手持式可見近紅外蘋果品質無損檢測系統設計與試驗

郭志明,王郡藝,宋 燁,殷曉平,鄒彩霞,鄒小波

·農產品加工工程·

手持式可見近紅外蘋果品質無損檢測系統設計與試驗

郭志明1,王郡藝1,宋 燁2,殷曉平3,鄒彩霞1,鄒小波1

(1. 江蘇大學食品與生物工程學院,鎮江 212013;2. 中華全國供銷合作總社濟南果品研究院,濟南 250220;3. 蘇州曉創光電科技有限公司,蘇州 215505)

為實現蘋果多產地多品質指標的現場快速無損檢測與評價,該研究基于可見近紅外光譜技術研發低成本、低功耗、小型化的蘋果品質手持式無損檢測終端。檢測終端集成寬譜LED光源和水果特征響應窄帶光電探測器,接入物聯網云端數據系統,實現檢測數據上傳和模型的遠程更新維護。利用研制的檢測系統可有效獲取不同產區蘋果500~1 050 nm波長范圍內的漫反射光譜,優選光譜預處理算法消除干擾并采用不同特征波長提取算法對數據進行降維,分別建立了多產地蘋果可溶性固形物含量、硬度和維生素C含量的通用檢測模型,模型的預測相關系數分別為0.926、0.798和0.704,預測均方根誤差分別為0.585%、1.405 kg/cm2和0.968 mg/100g。將通用檢測模型載入云端數據系統作為云模型,檢測樣本時調用云模型進行計算并反饋至檢測終端。通過多個產地獨立樣本的驗證表明,該系統可滿足蘋果產業現場無損檢測的實際需求,為手持式光譜檢測儀的實用化設計提供參考。

無損檢測;近紅外光譜;蘋果品質;云模型;多產地;手持式檢測系統

0 引 言

中國是世界上蘋果種植和消費的第一大國[1],國家統計局數據顯示,近年來中國蘋果產量總體呈慣性擴張態勢。蘋果營養價值豐富,包含多種維生素、氨基酸、膳食纖維等功能成分,具有延緩衰老、降低膽固醇等功效[2]。蘋果消費已由數量型向質量型轉變,由關注外觀品質向內部品質轉變,依據蘋果內部品質分級可以提高蘋果的附加值。蘋果產業迫切需要內部品質快速無損檢測分級評價技術與設備,但現有的無損檢測系統存在復雜環境抗干擾能力差、建模成本高、模型適用性差、傳感器系統復雜等問題,嚴重制約了該技術的實用化[3]。

無損檢測技術利用聲、光、電等手段檢測水果的化學成分和物理特性,常用的水果無損檢測技術包括光譜技術、介電特性技術、核磁共振技術、計算機斷層掃描技術等[4]。可見近紅外光譜技術因操作簡便、精確度高、客觀無損而成為目前最有潛力的水果內部品質無損檢測技術[5-6]。可見近紅外光譜主要是含氫基團分子振動倍頻和合頻的吸收光譜,包含被測樣本內部品質的相關信息。蘋果內部組分含有豐富的含氫基團,內部品質指標適用于可見近紅外光譜檢測[7-8]。目前,可見近紅外光譜技術在蘋果內部質量檢測已開展廣泛的研究[9-13],然而受產地、品種、收獲年份、果園管理模式等的影響,蘋果在成熟和貯藏過程中品質易發生變化[14],傳統模型的預測效果不能滿足實際需求且模型的更新和維護也較為困難,模型的穩定性和適用性制約了可見近紅外光譜技術的推廣應用[15-17]。此外,目前利用可見近紅外光譜技術的水果品質無損檢測設備多使用集成光譜儀進行二次開發,光源常使用鹵鎢燈,成本和能耗均較高,不利于在食品、農產品加工檢測行業推廣應用。研發小型化、低成本、低功耗的適用于多產地蘋果品質無損檢測系統,在蘋果質量評測上具有廣闊的應用前景[18-20]。

物聯網、大數據和云服務等新技術正快速推進農業智能化發展[21-22]。研究將建立的蘋果內部品質預測模型上載至云端服務器,通過5G/4G傳輸模塊與云模型進行交互,檢測結果實時回傳,方便模型的優化與更新。本研究集成寬譜LED光源和水果特征響應窄帶光電探測器,進行電路設計和軟硬件系統開發,建立多產地蘋果品質通用檢測模型,研制蘋果品質云模型的手持式可見近紅外無損檢測系統,以期實現蘋果內部品質快速無損原位檢測,為保障蘋果質量安全、增加蘋果附加值、提高中國蘋果國際競爭力等提供參考。

1 蘋果品質云模型的手持式可見近紅外無損檢測系統設計

蘋果品質云模型的手持式可見近紅外無損檢測系統由手持式檢測終端和物聯網云端數據系統組成。手持式檢測終端獲取蘋果光譜信息,通過通訊模塊將數據傳輸至物聯網云端數據系統,對模型庫中對應模型進行調用并計算,預測結果返回至檢測終端,同時將結果保存于檢測數據庫,方便數據查詢下載和統計分析。

手持式檢測終端硬件主要由光源、可見近紅外光電傳感器、溫度傳感器、可充電式鋰電池、顯示屏、控制電路、遮光圈、橡膠墊圈和殼體組成,如圖1所示。LED點光源呈圓周對稱排布,工作時將蘋果放置于檢測部位,檢測部位設計橡膠墊圈以防止蘋果受到機械損傷,并可隔絕漫反射光以外的雜散光,同時配置遮光圈,保證檢測時不受環境光的干擾,特別是室外光照環境。觸動檢測開關,光線以固定角度照射蘋果,經內部傳輸后漫反射光被可見近紅外光電傳感器所接收,由控制電路將信號進行處理并通過4G/5G模塊傳輸至云服務器,調用云模型獲取檢測結果。

1.1 微型光源模塊

可見近紅外光譜檢測系統需配置寬波段的光源,一般選用鹵鎢燈[23],但具有高功耗、低光利用率等問題,導致檢測系統大而重,限制了可見近紅外光譜技術現場、戶外快速無損檢測領域的應用推廣。定制開發寬譜LED光源,光強在550~1 000 nm波段范圍內隨頻率變化呈連續高強度分布,可以實現蘋果多品質指標同時檢測。此寬譜LED構建的環形光源組具有體積小、重量輕、發光均勻、響應速度快、抗震防水能力強、功耗低、使用壽命長等特點,可以在戶外環境中使用。LED光源發出的光線是定向的,總功率僅為72 mW,大部分光線能直接投射向蘋果表面,具有一定的焦距和工作平面。此外,發光強度可以通過電流強弱進行有效控制,可根據蘋果種類設置不同的光照強度以提高其通用性和適用性。

1.2 可見近紅外光電傳感器模塊

隨著微機電加工技術的發展,微型可見近紅外光譜儀發展迅速,現有的微型光譜儀可以分為色散型可見近紅外光譜儀、濾光片型可見近紅外光譜儀、調制型可見近紅外光譜儀等[24],具有體積小、集成度高、能耗低、便于二次開發等優點[25]。但其多數屬于通用性分析儀器,成本較高,并且在特定條件下性能不夠優良。本研究選用日本濱松公司生產的C14384MA-01超緊湊型可見近紅外光電傳感器,配置高靈敏度的CMOS線性傳感器,光譜有效響應范圍為500~1 050 nm,質量僅為0.3 g,具有質量輕、體積小、成本低的特點,在可見近紅外區分辨率為17 nm,能夠獲得連續波譜,滿足水果內部品質的檢測需求。

1.3 控制與通訊模塊

光譜信號被可見近紅外光電傳感器獲取后,由AD8092芯片設計的電路進行信號放大及基線調整,傳至SAR架構的ADC模數轉換芯片將光信號轉換為電信號,最后通過嵌入式單片機進行處理。集成現場可編程邏輯門陣列(Field Programmable Gate Array,FPGA)控制整個電路的時序,保證電路正常工作,ADC器件和光電傳感器的時序同步,數據平滑等預處理也通過FPGA進行處理,如圖2a所示。嵌入式主板設有5G/4G和GPS模塊,光譜數據被無線傳輸至云服務器,調用云模型進行計算,將檢測結果回傳至系統中并在顯示屏上實時顯示。在軟件開發過程中,構建蘋果內部品質監測平臺,如圖 2b所示。數據上傳至云端數據系統到返回檢測終端所用時間為1.5~2.0 s,測試的有效回傳率達100%,檢測結果記錄于云端數據庫,方便查詢下載和統計分析,實現蘋果品質原位實時檢測和監測。

1.4 軟件開發

蘋果品質手持式可見近紅外無損檢測系統軟件基于嵌入式實時操作系統Real Time-Thread進行模塊化開發,使用C語言編寫。模型調用具有兩種模式,模式一為直接調用內置于檢測系統中的模型實現單機實時獲取結果,模式二為調用置于云服務器中的云模型便于模型的更新與維護。此外,檢測結果存儲于云端數據庫,每條數據設置單獨的序列號,方便查詢下載分析,實現產區蘋果品質評價。

2 蘋果內部品質檢測云模型的建立

從國家現代農業(蘋果)產業技術體系各蘋果實驗站共獲得來自17個產地的富士蘋果529個,如表1所示。將蘋果樣品運輸到實驗室后,將其存儲在4 ℃的冰箱中。試驗之前,將蘋果從冰箱中取出并在室溫(25 ℃)下放置24 h,以減少由于溫度變化而引起的測量誤差。用濕紗布將所有樣品擦拭干凈并自然風干,然后將樣品逐一編號,分批選擇不同產地的樣品進行試驗。

表1 蘋果來源統計結果

2.1 蘋果品質測定

蘋果中的可溶性固形物含量(Soluble Solids Content,SSC)、硬度(Firmness)和維生素C含量(Vitamin C content)是評價蘋果品質的重要指標。蘋果SSC測定參考NY/T 2637—2014,采用折射儀法。使用的折射儀為ATAGO RX-5000α(ATAGO Company),測量前用蒸餾水對折射儀進行校正,用取樣器取蘋果赤道位置直徑約1 cm果肉,用紗布擠壓,將汁液滴入折射儀檢測窗口,獲得其SSC含量參考值。蘋果硬度測定參考NY/T 2009 —2011,采用硬度計法。使用TA-XT plus物性儀(Stable Micro System Company),采用P2探頭,預壓速度為1.5 mm/s,穿刺速度為1.0 mm/s,壓后上行速度為10.0 mm/s,測試距離為10 mm,觸發力為0.049 N。蘋果維生素C含量的測定參考GB 5009.86—2016,使用2, 6-二氯靛酚滴定法。

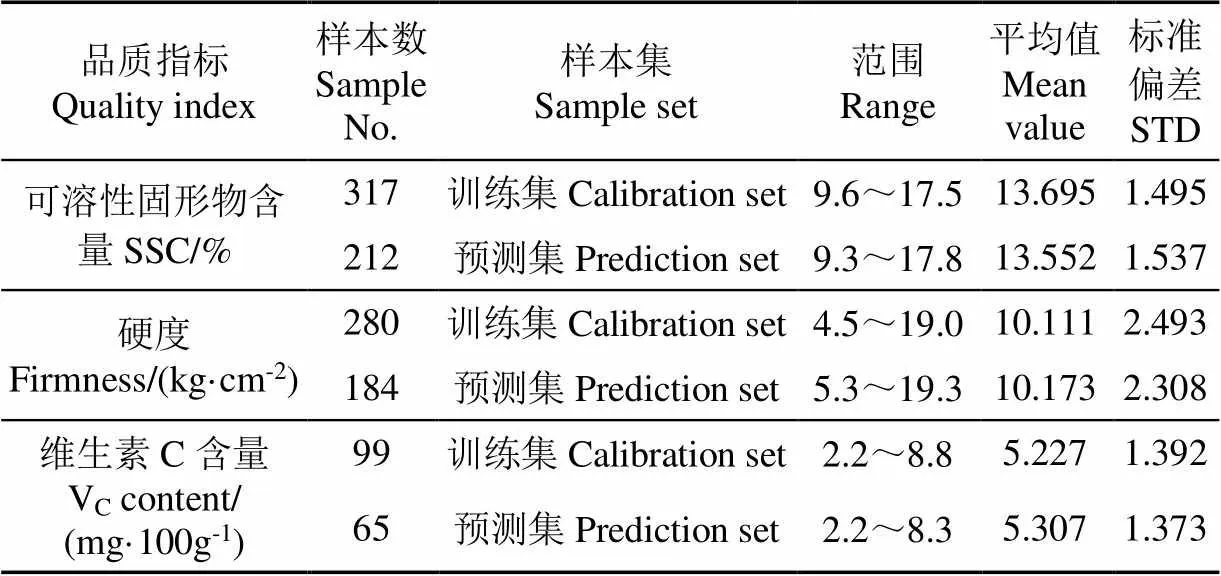

將529個蘋果樣本按照3∶2的比例隨機劃分為訓練集和預測集,品質指標統計結果如表2所示,通過訓練集和預測集樣本的范圍、均值和標準偏差等統計數據發現,樣本選擇具有較好的代表性和測試范圍。

表2 蘋果品質測定統計結果

注:范圍、平均值、標準偏差的單位為各指標單位。

Note:The units of range, mean value and STD are indicator units.

2.2 蘋果可見近紅外光譜采集與數據分析

檢測系統經優化設置平均次數為5,曝光時間為75 ms,采樣頻率為10 Hz,為消除暗噪聲所帶來的試驗誤差,采集水果光譜的同時采集其暗光譜與全反射光譜,并將光譜強度轉化為相對吸光度lg(1/),得到光譜與樣品組分含量的線性相關關系,其中為樣品的相對透過率。刪除無響應和噪聲較大的光譜邊緣區域,選擇波長范圍515~870 nm的光譜進行處理。

在可見近紅外光譜區域,蘋果中存在水和碳水化合物的C-H、O-H、N-H等化學鍵對應的典型重疊吸收[26]。圖3為原始可見近紅外光譜圖,可以看出所有蘋果樣品的光譜特征都表現出類似的變化趨勢。675 nm附近的吸收光譜與蘋果皮中的葉綠素a、葉綠素b和花色苷有關[27]。760 nm附近的吸收峰與水和碳水化合物的含量相關[28]。因此,基于可見近紅外漫反射光譜技術建立多產地蘋果品質預測模型是可行的。

在光譜采集過程中,由于受到儀器和樣品本身的干擾,原始光譜易受到譜峰重疊、基線漂移等影響,所建立的模型穩定性差、精度低。通過比較不同的光譜預處理方法發現Savitzky-Golay smoothing(SG平滑)可以有效提高模型的精度,經前期試驗SG平滑多項式次數設置為2,窗口數設置為7。其原因為SG平滑有效消除了基線漂移和傾斜。

2.3 多產地蘋果內部品質通用檢測模型的建立

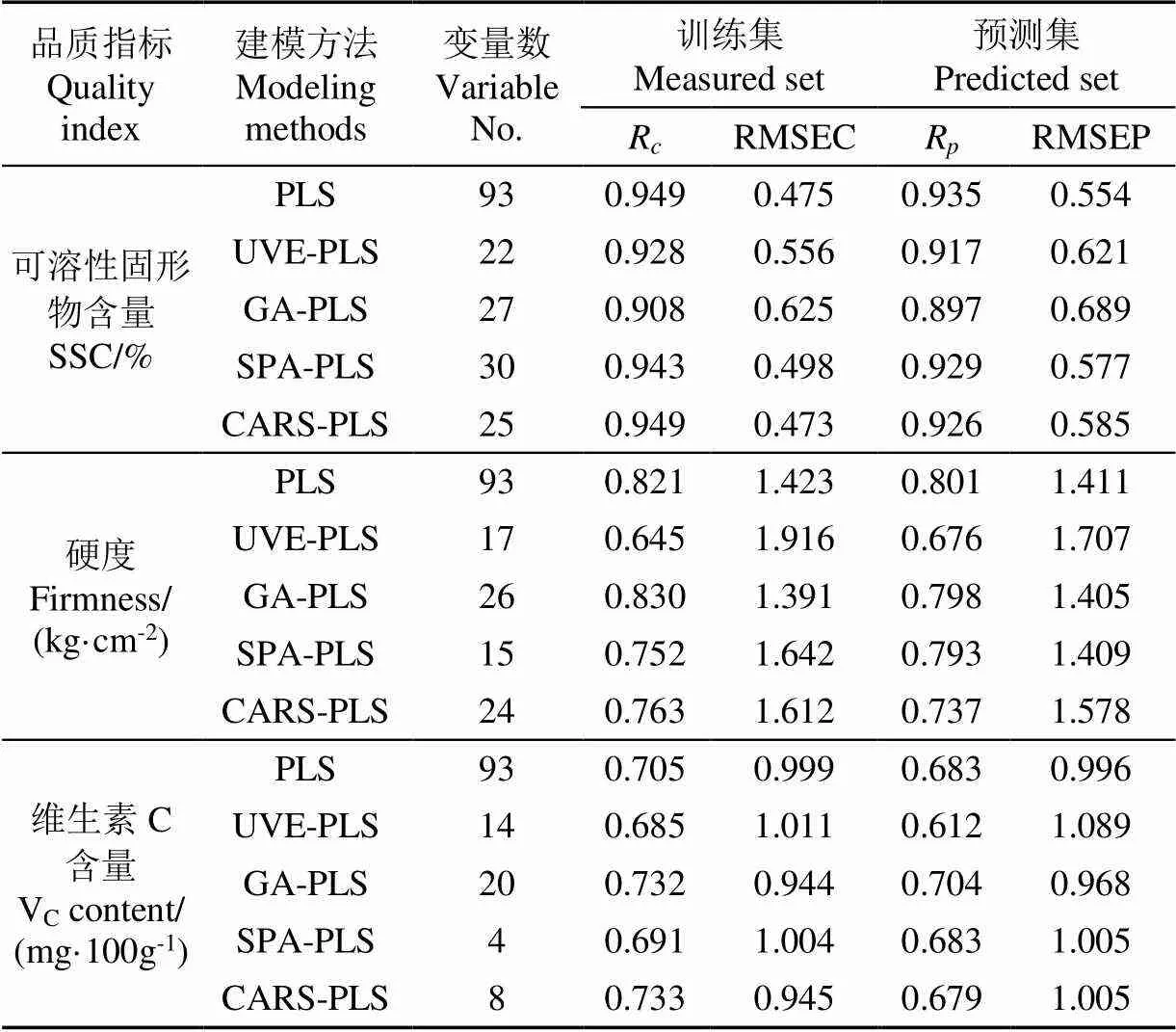

可見近紅外光譜帶包含無信息變量,變量選擇算法可以對光譜信息進行優化組合以降低模型計算量,從而達到簡化模型的目的。本研究使用無信息變量消除算法(Uninformative Variable Elimination Algorithm,UVE)[29],遺傳算法(Genetic Algorithm,GA)[30],連續投影算法(Successive Projections Algorithm,SPA)[31]以及競爭性自適應重加權采樣算法(Competitive Adaptive Reweighted Algorithm,CARS)[32]選擇特征波長,利用偏最小二乘法(Partial Least Square,PLS)分別建立多產地蘋果可溶性固形物含量、硬度和維生素C含量預測模型。模型性能使用訓練集均方根誤差(Root Mean Square Error of Calibration,RMSEC)和預測集均方根誤差(Root Mean Square Error of Prediction,RMSEP)以及相關系數(R和R)進行評價,其建模結果如表3所示

對比經過不同特征波長選擇算法處理的PLS模型結果選取最適合該樣本的特征波長選擇方案。以預測集相關系數為判別依據,當結果相當時選擇變量數較少的為最優模型。蘋果可溶性固形物含量模型的預測效果表現為CARS-PLS> SPA-PLS > UVE-PLS > GA-PLS。對于硬度模型,預測效果表現為GA-PLS>SPA-PLS>CARS-PLS> UVE-PLS。對于維生素C含量模型的預測效果表現為GA-PLS>SPA-PLS>UVE-PLS>CARS-PLS。SSC的CARS-PLS模型、硬度和維生素C含量的GA-PLS模型與全譜PLS模型相比,預測能力未有顯著提升,但變量數減少近3/4,簡化了模型。其模型散點如圖4所示,使用訓練集和預測集的分布表示模型的相關性。

表3 不同變量選擇算法的建模效果

注:R和R為訓練集和預測集相關系數,RMSEC和RMSEP分別為訓練集和預測集均方根誤差,單位為各指標單位。下同。

Note:RandRare correlation coefficients of calibration set and prediction set, RMSEC and RMSEP are root mean square errors of calibration set and prediction set, and the unit is each indicator unit. Same as below.

CARS將原始數據集通過蒙特卡洛采樣進行劃分,通過指數衰減函數對主要選擇變量進行優化,然后使用自適應加權采樣技術對特征變量進行提取,最后以RMSEC值作為判斷變量最佳組合的標準[33-34]。在蒙特卡羅采樣過程中,RMSEC值隨蒙特卡羅采樣次數的增加先減小后增大,對可溶性固形物含量的特征變量在第5次采樣時達到最小值。在相應的點選取25個特征變量,利用選取的變量建立PLS預測模型,可溶性固形物含量CARS-PLS模型的R=0.949,RMSEC=0.473%;R=0.926,RMSEP=0.585%。

GA是通過模擬生物進化過程搜索最優解的方法。對光譜區間515~870 nm間93個波長點進行二進制編碼,將進化后選擇的波長點進行建模,以RMSEC作為評價標準。在對硬度和維生素C含量編碼過程中分別選取頻率大于10和6的變量建立PLS模型。硬度GA-PLS模型的R=0.830,RMSEC=1.391 kg/cm2;R=0.798,RMSEP=1.405 kg/cm2,維生素C含量GA-PLS模型的R=0.732,RMSEC= 0.944 mg/100g;R=0.704,RMSEP=0.968 mg/100g。

硬度反映了蘋果的質構特性,體現的是組織致密程度,與光的散射特性相關;維生素C因含量低、變化范圍小,光譜響應信號相對較弱;硬度和維生素C的無損檢測是行業內的技術難題,本文研發的檢測系統基本與科研級的光譜儀的檢測性能相當,已優于感官評價的精度,基本可以滿足現場快速無損檢測需求。

2.4 云模型的載入與驗證

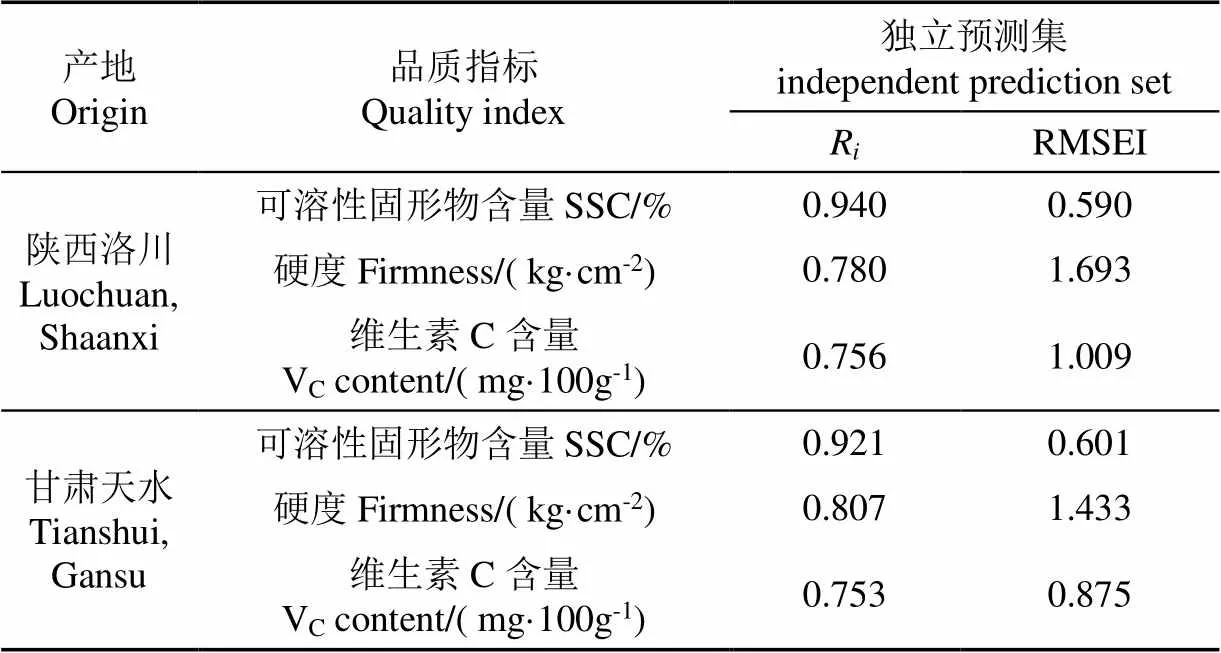

為評價云模型的適用性和穩定性,計算通用檢測模型的多項式系數方程,手動輸入至云端數據系統的模型數據庫中,調用云模型進行了多產地驗證應用。選取2個產地的紅富士蘋果樣本各30個,使用手持式檢測終端獲取其光譜信息,調用云模型進行計算,利用獨立預測相關系數R和獨立預測均方根誤差(Root Mean Square Error of Independent Prediction,RMSEI)評價模型的性能,結果如表4所示。

表4 單一產地通用模型驗證結果

兩個產地可溶性固形物含量、硬度和維生素C含量的獨立預測相關系數R平均值分別為0.931、0.794和0.755,獨立預測均方根誤差平均值分別為0.596%,1.563 kg/cm2和0.942 mg/100g,通用模型在預測單一產地蘋果品質時,由于其他產地品種影響,更多的生物特異性被考慮,預測精度對外部因素的變化并不敏感,使得檢測模型對未知樣本的檢測更加穩健。

2.5 云模型的更新與維護

將建立的蘋果內部品質檢測模型載入云服務器上,研發的蘋果品質手持式可見近紅外無損檢測系統通過光譜采集、數據傳輸、云模型調用、數據存儲、結果反饋和顯示實現檢測。基于原有樣本數據所建立的普適性預測云模型在實際應用中由于新品種、年份或檢測環境的影響會導致預測精度下降,需定期進行模型的維護和更新。添加少量具有代表性的新樣本,形成新的訓練數據集,對云模型的回歸系數進行更新[35-36],從而實現云模型的快速更新,提高云模型的適用性和穩定性。

3 結 論

1)基于可見/近紅外漫反射光譜技術,設計并研制了蘋果品質云模型的手持式可見近紅外無損檢測系統。集成寬譜LED光源和水果特征響應窄帶光電探測器,在滿足現場使用的同時可以實現蘋果的可溶性固形物含量、硬度和維生素C含量等多品質指標同時檢測。

2)以17個產地的蘋果為樣本,使用檢測系統獲取其光譜,經過Savitzky-Golay平滑預處理后使用競爭性自適應重加權采樣算法和遺傳算法分別進行特征波長提取以簡化模型,分別建立多產地蘋果的可溶性固形物含量、硬度和維生素C含量偏最小二乘通用檢測模型可溶性固形物含量競爭性自適應重加權采樣-偏最小二乘模型(Competitive Adaptive Reweighted Algorithm- Partial Least Square, CARS-PLS)預測相關系數R=0.926,預測均方根誤差RMSEP=0.585%。硬度遺傳-偏最小二乘模型(Genetic Algorithm- Partial Least Square, GA-PLS)的預測相關系數R=0.798,預測均方根誤差RMSEP=1.405 kg/cm2,維生素C含量GA-PLS模型的預測相關系數R=0.704,預測均方根誤差RMSEP= 0.968 mg/100g。

3)將通用檢測模型上傳至云服務器作為云模型,采集新樣本光譜數據后調用云模型進行了單一產地的驗證。兩個產地可溶性固形物含量、硬度和維生素C含量的獨立預測相關系數R平均值分別為0.931、0.794和0.755,獨立預測均方根誤差平均值分別為0.596%,1.563 kg/cm2和0.942 mg/100g,可以滿足實際檢測需求。

研究表明,所研發的蘋果品質云模型的手持式可見近紅外無損檢測系統可以實現多產地蘋果的多品質指標的快速無損檢測,可為小型化、低成本的手持式水果品質檢測系統的設計提供參考。進一步將蘋果品質手持式可見近紅外無損檢測系統作為感知終端,動態跟蹤各蘋果產區的果品統計信息,長期監測樹上蘋果如可溶性固形物含量等品質特征的變化規律,形成反饋機制,依據蘋果生長過程變化曲線,指導蘋果種植管理,提高蘋果整體優質率。另外,此系統可用于蘋果產業下游期貨的質量控制和上游育種質量監控,推動蘋果產業智能化發展。本系統的開發和設計同樣適用于其他類球形果蔬,將在進一步研究中進行驗證應用。

[1] Zhang Q, Zhou B, Min-Ji L I, et al. Multivariate analysis between meteorological factor and fruit quality of Fuji apple at different locations in China[J]. Journal of Integrative Agriculture, 2018, 17(6): 1338-1347.

[2] Argenta L C, Amarante C, Betinelli K S, et al. Comparison of fruit attributes of ‘Fuji’ apple strains at harvest and after storage[J]. Scientia Horticulturae, 2020, 272: 109585.

[3] 羅印斌,蔡艷麗,蘭菡,等. 農產品無損檢測方法應用現狀[J]. 食品工業科技,2018,39(15): 340-344.

Luo Yinbin, Cai Yanli, Lan Han, et al. Application status of nondestructive testing methods for agricultural Products[J]. Food Industry Science and Technology, 2018, 39(15): 340-344. (in Chinese with English abstract)

[4] Magwaza L S, Opara U L, Nieuwoudt H, et al. NIR Spectroscopy applications for internal and external quality analysis of citrus fruit-a review[J]. Food and Bioprocess Technology, 2012, 5(2): 425-444.

[5] 郭志明,郭闖,王明明,等. 果蔬品質安全可見近紅外光譜無損檢測研究進展[J]. 食品安全質量檢測學報. 2019,10(24):108-116.

Guo Zhiming, Guo Chuang, Wang Mingming, et al. Research advances in nondestructive detection of fruit and vegetable quality and safety by near infrared spectroscopy[J]. Journal of Food Safety and Quality Testing. 2019, 10(24): 108-116. (in Chinese with English abstract)

[6] 劉燕德,吳明明,孫旭東,等. 黃桃表面缺陷和可溶性固形物光譜同時在線檢測[J]. 農業工程學報,2016,32(6):289-295.

Liu Yande, Wu Mingming, Sun Xudong, et al. Simultaneous detection of surface deficiency and soluble solids content for Amygdalus persica by online visible-near infrared transmittance spectroscopy[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(6): 289-295. (in Chinese with English abstract)

[7] Ma T, Xia Y, Inagaki T, et al. Rapid and nondestructive evaluation of soluble solids content (SSC) and firmness in apple using Vis-NIR spatially resolved spectroscopy[J]. Postharvest Biology and Technology, 2021, 173: 111417.

[8] Nicola B M, Beullens K, Bobelyn E, et al. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review[J]. Postharvest Biology and Technology, 2007, 46(2): 99-118.

[9] Ma C A, Bobelyn E, Lammertyn J, et al. Calibration transfer between NIR diode array and FT-NIR spectrophotometers for measuring the soluble solids contents of apple[J]. Postharvest Biology and Technology, 2007, 45(1): 38-45.

[10] Fan S, Wang Q, Tian X, et al. Non-destructive evaluation of soluble solids content of apples using a developed portable Vis/NIR device[J]. Biosystems Engineering, 2020, 193: 138-148.

[11] Fan S, Zhang B, Li J, et al. Prediction of soluble solids content of apple using the combination of spectra and textural features of hyperspectral reflectance imaging data[J]. Postharvest Biology and Technology, 2016, 121: 51-61

[12] Xia Y, Fan S, Li J, et al. Optimization and comparison of models for prediction of soluble solids content in apple by online Vis/NIR transmission coupled with diameter correction method[J]. Chemometrics and Intelligent Laboratory Systems, 2020, 201: 104017.

[13] Zou X, Zhao J, Li Y. Selection of the efficient wavelength regions in FT-NIR spectroscopy for determination of SSC of ‘Fuji’ apple based on BiPLS and FiPLS models[J]. Vibrational Spectroscopy, 2007, 44(2): 220-227.

[14] Lu L, Zuo W, Wang C, et al. Analysis of the postharvest storage characteristics of the new red-fleshed apple cultivar ‘Meihong’[J]. Food Chemistry, 2021, 354(1): 129470.

[15] Dutot M, Nelson L M, Tyson R C. Predicting the spread of postharvest disease in stored fruit, with application to apples[J]. Postharvest Biology and Technology, 2013, 85: 45-56.

[16] Musacchi S, Serra S. Apple fruit quality: Overview on pre-harvest factors[J]. Scientia Horticulturae, 2018, 234: 409-430.

[17] Peirs A, Tirry J, Verlinden B, et al. Effect of biological variability on the robustness of NIR models for soluble solids content of apples[J]. Postharvest Biology and Technology, 2003, 28(2): 269-280.

[18] Beghi R, Giovenzana V, Civelli R, et al. Setting-up of a simplified handheld optical device for decay detection in fresh-cut Valerianella locusta L[J]. Journal of Food Engineering, 2014, 127(4): 10-15.

[19] Raffaele C, Valentina G, Roberto B, et al. A simplified, light emitting diode (led) based, modular system to be used for the rapid evaluation of fruit and vegetable quality: Development and validation on dye solutions[J]. Sensors, 2015, 15(9): 22705-22723.

[20] Yu X, Lu Q, Gao H, et al. Development of a handheld spectrometer based on a linear variable filter and a complementary metal-oxide-semiconductor detector for measuring the internal quality of fruit[J]. Journal of Near Infrared Spectroscopy, 2016, 24(1): 69-76.

[21] 吳亞壘,祁力鈞,張豪,等. 基于嵌入式互聯網的遠程智能噴霧控制系統設計[J]. 農業工程學報,2018,34(20):28-35.

Wu Yalei, Qi Lijun, Zhang Hao, et al. Design and experiment of remote intelligent spray control system based on embedded internet[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(20): 28-35. (in Chinese with English abstract)

[22] 郭文川,程寒杰,李瑞明,等. 基于無線傳感器網絡的溫室環境信息監測系統[J]. 農業機械學報,2010,41(7):181-185.

Guo Wenchuan, Cheng Hanjie, Li Ruiming, et al. Greenhouse monitoring system based on wireless sensor networks[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(7): 181-185. (in Chinese with English abstract)

[23] 郭志明,陳全勝,張彬,等. 果蔬品質手持式可見近紅外光譜檢測系統設計與試驗[J]. 農業工程學報,2017,33(8):245-250.

Guo Zhiming, Chen Quansheng, Zhang Bin, et al. Design and experiment of handheld near-infrared spectrometer for determination of fruit and vegetable quality[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(8): 245-250. (in Chinese with English abstract)

[24] 徐永浩,宋彪,陳曉帆,等. 微型可見近紅外光譜儀在蘋果糖度測量中的應用研究[J]. 激光技術,2019,43(6):735-740.

Xu Yonghao, Song Biao, Chen Xiaofan, et al. Application of micro near infrared spectrometer in measuring sugar content of apple[J]. Laser Technology, 2019, 43(6): 735-740. (in Chinese with English abstract)

[25] 王偉平,金里. 芯片級硅基光譜儀研究進展[J]. 光譜學與光譜分析,2020,40(2):333-342.

Wang Weiping, Jin Li. Research progress of on-chip spectrometer based on the silicon photonics platform[J]. Spectroscopy and Spectral Analysis, 2020, 40(2): 333-342. (in Chinese with English abstract)

[26] Rittiron R, Narongwongwattana S, Boonprakob U, et al. Rapid and nondestructive detection of watercore and sugar content in Asian pear by near infrared spectroscopy for commercial trade[J]. Journal of Innovative Optical Health Sciences, 2014, 7(6): 1350073.

[27] Zerbini P E, Maristella V, Rizzolo A, et al. Optical properties, ethylene production and softening in mango fruit[J]. Postharvest Biology and Technology, 2015, 101: 58-65.

[28] He X, Fu X, Rao X, et al. Assessing firmness and SSC of pears based on absorption and scattering properties using an automatic integrating sphere system from 400 to 1150 nm[J]. Postharvest Biology and Technology, 2016, 121: 62-70.

[29] 劉燕德,徐海,孫旭東,等. 不同品種蘋果糖度可見近紅外光譜在線檢測通用模型研究[J]. 光譜學與光譜分析,2020,40(3):922-928.

Liu Yande, Xu Hai, Sun Xudong, et al. Development of multi-cultivar universal model for soluble solid content of apple online using near infrared spectroscopy[J]. Spectroscopy and Spectral Analysis, 2020, 40(3): 922-928. (in Chinese with English abstract)

[30] 田敏,白金斌,李江全. 基于遺傳算法的液肥變量施肥控制系統[J]. 農業工程學報,2021,37(17):21-30.

Tian Min, Bai Jinbin, Li Jiangquan. Variable rate fertilization control system for liquid fertilizer based on genetic algorithm[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(17): 21-30. (in Chinese with English abstract)

[31] 廖宜濤,樊玉霞,成芳,等. 連續投影算法在豬肉pH值無損檢測中的應用[J]. 農業工程學報,2010,26(13):379-383.

Liao Yitao, Fan Yuxia, Cheng Fang, et al. Application of successive projections algorithm to nondestructive determination of pork pH value[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(13): 379-383. (in Chinese with English abstract)

[32] Li Q, Huang Y, Song X, et al. Moving window smoothing on the ensemble of competitive adaptive reweighted sampling algorithm[J]. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 2019, 214: 129-38.

[33] Fan S, Li J, Xia Y, et al. Long-term evaluation of soluble solids content of apples with biological variability by using near-infrared spectroscopy and calibration transfer method[J]. Postharvest Biology and Technology, 2019, 151: 79-87.

[34] Jiang H, Xu W, Chen Q. Comparison of algorithms for wavelength variables selection from near-infrared (NIR) spectra for quantitative monitoring of yeast (Saccharomyces cerevisiae) cultivations[J]. Spectrochimica Acta Part A Molecular and Biomolecular Spectroscopy, 2019, 214: 366-371.

[35] Mishra P, Woltering E, Brouwer B, et al. Improving moisture and soluble solids content prediction in pear fruit using near-infrared spectroscopy with variable selection and model updating approach[J]. Postharvest Biology and Technology, 2021, 171: 111348.

[36] 史云穎,李敬巖,褚小立. 多元校正模型傳遞方法的進展與應用[J]. 分析化學,2019,47(4):479-487.

Shi Yunying, Li Jingyan, Chu Xiaoli. Progress and applications of multivariate calibration model transfer methods[J]. Chinese Journal of Analytical Chemistry, 2019, 47(4): 479-487. (in Chinese with English abstract)

Design and experiment of the handheld visible-near infrared nondestructive detecting system for apple quality

Guo Zhiming1, Wang Junyi1, Song Ye2, Yin Xiaoping3, Zou Caixia1, Zou Xiaobo1

(1.,,212013,; 2.,,250220,; 3.,215505,)

Inner quality of fruit has been widely concerned as the impacts of a transition in lifestyles of different consumer segments in recent years. The grading fruits can be used to improve the added value in a fruit industry, according to the internal quality. It is urgent to rapidly detect the internal quality of fruits using non-destructive testing (NDT) grading evaluation. However, the practical application of current NDT technology was restricted seriously, including the low ability of anti-interference in a complex environment, high modeling cost, low model applicability, and complex sensor system. Alternatively, the near-infrared spectrum technology has been by far the most powerful NDT fruit internal quality, due to the easy operation, high precision, and objective condition. But the technology cannot be conducive to the popularization and application in the food, agricultural products processing industry, due to the high cost and energy consumption. Specifically, the spectrometer was integrated for the secondary development, while the light source was the tungsten halogen lamp. A small, low-cost, low-power multi-origin NDT system can be highly required for a broad application prospect in the apple quality evaluation. In this study, a novel portable near-infrared NDT detector was developed to estimate the inner quality of apples using a cloud model. The near-infrared diffuse reflectance spectroscopy was used to integrate the broad spectrum LED light source and fruit characteristic response narrow band photo detector. 14 LED light sources were also symmetrically arranged on a circle, where the luminous intensity was effectively controlled using the current intensity, according to the light intensity for the different types of apple. The detection section was designed with rubber gaskets and shielding rings for better use in the outdoors. The system software was adopted the modular design to import different Apple models, according to the needs of users to achieve multi-use of one machine. A prediction model was loaded onto the cloud server, and then the system transmitted the data to the cloud through built-in 5G/4G and GPS modules. The cloud model was invoked to realize the data storage, result feedback, and display for the detection suitable for the remote sharing and updating of the model. Taking the fruit quality handheld near-infrared NDT system as a sensing terminal, a design scheme was built for the fruit quality Internet of Things (IOT) monitoring platform. Online communication technology was also selected to detect and monitor the fruit quality in real time, providing support for fruit quality control during the intelligent development of the fruit industry. The apples from the 17 producing areas were selected as the research objects, in order to verify the performance of the system. The diffuse reflectance spectra of 500–1 050 nm were obtained by the detection system, and the soluble solids content, hardness, and vitamin C content were determined by the destructive experiments. 529 apple samples were randomly divided into the calibration set and prediction set in a ratio of 3:2. The calibration set was used to establish the model, and the stability of the model was then tested by the prediction set. A Savitzky-Golay (SG) smoothing pretreatment was then used to eliminate the baseline drift and skew for the more stable model. The competitive adaptive re-weighted sampling and genetic algorithm (GA) were also used to extract the characteristic wavelengths, in order to simplify the model for better applicability. The quantitative prediction models were determined for the soluble solid content, firmness, and vitamin C content of apples in different regions. Specifically, the predicted correlation coefficients were 0.926, 0.798, and 0.704, respectively. The predicted root mean square errors were 0.585 %, 1.405 kg/cm2and 0.968 mg/100g, respectively. Consequently, the testing system can be widely expected to realize the rapid nondestructive detecting of apple quality indexes in multiple production areas. This finding can provide a strong reference for the inspection of fruit quality using near-infrared spectroscopy.

nondestructive detection; near infrared spectroscopy; apple quality; cloud model; multi-origins; handheld detecting system

郭志明,王郡藝,宋燁,等.手持式可見近紅外蘋果品質無損檢測系統設計與試驗[J]. 農業工程學報,2021,37(22):271-277.doi:10.11975/j.issn.1002-6819.2021.22.031 http://www.tcsae.org

Guo Zhiming, Wang Junyi, Song Ye, et al. Design and experiment of the handheld visible-near infrared nondestructive detecting system for apple quality[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(22): 271-277. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.22.031 http://www.tcsae.org

2021-07-27

2021-10-24

國家重點研發計劃項目(2017YFC1600802);國家自然科學基金項目(31972151);江蘇省重點研發計劃項目(BE2019359);濟南市“高校20條”資助項目(2020GXRC028)

郭志明,教授,博士生導師,研究方向為農產品品質安全快速無損檢測技術。Email:guozhiming@ujs.edu.cn

10.11975/j.issn.1002-6819.2021.22.031

TP212.9

A

1002-6819(2021)-22-0271-07