Microstructure,optical,and photoluminescence properties of β-Ga2O3 films prepared by pulsed laser deposition under different oxygen partial pressures?

Rui-Rui Cui(崔瑞瑞), Jun Zhang(張俊), Zi-Jiang Luo(羅子江),Xiang Guo(郭祥), Zhao Ding(丁召), and Chao-Yong Deng(鄧朝勇),?

1Power Semiconductor Device Reliability Center of the Ministry of Education,Department of Electronic Science,College of Big Data and Information Engineering,Guizhou University,Guiyang 550025,China

2College of Computer and Information Engineering,Guizhou University of Commerce,Guiyang 550014,China

Keywords: β-Ga2O3,pulsed laser deposition,band gap,photoluminescence

1. Introduction

The transparent semiconductor material of β-Ga2O3,which has wider direct band gap(~4.9 eV),prominent chemical properties and thermal stability, can be used as a required research material in the future ultraviolet, deep ultraviolet optoelectronic devices, and high-frequency and highpower devices, and thus has attracted much attention in recently years.[1–6]The β-Ga2O3thin films have been prepared by molecular beam epitaxy,[7]metal–organic chemical vapor deposition,[8]pulsed laser deposition (PLD),[9]radio frequency(RF)magnetron sputtering,[10]vacuum thermal evaporation,[11]etc. Among these means, the PLD is more helpful in obtaining the high-quality metal oxide films due to its several advantages, such as the good control of the stoichiometry, resulting energetic materials, compatibility with background pressure,and easy control of growth temperature and oxygen pressure during preparation. The materials used as substrates for depositing β-Ga2O3epitaxial thin films include Ga2O3,Al2O3,Si,GaN substrate,etc.[9,12,13]Due to the cheap price and reliable technical indexes of the Al2O3and Si substrate used in many industrial applications, most of the reported β-Ga2O3epitaxial films are heteroepitaxial films.

The quality of β-Ga2O3epitaxial films is the key to semiconductor light-emitting devices and transparent electronic devices. The structure and properties of β-Ga2O3films could be affected by substrate, process and parameters. According to previous reports, some considerable changes in microstructure, optical properties, photoluminescence (PL) properties,etc. for β-Ga2O3films deposited on c-plane sapphire substrate at different oxygen partial pressures by PLD have been studied.[14–18]Wang reported the effect of oxygen pressure on microstructure of β-Ga2O3film prepared by PLD, and obtained the (ˉ201)-oriented epitaxial thin films on c-sapphire substrate.[19]Chen et al.[20]and Lu et al.[21]reported the deposition orientation, UV absorption spectra, and the UV response characteristics of the β-Ga2O3films prepared by PLD.Vu et al. found that the conductance and the energy band gap of β-Ga2O3thin films could be controlled by oxygen partial pressure.[14]Zhang et al. investigated the influence of oxygen pressure on the structural, optical transmission spectra and electrical properties.[22]Tak et al. studied the effect of point defects on the work function of β-Ga2O3film prepared by PLD through controlling the growth pressure.[23]Liu et al. reported the structure and photoluminescence properties of β-Ga2O3thin films prepared by PLD through changing oxygen pressure and analyzed their luminescence origin.[15]However, to date, the systematic researches about the influence of oxygen partial pressure on microstructure, thickness,optical properties, and photoluminescence properties of β-Ga2O3films have rarely been reported. Thus,in this work,we use the PLD to grow the Ga2O3films on Al2O3(0001) substrates under various oxygen partial pressures at 780?C, and systematically investigate the influence of oxygen partial pressure on crystal structure,surface morphology,thickness,optical properties,and photoluminescence properties of β-Ga2O3thin films through x-ray diffraction (XRD), atomic force microscope(AFM),scanning electron microscope(SEM),spectrophotometer, and spectrofluorometer. Meantime, we also discuss the mechanism of photoluminescence of β-Ga2O3thin films.

2. Experiment

Ga2O3films were prepared by a PLD on Al2O3substrates(0001), where a KrF excimer laser source(λ =248 nm)was used. The Ga2O3ceramic target was synthesized by a solidstate reaction method. The Ga2O3films were deposited at 780?C in the PLD system,with a repetition frequency of 3 Hz and the oxygen partial pressure of 10, 1, 0.2, and 0.0004 Pa,respectively. The energy density of the pulsed laser for the deposition was about 3 J/cm2. The Al2O3substrate was placed parallel to and at 45 cm far from the target. The target rotates uniformly during the growth. The films were deposited for about 40 min at different oxygen pressure and then,in-situ annealed for 30 min in a 2000-Pa O2atmosphere.

The crystal structure for each of the films was characterized by x-ray diffractometer with Cu K radiation (D/Max-RA, Rigaku, λ =1.5418 ?A) at a scanning speed of 2?/min in steps of 0.02?. The surface morphologies of the films were recorded by an atomic force microscope (Bruker Multimode 8).The thickness of β-Ga2O3layer was measured by scanning electron microscope(Regulus8100, Hitachi). The UV-visible(UV-Vis) absorption spectra were recorded on a spectrophotometer (U4100, HORIBA). The PL spectra were obtained with a HORIBA FluoroMax-4 spectrofluorometer equipped with a 150-W xenon lamp as an excitation source. All the measurements were carried out at room temperature.

3. Results and discussion

Figure 1 shows the XRD patterns of the Ga2O3films deposited on Al2O3(0001) substrates with oxygen partial pressure (p(O2)=10, 1, 0.2, and 0.0004 Pa) at 780?C. As can be seen, besides the diffraction peak of the Al2O3substrate(0006), the diffraction peaks at about 18.8?, 38.2?, and 59.2?can be observed clearly in each of all the films,which can be assigned to the (ˉ201), (ˉ402), and (ˉ603) lattice planes of the monoclinic β-Ga2O3(JCPDS file No.41-1103),respectively,demonstrating the polycrystalline nature of the films. When the films are deposited at the oxygen partial pressures of 10 Pa and 1 Pa, besides the aforementioned diffraction peaks, the(400), (ˉ601), and (ˉ801) lattice planes of β-Ga2O3located at about 30.2?,44.3?,and 59.8?are observed. And with the decreasing of oxygen partial pressure,the(400),(ˉ601),and(ˉ801)lattice plane disappear, and a single oriented β-Ga2O3film grown parallel to its (ˉ201) crystal plane is formed on the csapphire substrate at a relatively low oxygen partial pressure.Moreover,the intensities of the main diffraction peaks first increase and then decrease, indicating that the best crystallization of the film can be obtained under an oxygen pressure of 0.2 Pa.

Fig.1. XRD patterns of Ga2O3 films deposited on Al2O3 substrates(0001)under different oxygen partial pressures.

Fig.2. Crystal structure of β-Ga2O3.

The crystal structure of β-Ga2O3is given in Fig.2. The β-Ga2O3crystallizes into monoclinic structure,and its cell parameters are as follows: a=12.23 ?A,b=3.04 ?A,c=5.80 ?A,α=γ=90?,and β=103.8?,and the space group isC2/m.[24]It can be observed in Fig.2 that Ga atom occupies two lattice sites:[Ga1]that has tetrahedrally coordination,and[Ga2]that has octahedral coordination. There are three O sites in the structure: three-fold coordinated O1, three-fold coordinated O2,and four-fold coordinated O3 sites. Thus,β-Ga2O3crystal cell is composed of two GaO4tetrahedra and two edgesharing GaO6octahedra.[21]The(400)crystal plane is on the upper surface of the β-Ga2O3cell,and the(ˉ402)crystal plane is an oblique plane composed of O or Ga atoms of an octahedral in vitro triangle. Moreover,the(ˉ201)crystal plane is parallel to the(ˉ402)and their atomic arrangements are the same.As is well known,the larger the dangling bond density on the surface of a crystal plane, the greater the attraction to the reaction atoms is, so that the reaction atomic energy with less migration energy migrates to the crystal plane surface; similarly, if the dangling bond density on a crystal plane surface is smaller,the force to attract the reaction atoms is weak,and only the atoms with larger migration energy can migrate to the surface of that type of crystal plane. Chen et al. have pointed out that the surface of(400)crystal plane of β-Ga2O3has a higher density of suspended bonds than that of surface(ˉ201),thus,the(400)crystal plane of β-Ga2O3is more attractive to Ga and O atoms and requires less energy for the migration of reactive atoms.[20]Therefore, the (400) and (ˉ201)orientation of β-Ga2O3can be obtained under high oxygen pressure under which the migration energy of reactive atoms is lower. Meantime, some Ga atoms or O atoms do not even have enough energy to migrate to the surface of (400) crystal plane of β-Ga2O3, and these reaction atoms can migrate to other crystal planes which are less attractive to the reaction atoms as (ˉ601) and (ˉ801) lattice planes of β-Ga2O3are under 1-Pa and 10-Pa oxygen pressure conditions,which shows multi-orientation growth. However,when the oxygen pressure is 10 Pa, all the diffraction peaks intensities are weak due to the very low migration energy of reactive atoms. The lower the oxygen pressure,the higher the migration energy of the reaction atoms is and the more the (ˉ201)-direction β-Ga2O3is deposited. As shown in Fig.1,when the oxygen partial pressure is at 0.0004 Pa and 0.2 Pa,the high-quality(ˉ201)-oriented epitaxial β-Ga2O3films can be successfully grown on the csapphire substrates.

According to Fig.1, the full width at half maximum(FWHM) values of (ˉ201) diffraction peak at oxygen partial pressure of 10, 1, 0.2, and 0.0004 Pa are 0.470?, 0.314?,0.251?,and 0.251?,respectively. According to Scherrer’s formula, the average grain size of β-Ga2O3films can be estimated from the following equation:

where D, λ, β, and θ are the average grain size, the wavelength of x rays, the half-peak width of the diffraction peak,and the diffraction angle of Bragg diffraction when tested for 2θ, respectively. The values of D are calculated as indicated in Table 1. As can be seen, with the decreasing of oxygen pressure,the average grain size of β-Ga2O3films increases.

Table 1. Average crystallite size(D in unit nm)calculated from x-ray diffraction patterns and RMS roughness of β-Ga2O3 films deposited under different oxygen pressures.

Figures 3(a)–3(d) show the surface morphologies and cross-sectional images of β-Ga2O3films grown at the oxygen pressure of 10, 1, 0.2, 0.0004 Pa, respectively. The root mean square(RMS)values of roughness are also given in Table 1. The scan range is 2 μm ×2 μm. It can be seen that the island-like structures appear in all samples, and the surfaces of all films are uniform. In addition, the surface morphology is dependent on the oxygen partial pressure during growth. With the decrease of oxygen partial pressure, the grain size increases, which is consistent with the calculation result of XRD. The particle sizes of the film grown at the oxygen pressure of 10 Pa are much smaller. When the oxygen partial pressure reaches to 0.2 Pa, both large and small particles are randomly present in the film. When the oxygen partial pressure reaches to 0.0004 Pa, no obvious change in grain size is found, which is consistent with the XRD results. As is well known, when the oxygen pressure is high,the plasma produced by laser irradiation will collide with the oxygen molecules in the cavity many times during the transport in space and will lose some of its energy,thus,the migration energy of the surface adsorption atoms decreases. The adsorption atoms can nucleate on the substrate surface,but many adsorption atoms cannot be combined with each other, that is, only the adsorption atoms near the nucleus can be transferred to the nucleus and contribute to the crystallization, so the particle size is smaller. When the oxygen partial pressure decreases, the collision between laser plasma and oxygen molecules is bound to decrease,which reduces the energy loss of particles,thus facilitating the diffusion on the substrate surface. In addition,substrate heating also provides the necessary energy for atoms diffusion. Therefore,the mobility of the adsorbed atoms increases, more adsorbed atoms move to the nucleus,and the nearby structure begins to bind,leading to the grain size to increase. In addition,the maximum of the RMS roughness is 2.83 nm,indicating that the surfaces of obtained films are smooth.

The cross-section of the β-Ga2O3films grown at different oxygen pressures are shown in the insets of Fig.3, respectively. When the oxygen partial pressure increases from 0.0004 Pa to 1 Pa, the thickness values of the β-Ga2O3films increase from 90 nm to 202 nm. But when the oxygen pressure continues to increase to 10 Pa, the thickness values of the β-Ga2O3films decrease to 152 nm. This may be due to the fact that when the oxygen partial pressure continues to increase, the decrease of the migration energy of reactive Ga and O atoms can reduce the thickness of the β-Ga2O3films.As can be seen from the XRD results,when the oxygen partial pressure increases from 0.0004 Pa to 1 Pa,the β-Ga2O3films grown mainly parallel to(ˉ201)orientations. And the increase of oxygen pressure leads oxygen to be enriched on the substrate surface. Meantime,the O-rich condition is beneficial to the growth of(ˉ201)β-Ga2O3.[20]The effect of increasing oxygen pressure on the increase in thickness of the β-Ga2O3film exceeds the effect of the decrease of the thickness induced by reducing the migration energy of reactive atoms,thereby leading the thickness values of the β-Ga2O3films to increase.

Fig.3. AFM images of β-Ga2O3 films deposited under different oxygen pressures,with insets showing SEM cross-sectional images.

The room-temperature UV-Vis absorption spectra of β-Ga2O3films deposited at various oxygen partial pressures at 780?C are shown in Fig.4(a). An absorption edge of β-Ga2O3film is observed at about 275 nm when the oxygen pressure is 10 Pa. While the absorption band edge moves toward the shorter wavelength direction with the decreasing of oxygen pressure. When the oxygen partial pressure decreases to 0.0004 Pa, the absorption band edge decreases to 269 nm. As is well known, the Ga2O3has been proved to be a direct band gap material, the optical band gap (Eg) can be evaluated according to the relationship: (αhν)2∝(hν ?Eg),where hν is the incident photon energy, α is the absorbance coefficient.[25,26]The Egof β-Ga2O3film is obtained by extrapolating the linear portion of the plot of(αhν)2versus energy(hν)as demonstrated in Fig.4(b). The inset of Fig.4(b)shows the dependence of bandgap of β-Ga2O3films on oxygen partial pressure. As can be seen, the bandgap of the β-Ga2O3film increases from 4.76 eV to 4.91 eV with the oxygen partial pressure decreasing. The films exhibit shorter absorption edge of about 4.88 eV and 4.91 eV at lower oxygen partial pressure of 0.2 Pa and 0.0004 Pa, respectively. The result is consistent with the literature data.[14,27]Similarly,it is reported that the direct band gap of ITO film is blueshifted with the decrease of oxygen partial pressure,which is due to the carrier concentration decreasing by Burstein–Moss displacement.[28]In addition, the band gap of the film grown at 0.2 Pa is 4.88 eV,which is consistent with the reported result for Ga2O3bulk(~4.9 eV).[29,30]

Fig.4. (a)UV-Vis absorption spectra of β-Ga2O3 films deposited under different oxygen partial pressures,and(b)band gap calculation plot of β-Ga2O3 films,with inset showing dependence of bandgap on oxygen partial pressure.

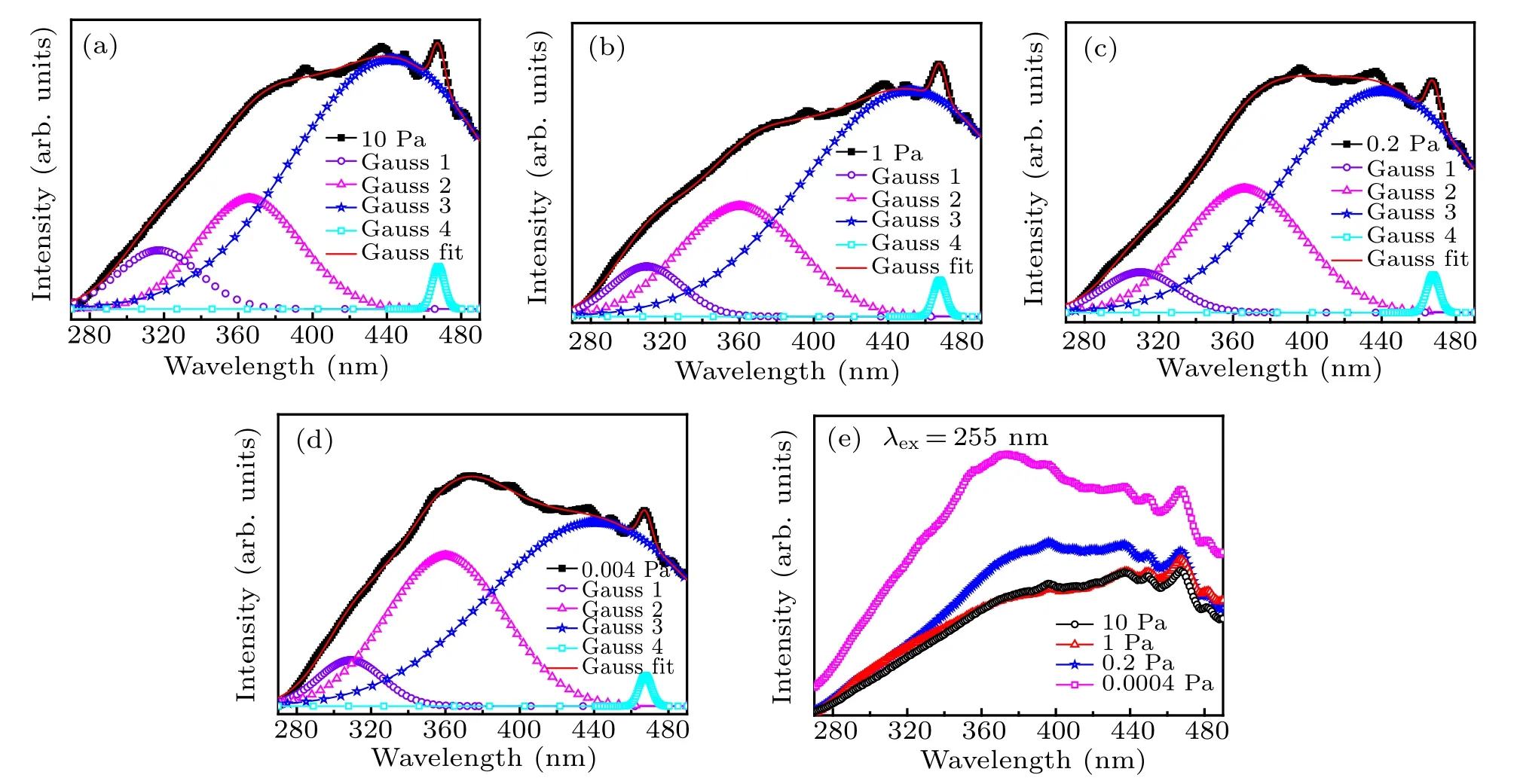

Fig.5. (a)–(d) Gaussian fitting peaks of PL spectra of β-Ga2O3 films grown under 10, 1, 0.2, and 0.0004 Pa, respectively, and (e) room temperature PL spectra of β-Ga2O3 films.

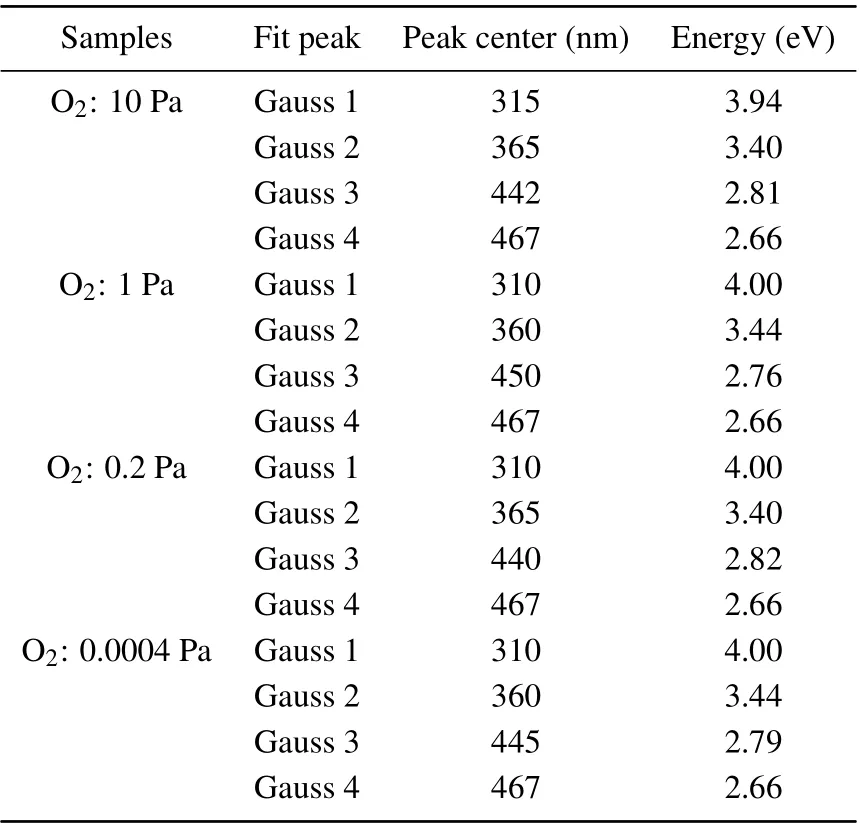

Table 2. Detailed peak fitting data of PL.

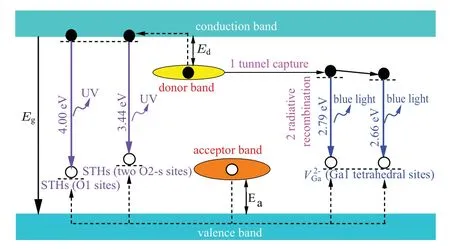

Fig.6. Mechanism model of PL of β-Ga2O3 film in UV and blue regions.

4. Conclusions

In this work, the effect of oxygen partial pressure on the microstructures,thickness,optical properties,and photoluminescence properties of β-Ga2O3films deposited on Al2O3substrate(0001)by PLD are investigated. The XRD and AFM results show that the film deposited at an oxygen pressure of 0.2 Pa has the best crystallinity and surface morphology. With the decrease of oxygen pressure,the bandgap of the β-Ga2O3films increases from 4.76 eV to 4.91 eV. The photoluminescence spectra contain a strong, broad, and asymmetric emission band from 270 nm to 490 nm located in the UV and blue light region and can be divided into four Gaussian fitting peaks. The UV and blue bands are related to STHs at O1 sites and between two O2-s sites, and V2?Gaat Ga1 tetrahedral sites.

Acknowledgment

We would like to thank Dr. Kaixin Guo and Guobin Ma for the test of Ga2O3films.

- Chinese Physics B的其它文章

- Statistical potentials for 3D structure evaluation:From proteins to RNAs?

- Identification of denatured and normal biological tissues based on compressed sensing and refined composite multi-scale fuzzy entropy during high intensity focused ultrasound treatment?

- Folding nucleus and unfolding dynamics of protein 2GB1?

- Quantitative coherence analysis of dual phase grating x-ray interferometry with source grating?

- An electromagnetic view of relay time in propagation of neural signals?

- Negative photoconductivity in low-dimensional materials?