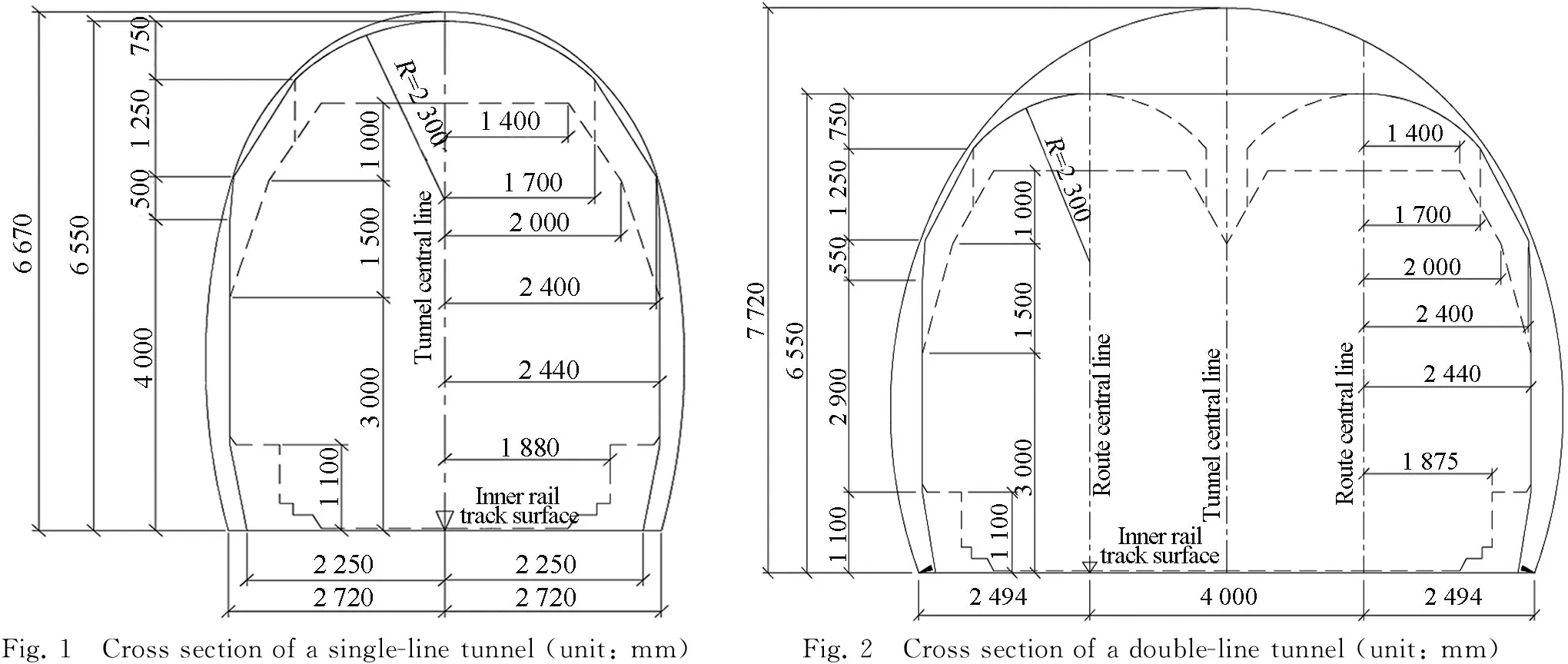

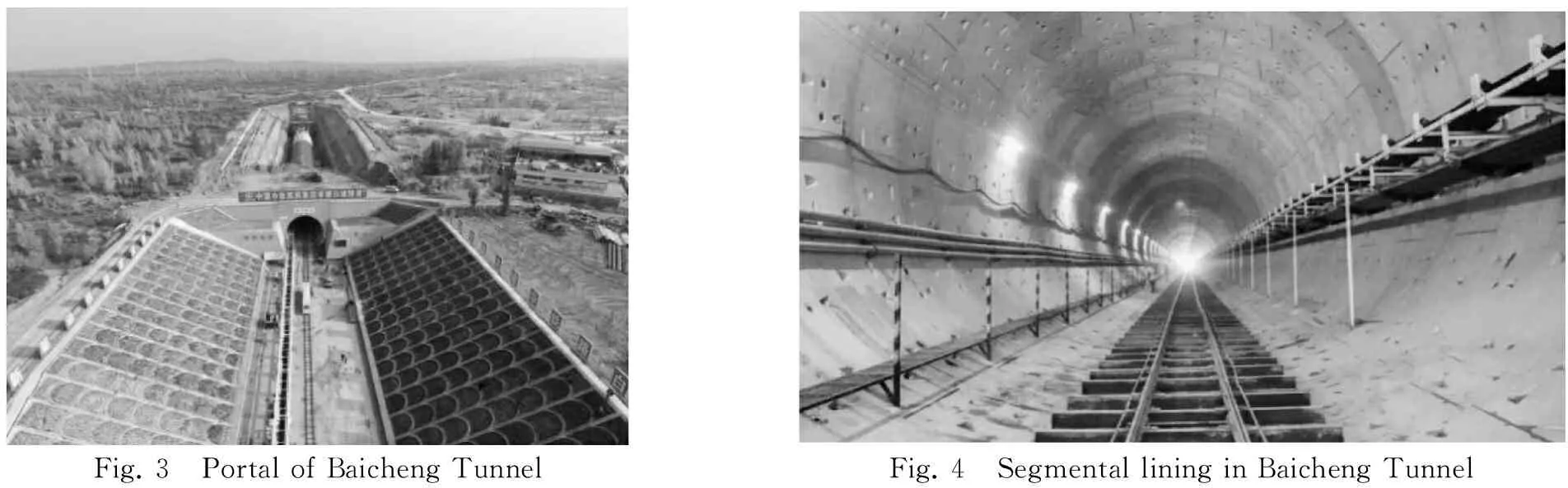

The Baicheng Tunnel is a single-hole double-line tunnel with a total length of 3 345 m and a maximum overburden depth of 81 m. The main strata along the tunnel alignment consist of fine sand and sandy loess, with 2 730 m tunnel section located in Class Ⅴ rock masses and 305 m in Class Ⅵ rock masses. The overburden depth of the tunnel section under the Baomao Highway is only 25 m, where the horseshoe-shaped earth pressure balance shield was used. The tunnel portal and segmental linings in the tunnel are shown in Fig. 3 and 4, respectively.

Fig.3 PortalofBaichengTunnelFig.4 SegmentallininginBaichengTunnel

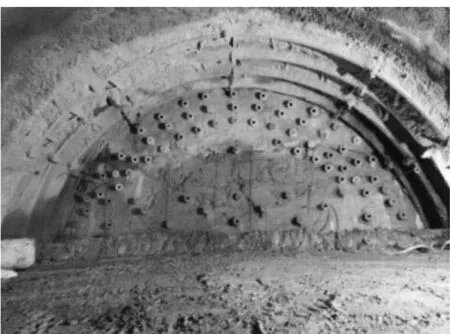

Fig. 5 Curtain grouting of upper section in the Yangcheng Tunnel

2.2.2 The Yangcheng Tunnel

The Yangcheng Tunnel is a single-hole double-line tunnel with a total length of 7 108 m and a maximum overburden depth of 213 m. The strata along the tunnel alignment mainly consist of Cretaceous Luohe formation sandstone (highly or completely weathered). Approximately 350 m tunnel section is located in water-bearing, completely weathered sandstone and sand and soil interbedding, where bypass pilot tunnel and curtain grouting (Fig. 5) were adopted, and great difficulties and high risks were involved during construction.

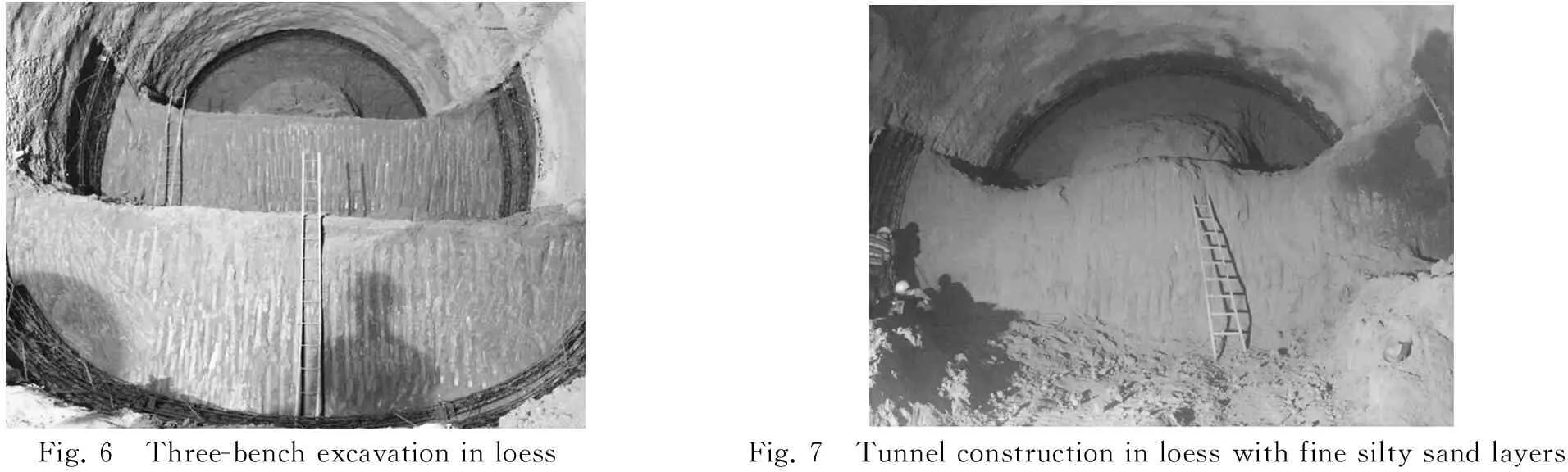

2.2.3 The Yangshan Tunnel

The Yangshan Tunnel is a single-hole double-line tunnel with a total length of 11 668 m and a maximum overburden depth of 277 m. The tunnel crosses soil-rock interface, new sandy loess, coal-bearing mudstone, and collapsible loess. Three-bench excavation was adopted (Fig. 6). Large deformation of soft rock was encountered for some tunnel sections, where steel lattice girders allowing for energy release and ground deformation were employed. The support parameters were adjusted timely during tunnel construction.

2.2.4 The Wanrong Tunnel

The Wanrong Tunnel is a single-hole double-line tunnel with a total length of 7 683 m and a maximum overburden depth of 90 m. The tunnel crosses new sandy loess, old sandy loess, and fine silty sand. The Wanrong Tunnel is currently the longest tunnel in loess for the Menghua Railway. Either full-face or partial-face horizontal jet grouting piles were adopted for advanced reinforcement. Three types of horizontal jet grouting piles, i.e., 40, 50, or 60 cm in diameter, were used. Tunnel construction in loess with fine silty sand layers is shown in Fig. 7.

Fig.6 Three-benchexcavationinloessFig.7 Tunnelconstructioninloesswithfinesiltysandlayers

2.2.5 The Zhongtiaoshan Tunnel

Fig. 8 Portal of the Zhongtiaoshan Tunnel

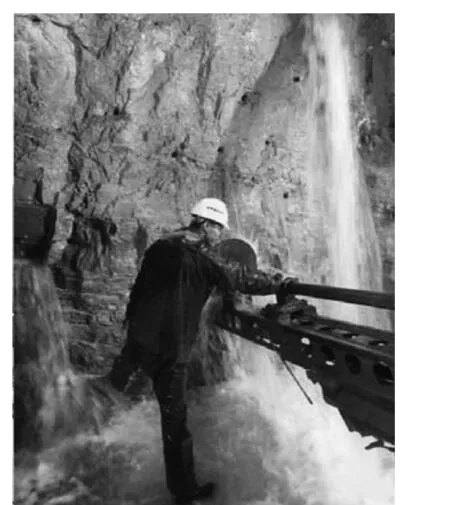

The Zhongtiaoshan Tunnel is a double-hole single-line tunnel with a total length of 18 405 m for its left line, 18 410 m for its right line and a maximum overburden depth of 840 m (see Fig. 8 for tunnel portal). The tunnel crosses 8 fault zones and Tertiary phreatic aquifer. Water inrush from rock joints is shown in Fig. 9. The maximum daily water inflow reached 50 485 m3and the reverse slope drainage was required. When tunneling through the Tertiary phreatic aquifer, the surrounding rock masses were prone to instability and collapse, leading to possible water and mud inrush. Combined measures including drainage holes, advanced dewatering and depressurization holes, and advanced pre-grouting and radial grouting were adopted. Fractured fault zones and karst areas with rich groundwater were encountered, where the tunnels were prone to collapses and sudden water and mud inrush. Tunnel construction involved great difficulties and high risks. Mitigation measures, including advanced geological forecast, advanced support and advanced ground improvement, were employed.

Fig. 9 Water inrush from rock joints in the Zhongtiaoshan Tunnel

2.2.6 The Xiaoshan Tunnel

The Xiaoshan Tunnel is a double-hole single-line tunnel, which has a total length of 22 751 m for its left line and 22 771 m for its right line, with a maximum overburden depth of 510 m. The tunnel portal is shown in Fig. 10. Four inclined shafts were constructed with a total length of 7 126 m. The main strata along the tunnel alignment are andesite, large-spotted andesite, rhyolite porphyry and other hypabyssal igneous rocks. Dolomite outcrop was revealed near the tunnel exit. The tunnel crosses 21 faults, among which the faults F5 and F6 are below rivers. The water pressure is very high, which can easily lead to water and mud inrush, ground collapse, and risk of high water pressure. Three-bench excavation with temporary inverted arch was employed. Advanced pre-grouting with shed pipes and temporary support were adopted.

2.2.7 The Xi′anling Tunnel

The Xi′anling Tunnel is a double-hole single-line tunnel, which has a total length of 18 063 m for its left line and 18 069 m for its right line. The tunnel portal is shown in Fig. 11. The tunnel passes through various unfavorable geological conditions, such as fractured fault zone, rock burst, soft rock prone to large deformation, water and mud inrush, gas, and karst, etc., which lead to great difficulties and high risks during construction.

Fig.10 PortaloftheXiaoshanTunnelFig.11 PortaloftheXi'anlingTunnel

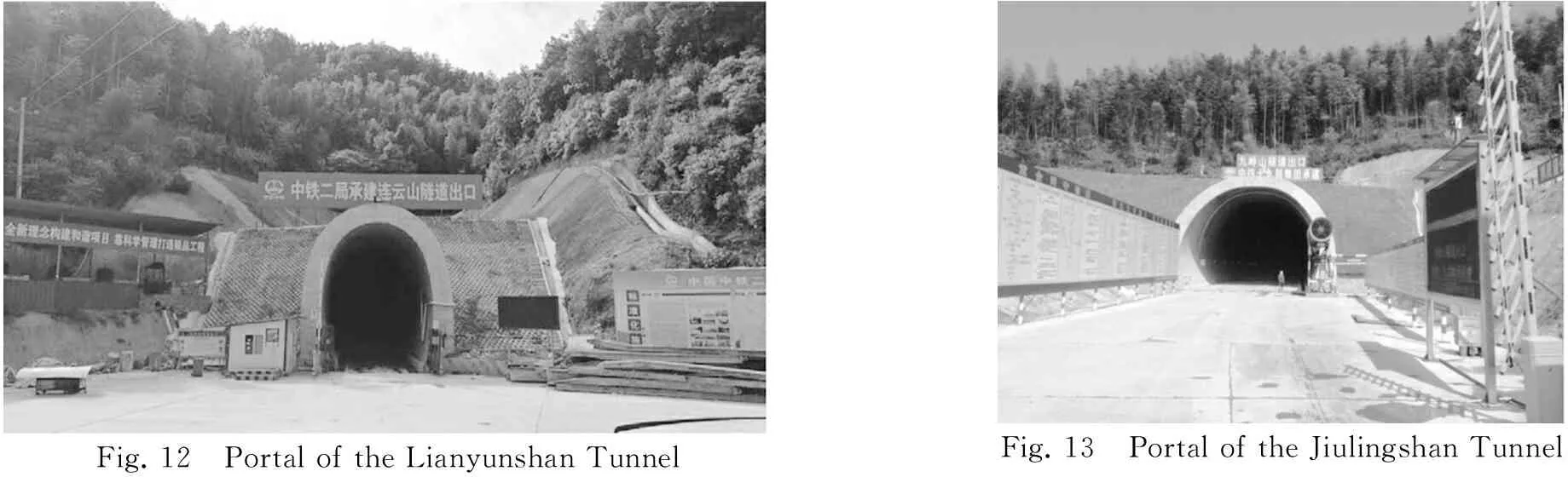

2.2.8 The Lianyunshan Tunel

The Lianyunshan Tunnel has a total length of 10 702 m with a maximum overburden depth of 566 m, and is the longest single-hole single-line tunnel for the Menghua Railway (see Fig. 12). Most tunnel sections pass through strata subjected to high or extremely high in-situ stresses, among which 4 301 m tunnel sections were constructed in soft rock, and 3 396 m in hard rock. The potential risks included large ground deformation, rock burst and other geological hazards.

2.2.9 The Jiulingshan Tunnel

The Jiulingshan Tunnel is a single-hole double-line tunnel with a total length of 15 371 m and a maximum overburden depth of 862 m (see Fig. 13). The tunnel crosses 6 fractured fault zones. Only 2 auxiliary tunnels were constructed. The maximum deadend tunneling distance was 5 057 m, which is the longest for the Menghua Railway project. The adverse geological conditions, including high in-situ stress, high temperature and rock burst, led to great construction difficulties. About 40 m of the tunnel exit was located in the shallow, water-rich and completely weathered granite stratum. Jet grouting piles were adopted for ground reinforcement.

Fig.12 PortaloftheLianyunshanTunnelFig.13 PortaloftheJiulingshanTunnel

Fig. 14 Portal of large-span three-line tunnel

2.2.10 The Shiyanling Tunnel

The Shiyanling Tunnel has a total length of 1 645 m, and a three-line cross section at the exit (see Fig. 14). The tunnel is featured by shallow overburden, fractured surrounding rocks and large excavation span. The tunnel cross sectional area is 216 m2, with a width of 18.74 m and a height of 14.24 m. The tunnel has the largest span along the Menghua Railway. Three-bench excavation with a central pillar was adopted. The construction measures were adjusted timely based on the monitoring data.

3 Application of tunneling equipment

In order to ensure the tunnel construction quality and safety for the Menghua Railway, reduce the labor intensity, improve the construction efficiency and enhance the mechanization level, all the contractors together with equipment manufacturers are encouraged to develop, test and promote professional mechanized tunneling equipment.

3.1 Mechanized equipment

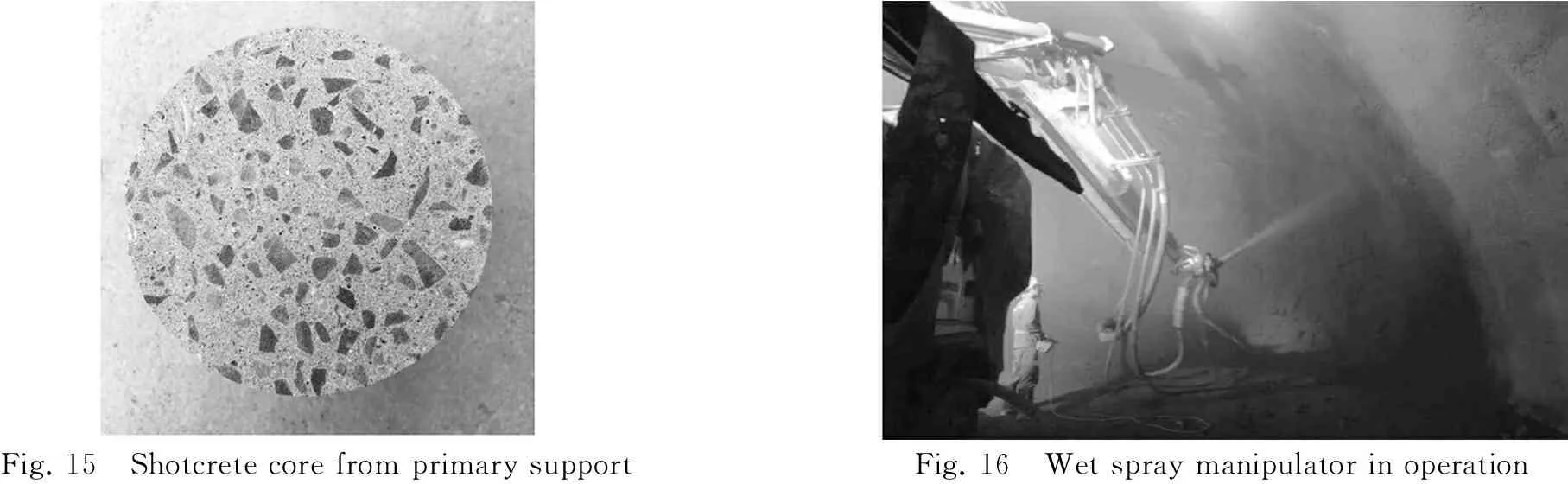

3.1.1 Wet spray manipulator

When the primary support is completed, the tunnel structure formed by the primary support and the surrounding rock should guarantee the tunnel stability during construction. The wet spray technology was adopted for shotcrete spray as the primary support. In order to ensure the early strength and the quality of shotcrete (as shown in Fig. 15), the shotcrete volume of wet spray trolley (Fig. 16) should not be less than 15 m3/h. More than 339 high-efficiency wet spray manipulators were used in the entire line of the Menghua Railway.

Fig.15 ShotcretecorefromprimarysupportFig.16 Wetspraymanipulatorinoperation

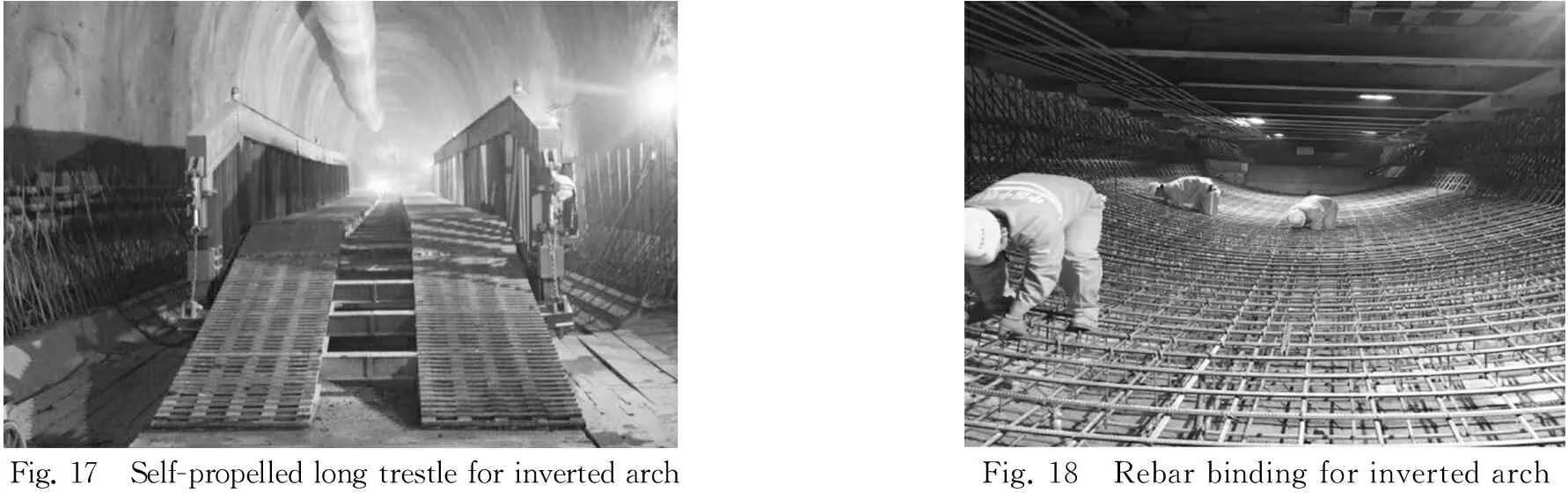

3.1.2 Self-propelled long trestle for inverted arch

In order to ensure the quality of inverted arch, the bottom for clearance should not be less than 24 m. The inverted arch of secondary lining and filled layer should be poured by 12 m or 24 m at one go. Self-propelled long trestle for inverted arch (Figs. 17 and 18) was adopted. More than 329 self-propelled long trestles were used for the Menghua Railway project. The length of the self-propelled long trestle is generally 36 m, and it is high enough to provide safe working space and ensure efficient operation of each process.

Fig.17 Self-propelledlongtrestleforinvertedarchFig.18 Rebarbindingforinvertedarch

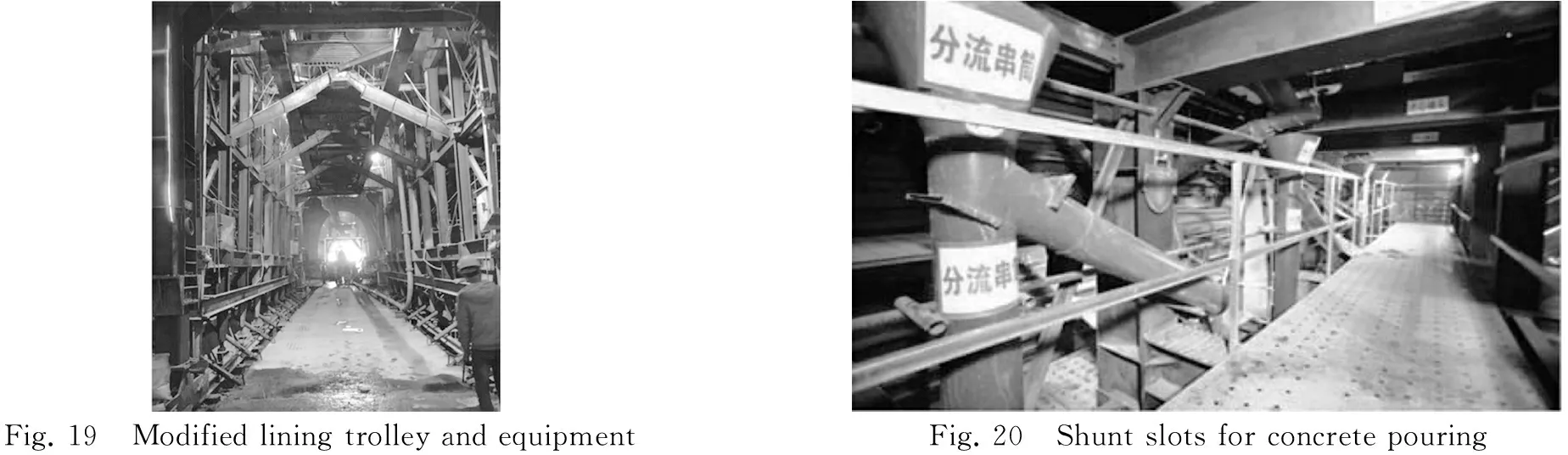

3.1.3 Modified secondary lining trolley and equipment

The casting process and equipment for secondary lining was improved (Fig. 19) by pouring concrete into the mold through shunt slots (Fig. 20) window by window, and avoiding concrete segregation caused by inadequate windows and concentrated pouring in the previous casting process. The modified process can ensure homogeneity of the secondary lining concrete and reduce the construction joints in secondary lining.

Fig.19 ModifiedliningtrolleyandequipmentFig.20 Shuntslotsforconcretepouring

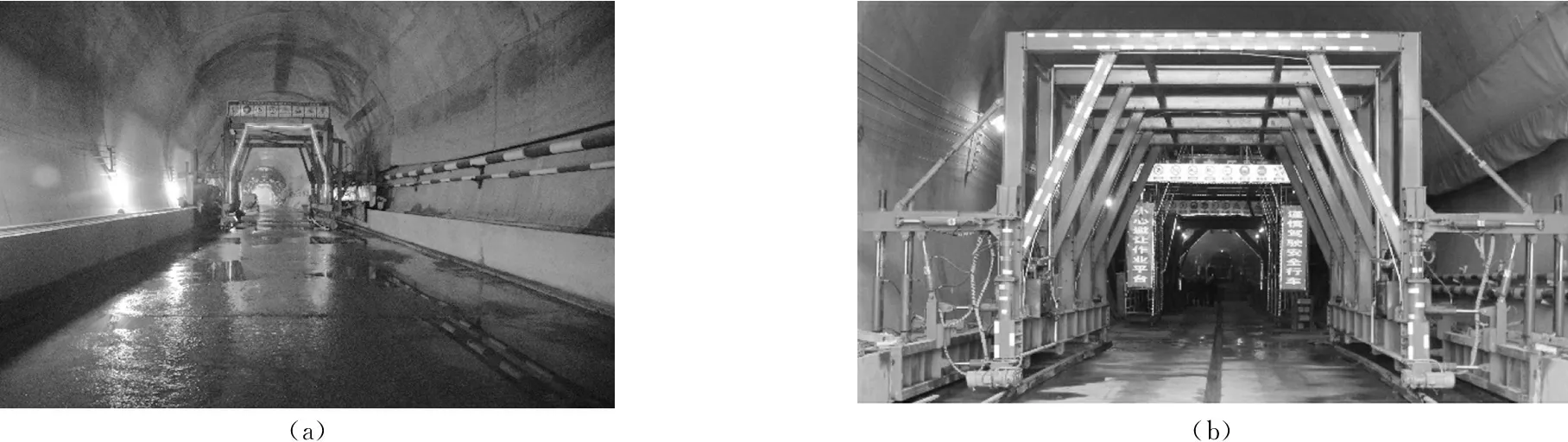

3.1.4 Maintenance equipment for secondary lining

In order to improve the concrete quality of secondary lining, the lining concrete shall be maintained in time (Fig. 21).

(a)(b)

Fig. 21 Maintenance equipments for secondary lining

3.1.5 Sliding formwork for trench and cable grooves

In order to ensure the quality of trench and cable grooves, sliding formwork was adopted for concrete casting in sections (Fig. 22).

(a)(b)

Fig. 22 Sliding formworks for trench and cable grooves

3.2 Innovations in mechanized equipment for tunnel construction

Fig.23 Large-section horseshoe-shaped shield

3.2.1 Horseshoe-shaped shield

The world's first large-section horseshoe-shaped earth pressure balance shield was developed and applied in the Baicheng Tunnel, as shown in Fig. 23. The shield is 10.95 m high and 11.9 m wide. For shallow tunnel excavation, no reinforcement measures are required in surface ground for safely tunneling under natural gas pipelines or highways. The maximum daily advance can reach 10 rings. A monthly advance rate of 308.8 m was recorded in March 2017. Its efficiency is more than three times higher than the traditional mining method under the same geological conditions.

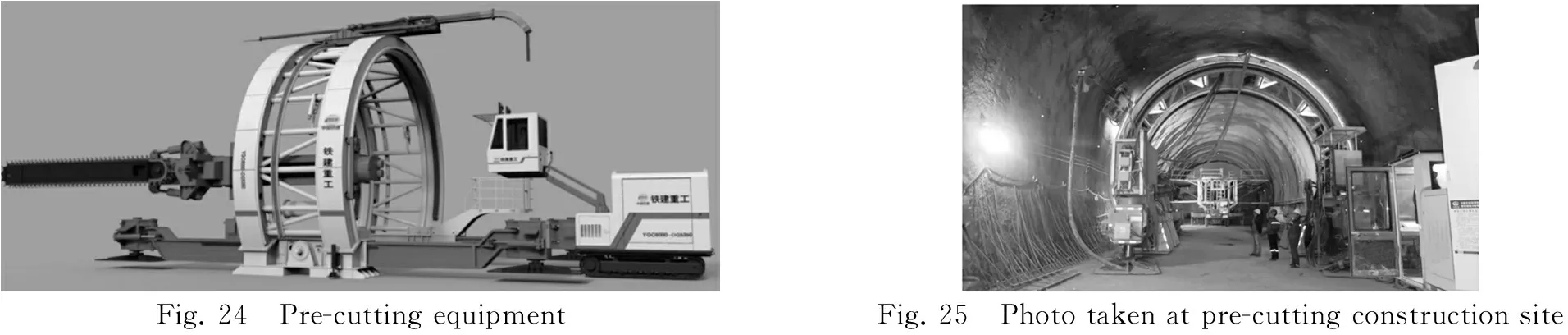

3.2.2 Pre-cutting equipment

Pre-cutting equipment (Fig. 24) was developed, and a new construction method suitable for soft soil tunnels was proposed. An experimental section was set up for the Haoyaoke Tunnel in Grade Ⅳ loess to carry out tests on the pre-cutting construction technology (Fig. 25).

Fig.24 Pre-cuttingequipmentFig.25 Phototakenatpre-cuttingconstructionsite

4 Demonstration of the working effects of key processes

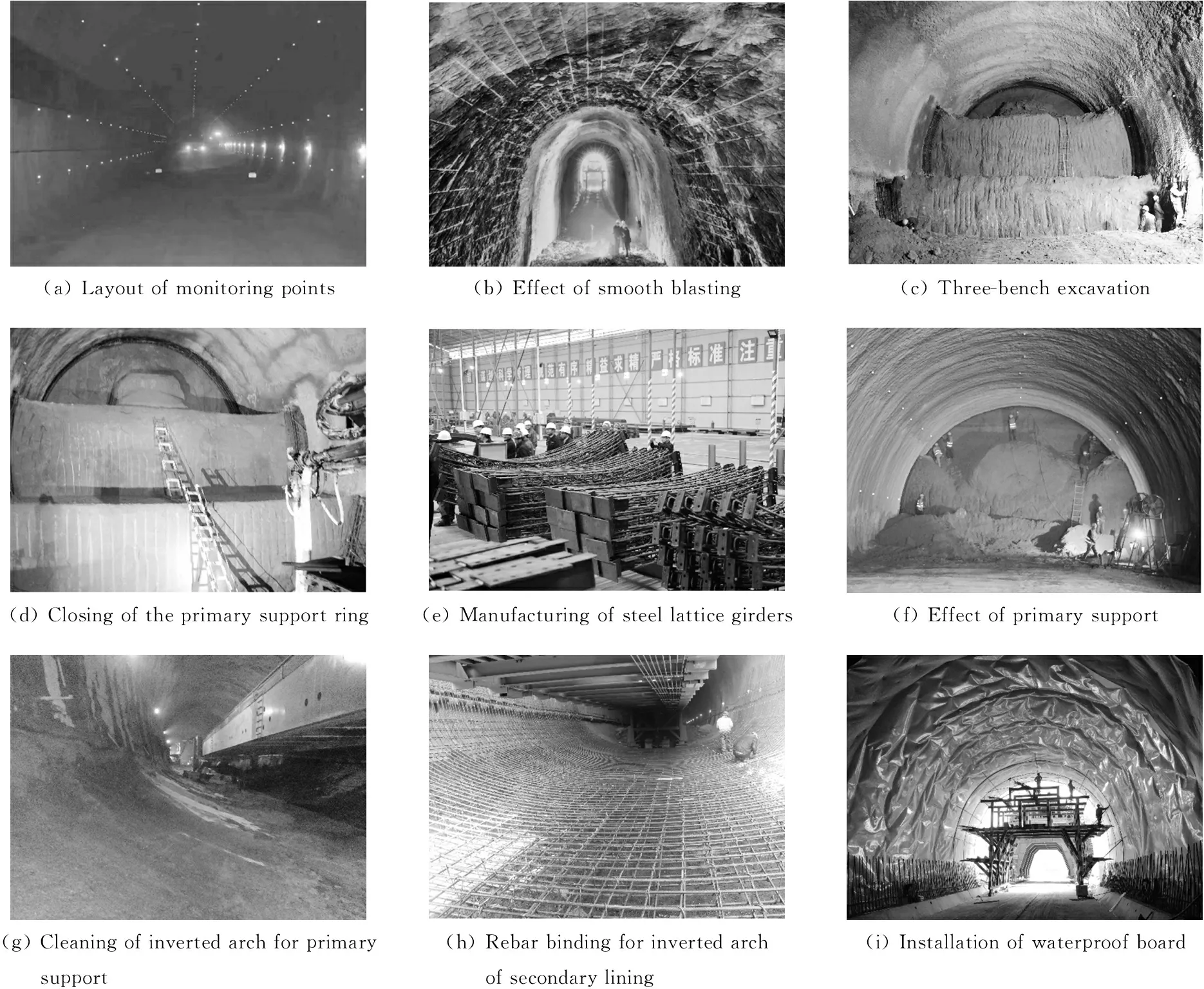

The tunnel construction strictly followed the principles of strengthening tunnel monitoring, erection of steel frame immediately after the tunnel face, closing of the primary support ring for inverted arch immediately after the lower bench excavation, advanced prediction, reinforcement and support, and proper selection of construction methods and supporting measures, rapid closing of linings and guarantee of lining quality. All these processes were performed to ensure safe tunnel construction and project quality(as shown in Fig. 26).

(a)Layoutofmonitoringpoints(b)Effectofsmoothblasting(c)Three-benchexcavation(d)Closingoftheprimarysupportring(e)Manufacturingofsteellatticegirders(f)Effectofprimarysupport(g)Cleaningofinvertedarchforprimarysupport(h)Rebarbindingforinvertedarchofsecondarylining(i)Installationofwaterproofboard

Fig. 26 Demonstration of the working effects of key processes

5 Project schedule and progress

1) As of November 30, 2017, a total number of 228 tunnels have been started, among which 156 tunnels have been holed through. The total length of tunnel excavation and support is 437 km, corresponding to a completion ratio of 82%.

2) At the end of 2017, more than 200 tunnels will be holed through, and the remaining long tunnels and difficult tunnels will be holed through before November 2018.

6 Project owner, design companies and contractors

Owner: Mengxi-Huazhong Railway Co., Ltd. The company is a mixed ownership enterprise jointly funded by 16 shareholders, of which private capital accounts for 15.7%.

Design companies: China Railway Design Corporation; China Railway Siyuan Survey and Design Group Co., Ltd; China Railway Tunnel Survey & Design Institute Co., Ltd; China Railway Engineering Consulting Group Co., Ltd; and China Railway Major Bridge Reconnaissance and Design Institute Co., Ltd.

Contractors: 14 group corporations of China Railway, 13 group corporations of China Railway Construction, and 8 other construction companies.