Hydrodynamic Analysis of a Spar Platform under Asymmetrical Mooring System

-,,,,-,-

(State Key Laboratory of Coastal and Offshore Engineering,Dalian University of Technology,Dalian 116024,China)

Abstract: When mining the oil and gas resources on the continental slope, the seabed topography at the location where the floating platform is located may have a relatively steep gradient,so an asymmetrical mooring system may be deployed. Based on a Spar platform, an asymmetrical mooring system is optimized to match the different anchor depth, and the horizontal stiffness of asymmetrical mooring system is relatively high. The motion response of platform and the dynamic characteristics of mooring system are compared through the coupled numerical simulation model in time domain. The results show that the response amplitude and mooring tension of platform with asymmetrical mooring system in the surge,sway and pitch are all in line with the engineering requirements,and it could improve the global motion performance of Spar platform.

Key words:asymmetric mooring system;Spar platform;dynamic response;mooring line tension

0 Introduction

The South China Sea has about one third of China’s oil reserves. Its depth is generally 500-2 000 m, so the focus of oil and gas development in South China Sea is the deep sea area.The applicable depth of Spar platform is generally 500-3 000 m. It has the advantages of large draught depth, good stability and motion performance, low cost and wide application range,which make it extremely competitive in deep ocean area and ultra-deep water.

The Spar platform has undergone three generations of development, followed by Classic Spar, Truss Spar and Cell Spar. Nowadays, most of them come into use in Gulf of Mexico. The three-generation platform structures are shown in Fig.1. Mekha et al[1]used the simplified Spar platform model with only three degrees of freedom: surge, heave and pitch. The Morison equation is used to calculate the drag resistance and the three-dimensional potential flow theory is used to calculate the inertial force. The dynamic responses of the platform are calculated and compared between the numerical results and model tests.Ran et al[2]used the numerical and experimental methods to analyze the dynamic response of truss Spar platform under different types of waves.The research shows that the low-frequency surge and pitch responses are significantly greater than the wave-frequency responses, while the presence of the ocean current could reduce the slow drift response of platform. Agarwal et al[3]used the linear Airy wave theory and Morison equation to predict the wave loads on the main body of Spar platform,and solved the iterative equation of dynamic by using the Newmark-βmethod.The integral recovery stiffness matrix is divided into three parts: the stiffness of water plane, the stiffness in the horizontal direction of nonlinear mooring system and the stiffness of vertical spring. Koo et al[4]calculated the heave and pitch responses of Spar platform under regular and irregular waves, then studied the effects of damping and additional stiffness on Matthew’s instability.The study shows that the occurrence of Matthew's instability is greatly affected by the damping, so it is necessary to accurately predict the damping of platform. Considering the effects of first-order and second-order random wave loads and time-varying displacements and transient wave heights, Liu[5]established the coupled equations of motion for the Spar platform to calculate and compare the dynamic responses of platform under different sea conditions.

Fig.1 Three generations of Spar platform

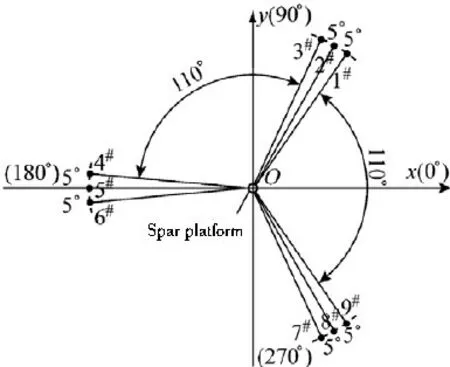

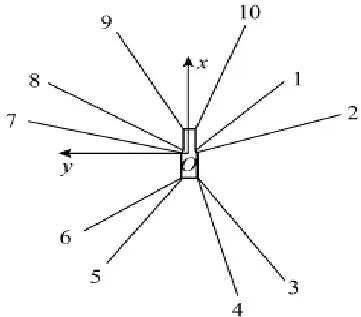

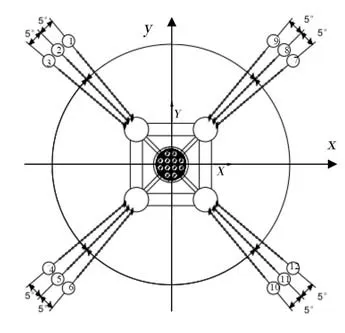

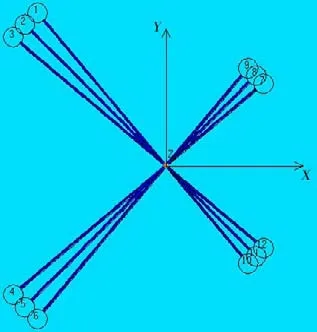

The mooring system is used to position the floating platform. The design of mooring system is a complex process, and the layout of mooring system is a very important factor that should be considered. Currently, the layout of mooring systems is mainly based on symmetrical arrangements. Some Spar platforms use asymmetrical arrangements on thex-axis ory-axis[6-9], where each mooring line has the same physical properties,such as material,wet weight,length,diameter,and pretension,as shown in Fig.2.Sometimes,the mooring lines of several different physical properties will also need to be used, while the sea area where the mooring system is located is not flat,thezvalue of mooring line at the seabed point will also be different.For example,Xu et al[10]used this asymmetrical mooring arrangement when studying the installation of the jacket platform, as shown in Fig.3. There is also the use of semi-submersible platforms in shallow water as a floating base near the island reef. Hou et al[11]used the software AQWA to carry out numerical simulation calculations of floating trestle bridges, and conducted comparative analysis with the results of pool tests to predict and research the motion response of single floating bridges near the island reef. Focusing on the complex island reef topography of the South China Sea,Wang et al[12]adopted an asymmetric arrangement of anchor chains and designed a mooring system that adapts to the positioning of the platform under extremely shallow water.The positioning ability is calculated and analyzed, and the feasibility of mooring system is verified. The results could provide reference for the design of platform mooring system in the extremely shallow water environment.

Fig.2 Layout of an asymmetrical mooring system of Spar

Fig.3 Layout of mooring system of jacket platform installation

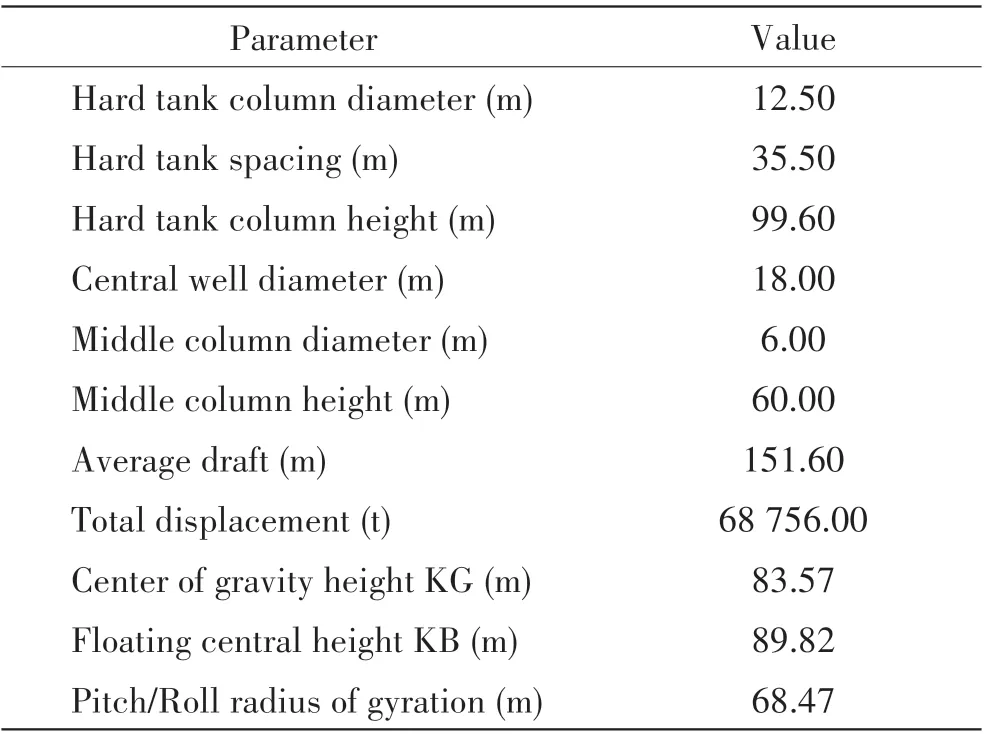

Through the comparative analysis of the characteristics of various types of floating platforms, combined with the characteristics of the semi-submersible platform and Truss Spar, the Deep Draft Multi-Spar(DDMS)Platform is proposed by a research team in Deepwater Engineering Research Center of Dalian University of Technology[13]. The single large-diameter column from Spar platform is separated into four relatively small-diameter columns and a closed center well is set in the middle to protect the riser from waves and currents. In the lower part of hard tank,the heave plates are arranged to improve the hydrodynamic performance of the platform.A ballast tank is installed at the bottom of platform,and four small columns are connected with the hard tank to provide good stability for the platform.The schematic diagram of DDMS platform is shown in Fig.4.The main structural parameters are shown in Tab.1.Compared with the traditional single-column Spar platform, DDMS has less difficulty of construction, transportation and installation, but larger upper deck platform area. Therefore, the cost-effectiveness of DDMS are relatively high.

Fig.4 DDMS platform

Tab.1 Main parameters of DDMS platform

The research work of this paper is mainly aimed at the DDMS platform with asymmetrical mooring systems.Based on AQWA software,the hydrodynamic model of platform is established,and an asymmetrical mooring system is designed and optimized. The coupling analysis method is used to study the motion responses of DDMS platform and the dynamic characteristics of asymmetrical mooring system under irregular wave,wind and current.Meanwhile,the results are compared with the symmetrical mooring system.

1 Solving the equation of motion

1.1 Time-domain coupled equations of motion

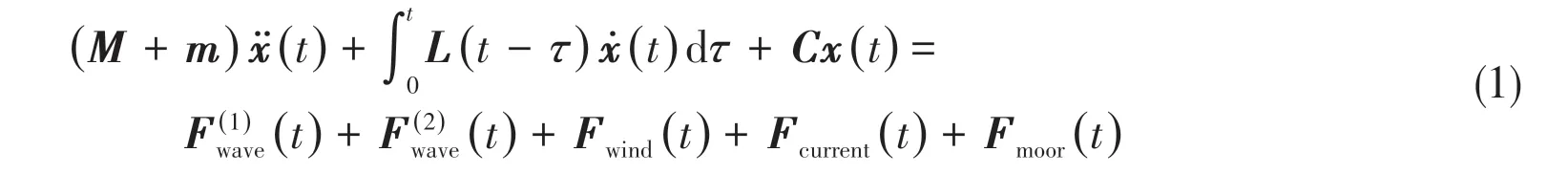

The mooring system and floating platform in the ocean are affected by the coupled effects of irregular wave,wind and current.The time domain coupling equation of motion is shown in Eq.(1).

where,Mis the mass matrix of floating body structure;mis the additional mass matrix of floating body structure;Lis the delay function matrix of system;Cis the restoring force coefficient matrix;x(t)is the displacement vector of six degree-of-freedom of platform;andare the first-order and second-order wave loads, respectively;FwindandFcurrentare the wind loads and current loads,respectively;Fmooris the force of mooring line to the floating structure.

1.2 Load solution

For large-dimensional deep-water floating platforms, the high-order boundary element method is generally used for hydrodynamic solution to obtain the wave force in frequency domain.Through the inverse Fourier transform,the first-order and second-order wave force transfer functions are used to convert the frequency domain calculation results into those in the time domain.The delay function can be obtained by the inverse Fourier transform of the damping coefficients in the frequency domain,as shown in Eq.(2).

whereλ(ω)is the damping coefficient.

The wind load acts on the structure above the waterline of entire offshore platform.The calculation of wind load is mainly related to the wind speed and the shape of structure.The general expressions of wind force and the wind torque on the structure are shown in Equations(3)-(4).

where,ρa(bǔ)is the density of air;Cdis the coefficient of wind resistance;Ais the projected area of component in the wind direction;U10is the wind speed at a height of 10m above the sea surface;Lis the distance between the gravity center of platform and the center of wind force.The simplified projected area is chosen to calculate the wind load without considering the voids and mutual obscuration between components.

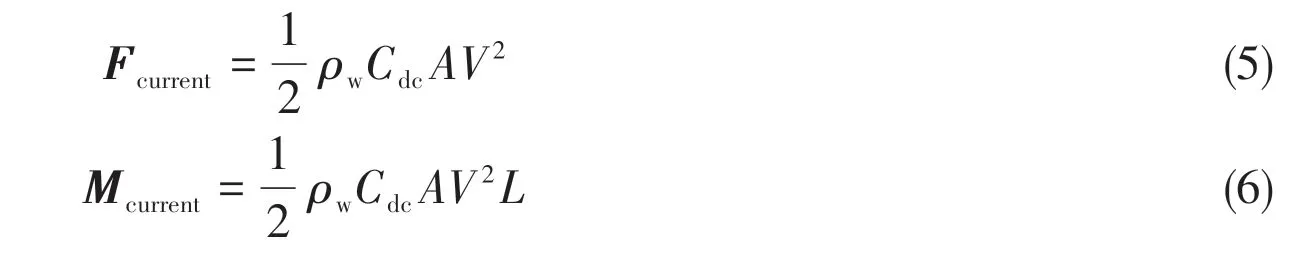

Assuming that the current distribution is uniform,the general expressions of the flow forces and flow forces moment on the structure are shown in Eqs.(5)-(6).

where,ρwis the density of seawater;Cdcis the fluid drag coefficient;Ais the projected area of component in the direction of current;Vis the velocity of current,Lis the distance between the gravity center of platform and the center of current force.

The force of mooring system on the platform is shown in Eq.(7)

where,K'andC'are the stiffness and damping matrix at the connection point of mooring line and platform, respectively;T'is the displacement transformation matrix between the platform gravity center and the mooring line connection point;xmis the displacement vector of mooring line and platform connection point.

1.3 Iterative solution

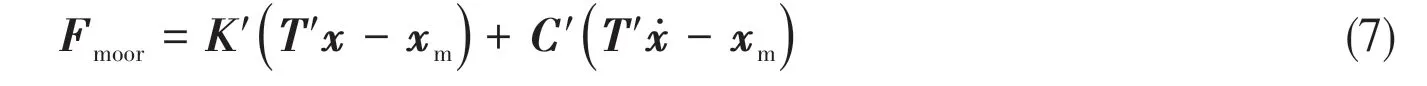

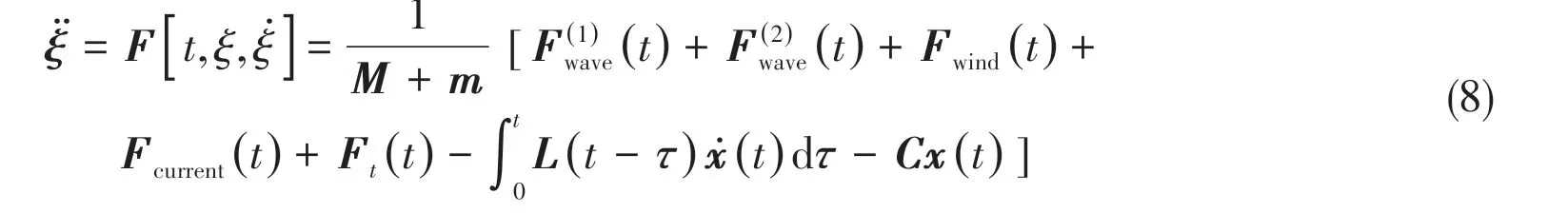

The iteration method can be used to solve the motion equation of floating body in the time domain.The motion Eq.(1)is written as the second-order differential equation as shown in Eq.(8).

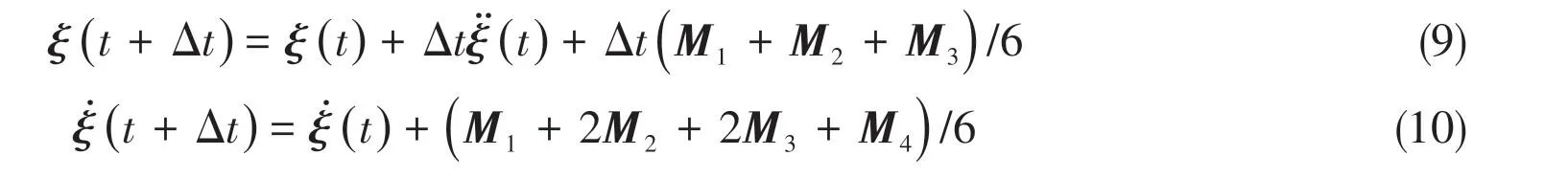

The Eq.(8)can be solved by the fourth-order Runge-Kutta method.At timet+ Δt,the displacement and velocity of platform are shown in Eqs.(9)and(10).

where,

2 Mooring design

2.1 Symmetrical mooring arrangement

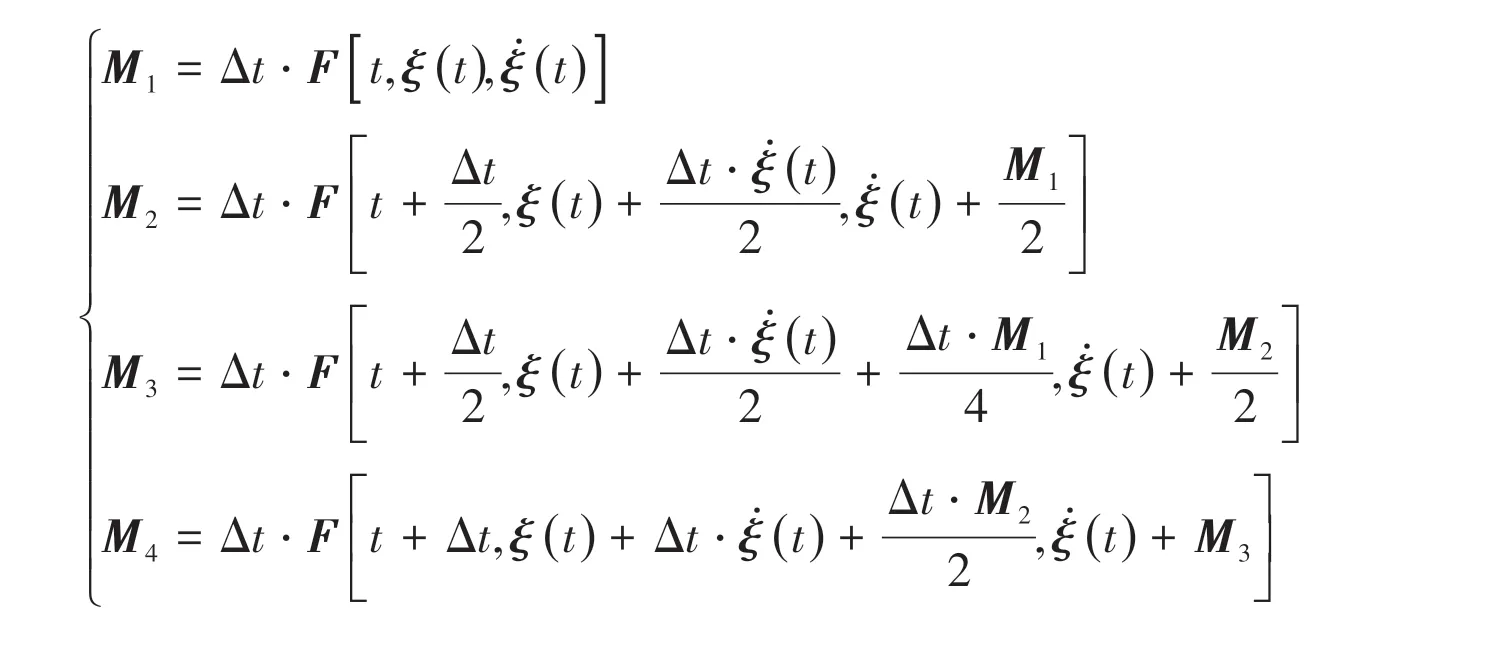

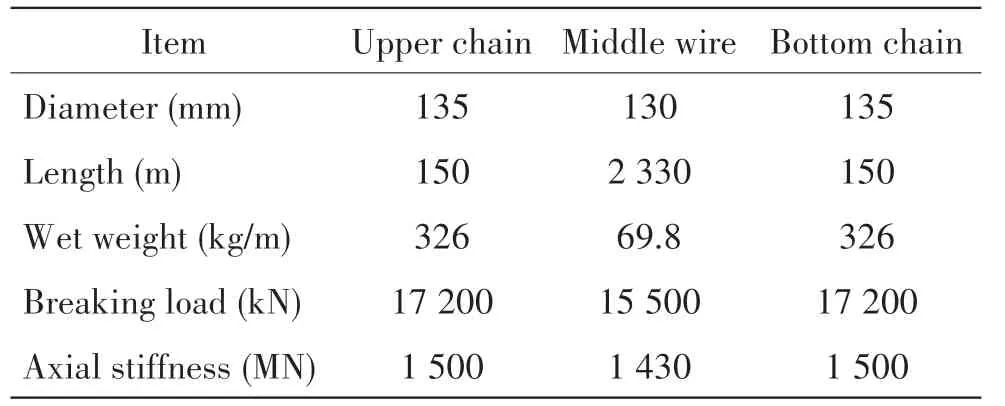

At a depth of 1 500 m, a symmetrical semi-taut mooring arrangement is adopted, and 12 mooring lines are used, which are divided into four groups and arranged on four columns, respectively. Each group is separated by 90 degrees. The layout is shown in Fig.5. Each mooring line is combined by three segments that are chain, wire and chain. The material properties of each segment are shown in Tab.2. The pretension is 3 220 kN, and the coordinates of anchor points are shown in Tab.3.

Tab.2 Material parameters of the mooring line

Fig.5 Symmetrical mooring system layout

Fig.6 Asymmetric mooring system layout

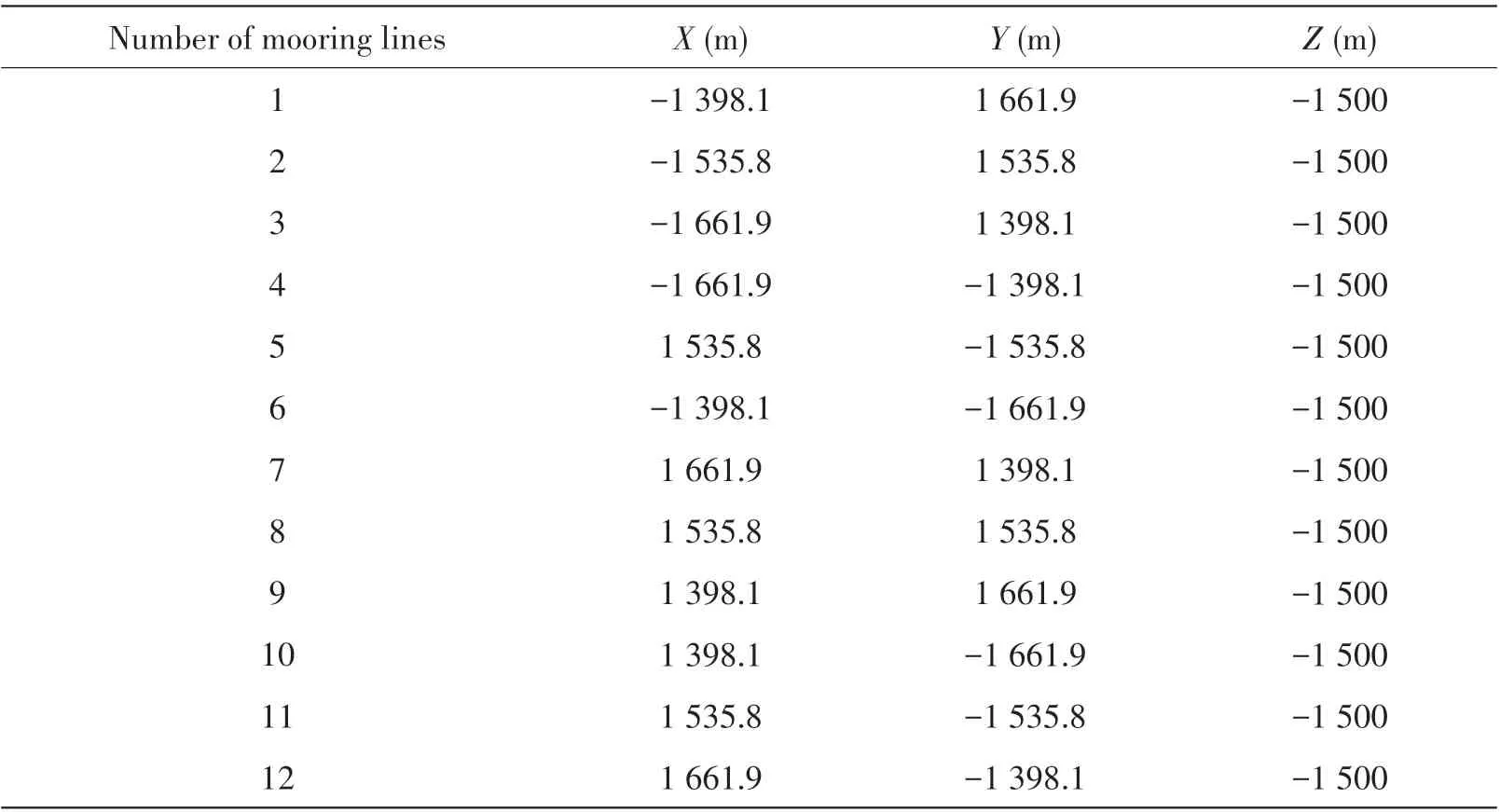

Tab.3 Anchor coordinates of symmetrical mooring system at 1 500 m depth

2.2 Optimization design of asymmetrical mooring

The arrangement of asymmetrical mooring systems is similar to the symmetrical mooring systems,except that the anchorage depth of mooring lines#7-12 in Fig.5 is changed from 1 500 m to 1 200 m.The layout is shown in Fig.6.In order to ensure the stability of platform,the initial pretension (3 220 kN) and the pretension angle of deep water side (#1-6 mooring line) and the shallow water side(#7-12 mooring line)should be the same in the design.

In the static analysis of mooring line, the elastic elongation and the current force on the mooring line are taken into account by using the segmented extrapolation method[14]. An asymmetry mooring system optimization applet is programmed by MATLAB. Keeping the lengths of upper and bottom chain unchanged,the length of middle wire section of mooring line is used as the variable,and the optimized length of middle wire is 1 484 m.The coordinates of anchor points are shown in Tab.4.

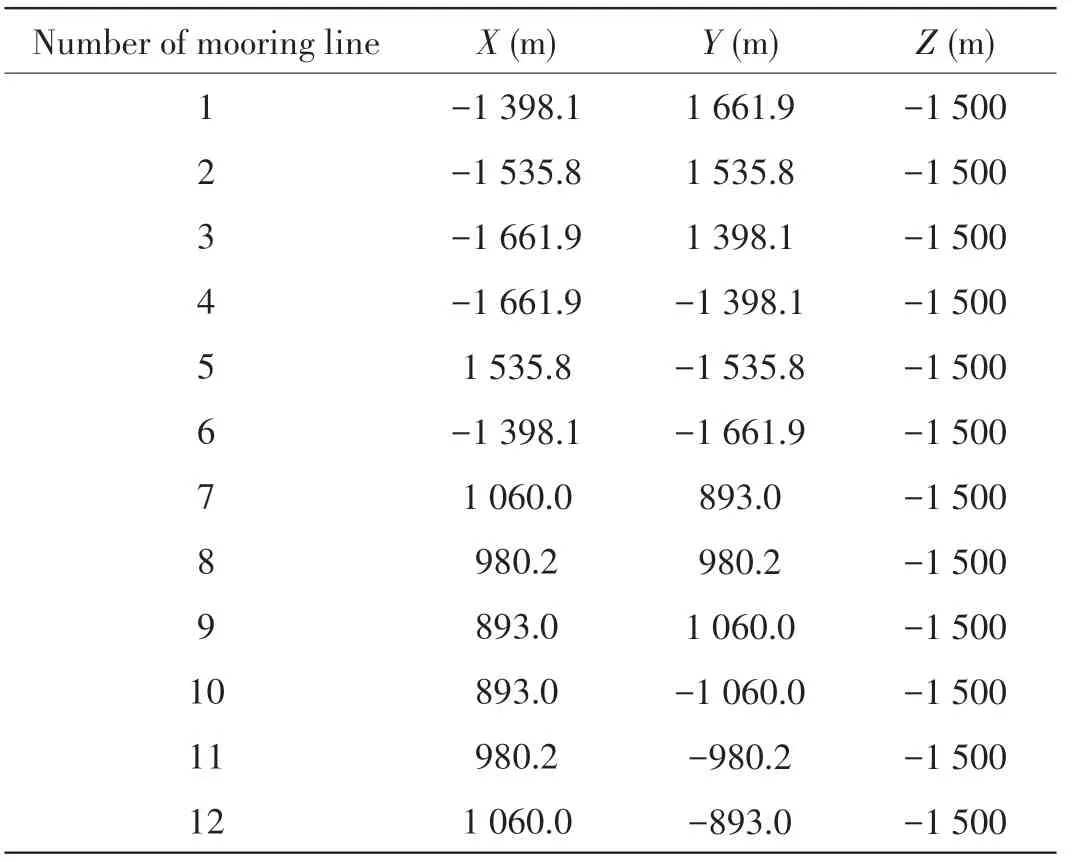

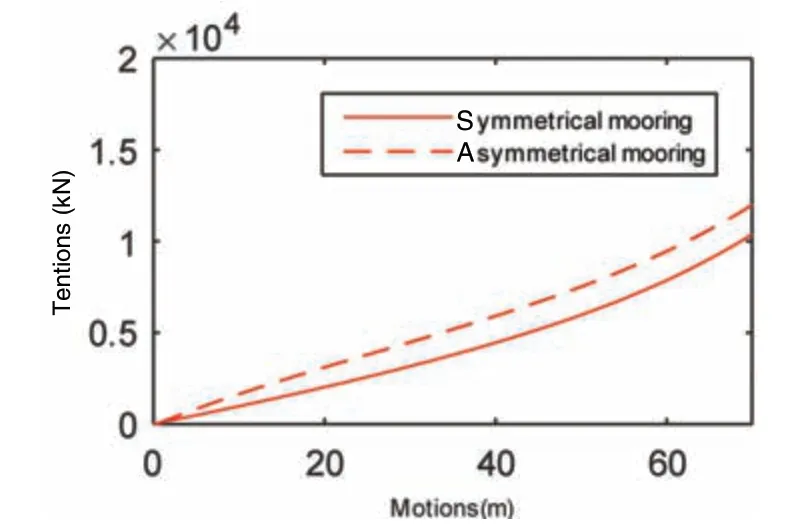

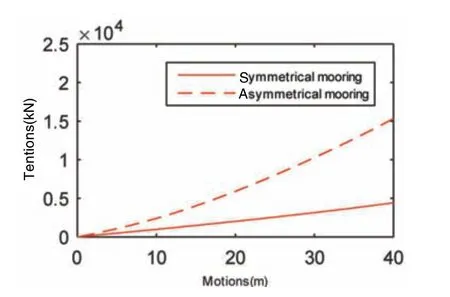

The stiffness of mooring line is nonlinear and the mooring system restoring force curve is plotted to characterize the restoring force of mooring system.The symmetrical mooring system only needs to consider the restoring force inXdirection (orydirection), but the asymmetrical mooring needs to consider both inXandYdirections.As shown in Figs.7-8,it can be seen that the restoring force characteristics of these two mooring systems are relatively consistent inXdirection,whereas the asymmetrical mooring system is much larger in theYdirection. The asymmetrical mooring system has a stronger nonlinear effect,and the stiffness of asymmetrical mooring system inYdirection is much greater than that inXdirection.

Tab.4 Anchor coordinates of asymmetrical mooring

Fig.7 Restoring force of mooring system in X direction

Fig.8 Restoring force of mooring system in Y direction

3 Results and analysis

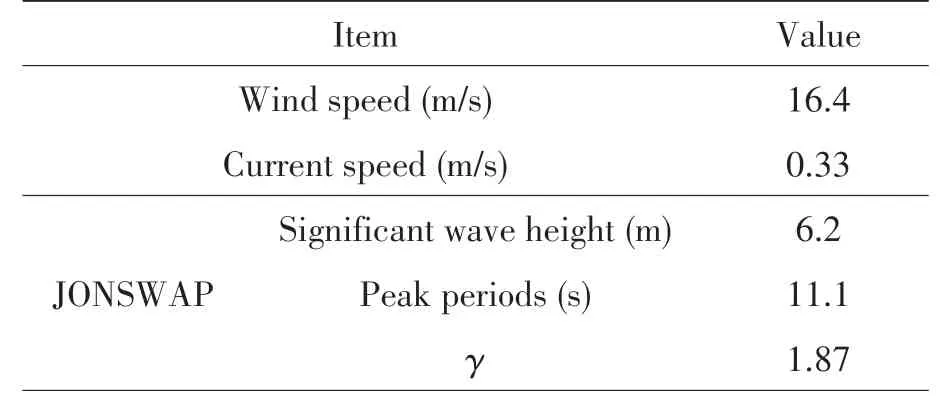

In general[15], under the normal operating sea state conditions, the amplitude of surge response of platform should not exceed 2%-3% of water depth, the amplitude of heave motion should not exceed 3 m, and the amplitude of pitch should be less than 6°. For mooring systems, in accordance with API RP 2SK[16], the safety factor,which is the ratio of mooring line breaking strength to the maximum mooring line tension,should not be less than 1.67.The one-year return period in South China Sea is chosen as the operating sea state conditions,as shown in Tab.5.The JONSWAP wave spectrum,API wind spectrum and the uniform current distribution are used in the numerical simulation.The combinations of wind,wave and current direction are used to analyze the platform response,and the incident angle isXdirection.

Tab.5 Environmental conditions

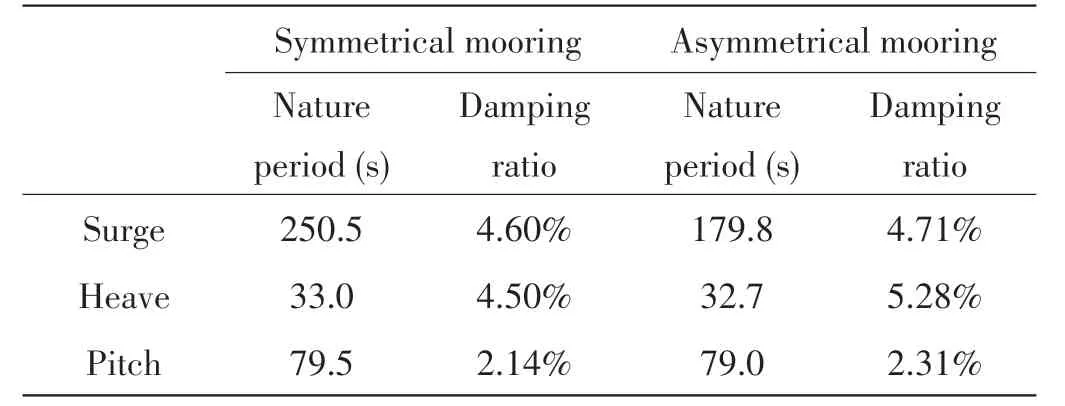

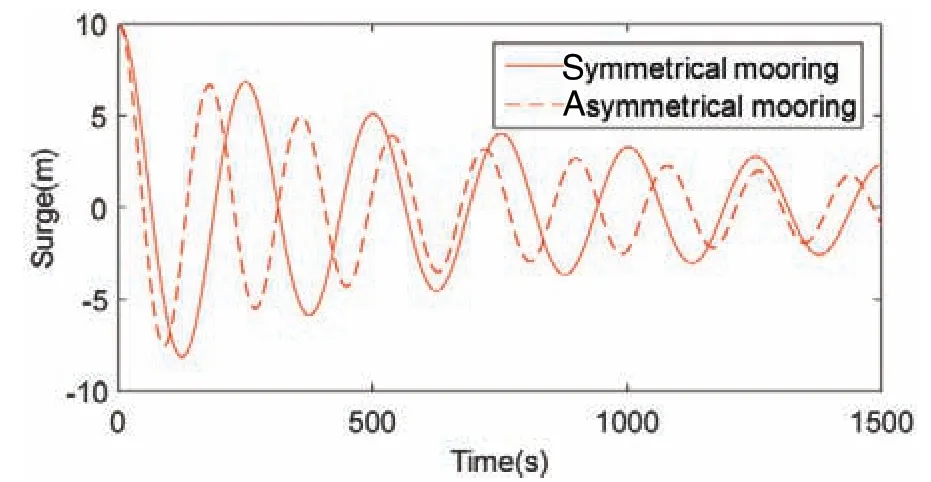

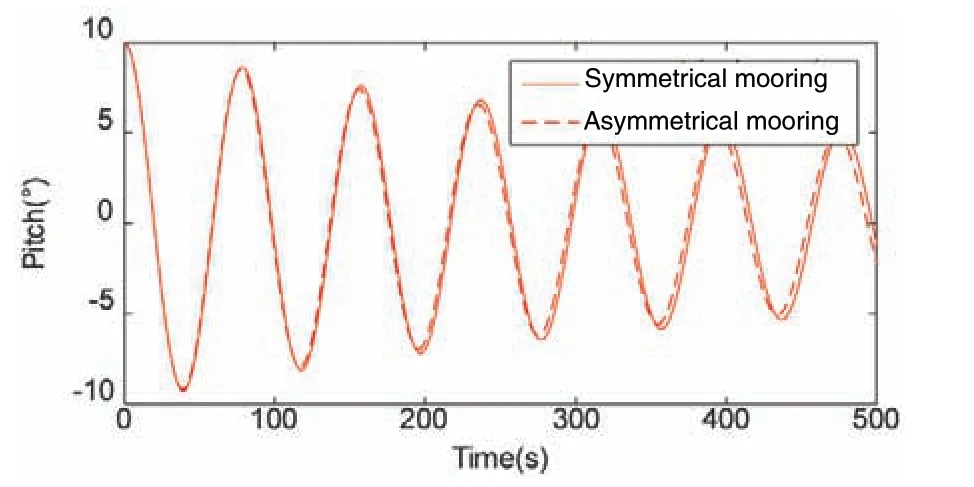

3.1 Free decay test

The main structure of DDMS platform is symmetrical about theX-axis andY-axis. The analysis mainly considers the motion response of surge,heave and pitch motions.The free decay test results in still water under the symmetrical and asymmetrical mooring systems are shown in Figs.9-11. The first 6 cycles of free decay is used to calculate the natural period and damping ratio.According to Tab.6,the natural period of surge using asymmetrical mooring is significantly smaller than that of the symmetrical mooring, while the heave and pitch are not much different.The natural period of heave motion meets the requirement of larger than 20 s. This is due to the fact that the mooring system provides a great stiffness in the horizontal direction,which can significantly reduce the natural period of surge, while the heave and pitch mainly depend on the hydrostatic stiffness of platform,and the mooring system has little influence.The asymmetricalmooring system contributes significantly to the damping ratio. The damping ratios of surge, heave and pitch increase by 2.39%,14.78% and 7.94% compared to the symmetrical mooring system,respectively.

Tab.6 Statistics of free decay

Fig.9 Surge decay

Fig.10 Heave decay

Fig.11 Pitch decay

3.2 Motion response of platform

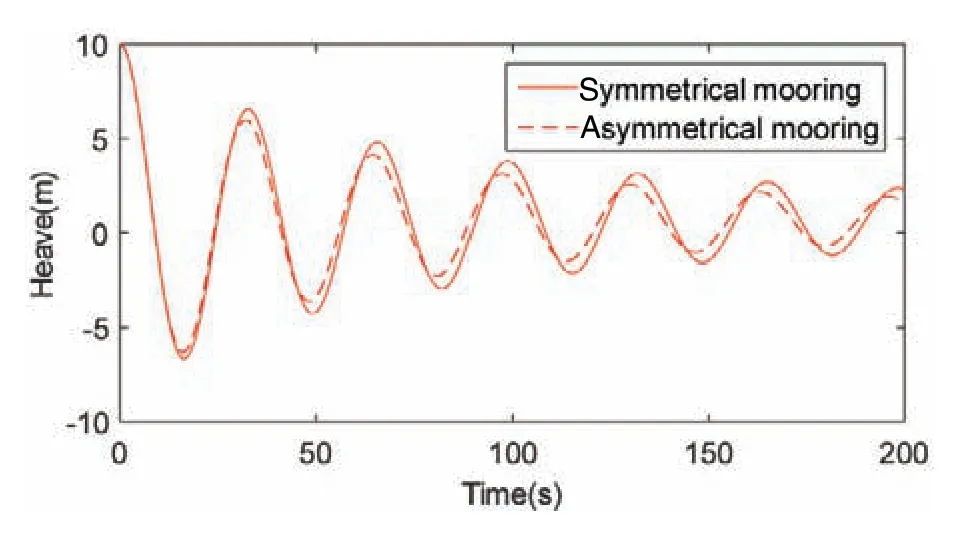

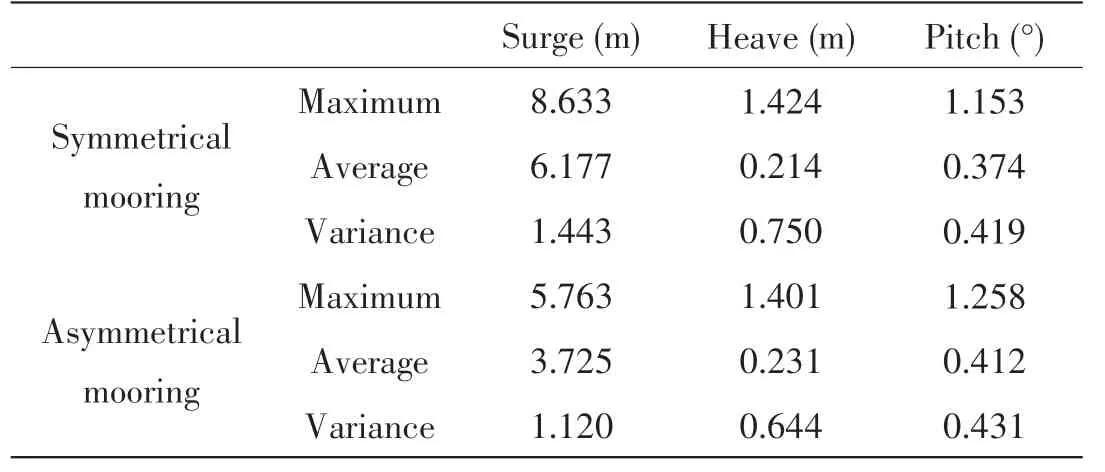

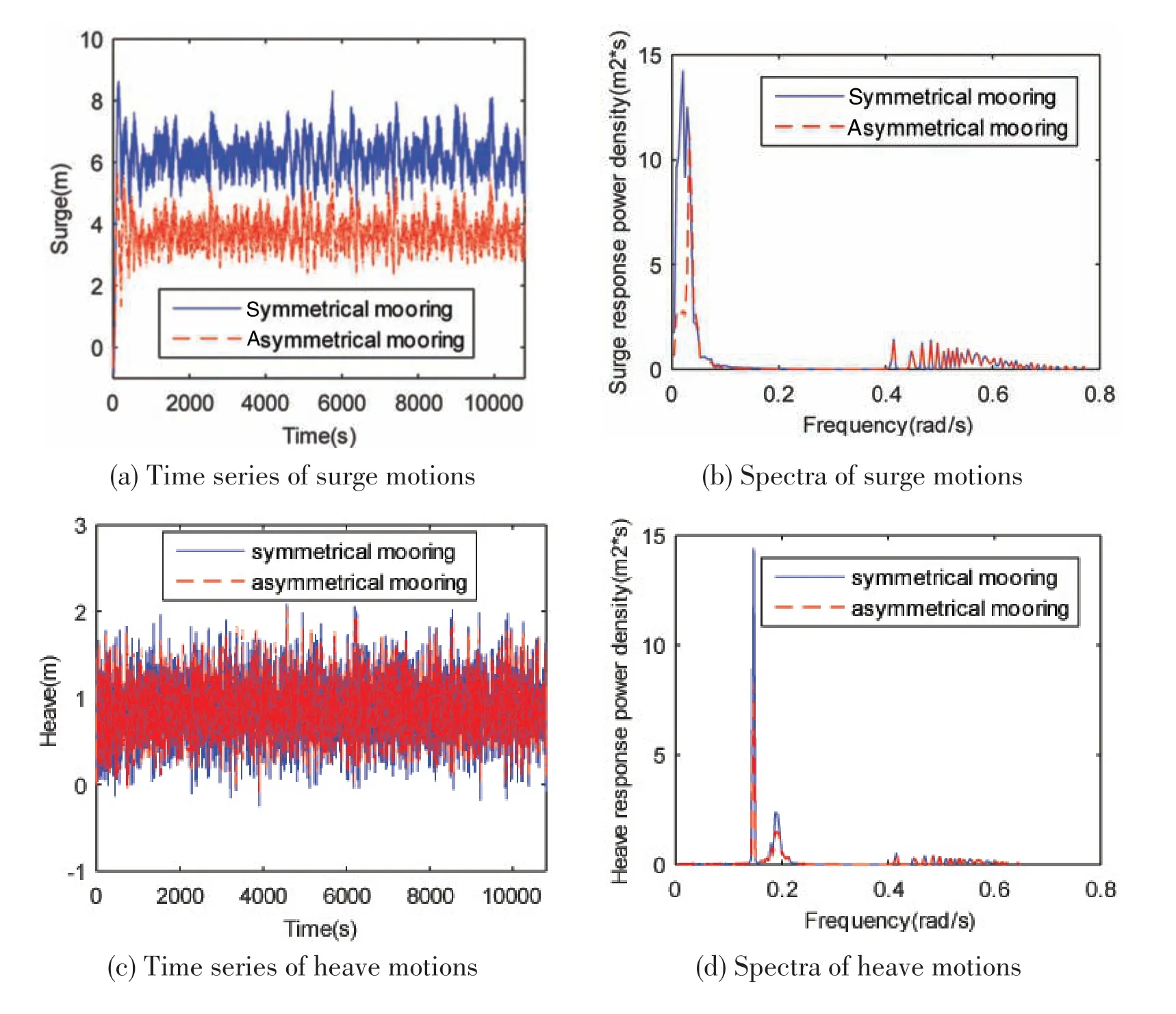

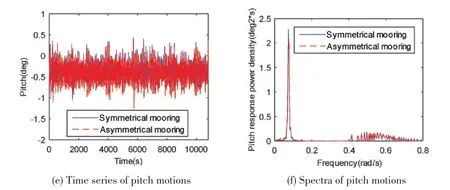

The iteration time step used in the numerical simulation is 0.1 s and the simulation duration is 3 h. The motion responses statistics of platform under the symmetrical mooring and asymmetrical mooring systems are given in Tab.7.It can be seen that the motion response amplitude of platform under two types of mooring systems both can meet the engineering requirements,and the surge motion of platform under the asymmetrical mooring system is obviously smaller. Fig.12 shows the time series of motion response and the corresponding spectrum.According to the motion response spectrum, it can be seen that the peak value of motion response is between 0 and 0.2 rad/s in low frequency range, which is very small in the wave frequency range,and indicates obvious low frequency motion characteristics.

Tab.7 Motion response of platform

Fig.12 Motion response of platform

3.3 Tension response of mooring lines

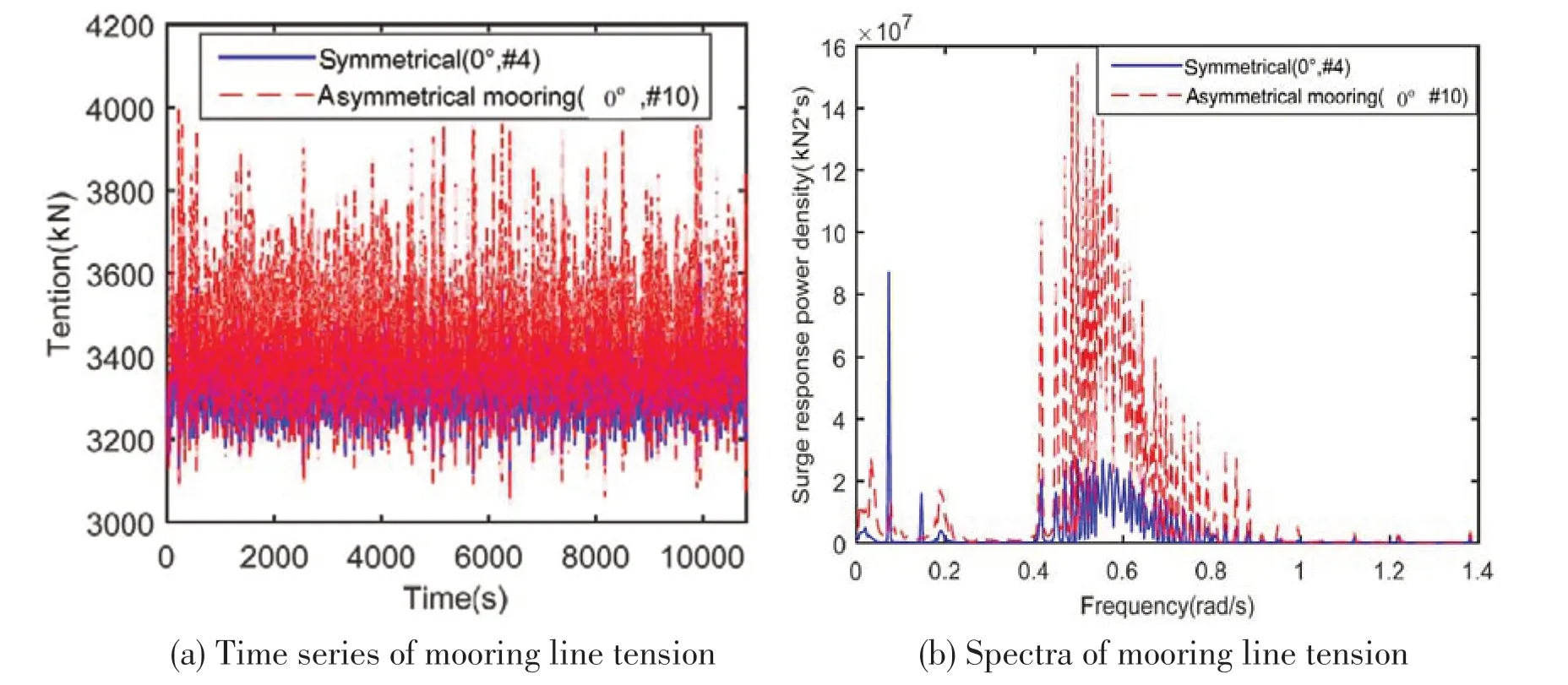

For symmetrical mooring systems,the maximum mooring line tension is 3.626 MN,and the corresponding mooring number is #4, and the safety factor is 4.744. For asymmetrical mooring systems, the maximum mooring line tension is 4.030 MN, and the corresponding mooring number is#10,and the safety factor is 4.268.Therefore,the safety factor of mooring lines under both mooring systems is greater than 1.67, which meets the engineering requirements. The corresponding time series of mooring line tension and tension spectrum are shown in Fig.13.According to the tension spectrum, it can be seen that the peak value of tension under the symmetrical mooring system is in the low frequency range, while the peak value of tension under the asymmetrical mooring system is concentrated in the wave frequency range and is relatively large.This indicates that the mooring line strength requirements are higher for asymmetrical mooring systems.

Fig.13 Tension response of mooring line

4 Conclusions

The mooring system plays a very important role in ensuring the safe operation of floating platform. This paper researches the response of platform motion and the mooring tension response based on the symmetric and asymmetric mooring systems, and combines them to draw conclusions as follows:

(1) Keeping the initial pretension and the pretension angle unchanged, the asymmetrical mooring system can be optimized through only changing the length of middle segment, and the stiffness of optimized asymmetrical mooring system is greater than that of initial symmetrical mooring system in bothXandYdirections.

(2) The asymmetrical mooring system designed in this paper can provide larger damping and obviously reduce the surge motion amplitude of platform. Besides, the motion response of platform has obvious low frequency characteristics.

(3) The safety factor of optimized asymmetrical mooring system meets the requirements of specification,but the maximum mooring line tension is much larger.Moreover,the peak value of tension response under the symmetrical mooring system is in the low frequency range while the peak value of tension under the asymmetrical mooring system is concentrated in the wave frequency range.

- 船舶力學(xué)的其它文章

- Effective Elastic Modulus Characteristics of Buoyancy Materials of Full-ocean-depth Manned Submersible

- Fatigue Strength Assessment of Welded Joints Using Strain Energy Density Method Based on NSIF

- Effects of Inflow and Outflow of Floodwater on the Parametric Roll of a Damaged Ship

- Analysis of Drilling Riser in Re-entry Operation Under Complex Currents

- Nonlinear Numerical Simulation for Flexible Pipes Carcass Wet Collapse

- Numerical and Experimental Study for SCR with Cable3D