重型立式車床底座熱場與自然對流換熱特性

楊曉冬 劉紅博 劉祥彬 金朝暉

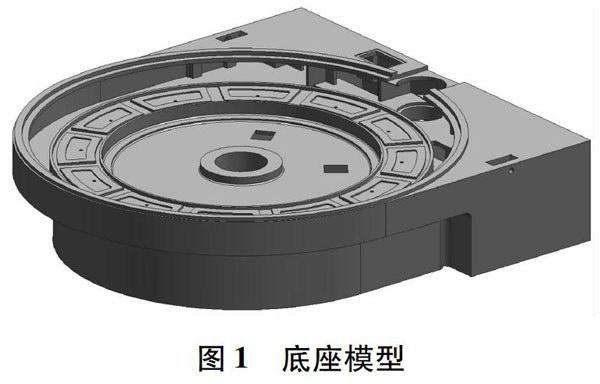

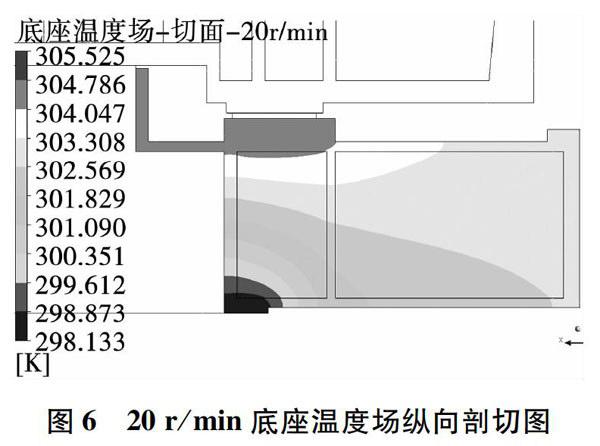

摘 要:重型數(shù)控立式車床的底座是保證機床穩(wěn)定性和精度的核心部件之一。針對機床轉(zhuǎn)速提高引起的底座熱集中問題,為探明機床轉(zhuǎn)速提高對底座熱場和散熱的影響,依據(jù)傳熱學和流固耦合力學建立了重型立式車床底座的對流換熱數(shù)學模型和流固耦合熱場模型。通過對重型數(shù)控立式車床的底座熱場模型進行數(shù)值模擬,揭示了機床底座的熱傳遞規(guī)律,探明了轉(zhuǎn)速對底座熱場和換熱強度的作用。流固耦合數(shù)值模擬結(jié)果與數(shù)學模型結(jié)果對比結(jié)果表明兩者基本吻合,為重型數(shù)控車床底座的設計和分析提供了有價值的理論依據(jù)。

關(guān)鍵詞:

重型立式車床;熱場;流固耦合;對流換熱

DOI:10.15938/j.jhust.2018.03.023

中圖分類號: TH133.36

文獻標志碼: A

文章編號: 1007-2683(2018)03-0133-06

Natural Convection and Thermal Field Numerical

Simulation of Heavy-Duty Vertical Lathe Base

YANG Xiao-dong1, LIU Hong-bo1, LIU Xiang-bin2, JIN Zhao-hui3

(1.School of Mechanical Engineering, Harbin University of Science and Technology, Harbin 150080, China;

2.Repack Flight Personnel for Bomber and Carrier, 93199 Troops of the PLA, Harbin 150000, China;

3.CRRC Qiqihar Rolling Stock CO., LTD. Qiqihar 161000, China)

Abstract:The base of heavy-duty CNC vertical lathe is one of the core components to ensure stability and precision of the lathe. Aiming to the issue of heat concentration internal structure of lathe-base, to verify the influence that velocity increasing impacts on heat generate and heat dissipation, convection mathematical model and FSI (fluid-solid-interaction) heat transfer model of the base of heavy vertical lathe was established according to heat transfer theory and fluid-solid-interaction theory. The results of numerical simulation of heat transfer model of the base reveal the heat transfer regularity and the influence of velocity that impacts on thermal field, heat dissipation intensity of the base. Comparison result between FSI numerical simulation results and mathematical model results show that they are basically consistent. It provides a valuable theoretical basis for heavy-duty CNC vertical lathe design and analysis.

Keywords:heavy-duty vertical lathe; thermal field; fluid-solid-interaction; convection heat transfer

0 引 言

重型立式車床主要服務于水電核電、航空航天、艦船制造和國防工業(yè)等國家重點行業(yè),是重型制造行業(yè)的主要加工設備,尤其對于大半徑旋轉(zhuǎn)曲面類零件的加工,有著獨特的優(yōu)勢。20世紀30年代德國Salomon博士提出了高速切削理念,其意義不僅在于提高生產(chǎn)效率,工藝性、能耗和表面粗糙度都會改善,高速切削技術(shù)逐步成為切削加工的主流技術(shù)是大勢所趨[1]。提高立式車床轉(zhuǎn)速的過程中出現(xiàn)了一些問題,車床轉(zhuǎn)速提高會使靜壓軸承發(fā)熱加劇,造成熱集中,引起車床的熱變形,導致機床精度降低,嚴重時甚至使軸承的實際結(jié)構(gòu)偏離理論設計模型。因此如何在保證機床本身的精度和穩(wěn)定性的前提下提高轉(zhuǎn)速,成為了目前亟需解決的關(guān)鍵問題之一,而掌握重型立式車床的發(fā)熱與散熱規(guī)律則是解決問題的前提[2-3]。……