Change rules of a stratospheric airship’s envelope shape during ascent process

Zhao Shuai,Liu Dongxu,Zhao Da,Wu Gang,Yin Shi,Zhou Pan

School of Aeronautic Science and Engineering,Beihang University,Beijing 100083,China

Change rules of a stratospheric airship’s envelope shape during ascent process

Zhao Shuai,Liu Dongxu*,Zhao Da,Wu Gang,Yin Shi,Zhou Pan

School of Aeronautic Science and Engineering,Beihang University,Beijing 100083,China

Non-forming launch;Pressure gradient;Stratospheric airship;Wrinkles;Zero-pressure level

Stratospheric airship is a special near-space air vehicle,and has more advantages than other air vehicles,such as long endurance,strong survival ability,excellent resolution,low cost,and so on,which make it an ideal stratospheric platform.It is of great significance to choose a reasonable and effective way to launch a stratospheric airship to the space for both academic research and engineering applications.In this paper,the non-forming launch way is studied and the method of differential pressure gradient is used to study the change rules of the airship’s envelope shape during the ascent process.Numerical simulation results show that the head of the envelope will maintain the inflatable shape and the envelope under the zero-pressure level will be compressed into a wide range of wrinkles during the ascent process.The airship’s envelope will expand with the ascent of the airship and the position of the zero-pressure level will move downward constantly.At the same time,the envelope will gradually form a certain degree of stiffness under the action of the inner and external differential pressure.The experimental results agree well with the analytical results,which shows that the non-forming launch way is effective and reliable,and the analytical method has exactness and feasibility.

1.Introduction

Near space is the space region of earth’s atmosphere that lies between 20 and 100 km above the sea level,encompassing the stratosphere,the mesosphere,and the lower thermosphere.1–3In recent years,with the progress of science and technology,near space with its unique advantages of resources has become the focus of attention in the world.4,5A stratospheric airship has many advantages such as long hanging time,low cost,strong survival ability,excellent resolution,and so on.6–8It has a wide applicable prospect and developmental potential in the fields of monitoring and early warning,navigation and positioning,communications relay,meteorological observation,space exploration,etc.9–11

When a stratospheric airship is launched to the near space,it will undergo complex changes of the external environment.12–14To choose a reasonable and effective way to launchthe airship is very important for the success of the stratospheric airship.15,16In general,there are two ways to launch a stratospheric airship,forming launch way and non-forming launch way.Forming launch is that the air and helium are charged into an airship’s envelope to form the shape of the airship before launch,and it will maintain the shape of the airship during the ascent process.Whereas as for non-forming launch,only a small amount of lifting gas is charged into the envelope before launch.Because the environmental atmospheric pressure will decrease gradually,the airship will expand gradually during the ascent process,and the lifting gas will continue to expand until it completely inflates the envelope to form the rigid aerodynamic shape required for operation at the predetermined resident height.The airship will keep its shape under the action of internal and external overpressure at the resident height.

It is very important to study the change rules of the envelope shape during the launch and ascent process of an airship.The high altitude sentinel(HiSentinel17)airship sponsored by the United States Army Space and Missile Defense Command was launched with the non-forming launch way.

In this paper,the non-forming launch way is studied.The adjustment of an airship’s attitude is not considered,that is,it is assumed that an airship will maintain the vertical upward attitude during the ascent process.By using the differential pressure gradient method to simulate the ascent process of an airship,the change rules of the airship’s state at different stages of the ascent process can be obtained.

2.Principle of ascent and ceiling of airship

2.1.Principle of ascent

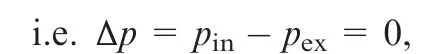

Fig.1 Internal and external pressure distributions of envelope during ascent process.

2.2.Ceiling height of stratospheric airship

With the ascent of the airship,the internal helium will gradually expand and the zero-pressure level will move downward.At the same time,the pressure field will change,too.By changing the location of the zero-pressure level,we can approximately simulate the airship’s ascent process until it reaches the predetermined resident height.

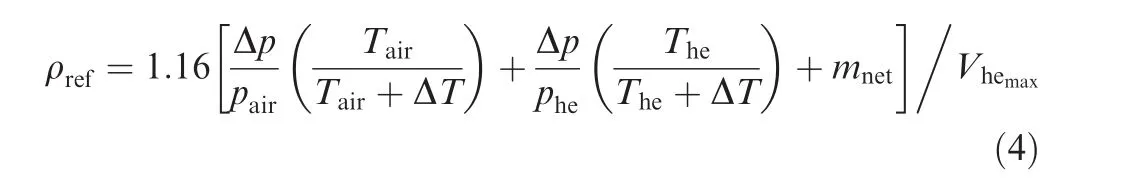

The net buoyancy of the airship is

whereBis the buoyancy of airship,and

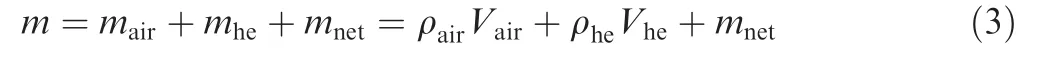

The total mass of the airship can be written as

Without considering the temperature and pressure differences between the inside and outside of the airship,Eq.(4)can be simplified as

whereVhemaxis the largest helium volume of airship at the resident height.

According to the standard atmospheric model,it can be known that the density of the air is related to the flight height.Therefore,from Eq.(4),we can know that the airship’s maximum ceiling height is determined by the structural mass of the airship,the largest helium volume,the super-hot,and the super-pressure.The helium will fill the envelope except for the reserved air bag at the resident height.The whole volume of the envelope subtracting the volume of the reserved air bag is the largest helium volume.In this paper,the volume of the reserved air bag is zero.When considering the temperature and pressure differences,24the maximum ceiling height of the airship will be in the nearby range determined by Eq.(5).

Under the action of the internal and external pressure difference of the airship,it will keep an overpressure state at the resident height.25–27Meanwhile,the airship will keep its shape under the action of overpressure,so the buoyancy of the airship is constant.By keeping the constant buoyancy,the airship can achieve resident or cruise at the predetermined height.The envelope’s overpressure load is jointly determined by the temperature difference between day and night or seasons in the stratosphere,thermal radiation characteristics of the envelope material,the airship’s envelope volume,and other factors.28–30In general,a stratospheric airship’s envelope materials can withstand overpressure ranging from 0 to 1000 Pa.31

3.Finite element simulation analysis

3.1.Judgement of membrane element stress state

The earliest method about the wrinkling analysis of a membrane is the tension field theory proposed by Wagner.32Mansfield33improved the theory with a reasonable density of relaxation energy instead of the original strain energy,and then Pipkin34used it for isotropic membrane wrinkling analysis.In 1961,Stein and Hedgepeth35proposed the Stein-Hedgepeth theory,which is mainly used for partial wrinkle analysis of a thin membrane.Kang and Lm36and Adler37made some improvements on the basis of the theory to widen the applicability of the method.The bifurcation theory can be used to get the speci fic shape of the wrinkle that is the wrinkle’s amplitude and wavelength.38Fujikake et al.39studied wrinkle questions by modifying the constitutive matrix in a tension thin membrane structure.

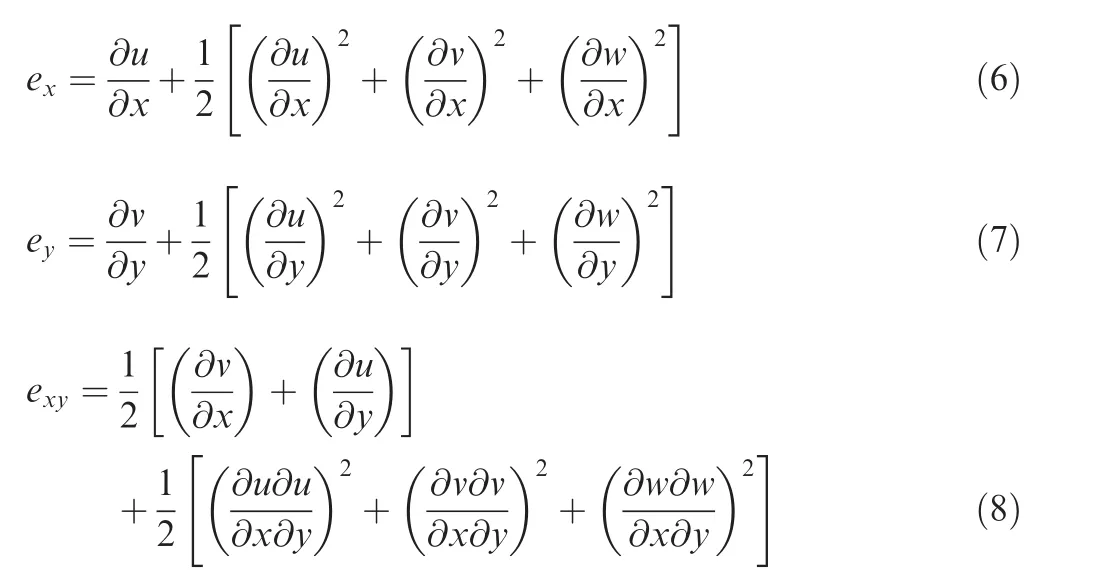

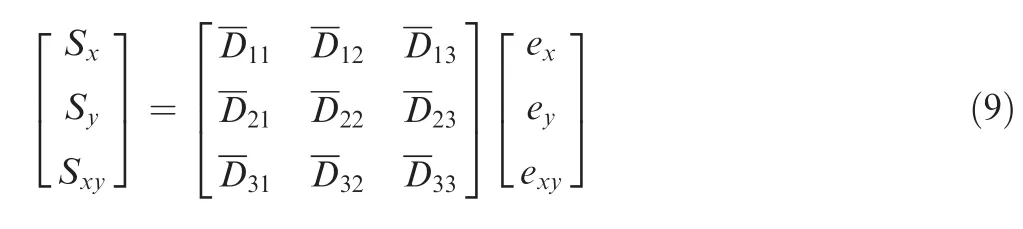

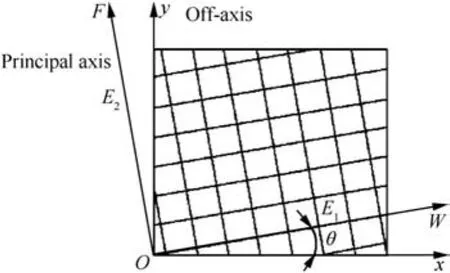

In the Lagrange coordinate system,under the action of an external force,PointMof the deformation body moves to pointM0,as shown in Fig.2.u,v,andware the projections of the displacement along thex,y,andzaxes,respectively.For thin membrane materials,the displacement in the thickness direction can be ignored,so the geometric equations of strain can be written as40,41

Fig.2 Diagrammatic sketch of deformation.

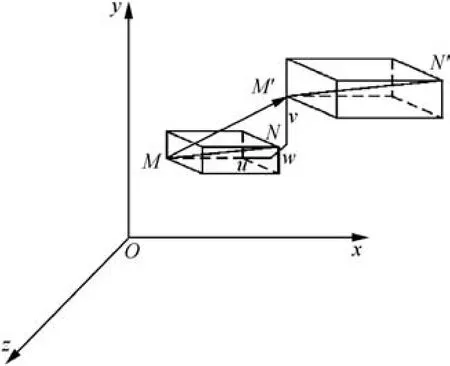

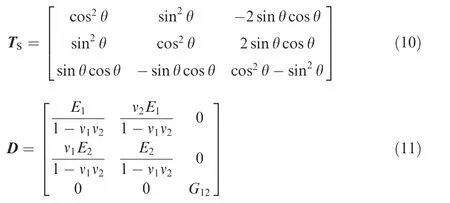

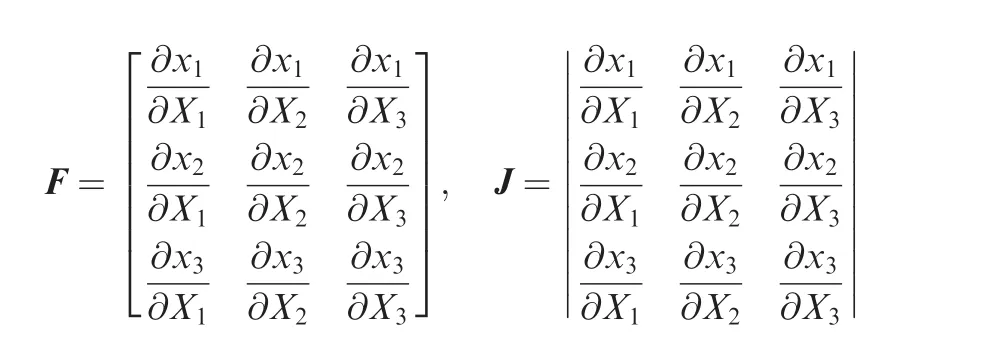

where h is the angle between the off-axis and the principle axis,as shown in Fig.3,E1andE2are the elastic modulus in the warp and zonal directions,G12is the shear modulus,m1is the zonal direction Poisson’s ratio caused by the warp direction,and m2is the warp direction Poisson’s ratio caused by the zonal direction.

Fig.3 Diagrammatic sketch of off-axis and principle axis.

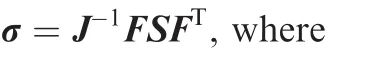

and wherex1,x2andx3are the three axes in the space coordinate system,X1,X2andX3are the three axes in the material coordinate system.

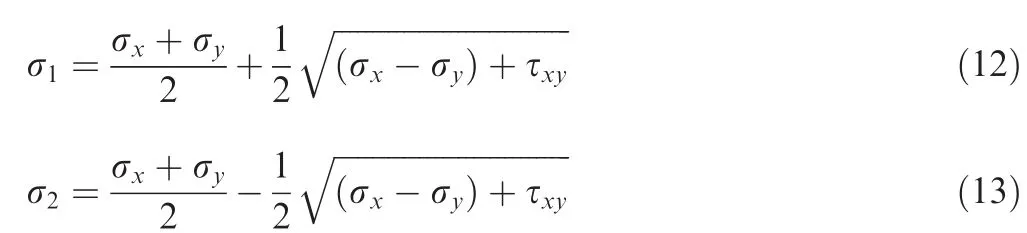

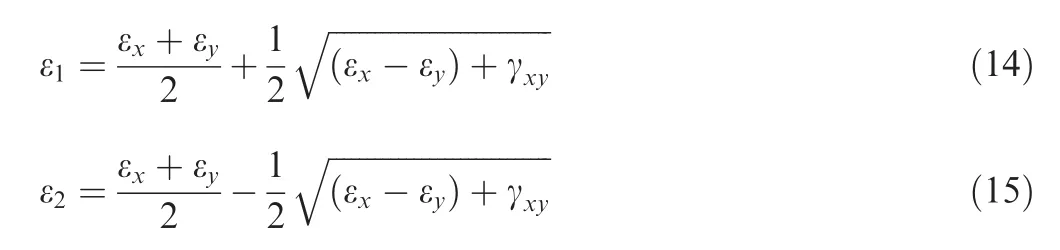

Then the principal stress can be obtained as follows:

where rxand ryare the stress inx-axis and y-axis direction,sxyis the shear stress.

where exand eyare the strain inx-axis and y-axis direction,cxyis the shear strain.

Finally we can judge the stress state of the membrane by principal stress-principal strain principles.40,42,43That is:

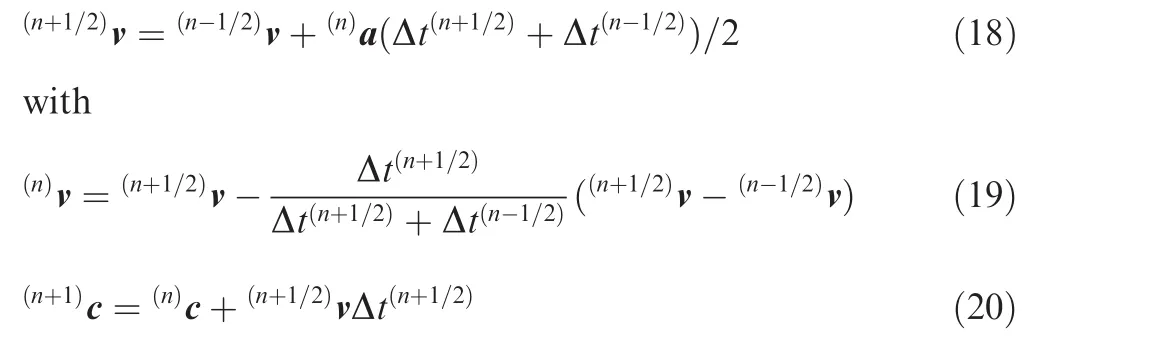

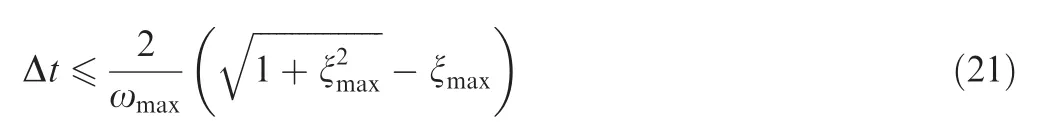

3.2.Explicit time integration

To analyze the change rules of the envelope’s states in different stages of the ascent process,the explicit time integration method is used.The nonlinear discrete equation of motion for a wrinkling membrane at time step(n),obtained from a total Lagrangian finite element formulation,can be written as

Given a new estimation of the nodal displacements at every time step,at each integration point of an element,a judgment is made on the wrinkling criterion,whether it is taut,wrinkled,or slack.According to the wrinkling criterion,change the constitutive matrix of the membrane materials,40and then go to the next time step.

4.Numerical results and discussion

4.1.Related parameters of airship

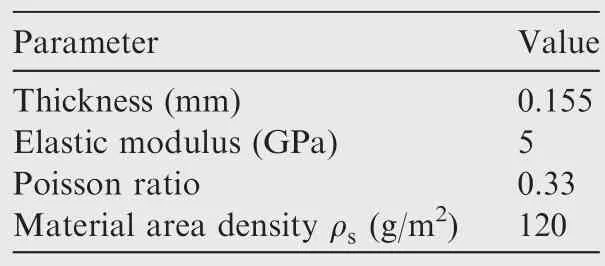

Since the stratospheric airship is very large,at the same internal and external differential pressure of the airship,the larger diameter of the airship,the higher requirement for the envelope material strength.26The special and complicated stratospheric environment such as the temperature difference between day and night or seasons,high radiation,and high ozone,puts forward higher requirements for the envelope’s material.4The properties of the material are shown in Table 1.The length of the airship model isL=75 m,the maximum radius of the cross section isR=12 m,and the slenderness ratio is 3.125.

Table 1 Performance parameters of skin material of airship.

4.2.Model establishment

The airship’s envelope is a symmetrical structure,which can be obtained by rotating a generatrix around the symmetrical axis.In this paper,the whole model is established including the envelope,the drag net,and the tension rope.The drag net is on the top of the envelope to fasten the envelope through the tension rope,and the other end of the rope is fixed to the ground.The envelope’s wrinkling deformation,which is induced by the gradient pressure field and gravity load,can be simulated using the dynamic finite element analysis method.Firstly,we can fix the bottom of the airship to the ground and exert the gradient pressure field and gravity load to simulate the initial launch state.Then we can release the bottom of the airship to simulate the ascent process.The effect of gravity is considered in the whole model.By constantly adjusting the position of the zero-pressure level of the airship,the change rules of the airship in different ascent stages can be obtained.

In order to get the deformation state of the airship’s head more accurately at the initial launch state,it is necessary to use a smaller grid to get more accurate results.At the same time,in order to save the computation time,only the airship’s head is modeled and analyzed.

4.3.Results and discussion

In this paper,it is assumed that the airship will maintain the vertical upward attitude during the ascent process,so the adjustment of the airship’s attitude is not considered.Before the launch of the airship,an appropriate amount of lifting gas should be charged into the envelope to meet the resident or cruise requirement of buoyancy.By estimating,at the initial launch state after the lifting gas is charged into the envelope,the zero-pressure level position is approximately 17 m under the top of the airship.

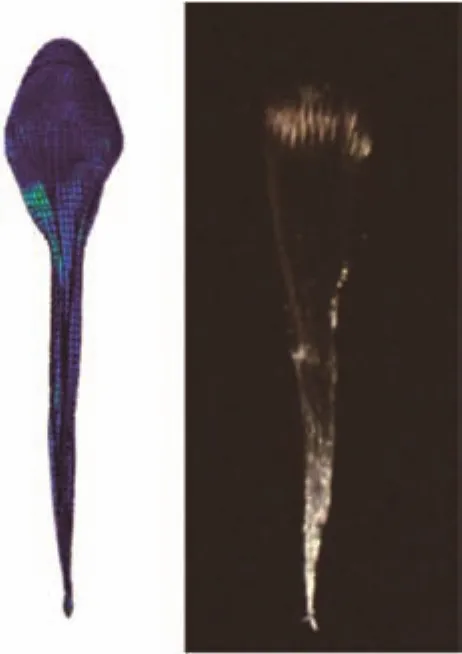

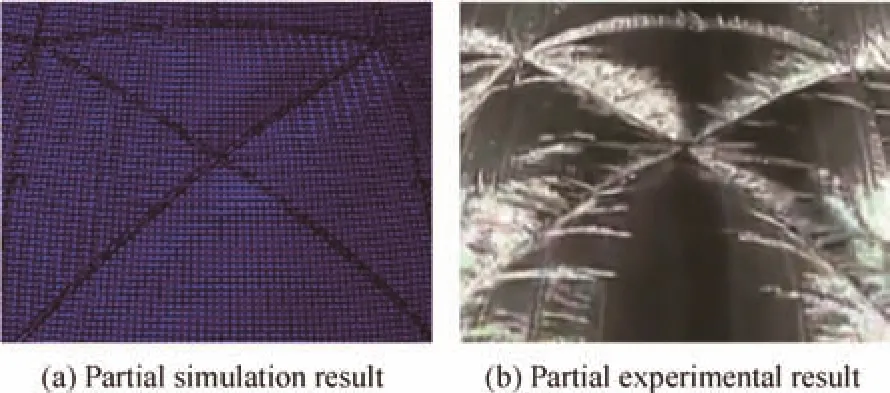

(1)At the initial state of launch,we can set y0=17 m,the simulation results and the experimental results of the airship’s envelope shape are shown in Fig.4.

The simulation results and the experimental results agree well.The region above the zero-pressure level expands to the shape of the airship’s head.Meanwhile,the bottom region is compressed to fold together under the action of external atmospheric pressure.

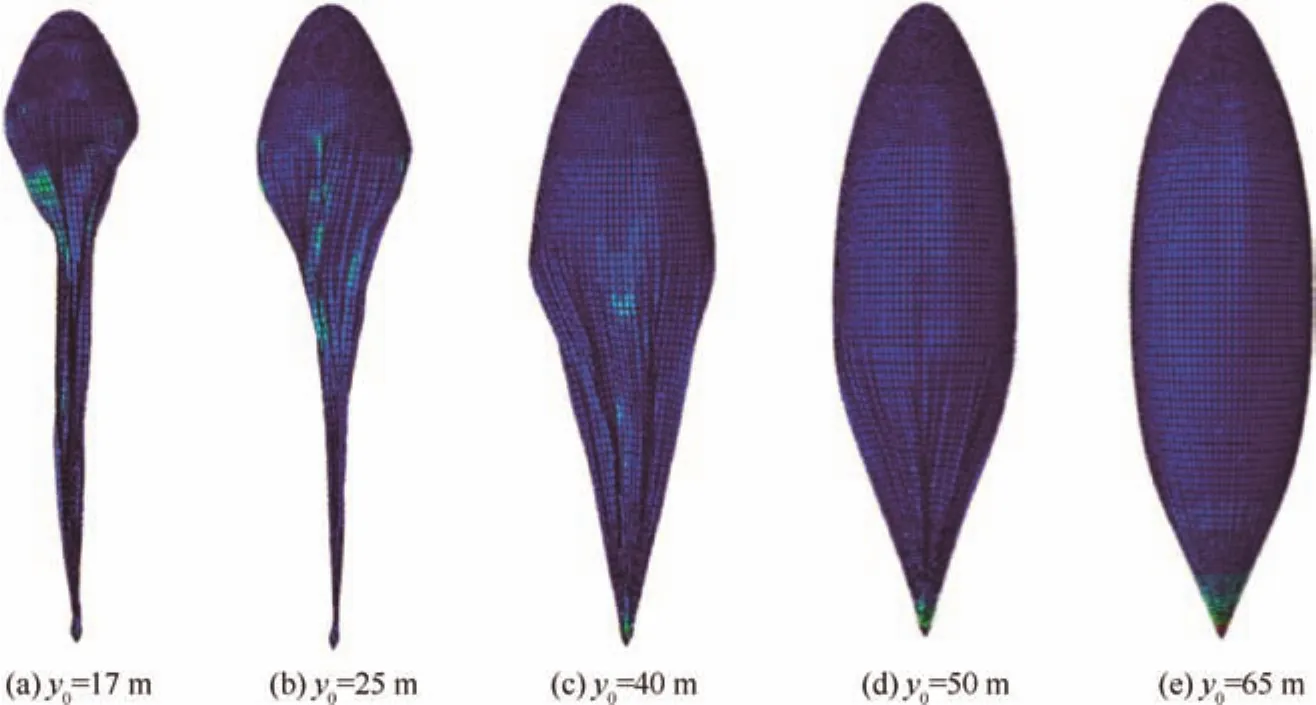

(2)To simulate the whole ascent process,we can set the position of the zero-pressure level at 17,25,40,50,and 65 m.Fig.5 shows the change rules of the envelope shape.

Fig.4 Comparison of simulation results and experimental results when y0=17 m.

Fig.5 Change rules of envelope shape.

During the ascent process of the airship,the external environmental pressure will reduce gradually.The internal helium volume will gradually expand,and the position of the zero-pressure level will move downward constantly.With the constant adjustment of the zero-pressure level,the envelope will form a certain degree of stiffness under the actions of the inner helium and the external pressure.As for a practical stratospheric airship,a payload system,a propulsion system,and an energy system are necessary.With the vertical ascent process,these systems will lead to the center of gravity not consistent with the center of buoyancy,so the airship will automatically adjust the attitude to the horizontal direction.At the same time,the airship will continue to rise until it get to the predetermined resident height.The airship will produce overpressure which makes the airship fully inflated to the rigid aerodynamic shape required for operation.Since then,the airship will achieve resident or cruise at the predetermined height.

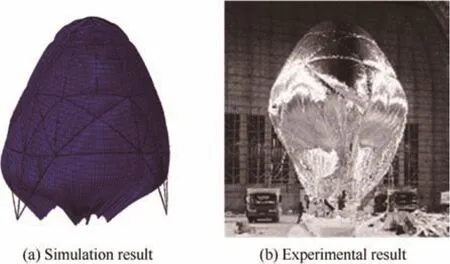

(3)A smaller grid is used to get a more accurate deformation state of the airship’s head.The simulation results and the experimental results are shown in Figs.6 and 7,respectively.

Fig.6 Simulation result and experimental result of head.

Fig.7 Partial simulation result and experimental result of head.

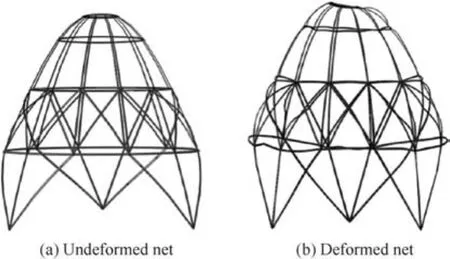

Fig.8 Undeformed model and deformed model results of net.

The drag net on the top of the envelope is connected to the ground by the tension rope,and we can release the rope properly to adjust the launch attitude of the airship and make the wrinkled part of the airship leave the ground.The undeformed model and deformed model results of the net are shown in Fig.8,respectively.

In the initial launch state,the simulation results of the airship’s head agree very well with the experimental results.Under the action of atmospheric pressure,the airship will get upward buoyancy,and the buoyancy is born by the drag net,so we can observe a dent obviously in the connecting region of the airship’s head and drag net.

5.Conclusions

(1)The coincidence between the simulation results and the experimental results reveals that the model is reasonable and correct.It also shows that the non-forming launch way is effective and reliable,and the simulation method has exactness and feasibility.

(2)The shape of the airship’s envelope can be simulated by the gradient of the pressure field,and the change rules of the envelope can be obtained by continuously adjusting the position of the zero-pressure level.For further research,during the ascent process,we can use this analytical method to check whether the payload system,propulsion system,and energy system will interfere with each other.Based on the result,we can determinate the location of each system reasonably.

(3)The pressure gradient will change gradually along with the change of the ascent height.The position of the zero-pressure level will also constantly move downward with the expanding of the envelope.This is a dynamic and coupling change process,so the analytical method may have some limitations,but for the entire ascent process,the method still has a great reference value.

Acknowledgments

The reviewers of this paper have provided the authors many valuable suggestions.This study was supported by the Achievements Cultivation Fund of Beihang University(No.YWF-15-CGPY-HKXY-001).The authors wish to express their thanks to all.

1.Colozza A,Dolce JL.High-altitude,long-endurance airships for coastal surveillance.Wahsington,D.C.:NASA;2005.Report No.:NASA/TM-2005-213427.

2.Colozza A.Initial feasibility assessment of a high altitude long endurance airship.Wahsington,D.C.:NASA;2003.Report No.:NASA/CR-2003-212724.

3.Jamison L,Sommer GS,Porche III IR.High-altitude airships for the future force army.Santa Monica(CA):RAND Corporation;2005.Report No.:DASW01-01-C-0003.

4.Gu ZM.Research of stratospheric airships’skin material.Spacecr Recov Remote Sens2007;28(1):62–6[Chinese].

5.Wang YF,An YW,Yang JH.Current situation and development trend of near space airship.Technol Found National Defence2010;1:33–7[Chinese].

6.Schmidt DK,Stevens J,Roney J.Near-space station-keeping performance of a large high-altitude notional airship.J Aircraft2007;44(2):611–5.

7.Wang MJ,Huang XS.Development of stratospheric airship platform and its key technology analysis.Ordnan Indust Automat2007;26(8):58–60[Chinese].

8.Ma ZY,Hou ZX,Yang XX.Structural performance analysis of large-scale flexible inflatable structures for stratospheric airships.J Nat Univ Defense Technol2015;4:25–30[Chinese].

9.Yao W,Li Y,Wang WJ,Zheng W.Development plan and research progress of stratospheric airship in USA.Spacecraft Eng2008;17(2):69–75[Chinese].

10.Cui EJ.Research statutes,development trends and key technical problems of near space flying vehicles.Adv Mech2009;39(6):658–73[Chinese].

11.Li YY,Li Z,Shen HR.Analysis on development and application of near space vehicle.J Acad Equip Command Technol2008;19(2):61–5.

12.Kim DM,Lee YG,Kang WG.Korea stratospheric airship program and current results.Restion:AIAA;2003.Report No.:AIAA-2003-6782.

13.Lee YG,Kim DM,Yeom CH.Development of Korean high altitude platform systems.Int J Wireless Inform Networks2006;13(1):31–42.

14.Ouyang J,Qu WD,Xi YG.Stratospheric verifying airship modelingand analysis.JShanghaiJiaotongUniv2003;37(6):956–60[Chinese].

15.Li LL,Guo WM,He JF.Current situation and development of foreign near space airship.Ordnan Indust Automat2008;27(2):32–4[Chinese].

16.Roney JA.Statistical wind analysis for near-space applications.J Atmos Solar-Terrest Phys2007;69(13):1485–501.

17.Smith S,Lee M.The HiSentinel Airship.Restion:AIAA;2007.Report No.:AIAA-2007-7748.

18.Ma YP,Lǜ MY,Wu Z,Liu DX.Simulation of near-space airship based on wrinkle during ascent.J Beijing Univ Aeronaut Astronaut2009;11(11):1298–301[Chinese].

19.Baginski FE.A mathematical model for a partially inflated balloon with periodic lobes.Adv Space Res2002;30(5):1167–71.

20.Kang W,Suh Y,Woo K,Lee I.Mechanical property characterization of film-fabric laminate for stratospheric airship envelope.Compos Struct2006;75(1–4):151–5.

21.Baginski FE.Nonuniqueness of strained ascent shapes of high altitude balloons.Adv Space Res2004;33(10):1705–10.

22.Baginski FE,Collier W.Modeling the shapes of constrained partially inflated high-altitude balloons.AIAAJ2001;39(9):1662–72.

23.Baginski FE,Brakke KA.Modeling ascent configurations of strained high-altitude balloons.AIAA J1998;36(10):1901–10.

24.Yao W,Li Y,Wang WJ,Zheng W.Thermodynamic model and numerical simulation of a stratospheric airship take-off process.J Astronaut2007;28(3):603–7[Chinese].

25.Liu DX,Yang YQ,Lu¨MY,Wu Z.Effect of envelope thermal radiative properties on the stratospheric super-pressure LTA vehicle helium temperature.J Beijing Univ Aeronaut Astronaut2010;36(7):836–40[Chinese].

26.Wang WJ,Li Y,Yao W,Zheng W.Estimation of the relationship between the pressure in airship balloon and the tension in its envelope.J Astronaut2007;5,1109-2[Chinese].

27.Liao L,Pasternak I.A review of airship structural research and development.Prog Aerosp Sci2009;45(4):83–96.

28.Shi H,Song B,Yao Q,Cao X.Thermal performance of stratospheric airships during ascent and descent.J Thermophys Heat Transf2009;23(4):816–21.

29.Xu XH,Cheng XT,Ling XG.Thermal analysis of a stratospheric airship.J Tsinghua Univ(Sci Technol)2009;49(11):1848–51[Chinese].

30.Fang XD,Wang WZ,Li XJ.A study of thermal simulation of stratospheric airships.Spacecr Recov Remote Sens2007;28(2):5–9[Chinese].

31.Liu LB,Lu¨MY,Xiao HD,Cao S.Calculation and simulation of stratospheric airship capsule stress considering the pressure gradient.J Beijing Univ Aeronaut Astron2014;40(10):1386–91[Chinese].

32.Wagner H.Flat sheet metal girders with very thin metal web.Z Flugtechn Motorluftschiffahrt1929;20:200–314.

33.Mansfield EH.Tension field theory:A new approach which shows its duality with inextensional theory.Applied Mechanics.Berlin:Springer;1969,p.305-20.

34.Pipkin AC.The relaxed energy density for isotropic elastic membranes.J Appl Math1986;36(1):85–99.

35.Stein M,Hedgepeth JM.Analysis of partly wrinkled membranes.Washington,D.C.:NASA;1961,p.122-56.

36.Kang S,Lm S.Finite element analysis of wrinkling membranes.J Appl Mech1997;64(2):263–9.

37.Adler AL.Finite element approaches for static and dynamic analysis of partially wrinkled membrane structures[dissertation].Boulder(CO):University of Colorado;2000,p.65–75.

38.Li ZW,Yang QS,Liu RX.Review of methods of wrinkling analysis of membrane structures.China Safety Sci J2004;14(7):16–20[Chinese].

39.Fujikake M,Osamu K,Seiichiro F.Analysis of fabric tension structures.Comput Struct1989;32(3–4):537–47.

40.Tan F,Yang QS,Li ZW.Wrinkling criteria and analysis method for membrane structures.J Beijing Jiaotong Univ2006;30(1):35–9[Chinese].

41.Yang QS,Jiang YN.Analysis and design of tensioned cable–membrane structures.Beijing:Science Press;2004.p.89–93[Chinese].

42.Tan F,Yang QS,Zhang J.Finite element method of wrinkling analysis of membrane structure.Eng Mech2006;23(1):62–8[Chinese].

43.Tan F,Zhao J,Yang QS.Integrated program CAFA1.0 for cable and membrane structures.Spatial Struct2003;9(4):33–8[Chinese].

4 March 2016;revised 11 July 2016;accepted 28 August 2016

Available online 16 February 2017

*Corresponding author.

E-mail addresses:zhaoshbuaa@163.com(S.Zhao),liubuaa@163.com(D.Liu),buaazd@yeah.net(D.Zhao).

Peer review under responsibility of Editorial Committee of CJA.

CHINESE JOURNAL OF AERONAUTICS2017年2期

CHINESE JOURNAL OF AERONAUTICS2017年2期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- High-temperature tribological behaviors of a Cr-Si co-alloyed layer on TA15 alloy

- Analysis and control of the compaction force in the composite prepreg tape winding process for rocket motor nozzles

- Impact of lubricant traction coefficient on cage’s dynamic characteristics in high-speed angular contact ball bearing

- Variable stiffness design of redundantly actuated planar rotational parallel mechanisms

- Adaptive formation control of quadrotor unmanned aerial vehicles with bounded control thrust

- Constrained adaptive neural network control of an MIMO aeroelastic system with input nonlinearities