Textile companies’orders and inventory pressures increased in the first quarter

According to the tracking data of the China Cotton Textile Association (CCTA) in March 2020, the production and sales situation of the cotton textile industry has improved month-on-month with the acceleration of the companys resumption of production. Since late March, the COVID-19 pandemic has spread globally, export orders have plummeted, and production has slowed. Recently, pressure on orders and inventories of cotton textile companies has further increased.

Raw material procurement increased month-on-month, cotton prices stabilized after falling

The purchase volume of imported cotton is basically the same as that of last month. According to data from the General Administration of Customs, China imported 610,000 tons of cotton in the first quarter, a year-onyear decrease of 8%. The average monthly price of the international cotton price A index in March was 67.69 cents/lb, down 11.6% from the previous month, which was greater than the decline in domestic cotton prices and continued the downward trend.

The purchase volume of non-cotton fiber in raw materials increased by 91.33% month-on-month. In March, the average monthly price of polyester staple fiber fell by more than 10% month-on-month; the average monthly price of viscose staple fiber continued to be basically flat month-on-month. With the crude oil price war “preliminarily reached an agreement to reduce production”, the price of polyester staple fiber has stabilized and the markets pessimism has eased.

Both raw material consumption and inventory decreased year-on-year

In March, the raw material consumption of cotton textile enterprises increased by 108.46% month-on-month, and about 95% of the enterprises increased month-on-month. In the first quarter, the cumulative raw material consumption of tracking enterprises was 24.32% year-on-year.

As of the end of March, raw material inventories fell by 3.09% month- on-month, of which 95% of enterprises raw cotton inventories increased; 91% of non-cotton fiber inventories increased. Compared with the same period last year, raw material inventories fell by about 16% year-on-year.

Yarn and cloth production decreased by 20% year-on-year, equipment utilization rate was less than 90%

Tracking enterprise data showed that the output of yarn and cloth in March increased by 113.27% and 90.57% respectively. In the first quarter, the cumulative yarn output and cloth output of tracking enterprises decreased by 23.91% and 20.20% respectively year-on-year. In March, the upstream and downstream markets of the industrial chain gradually recovered, and enterprises accelerated the resumption of production. In addition, the production base in February was relatively low, which led to a substantial increase in output, but it has not yet recovered to the level of the same period last year.

As of the end of March, the utilization rate of spinning and weaving equipment of tracking enterprises was around 88%, which was 10 and 14 percentage points lower than the same period of the previous year. Among them, 77% of the enterprises spinning equipment utilization rate was above 80%, accounting for 12 percentage points higher than last month; 80% of enterprises weaving equipment utilization rate was above 80%, accounting for 2 percentage points higher than last month. It is understood that the number of companies that have switched to produce masks has gradually increased.

Recently, export orders have been largely cancelled or delayed, and the production of enterprises has been greatly affected. According to the enterprises, orders for direct exports and indirect exports have decreased significantly, and the pressure on export-to-domestic sales has been greater. Some small and medium-sized enterprisesorders for processing from large enterprises have also decreased accordingly. The operating rate has declined, and weaving companies are more obvious than spinning companies.

The sales volume fell with the price of yarn and cloth, and the total profit was halved year-on-year

Tracking enterprise data shows that the sales volume of yarn and cloth in March increased by 143.56% and 108.55% respectively, affected by the global pandemic situation and the decline in raw material prices. From the perspective of the decline, the price of polyester yarn is higher than that of pure cotton yarn and viscose yarn.

As of the end of March, the percentage of loss-making enterprises was 45.30%. In the first quarter, the cumulative operating income of tracking companies decreased by 20.45% year-on-year, of which 88% of companies had a year-on-year decrease; the total profit decreased by 48.11% year-on-year, of which 77% of companies had a year-on-year decrease.

As of the end of March, yarn inventory increased by 1.74% month-onmonth, and cloth inventory increased by 2.96% month-on-month. Since late March, the companys production has begun to show signs of slowing down. In order to maintain operations and stabilize employees, the company has to increase production of conventional products, and inventory pressures have increased.

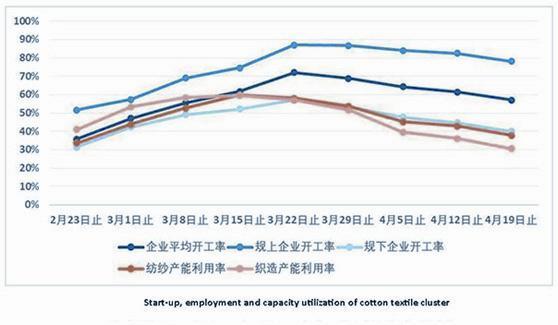

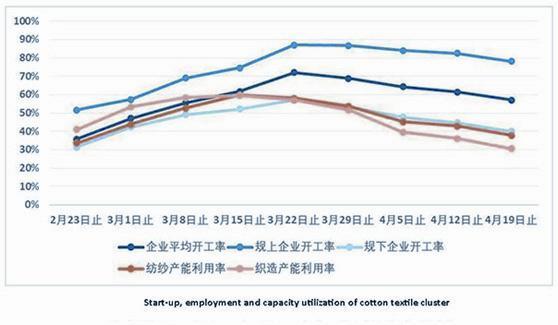

Cluster production improves in the early stage and slows down in the later stage

According to the follow-up survey of the cluster situation, with the stabilization of the pandemic situation in early and mid-March, the operating rate, equipment utilization rate and staff arrival rate of each cluster gradually increased. Starting in late March, affected by the foreign trade situation, the companys production slowed down significantly.

As of April 19, the average operating rate of the tracking cluster was about 57%, of which the operating rate of the enterprises above designated size was about 78%, and the enterprises below designated size had insufficient operations; the utilization rate of spinning and weaving equipment was below 40%.

According to the cumulative economic operation data from January to March 2020, through comparative analysis with the data of the same period last year, indicators such as the output and output value of the tracking cluster in March decreased significantly. In terms of output, the cumulative output of various types of yarn in cluster enterprises decreased by 33.6% year-on-year, and the output of cloth decreased by 37.2% year-on-year; in terms of economic indicators, the operating income of cluster companies decreased by 24.5% year-on-year, and the total profit decreased by 53.4% year-on-year.

In March, the overall production of the cluster showed a recovery trend, and most enterprises focus on the order before the Spring Festival. Affected by the pandemic situation, there are fewer new orders, the staff arrival rate is still insufficient, and the companys operating rate is relatively low, resulting in a year-on-year decline in output value.

- China Textile的其它文章

- aining China International Home Textiles Cloud Expo goes live this year,launching a new“cloud”model

- Strike hard to maintain the order of the melt blown nonwovens market

- A 500K Ton/Year PET Project Breaks Ground in Korla,Bayingol Mongolia of Xinjiang

- A Glimpse of Industrial Park in Xinjiang amid Virus Fighting

- From January to March,the profits of industrial enterprises above designated size decreased by 36.7%

- Manmade fiber industry hit hard with profits fallout by 75%