Dielectrowetting actuation of droplet: Theory and experimental validation?

Yayan Huang(黃亞儼) Rui Zhao(趙瑞) Zhongcheng Liang(梁忠誠)Yue Zhang(張月) Meimei Kong(孔梅梅) and Tao Chen(陳陶)

1The Microfluidic Optical Technology Research Center,School of Electronic and Optical Engineering,Nanjing University of Posts and Telecommunications,Nanjing 210023,China

2Beijing Institute of Space Mechanics&Electricity,Beijing 100094,China

Keywords: dielectrowetting,contact angle,height,COMSOL,droplet

1. Introduction

Microfluidic controlling technology plays a critical role in micro-total analysis systems or lab-on-a-chip systems.[1–3]The controllable adjustment of the microfluidic can be realized by various methods, including thermal,[4]mechanical force,[5]dielectrowetting,[6–8]electrowetting,[9–19]and so on.Electrowetting technology has been found numerous potential applications in prism,[11,12]liquid lens,[13]displays,[14]labon-a-chip,[15]and light valve.[16]However, it still has some limitations,such as demand of conducting fluid,contact angle saturation and electrolysis, which affects its application and development.[20,21]

Unlike electrowetting, dielectrowetting is a technology that applies a non-uniform electric field to control the wettability of a non-conductive liquid, which avoids electrolysis,joule heating,microbubbles,etc.[22]Benefiting from the above advantages,dielectrowetting technology receives extensive attention and research in recent years. In 2006, Chenget al.demonstrated a miniature droplet lens depending on dielectrowetting effects,whose focal length ranged from 1.6 mm to 2.6 mm in 220 ms.[23]In 2010, Tsai and Yeh proposed a liquid iris diaphragm by using dielectric force, whose aperture could vary from 4 mm to 1.5 mm at 160 V·rms.[24]In 2011,McHaleet al.put forward how dielectrowetting reduce the contact angle of a droplet by interdigital electrode.[25]In 2017,Genget al.reported four droplet operations (creating, transporting, splitting, and merging of droplets) by aid of dielectrowetting technology.[6]In 2018,Kimet al.presented a novel light steering device operated by dielectrowetting actuation for diverse optical applications.[26]In 2021, Lianget al.developed a dielectrowetting-based optofluidic phase modulator by wheel spoke coplanar-electrode, its optical phase modulation can reach 9.366πwhen the voltage reached 150 V.[27]These works provided references and guides for dielectrowettingbased devices design, however, the contracting feature of the droplets actuated by dielectrowetting and the mechanisms involved remain obscure.

In this paper, we analyze the wettability property of an insulating droplet under the action of dielectric effect generated by the wheel spoke coplanar-electrode. Based on energy conversation,a theoretical model is constructed to predict the transient contact angle and the height of the droplet at different voltages. In the meantime, the evolution of the droplet contracting is simulated by COMSOL, and a measurement platform is established to monitor the change process of the droplet profile. Series of experiments are carried out to verify the prediction of theory and the simulation of COMSOL.

2. Theoretical analysis

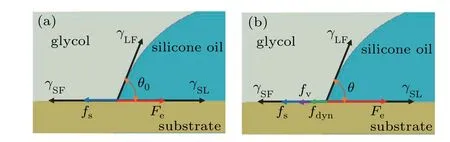

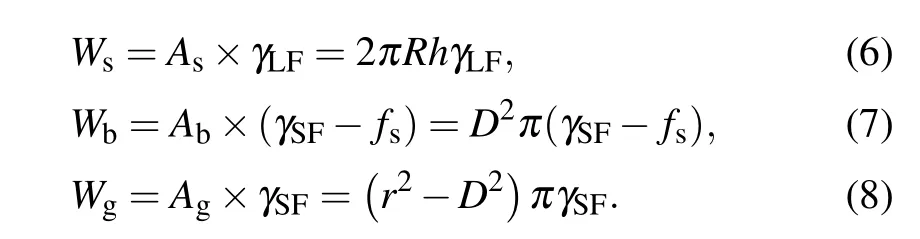

Figure 1 describes the force balance of silicone oil droplet surrounded by glycol near three-phase contact line during dielectrowetting evolution, whereγLF,γSF, andγSFare the surface tensions at the silicone oil/glycol interface, silicone oil/substrate interface, and glycol/substrate interface respectively;θis the equilibrium contact angle,fsis the pinning force,Feis the dielectric field force of an electrically neutral object in an uneven electric field,[25]fvis the viscous friction force,fdynis the dynamic friction force. When the dielectric field forceFeis not stronger enough to against the pinning force,[28,29]the droplet remains stationary,i.e., it is in static state. Hence the apparent contact angle remains unchanged as shown in Fig.1(a). Once the electric field forceFeexceeds the maximum pinning frictionfs,the droplet begins to move,and the apparent contact angle begins to increase and eventually evolves into the moving state as shown in Fig.1(b). Here the transition from the static state to the moving state depends on the dielectric field forceFe,i.e.,the threshold voltageUth.

Fig.1. Sketch of force balance at three-phase line in dielectrowetting evolution: (a)in static state and(b)in moving state.

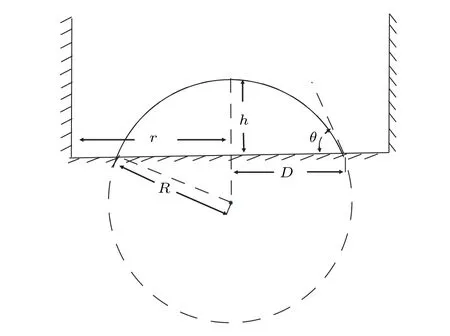

Fig.2. Diagram of silicone oil droplet with radius R and contact angle θ.

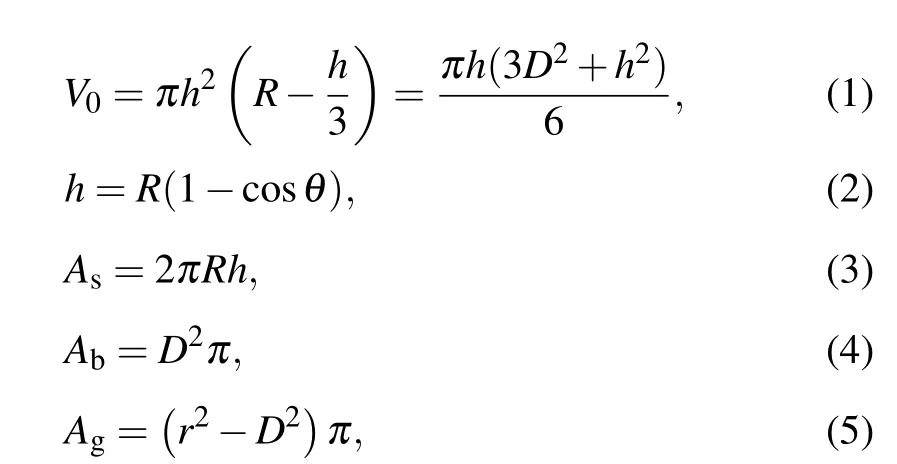

The droplet illustrated in Fig. 2 is assumed to remain spherical during the dielectrowetting evolution. According to the calculation formulas of the volume and area for the spherical cap,the following relationships can be achieved:

whereV0is the volume of silicone oil droplet,θis the contact angle,his the height of the droplet,Ris the spherical radius of the droplet,Dis the contact radius among substrate and droplet,ris the radius of the cavity,Asis the interface area of the silicone oil/glycol,Abis the interface area of the substrate/silicone oil, andAgis the interface area of the substrate/glycol.

In the static state, the silicone oil/glycol surface tension energy(Ws),silicone oil/substrate surface tension energy(Wb),and glycol/substrate surface tension energy (Wg) can be respectively given as follows:

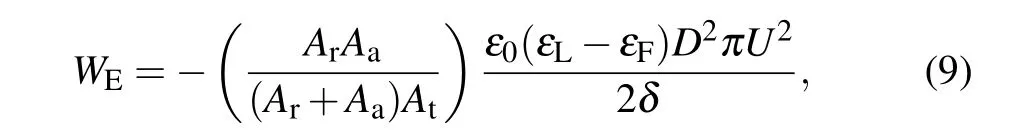

Since the distribution of the dielectric field force depends on electrode structure,electrode polarity,and the interface area between electrode and droplet,the dielectric energyWEgenerated by electric field can be represented as[30,31]

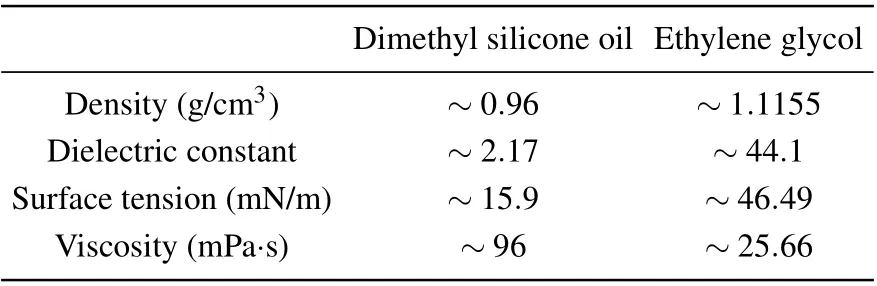

whereδis penetration depth of electric field,εL,εF, andε0are the relative permittivities of the silicone oil,glycol,and the dielectric constant in a vacuum respectively;Aa,Ar,andAtdenote cover area of the droplet above the driving electrode,the reference electrode,and the entire electrode respectively. The electrode structure designed in this work is the wheel spoke coplanar–electrode structure as shown in Fig.3(b).

The total interfacial potential energyWTcan be written as the sum ofWs,Wb,Wg,andWE,

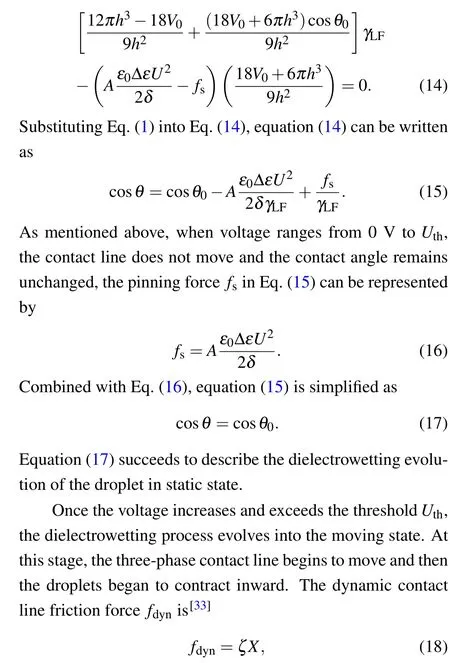

The dielectrowetting system satisfies the law of energy conservation once the droplet reaches equilibrium,hence one can have dWT/dh=0,and

whereζis the coefficient of contact line friction,andXis the moving velocity of contact line.

The viscous friction forcefvis linear with the velocity of droplet[34,35]

hereμis the viscosity of silicone oil droplet.

The relationship between moving velocity of the contact lineXin Eq.(18)and voltageUis given as follows:[36,37]

whereK=k1(6μ+ζ)is determined by fitting the equation to the experimental data at the point of threshold potential.

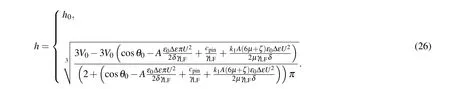

Substituting Eq.(25)into Eq.(2),the height of droplet is achieved as follows:

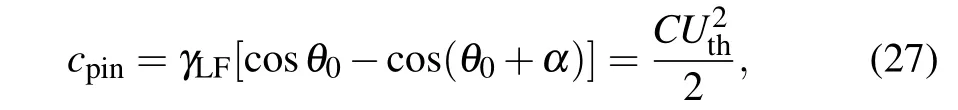

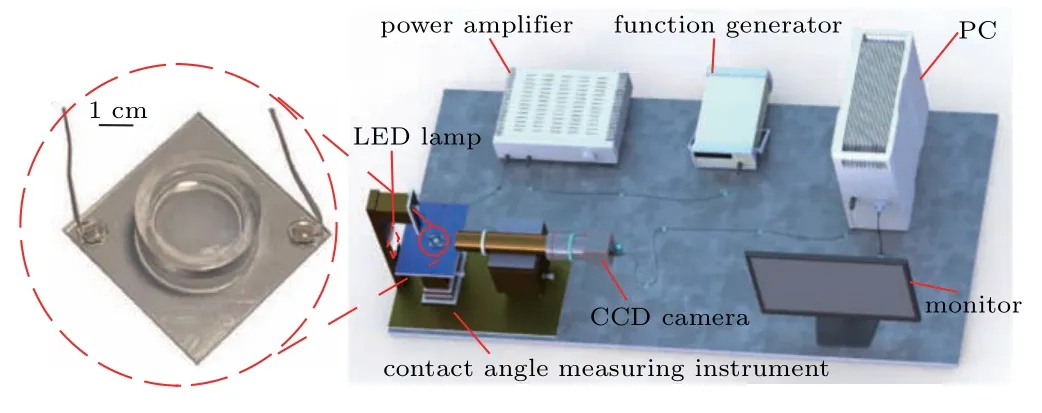

The threshold voltagesUthin Eqs. (25) and (26) can be calculated theoretically with the aid of Eqs. (27) and (28) listed below.

WhenU=Uth, the dielectrowetting forceFeis greater than the maximum pinning forcecpin,[38]which triggers the droplet to contract inward. Consequently

whereαis the difference between advancing angle and receding angle. Rearranging Eq.(27),the threshold potentialUthis written as

3. Experimental procedure

In Fig.3,a 70-μL silicone oil droplet(Dow Corning 200 series)is deposited in the center of the substrate by a syringe pipette,which is placed in a clear acrylic cavity and immersed in an immiscible glycol liquid. The coplanar-electrode is designed as shown in Fig.3(b), the corresponding radius of the two concentric circles is 5 mm and 15 mm respectively. The planar ITO electrode is coated with about 5-μm SU8 as a dielectric layer, and then about 400-nm hydrophobic layer. To keep the silicone oil droplet fixed in the center of the substrate,the fluoropel is only coated on the central area(~20 mm in diameter).The relative parameters of liquids are listed in Table 1(room temperature 20°C).[39]

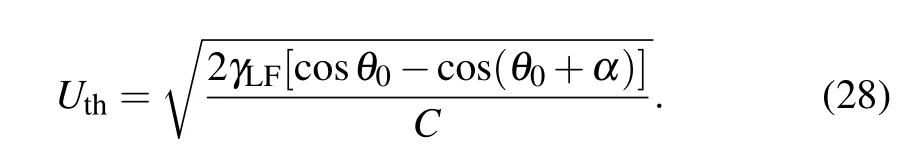

Table 1. Parameters of liquid medium.

Fig. 3. Diagram and principle of dielectrowetting: (a) cross-section view;(b)wheel spoke coplanar–electrode structure(top view);(c)initial state;(d)contracting state.

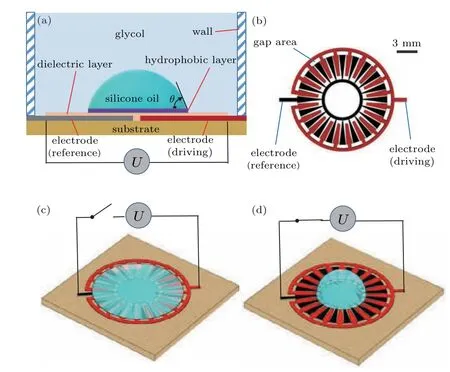

Fig.4. Schematic diagram of measurement system.

Since the density of the two liquids is similar, the interface of the two liquids is assumed to be spherical. Here the working voltage is a sinusoidal AC signal with a frequency of 500 Hz. When the working voltage is bigger enough,the contact angle of the droplet increases and the shape of the droplet changes, which is corresponding to the contracting process from Fig. 3(c) to Fig. 3(d). The change of contact angle and the height of the droplet is monitored and measured with drop shape analysis systems (SCI3000F, shown in Fig. 4), which are repeated 3 times at fresh sample locations.

4. Results and discussion

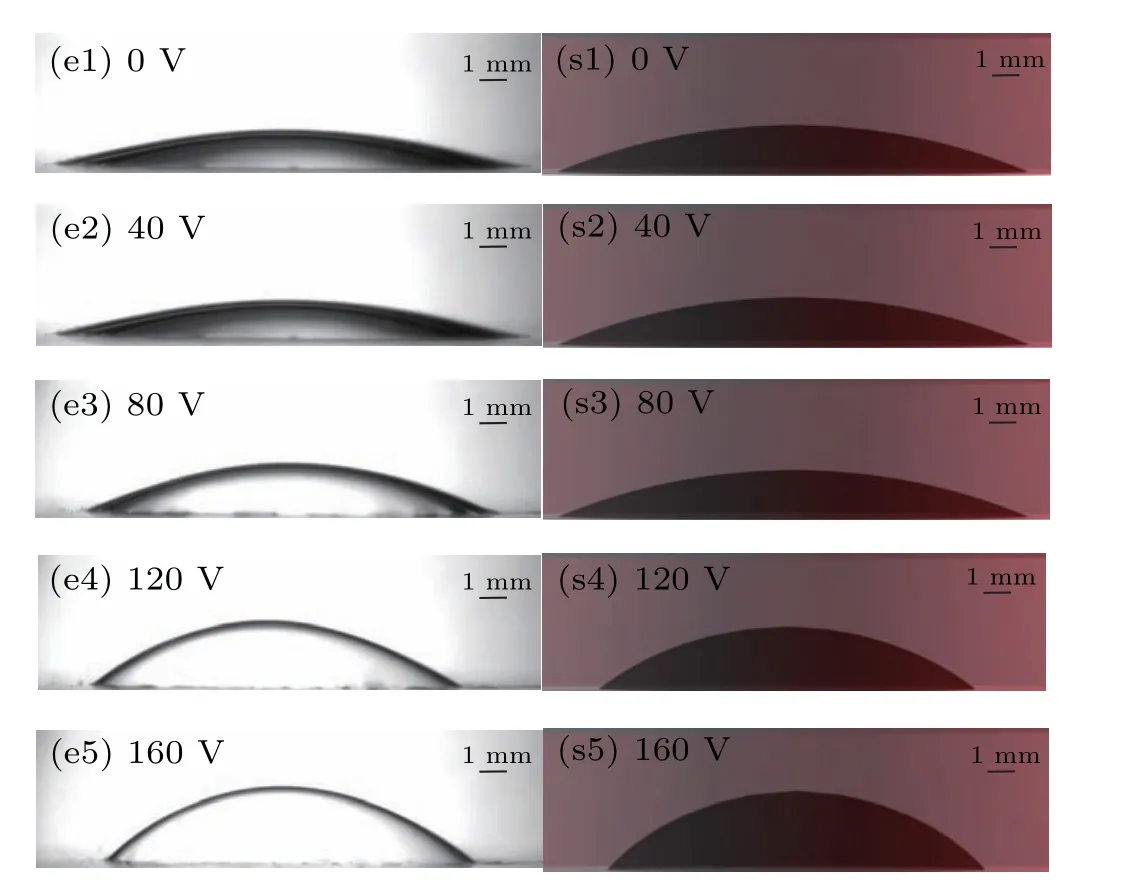

Figures 5(e1)–5(e5)provides the changing profile of silicone oil droplet captured at 0 V, 40 V, 80 V, 120 V, 160 V respectively. When the voltage is in the range of 0 V–55 V,no obvious change in droplet profile. This stage is called the static state,and 55 V is defined as the voltage threshold.When the voltage increases up to 55 V,the droplet starts to contract inward and then evolves into the in moving state. Continuing increasing of voltage,visible change of contact angle and height of the silicone oil droplet can be seen in Figs. 5(e3)–5(e5) corresponding toU=80 V, 120 V, 160 V respectively.When the voltage is 160 V, the contact angle of silicone oil droplet is 48°and the relevant stable height is 2.03 mm.

Fig.5. The droplet profile changing during driven procedure: (e1)–(e5)captured by CCD camera,(s1)–(s5)simulated by COMSOL.

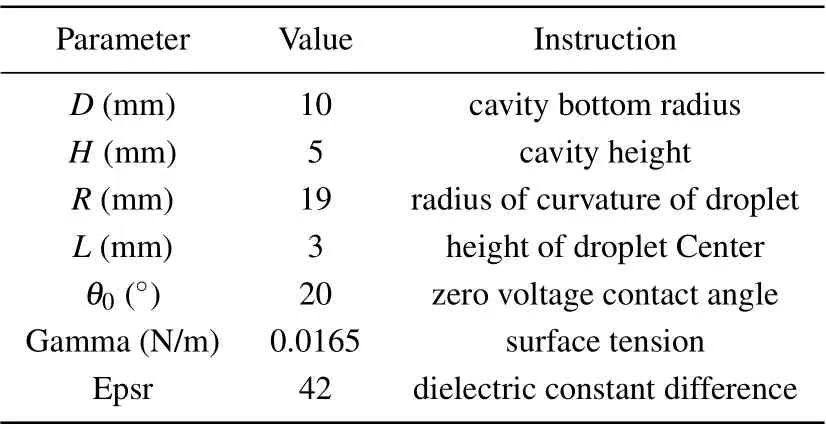

The contracting model based on Eq. (25) is constructed in COMSOL Multiphysics 5.4(a),and the relative parameters are provided in Table 2. The simulated profiles of droplet at different voltages are shown in Fig. 5(s1)–5(s5). Comparing the simulations with experiments, finally we get the simulation results that coincide with the experimental results.

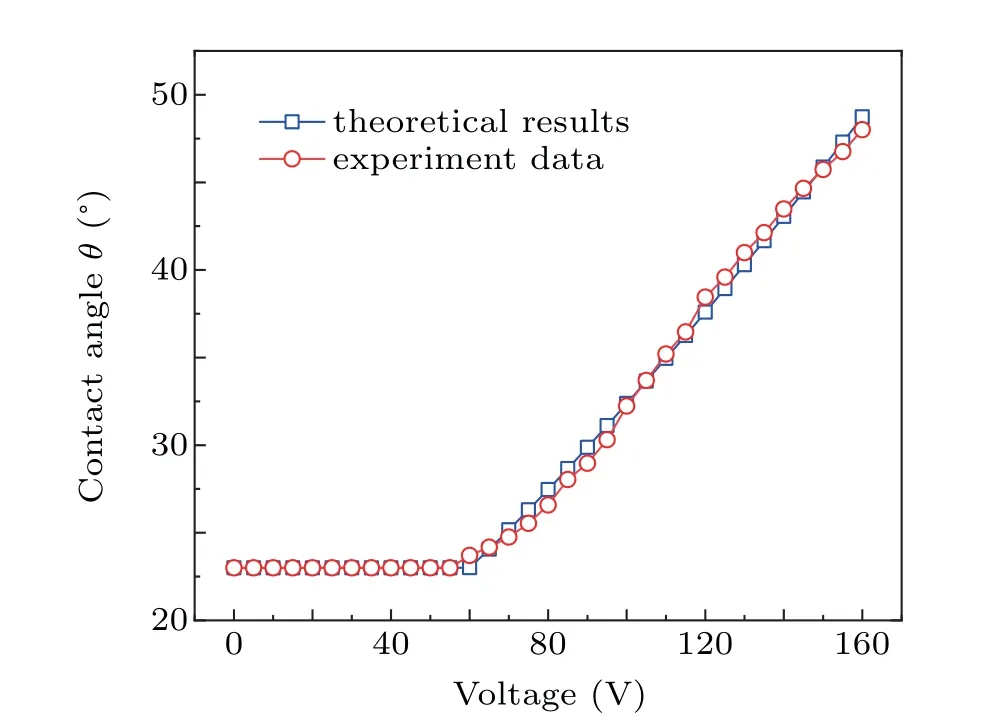

The contact angle is plotted as line with hollow circle(○)in Fig. 6. The line with hollow square (□) in Fig. 6 is the theoretical values predicted by Eq. (25), which shows good consistence with our experimental results. When the voltage is smaller than 55 V, the droplet remains stationary and consequently the contact angle is constant. When the voltage reaches 55 V,the droplet begins to contract inward. When the voltage ranges from 55 V to 160 V,the corresponding transient contact angle increase linearly from 23°to 48°.

SubstitutingγLF=16.5 mN/m,δ=66μm,ε0=8.85×10?12,?ε=42,θ0=23°,α=28°into Eq.(28),the theoretical threshold potentialUth=57 V is achieved,which is almost close to the experimental threshold value 55 V.

Table 2. Parameters of simulation model parameters.

Fig.6. Comparison of contact angle versus voltage among experimental data and theoretical results.

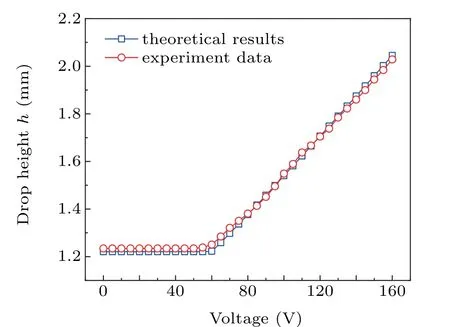

Fig.7. The height of the droplet versus voltage.

Figure 7 illustrates the variation of stable height of the droplet at different voltage. The line with hollow circle(○)represents the experimental data while the line with hollow square (□) denotes the theoretical values predicted by Eq.(26). There is no obvious change in height when voltage is smaller than 55 V. When the voltage increases from 55 V to 160 V, the height of the droplet increases from 1.23 mm to 2.03 mm,and the maximum height variation approaches to 0.8 mm. Our theoretical curve succeeds to predict the change of the height, which shows good agreement with the related experimental results.

5. Conclusion

The focus of this work is to study the dielectrowetting property of silicone oil droplet under the action of dielectric effect.A theoretical model based on energy conversation is established to predict the transient contact angle and the height of the droplet at different voltages. In the meantime, the dielectrowetting evolution of the droplet profile is simulated by COMSOL.Series of experiments are carried out to verify the prediction of theory and the simulation of COMSOL. As for the dielectrowetting process,it experiences two states,i.e.,the static state and the moving state. When the voltage is smaller than 55 V,the droplet remains stationary,i.e.,it is in the static state; when the voltage increases above 55 V, the droplet begins to contract,i.e., it is in the moving state. The contact angle of the droplet increases linearly from 23°to 48°, and the relative height of the droplet changes from 1.23 mm and 2.03 mm when voltageUranges from 55 V to 160 V.

- Chinese Physics B的其它文章

- Physical properties of relativistic electron beam during long-range propagation in space plasma environment?

- Heterogeneous traffic flow modeling with drivers’timid and aggressive characteristics?

- Optimized monogamy and polygamy inequalities for multipartite qubit entanglement?

- CO2 emission control in new CM car-following model with feedback control of the optimal estimation of velocity difference under V2X environment?

- Non-peripherally octaalkyl-substituted nickel phthalocyanines used as non-dopant hole transport materials in perovskite solar cells?

- Dual mechanisms of Bcl-2 regulation in IP3-receptor-mediated Ca2+release: A computational study?