Axial Compression Properties of 3D Woven Special-Shaped Square Tubular Composites with Basalt Filament Yarns

ZHANG Huawei(張華偉), WANG Jingjing(王晶晶), Lü Lihua(呂麗華)

School of Textile and Material Engineering, Dalian Polytechnic University, Dalian 116034, China

Abstract: In order to avoid the delamination of traditional laminated tubular composites, on an ordinary loom, the 3D woven special-shaped square tubular fabrics were woven with environment-friendly basalt filament yarns, and then the 3D woven special-shaped square tubular composites were prepared with epoxy resin by a vacuum-assisted resin transfer molding(VARTM) process. Through experiments and software fitting, the axial compression properties of composites were analyzed. The polynomial fitting formulas of load-displacement curve and energy-displacement curve were obtained by using least square methods. The results showed that the 3D woven special-shaped square tubular composites had good axial compression performance, and with the increase of the composite thickness, compressive strength and energy absorption increased significantly. The failure mode was analyzed in the paper, thus revealing the failure stress propagation, local stress concentration, and failure morphology. It provides an effective reference for the design and application of the 3D woven special-shaped square tubular composite.

Key words: 3D woven fabric; square tubular composite; compression property; failure mode; polynomial fitting

Introduction

With the sustained and rapid development of economy and technology, the transportation industry has become increasingly diversified. In addition to traditional roads, railways, waterways and aviation, the pipeline transportation industry attracts increasing attention. The tubular composites are regarded as one of the most important lightweight materials in the pipeline transportation industry. Tubular composite is composed of a tubular fabric as reinforcement and resin as matrix[1]. According to the low interlaminar strength, easy delamination and poor integrity of the ordinary laminated tubular composites, the 3D tubular composites which are composed of 3D tubular fabrics as reinforcement and resin as matrix emerge. The 3D tubular composite is a kind of structural original with reasonable stress form, which has the characteristics of light weight, high specific strength, excellent fatigue resistance and good corrosion resistance. Its application is mainly concentrated in pipeline transportation, aerospace, biomedical engineering and automotive industry[2-4]. However, the 3D circular tubular composite cannot fully meet the actual needs in a specific environment such as nickel base alloy special-shaped tube[5], special-shaped tube truss[6], and special-shaped tube sheet heat exchanger[7]. Moreover, the square structure of the material with flat surface is easier to assemble with other parts[8-9]. The 3D woven special-shaped tubular composites have more advantages in practical application, and their development has a very important practical significance.

The 3D tubular composites can be divided into three categories: 3D braided tubular composites, 3D knitted tubular composites and 3D woven tubular composites[10-11]. The 3D braided tubular composites have been studied for the longest time. Cao and Chen[12]successfully prepared 3D four-direction and 3D five-direction braided tubular composites with glass fiber and epoxy resin. The 3D braided tubular composites have unstable mechanical properties and limited sample size, so their application is greatly limited. The 3D knitted tubular composites have advantages in the preparation of special shape structural parts. Zhang and Long[13]exhaustively presented the structure design and knitting technique of a sandwich fabric and a 3D shaped knitted fabric respectively on a computerized flat knitting machine. The preparation of 3D knitted tubular composites needs special equipment, and its unique loop structure cannot maintain the stability of the material, which greatly damages the mechanical properties of the composites. Then, the 3D woven tubular composites have the characteristics of strong designability, high interlaminar strength, low material loss and high mechanization potential. Guoetal.[14]applied the technologies of jacquard looms and dobby shedding looms to circular looms, and then used mold to control the cross-section shape of fabrics. The whole variable cross-section tubular preform was woven. The application of 3D woven tubular composites is limited because they need special looms. Based on this, researchers have carried out a lot of exploration on the weaving technology of tubular composite preforms. Yietal.[15]completed the structure and process design of three kinds of 3D woven tubular preforms by the theory of flattening-weaving-unfurling. Huang[16-17]designed and prepared ordinars tubular fabrics, warp multi-tubular fabrics, weft multi-tubular fabrics and crossed tubular fabrics by the theory of flattening-weaving-unfurling. The theory of flattening-weaving-unfurling has greatly promoted the weaving technology of the 3D woven tubular fabrics on ordinary looms, and provided a reference for low-cost preparation of the 3D woven tubular fabrics. On the basis of this technology, researchers conduct more in-depth mechanical researches on woven tubular composites. Zhangetal.[18]prepared a new type of 3D woven tubular composites and studied axial compression properties. The results showed that the choice of winding yarns was very important to improve the axial compression strength. Zhang and Tan[19]investigated the dynamic impact response of the woven tubular composite structures under transverse low-velocity impact and compression after impact test. Hajjarietal.[20]prepared the woven tubular composites of various sizes with glass fiber and epoxy resin. The compression performance of the tubular composites was evaluated experimentally and numerically in quasi-static axial compression tests. The results showed that the tubular composites had similar energy absorption properties to metal tubes. Axial and transverse compression behaviors of tubular woven preform reinforced composite pipes were compared with those of pipes that were manufactured by the conventional filament winding method[21]. The test results indicated that under transverse and axial compression, composite pipes developed in this study showed superior strength values to filament wound ones. Zhuetal.[22]successfully fabricated 3D woven tubular composites. Through experiments and finite element simulation, the axial compression performance of the material was analyzed. To sum up, 3D woven tubular composites is mostly regular circular cross section, and the research on irregular square tubular fabrics is relatively less. With the continuous innovation of science and technology, square tubular composites are more and more widely used in products due to their superior cross-section properties.

In this paper, the 3D woven special-shaped square tubular composites with different thicknesses were prepared with low-cost and environment-friendly basalt filament tows[23-24], and the compressive properties were tested to explore the failure mode and mechanism.

1 Experiments

1.1 Materials and equipments

Basalt filament tows of 800 tex(Zhejiang GBF Basalt Fiber Co., Ltd., Dongyang, China), epoxy resin(Wuxi Qianguang Chemical Raw Material Co., Ltd., Wuxi, China), a semi-automatic loom SGA598(Jiangyin Tong Yuan Spinning Machine Co., Ltd., Jiangyin, China), and a pneumatic press GSG-2047(Guangzhou Husong Electromechanical Trading Co., Ltd., Guangzhou, China) were used.

1.2 Design of 3D woven special-shaped square tubular fabrics

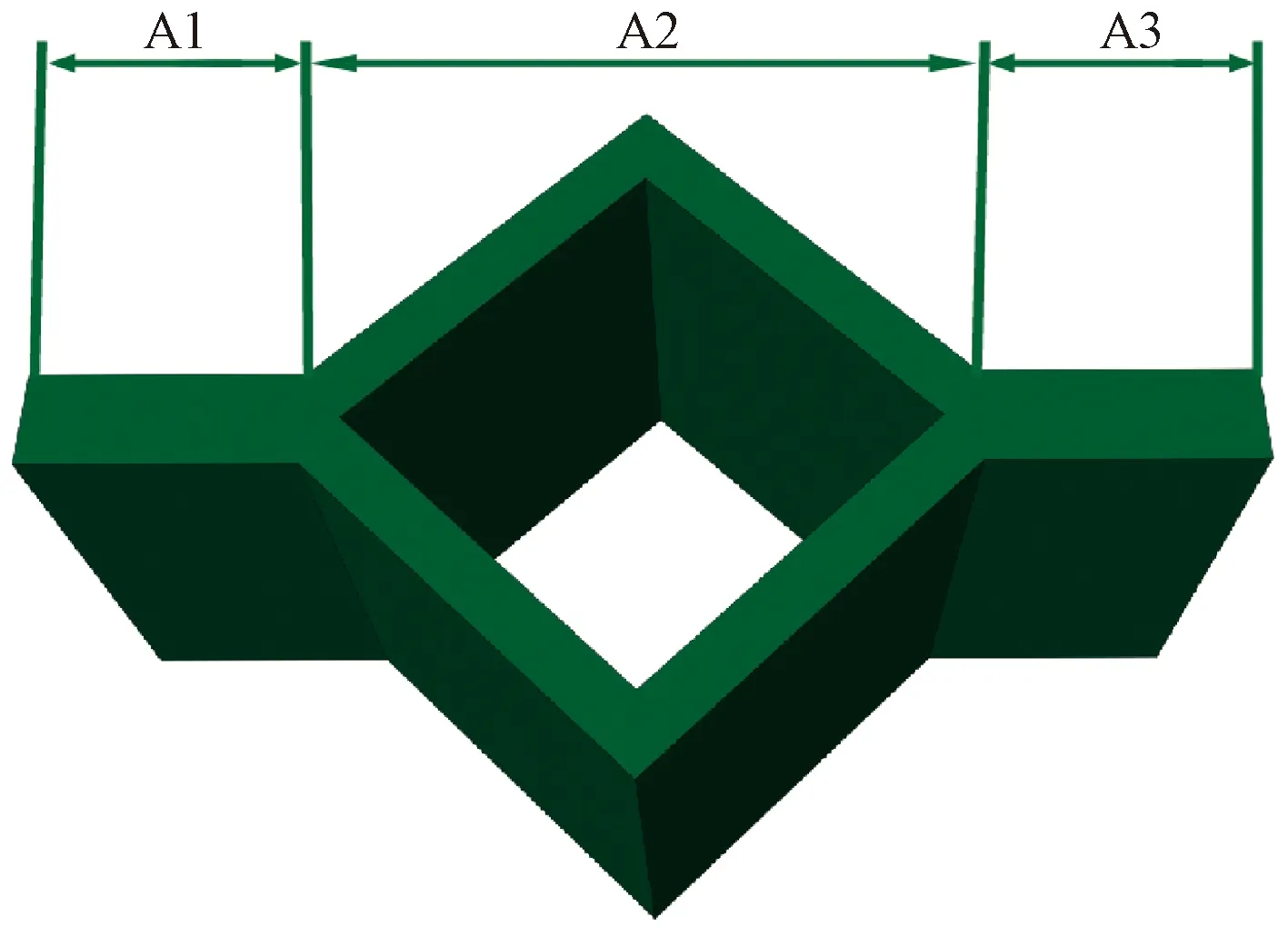

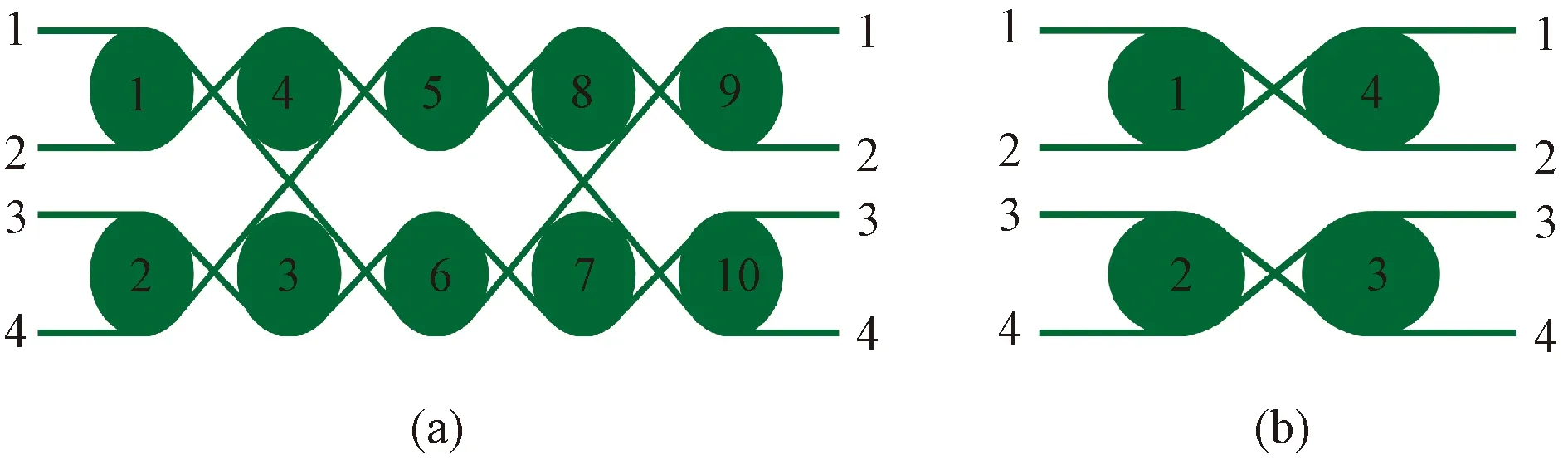

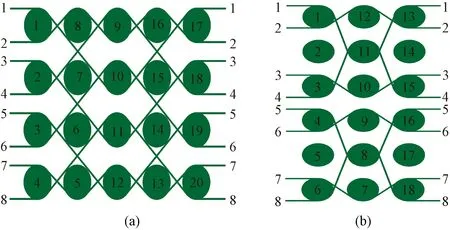

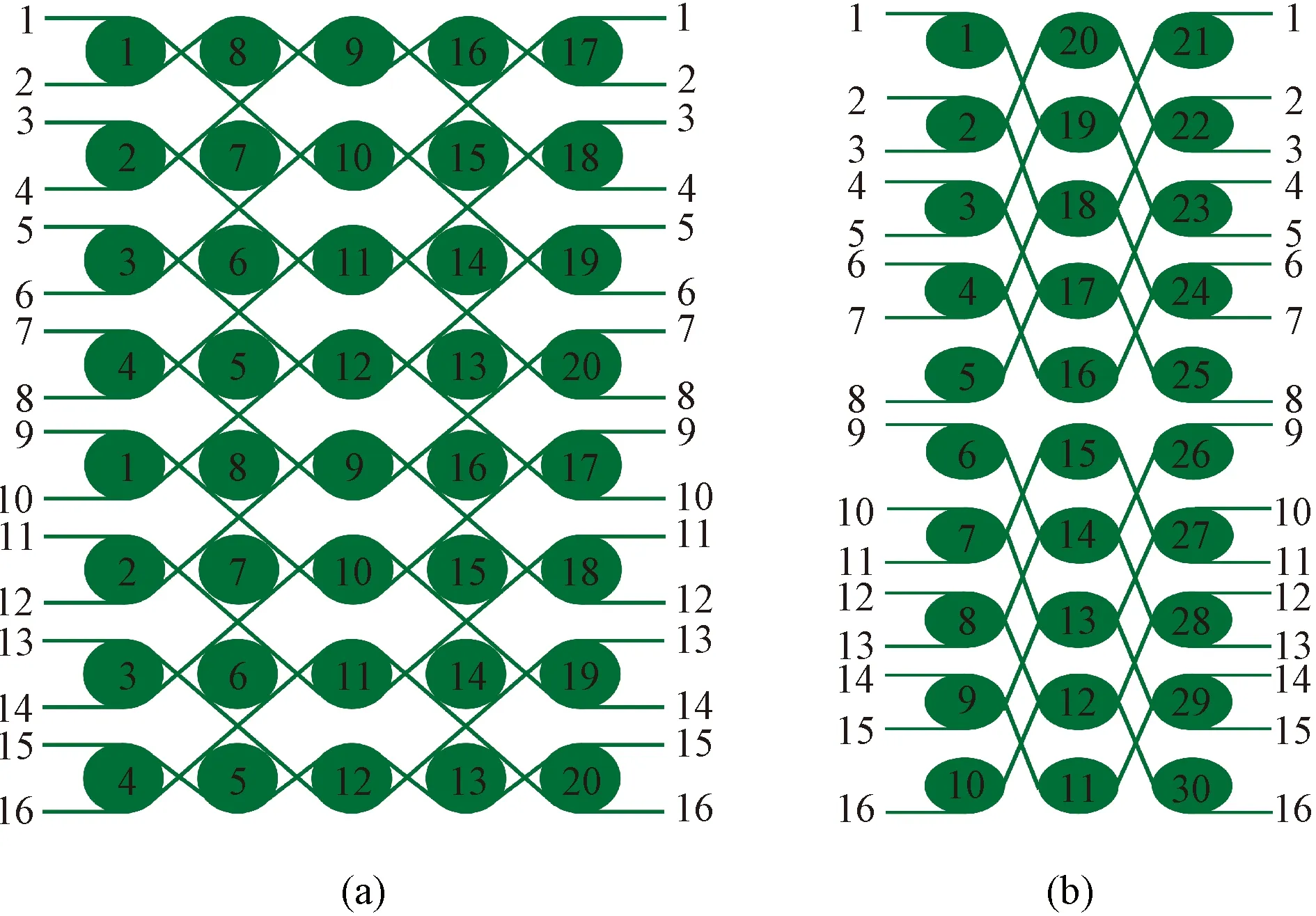

The fabric structure was divided into three weaving areas. As shown in Fig. 1, there was one structure in A1 and A3 areas, and another structure was in A2 area. The thicknesses of the 3D woven special-shaped square tubular fabric were designed to be 4, 2 and 1 mm. The fabric size of A1 and A3 areas is twice that of A2 area. The warp structural drawings were shown in Figs. 2-4. Figures 2(a), 3(a) and 4(a) were the warp structural drawings of A1 and A3 areas, and Figs.2(b), 3(b) and 4(b) were the warp structural drawings of A2 area. In Figs. 2-4, the curve represents warp, the circle represents weft, the number in the circle represents weft insertion sequence, and the number on the left represents the number of heald frames.

Fig. 1 Diagram of 3D woven special-shaped square tubular fabric

Fig. 2 Warp structural drawings of 3D woven special-shaped square tubular fabric with thickness of 1 mm: (a) A1 or A3 area; (b) A2 area

Fig. 3 Warp structural drawings of 3D woven special-shaped square tubular fabric with thickness of 2 mm: (a) A1 or A3 area; (b) A2 area

Fig. 4 Warp structural drawings of 3D woven special-shaped square tubular fabric with thickness of 4 mm: (a) A1 or A3 area; (b) A2 area

1.3 Preparation of 3D woven special-shaped square tubular composites

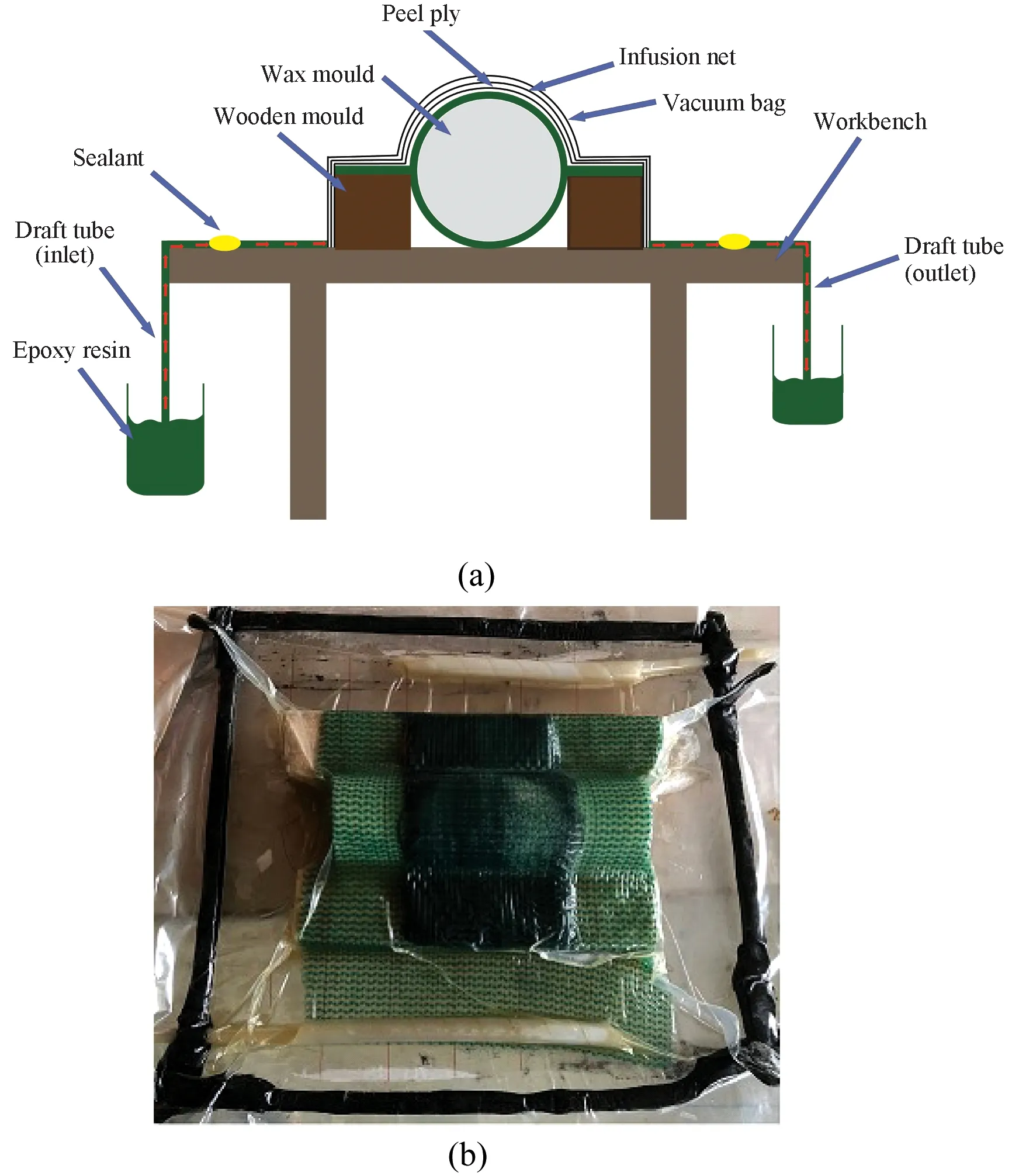

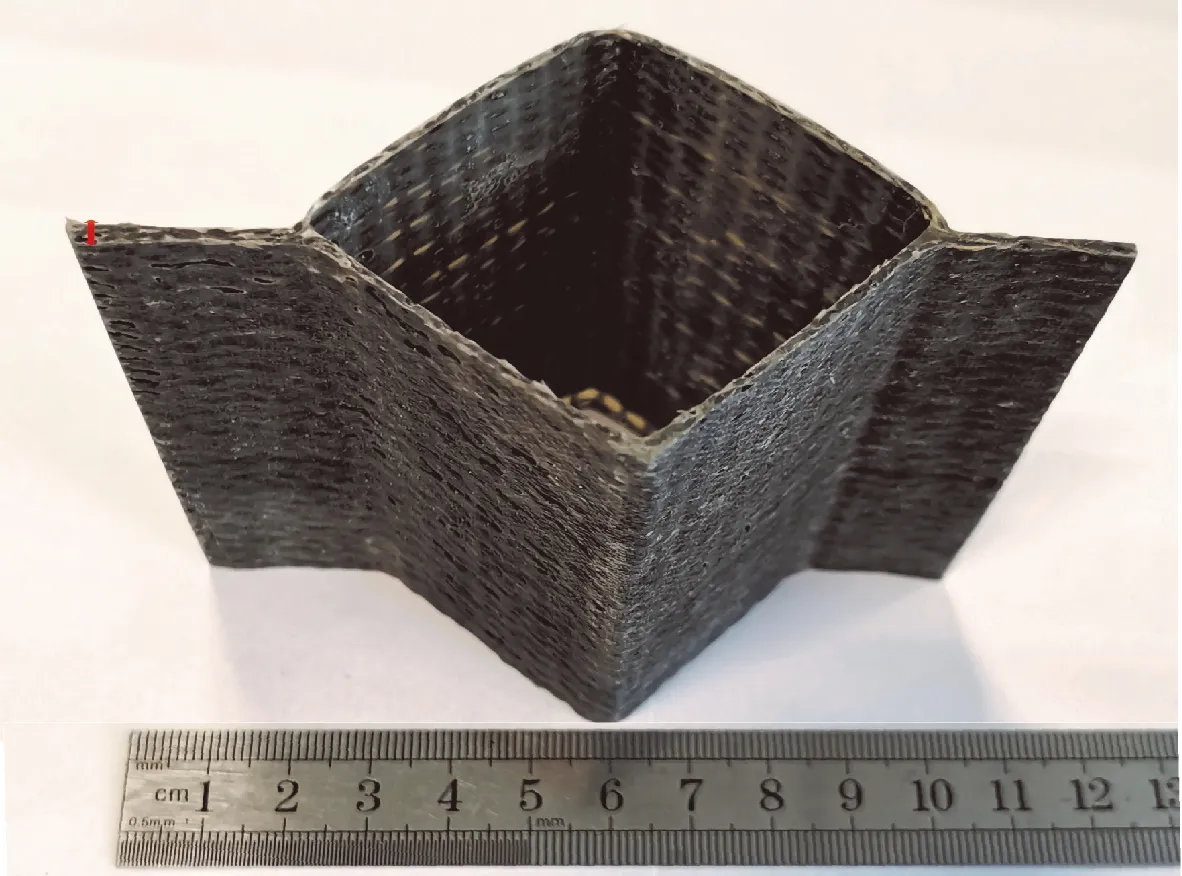

The 3D woven special-shaped square tubular composites were prepared by vacuum-assisted resin transfer molding(VARTM)(shown in Fig. 5). The volume ratio of resin, curing agent and accelerator was 100∶3∶3. The 3D woven special-shaped square tubular composite with thickness of 2 mm was shown in Fig. 6.

Fig. 5 VARTM process of composites: (a) theoretical forming diagram; (b) actual forming diagram

Fig. 6 3D woven special-shaped square tubular composite with thickness of 2 mm

1.4 Compression performance test

The mechanical property test standard was GB/T 5350—2005. The prepared composite was cut into a sample with a height of 30 mm and a width of 90 mm. The test was carried out on a universal testing machine(Jiangsu Tuobo Company, Nantong, China) with the test speed of 10 mm/min.

2 Results and Discussion

2.1 Experimental and fitting load-displacement curves

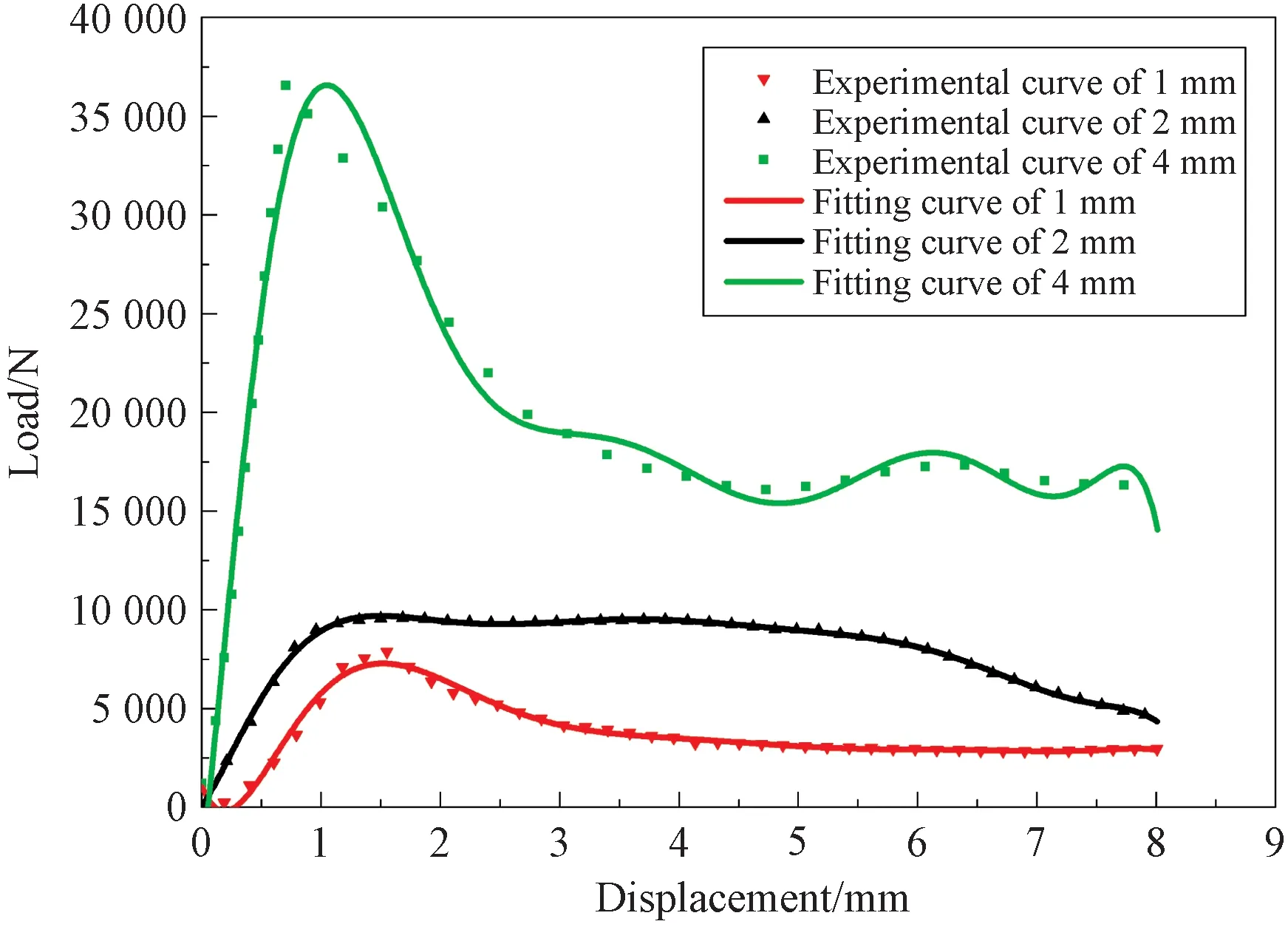

The experimental and fitting load-displacement curves of the 3D woven special-shaped square tubular composites were shown in Fig. 7. In the experimental process, three composites with different thicknesses were tested under the same experimental conditions.

Fig. 7 Experimental and fitting load-displacement curves of composites with three different thicknesses

In Fig. 7, the loads of the 3D woven special-shaped square tubular composites increased sharply with the increase of the thicknesses, which indicated that the load of composites was sensitive to composite thickness. From the trend of the curve, it was seen that the thickness of the 3D woven special-shaped square tubular composite had a significant effect on the load. This was mainly because the stress direction of the 3D woven special-shaped square tubular composite was axial. The main supporting part was A1 and A3 areas, and A2 area only played a secondary supporting role. With the increase of thicknesses, the compression load of the whole 3D woven special-shaped square tubular composites got greater.

Moreover, the load-displacement curves were divided into three stages. In the first stage, the composite was fully subjected to stress and exhibited elasticity, so the load-displacement curve increased linearly. According to the overall stress, the microcracks were distributed in the whole structure of the composite, and there was no obvious resin damage on the surface of the composite. In the second stage, as the indenter continued to work, the load increased slightly to the peak. At this time, the microcracks spread rapidly from the inside to the outside, and the resin was damaged a lot. Due to the buckling deformation of the fiber in some areas, resin and fibers were separated. In the third stage, after the load reached the peak, due to the continued compression of the indenter, the bearing capacity of the composite decreased. At this period of time, the deformation of the fiber occurred. When the deformation increased to a certain extent, some fiber fracture occurred, and the surface of the material was wrinkled. However, due to the existence of lots of unbroken fibers, the shape of the composite could still be preserved completely. The composite appeared to suffer plastic deformation failure.

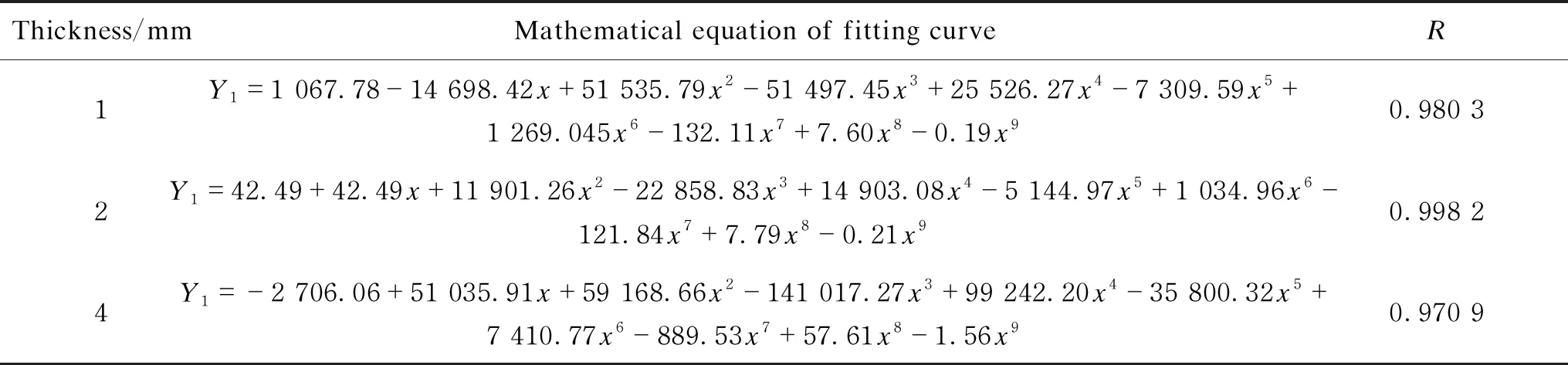

The least square method was used to fit in the software. After many times of fitting, the ninth order polynomial fitting method was adopted, and fitting curves were obtained. The experimental and fitting load-displacement curves of the 3D woven special-shaped square tubular composites with different thicknesses were shown in Fig. 7. The mathematical equation of fitting curves and the correlation coefficients between load and displacement were shown in Table 1. As shown in Table 1, the fitting result was related to the correlation coefficientR. The closer the value ofRapproaches to 1, the curve fitting effect is better. It was seen from the correlation coefficient in Table 1 thatRbetween load and displacement was greater than 0.79, so the correlation between them was very good. The mathematical equation of the fitting curves was used to simplify the functional relationship between load and displacement. Meanwhile, it could provide numerical calculation for engineering application.

Table 1 Mathematical equation of fitting curve and correlation coefficient between load and displacement

2.2 Experimental and fitting energy-displacement curves

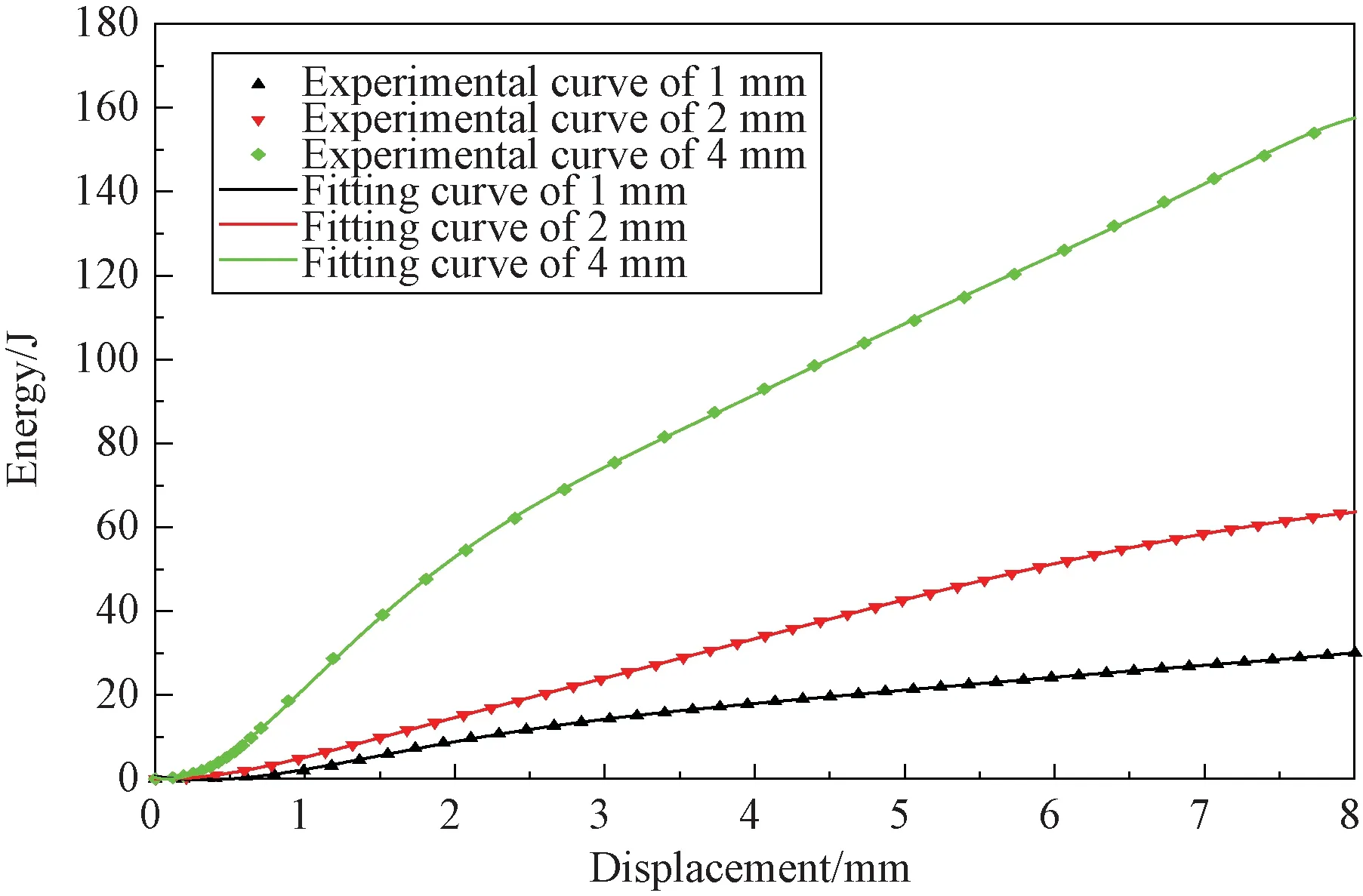

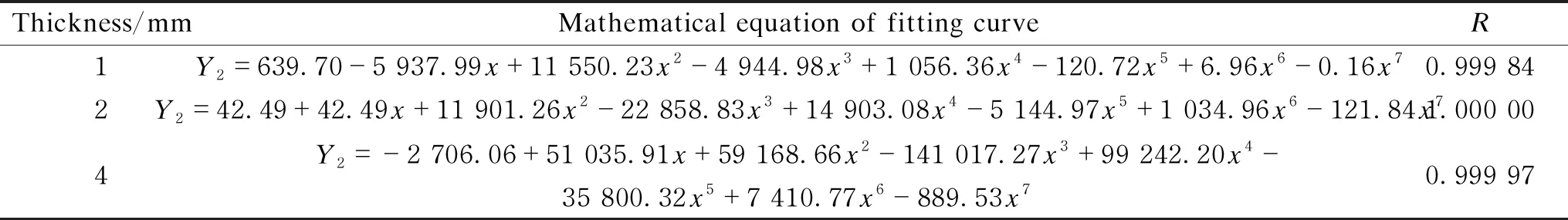

The energy absorption property of composites is an important index to measure the mechanical properties of composites. Figure 8 shows the experimental and fitting energy-displacement curves of 3D woven special-shaped square tubular composites with three different thicknesses.

It was clearly seen from Fig. 8 that at the same displacement, with the increase of the thickness, the energy absorption value increased. The peak of energy absorption values with three different thicknesses are 30.01, 63.71 and 152.11 J, respectively. The peak of energy absorption value increased with the increase of the composite thickness, and the increasing trend was obviously boosting.

Fig. 8 Experimental and fitting energy-displacement curves of composites with three different thicknesses

Table 2 showed the mathematical equation of energy-displacement fitting curves and the correlation coefficients between energy and displacement. It was seen from Table 2 that the correlation between energy and displacement was high, and the fitting curve was in good agreement with the experiment. This showed that the least square method was correct, and the mathematical model could describe the relationship between energy and displacement well.

Table 2 Mathematical equation of fitting curve and correlation coefficient between energy and displacement

3 Compression Failure Mode and Mechanism

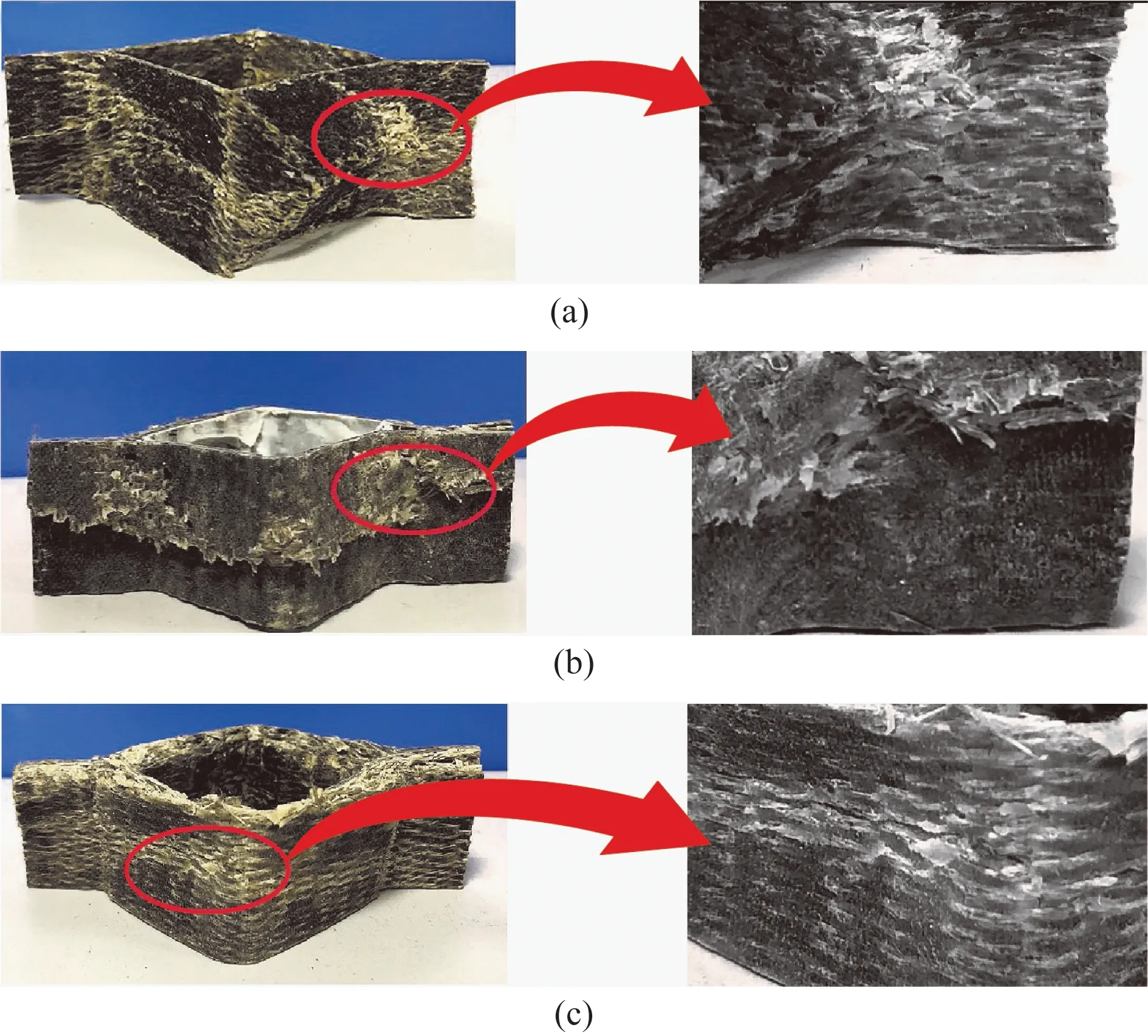

The final failure photographs of 3D woven special-shaped square tubular composites were shown in Fig. 9.

Fig. 9 Final failure photographs of 3D woven special-shaped square tubular composites with different thicknesses: (a) 1 mm; (b) 2 mm; (c) 4 mm

The failure mode of the 3D woven special-shaped square tubular composites was mainly shear failure and the failure mostly occurred at the upper middle region. In the compression process, resin cracking and the shedding phenomenon were notable.

4 Conclusions

Through reasonable design, three kinds of special-shaped square tubular woven fabrics with different thicknesses were produced at low cost on ordinary looms. The 3D woven special-shaped square tubular composites were prepared with epoxy resin by VARTM. The results showed that the 3D woven special-shaped square tubular composites with the thickness of 4 mm had the maximum load and energy absorption value, while the 3D woven special-shaped square tubular composites with the thickness of 1 mm had the minimum load and energy absorption value. With the increase of the thickness, the compressive properties of the 3D woven special-shaped square tubular composites were obviously improved. The 3D woven special-shaped square tubular composites had excellent mechanical properties. During the test, the composite showed good compressive strength without delamination and splitting. 3D woven special-shaped square tubular composites had different compressive properties with different thicknesses, but they all had the same failure mode and failure mechanism.

Through the analysis of the fitting results, it showed that the polynomial fitting formula was obtained by using the least square method, and the effect of fitting curve was good. The mathematical equation established by this method can simplify the functional relationship among load, energy and displacement, which is convenient for engineering application.

Journal of Donghua University(English Edition)2021年5期

Journal of Donghua University(English Edition)2021年5期

- Journal of Donghua University(English Edition)的其它文章

- Ecological Dyeing of Polyamide 6, 6(PA66) Fabrics with Monascus Pigments in Decamethylcyclopentasiloxane(D5) Solvent

- Effects of Microstructure on Quasi-Static Transverse Loading Behavior of 3D Circular Braided Composite Tubes

- Electrical-Mechanical Coupling Behaviors and Thermal-Resistance Effects of 3D Braided Composites

- Efficient Probabilistic Load Flow Calculation Considering Vine Copula-Based Dependence Structure of Renewable Energy Generation

- Turing Instability of Diffusive Predator-Prey System with Gompertz Growth

- Blockchain-Based Log Verification System for Cloud Forensics