巖石災變非連續結構與多物理場效應的透明解析與透明推演

鞠 楊,任張瑜,鄭江韜,毛靈濤,王 凱,周宏偉,謝和平

(1.中國礦業大學(北京) 煤炭資源與安全開采國家重點實驗室,北京 100083;2.中國礦業大學(北京) 應急管理與安全工程學院,北京 100083;3.中國礦業大學(北京) 能源與礦業學院,北京 100083;4.深圳大學 深地科學與綠色能源研究院,廣東 深圳 518060)

煤炭對我國經濟社會發展與能源安全作出了巨大貢獻,在我國能源體系中起著壓艙石和兜底保障作用。我國能源資源稟賦特征是“富煤、貧油、少氣”,已探明化石能源儲量中煤炭占比達94%。習近平總書記在近期的中央經濟工作會議上指出“要立足以煤為主的基本國情,抓好煤炭清潔高效利用,增加新能源消納能力,推動煤炭和新能源優化組合。要狠抓綠色低碳技術攻關”。2020年,習近平總書記在第75屆聯大一般性辯論上提出“二氧化碳排放力爭于2030年前達到峰值,努力爭取2060年前實現碳中和”。在“碳達峰、碳中和”國家重大戰略決策背景下,深入研究如何充分發揮煤炭的保障能源與戰略資源的作用、實現煤炭綠色低碳開發與潔凈利用迫在眉睫。

地球深部蘊藏著豐富的煤炭資源,巖石是煤炭資源開發與工程建設的主要對象,狹義上,巖石指實驗室尺度的巖塊,廣義上,巖石指工程尺度的巖體。煤炭開發與工程建設活動打破了初始地應力場的平衡狀態,引起巖石應力場重分布,誘發沖擊地壓、瓦斯突出、礦震、生態環境破壞等重大災害。然而,人們對煤炭賦存狀態、巖石構造演化以及生產開發活動的影響認知還不夠,傳統開采理論與技術難以精準探測和描述巖石復雜結構及開采引發的演化過程,也缺乏對開采巖石力學行為與致災機理的科學解析和準確表征,因而難以對煤炭生產與工程建設活動可能引發的工程災害進行超前預警和科學防控。解決這些基礎科學與技術難題已成為創新發展煤炭資源綠色智能安全開發理論與技術的重大基礎性前沿課題。

煤炭綠色智能安全開采基礎理論之一是巖石力學。然而,傳統的巖石力學理論在定量分析和描述生產開發活動引發的巖石結構與力學行為變化及災變機理時存在諸多困難,例如,① 天然巖石賦含大量跨尺度、幾何非規則的孔隙、裂隙、節理或層理等非連續結構,傳統的巖石力學方法,在連續均勻介質假定的基礎上,在代表性體元(Representation Volume Element,RVE)尺度上,研究巖石的應力、應變、滲流與災變等行為,建立巖石的宏觀本構模型、強度準則和失效判據等,難以準確描述和定量解析巖石內部非連續結構特征及其對巖石力學行為與孕災-致災機理的影響。同時,由于人們對RVE尺度內不連續結構引發的應力場、變形場和滲流場的變化認識不足,導致確定合理的RVE尺度非常困難,基于連續均勻假設所建立的本構模型、強度準則和失效判據可能失去代表性,造成采用傳統的理論模型與數值方法解決工程實際問題時存在較大偏差。這些困難制約了構建考慮內部非連續結構效應的巖石力學與災變分析體系;② 開采擾動引發的巖石內部非連續結構演化、物質-力學相互作用與多物理場耦合致災是一個“看不見、摸不著”的“黑箱”過程,現有的巖石力學理論和方法難以直觀顯示和準確描述,缺乏定量解析這種“黑箱”內部應力場、變形場和滲流場等多物理場的方法、理論和模型;③ 由于難以準確獲取、直觀顯示和定量解析生產與建設活動引發的巖石非連續結構演化、多物理場耦合致災機理及災變力學特征,現有的礦山災害防控多采用“隨采隨治”策略,難以超前研判不同開采方式和工藝可能引發的工程災害的時間、位置和量級,難以實現開采災害的超前預警和科學防控。巖石力學的這些基礎難題已成為制約煤炭綠色智能安全開采理論與災害防控技術發展的瓶頸,迫切需要建立和發展顛覆性理論與變革性技術。

當前新興技術的發展為直觀描述和定量表征巖石內部復雜非連續結構、應力場、變形場、滲流場與災變機理創造了條件。針對巖石內部非連續結構、物理場演化及災變行為難以透明顯示和定量解析的難題,筆者采用高分辨μCT成像、3D數字重構、3D打印、光彈性法、數字圖像相關法和三維流場示蹤等技術和方法,提出了巖石內部非連續結構、應力場、應變場、滲流場演化與多場耦合致災機理的透明解析與透明推演方法,基本思路是:構建含復雜非連續結構RVE尺度的巖石數字模型和透明物理模型,研制具有與天然巖石相同或相近物理力學性能、具有應力敏感性的透明3D打印材料,研究確定合理尺寸的非連續巖石RVE單元;采用透明可視化方法,在RVE尺度上,透明顯示和定量表征巖石非連續結構特征及其對巖石內部應力場、應變場、滲流場的影響與耦合致災機理;基于巖石多物理場的透明定量解析,建立關聯內部非連續結構及物理力學效應的巖石本構模型、強度準則及災變判據;構建RVE尺度的巖石透明模型與天然巖石非線性物理量之間的轉換關系及相似律模型,形成基于RVE尺度多物理場透明解析的非連續巖石力學與災變分析理論的基礎框架。在此基礎上,將實驗室透明物理模型研究與工程現場探測相結合,透明顯示并定量分析工程尺度下巖石結構演化、能源物質運移、力學耦合作用與致災過程。

近年來,國內外學者圍繞巖石復雜結構的三維數字重構方法、3D打印材料研制、透明物理模型制備、尺度效應、三維模型應力場、變形場和滲流場演化以及災變機理的透明定量表征開展了大量研究。筆者簡要總結了國內外學者及筆者在上述方面的研究進展,分析了未來發展與面臨的挑戰。本文意在為發展非連續巖石力學與災變分析理論、實現煤炭綠色智能安全開采及災害超前預警防控提供理論研究與技術應用參考。

1 巖石非連續結構的數字模型

1.1 非連續結構探測方法

巖石物理力學性質與災變行為很大程度上取決于其內部非連續結構。近年來,工業X射線CT掃描(X-ray CT)、磁共振成像(MRI)和聚焦離子束電鏡掃描(FIB-SEM)等先進成像技術的發展,為識別和準確表征巖石內部跨尺度非連續結構提供了有力手段。筆者基于X射線CT掃描數據構建了巖石非連續結構的三維數字模型及其RVE單元模型。該方法可直觀顯示和定量刻畫巖石內部微細觀尺度的非連續結構,已廣泛應用于巖石力學研究。與CT成像技術相比,FIB-SEM是一種破壞性方法,但具有更高的分辨率,可達1~10 nm,為研究巖石內部納米尺度非連續結構提供了有效方法,但觀測區域小和破壞性限制了該技術在某些情況下的應用。MRI在空間和時間分辨率方面相對靈活,具有快速識別內部結構變化的優勢,但分辨率相對較低。將上述方法相結合可實現巖石內部跨尺度非連續結構的直觀定量觀測,有利于在RVE尺度范圍內定量刻畫巖石復雜的內部結構并構建反映內部跨尺度結構的巖石RVE模型。

1.2 非連續結構的重構方法與模型

實驗室及現場原位探測提供了巖石內部非連續結構的詳細信息,但考慮到地層巖心鉆探的難度、高精度成像的高成本以及巖石非均質非連續性帶來的物理力學量對比分析的困難,發展一種便捷、經濟和可重復的巖石非連續結構的直觀定量描述手段十分重要。近些年,利用有限地質探測數據和計算機重構算法來重構巖石三維非連續結構的研究取得了飛速發展。隨機生成、多點統計信息、模擬退火、基于過程的方法和機器學習等方法被廣泛用于重構和刻畫巖石內部復雜非連續結構。

隨機生成方法可以簡單、直接地構建出巖石內部非連續結構。例如,基于統計信息,WANG和PAN提出了一種多參數隨機生成-生長的方法來生成不同類型的多孔結構;筆者改進了隨機球及裂隙填充法,通過控制球及裂隙的大小和孔隙度參數來生成頁巖孔隙結構;為了研究粗糙裂縫的流體輸送特性,筆者應用分形理論直接生成了粗糙裂縫。這些隨機生成方法通常具有較高的重構效率,準確性取決于重構過程中所使用的關鍵信息。

多點統計信息法使用模板掃描訓練圖像來提取局部多點特征,并將這些特征模式運用到新的重構圖像中。重構過程中考慮了多點統計信息,可以較好地再現多孔介質的幾何形狀和連通性。

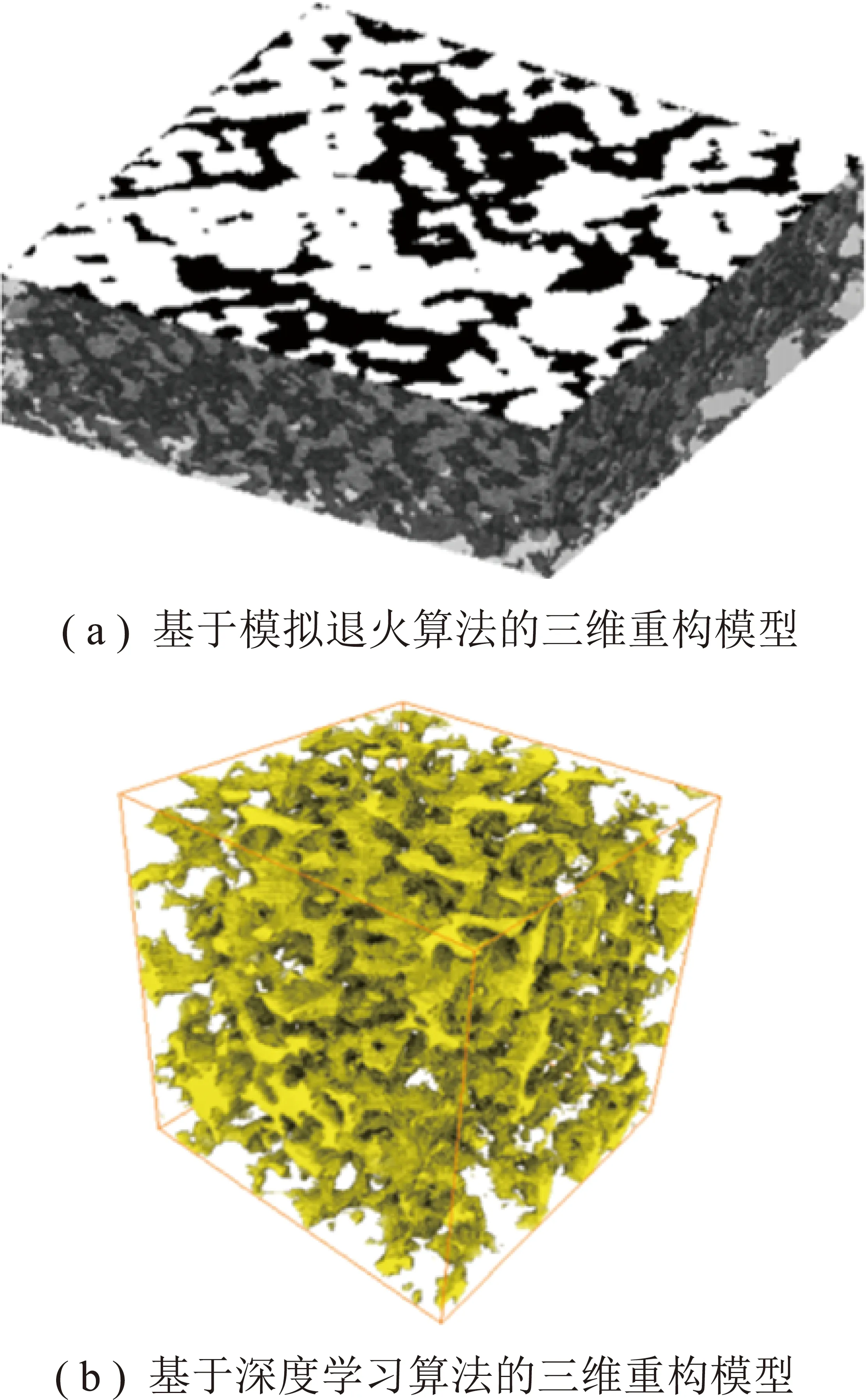

模擬退火法是一種被廣泛使用的重構方法,它通過不斷調換代表孔隙相與固體相的數據點對的位置來重構模型,這種方法可以將任意類型的目標函數納入重構。但由于需要進行大量的位置調換,并生成大量的中間結構,重構速度較慢。近年來,為了提高巖石數字模型的重構精度和重構效率,各國學者在模擬退火算法的基礎上,采用高階相關函數、方向相關函數、優化的模擬退火算法、不同權值相關函數、多尺度重構和并行計算等方法來構建巖石非連續結構三維RVE數字模型。筆者基于該原理,提出了改進的并行模擬退火算法,對巖石孔隙結構進行了高效準確的三維重構(圖1)。

基于沉積巖成巖過程來重建沉積巖孔隙結構的方法由?REN和BAKKE率先提出,該方法考慮了壓實、顆粒沉積和成巖過程,具有廣泛應用前景。

圖1 巖石孔隙結構三維重構模型Fig.1 3D reconstruction model of rock pores

機器學習方法通過大量真實的巖石掃描圖像來建立和訓練神經網絡,利用訓練好的網絡來生成巖石三維復雜結構。這種方法需要大量的數據樣本,但神經網絡訓練完成后可以在較短的時間內生成具有較好相似度的真實結構(圖1(b))。受限于神經網絡的能力,目前大多數重建工作主要局限于64和128的RVE尺度規模。特別是,由于神經網絡原理的難解釋性和泛化能力差等問題,該方法在重建結果的準確性和普適性等方面面臨諸多挑戰,有待進一步改進。

需要指出的是,盡管研究表明數字化方法可以經濟有效地獲取和透明顯示巖石內部非連續結構,但目前研究主要集中在利用有限微觀結構信息進行巖石RVE模型重構。使用低階統計信息提高了RVE模型重構效率,但犧牲了模型精度。隨著計算機運算能力進一步提高,有望采用更多的高階統計信息來提高RVE模型的重構精度,這將是巖石內部非連續結構三維數字化重構與透明表征研究的發展方向。

2 3D打印模型材料研制

3D打印技術已廣泛應用于巖石力學研究,該技術為重復制備內部包含復雜非連續結構的巖石物理模型并定量分析非連續結構對巖石災變力學行為的影響提供了可能性和新途徑。然而,除內部非連續結構因素外,巖石物性也是影響巖石物理力學性質與災變行為的重要因素,研制能夠反映天然巖石物性的3D打印材料是利用3D打印模型開展非連續巖石災變力學行為面臨的重要挑戰。

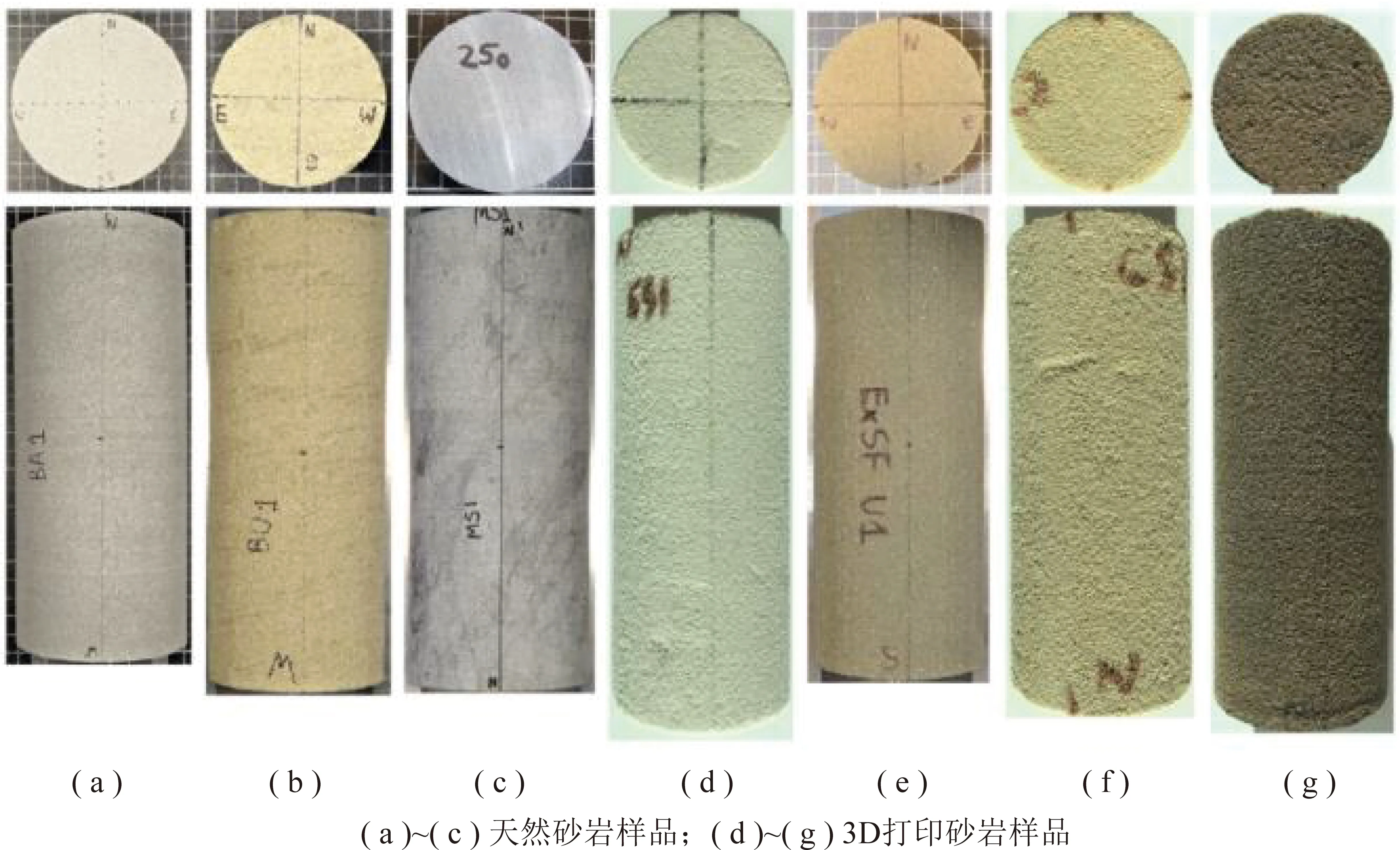

針對此問題,國內外學者采用不同3D打印技術,例如,光固化成型技術、熔積成型法、選擇性燒結成型法等,研究了硅砂、石膏、光敏和熱固性樹脂等常用打印材料的物理力學性質,探究了這些材料用于制備天然巖石模型的適用性。例如,PERRAS等對比分析了天然砂巖和3D打印模型的抗壓強度、抗拉強度、剛度、裂紋生成、裂紋損傷閾值和應變行為等,發現Sand-Furan 3D打印試樣的力學性能與天然砂巖最接近(圖2);ZHU和ZHOU研究了陶瓷、石膏、PMMA、SR20丙烯酸共聚物和光敏樹脂5種可打印材料在單軸壓縮下的力學性能和破壞模式,指出采用立體光固化成型法(Stereo Lithography Appearance,SLA)的光敏樹脂材料最適合模擬脆性和堅硬巖石,他們通過靜態和動態巴西劈裂試驗發現光敏樹脂模型表現出與天然巖石相同的破裂行為。GELL等研究了用于制備巖石試件的水泥、樹脂和含砂混料的力學性質,指出3D打印試件可以實現巖樣內部非連續結構的精細化復制,比傳統澆注制樣更具優勢。

除了如何使3D打印模型具有與天然巖石一致的非連續結構和物性外,如何能夠準確反映和量化非連續巖石內部應力場也是3D打印材料研究面臨的重要挑戰。為了獲得高應力敏感性、可用于透明顯示和定量表征巖石內部應力的3D打印材料,筆者利用美國Stratasys公司生產的Object Connex 500和J750 3D打印機,制備了用于打印材料物理力學性能測試的標準試件,詳細研究了3D打印材料VeroClear的組成成分、基本物理力學性能、打印成型方式及模型后處理的影響、應力雙折射效應(圖3(a),(b))、光熱曲線(圖3(c))、應力凍結性質(圖3(d))以及高低溫下的塑性及脆性性質等。其中,Object Connex 500和J750打印機的最小成型厚度分別為16和14 μm。實驗結果表明:VeroClear具有良好的應力雙折射效應和應力凍結性能,這種打印材料在一定條件下具有與煤、砂巖相似的物理力學性質與破壞模式,而且可用于透明顯示和定量表征受載破壞過程中巖石非連續結構內部應力場的演化,為透明解析巖石RVE模型內部三維應力場提供了條件和基礎。

圖2 天然砂巖樣品及3D打印砂巖樣品[35]Fig.2 Natural sandstone samples and 3D printed sandstone samples[35]

圖3 3D打印材料的物理力學性能Fig.3 Physical and/or mechanical properties of 3D printing materials

需要指出的是,盡管國內外學者做了大量工作,但從材料物性及物理力學性能角度來看,3D打印模型材料與天然巖石尚有不小差距,還需進一步研究和改性現有的打印材料。根據目前的研究結果,改善3D打印材料性能可有以下途徑:① 在分子結構層面設計打印材料;② 調整模型打印方式與參數;③ 增添不同成分的微觀結構來模擬天然巖石并改進打印模型的物理力學性質;④ 優化打印模型后處理等,希望應用這些技術使打印模型能夠代替或更好地模擬天然巖石。

3 巖石非連續結構的透明物理模型

利用現場和實驗室探測技術及數字重構方法可以建立直觀定量描述巖石RVE單元內跨尺度非連續結構的數字透明模型。然而,由于人們對RVE尺度內不連續結構引發的應力場、變形場和滲流場的變化及其內稟物理機制認識不足,在數字模型基礎上,將基于連續性假設所建立的本構模型、強度準則和失效判據用于巖石災變數值模擬分析,預測結果往往與工程實際存在較大偏差。因此,開展物理模型實驗揭示巖石災變“黑箱”過程與物理本質、建立準確的體現內部非連續結構效應的本構模型、強度準則與失效判據是解決工程實際問題的必由之路。然而,如何重復制備含復雜內部結構的物理模型一直是巖石物理模型實驗研究的一個難題。

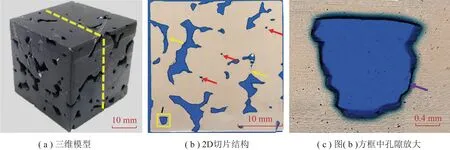

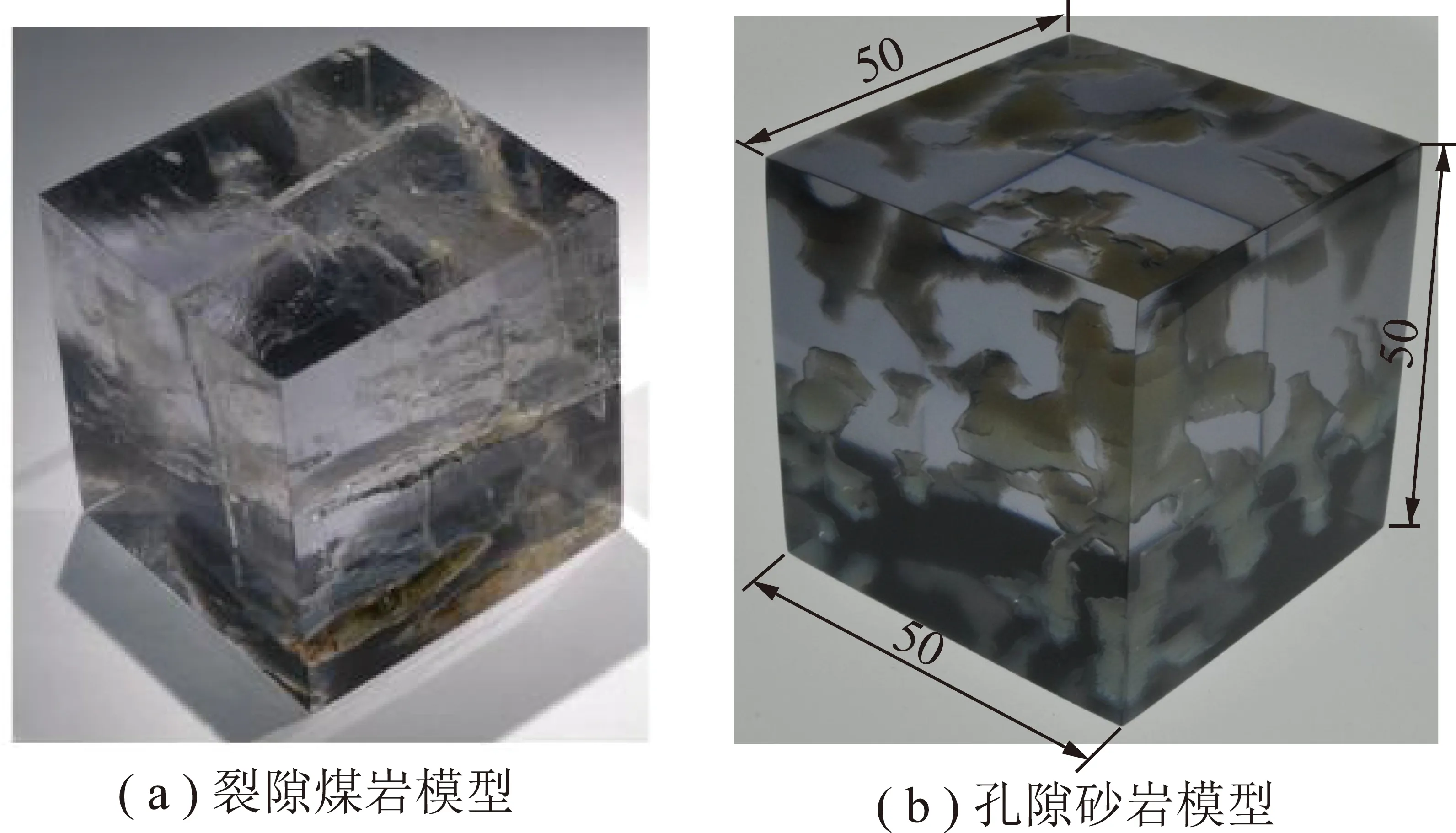

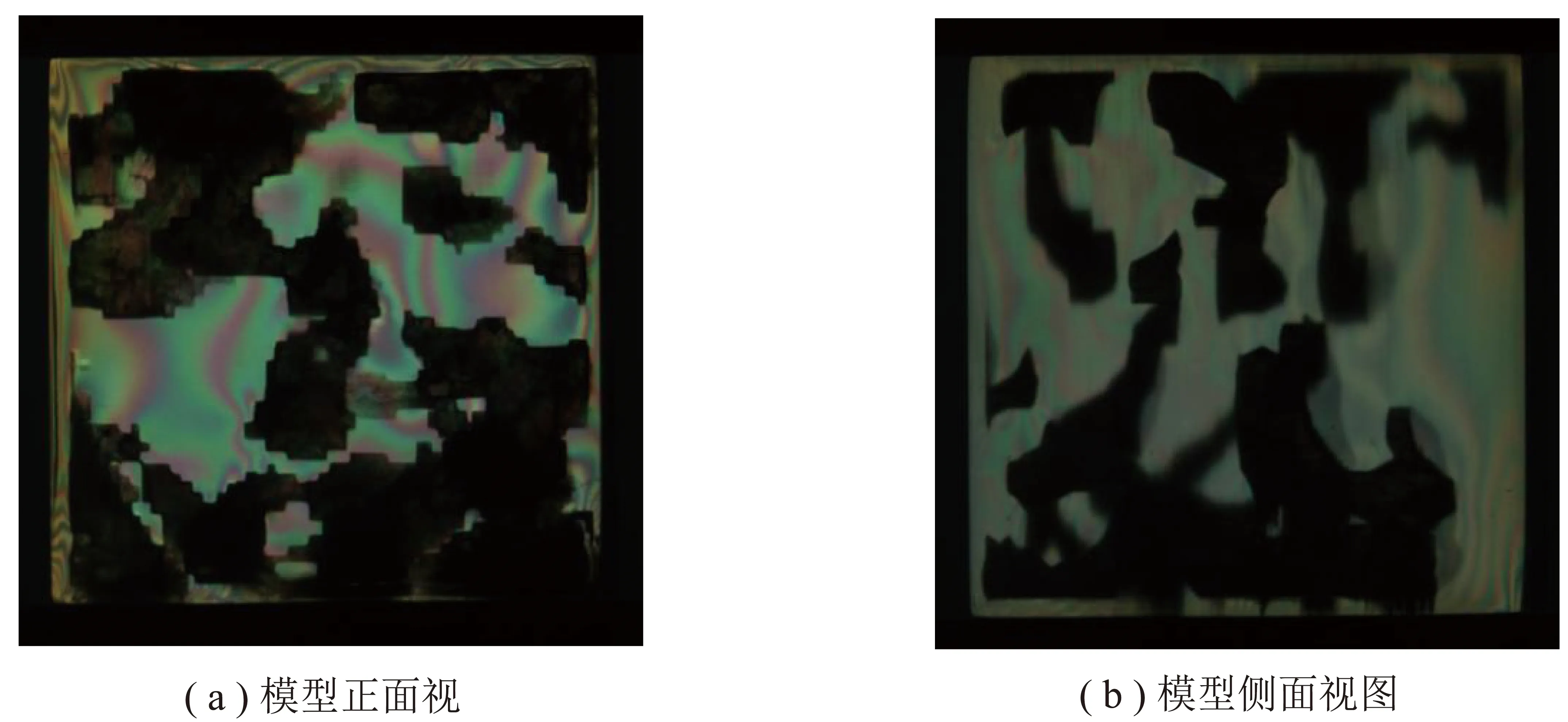

近年來,快速發展的3D打印技術為解決上述難題提供了途徑。人們基于數字模型與3D打印模型材料,采用不同的3D打印技術制備了與天然巖石物性相似且內部結構一致的物理模型。例如,為了研究打印制備的孔隙模型的力學性質和滲流特征,ISHUTOV等利用CT成像和3D打印技術制備了天然砂巖孔隙結構的物理模型(圖4)。JIANG等打印制備了與天然巖石內部節理分布一致的物理模型,指出3D打印技術能夠制備含有復雜孔隙和裂隙結構的巖石模型,可用于巖石力學性質研究。然而,由于采用不透明3D打印材料,上述方法制備的巖石物理模型無法直觀顯示和定量表征巖石內部物理場變化與災變過程。為了透明顯示和定量解析巖石內部非連續結構及物理場演化與災變過程,筆者采用自主研發的原位三軸加載CT成像系統(美國、英國與中國發明專利)與分形數字重構方法,應用研制的透明3D打印材料,制備了具有與天然巖石一致非連續裂隙、孔隙結構及相近物理力學性質的巖石透明物理模型(圖5)。

圖4 3D打印孔隙巖石模型[47]Fig.4 3D-printed models of porous rocks[47]

為了模擬賦含非均質非均布顆粒與礦物充填的巖石,作者基于多材料打印技術,采用不同力學性質的材料復制天然巖石中的不同成分,例如,筆者采用兩種不同打印材料模擬骨料和基體,并按照骨料和孔隙的實際分布打印制備了混凝土透明模型(圖6)。

值得關注的是,天然巖石含有大量跨尺度的孔隙、裂縫、顆粒和節理等微結構,在CT掃描識別精度范圍內,部分微結構在CT圖像中可能僅占有1個體像素,可采用體像素打印技術制備這類模型。體像素打印是一種在體像素尺度上使用多種材料進行3D打印的技術,可以對每個體像素賦予不同的材料屬性。對于內部組成極其復雜、跨尺度且難以精確構建數字模型的非連續結構,可以直接在CT圖像的基礎上,采用體像素打印方式制備透明物理模型,該方法將大幅度提高復雜物理模型的制備精度。

圖5 巖石透明物理模型[14,42]Fig.5 Transparent models of rocks[14,42]

圖6 混凝土透明模型[52-53]Fig.6 Transparent model of concrete [52-53]

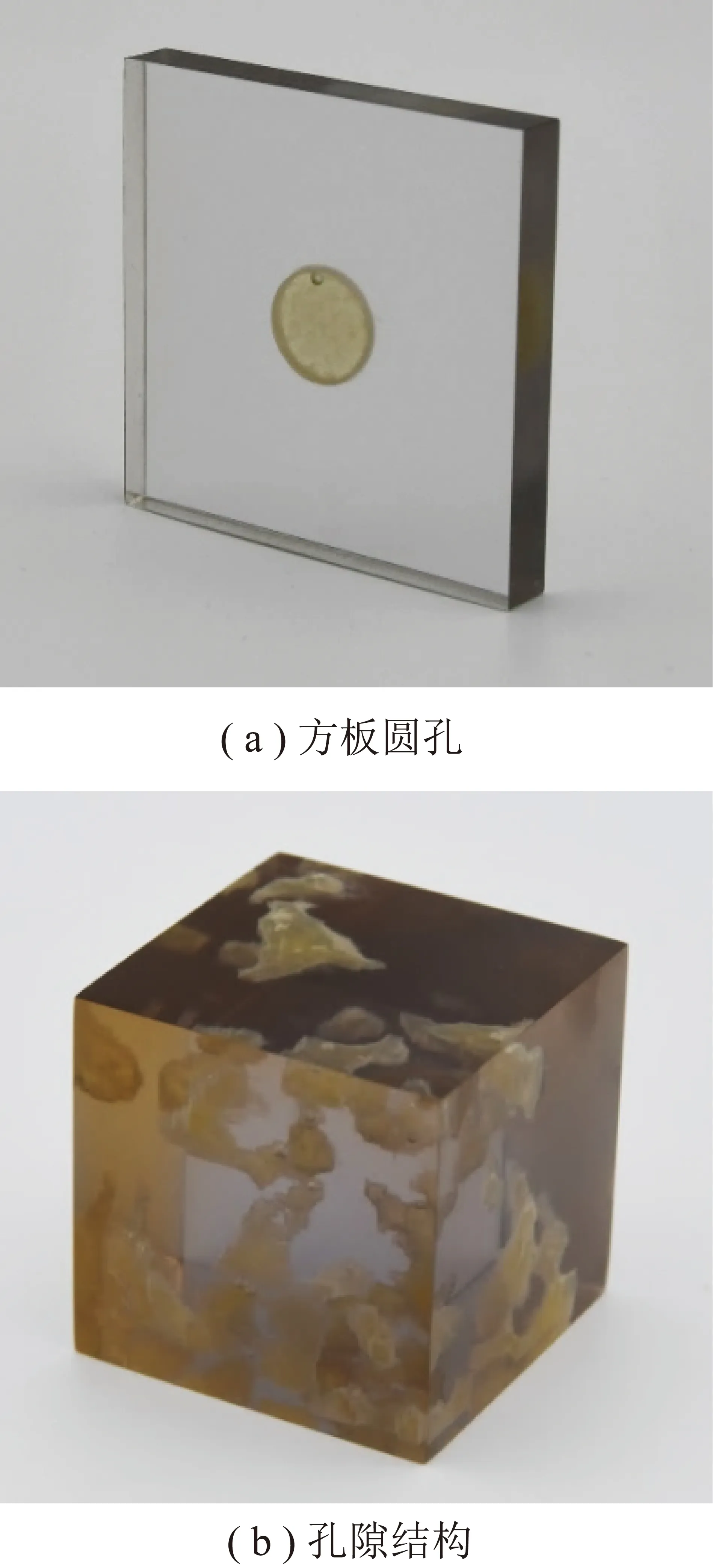

此外,為了模擬天然巖石孔隙或裂隙中的流體介質(油、水、氣等),筆者采用固液兩相打印技術,實現了包含流體介質的三維RVE模型一體化打印制備。圖7為打印制備的內嵌流體的方板圓孔模型和孔隙結構模型,液體頂部留有微小氣泡。結合體像素3D打印技術,通過設計固液材料的體像素空間分布,可以實現任意位置處孔隙、裂隙包含不同液體的三維模型制備。

圖7 內嵌液體的方板圓孔和孔隙結構的透明3D打印模型Fig.7 3D-printed models of a square plate embedded a circle pore and a porous rock, filled with liquids

4 RVE模型尺度

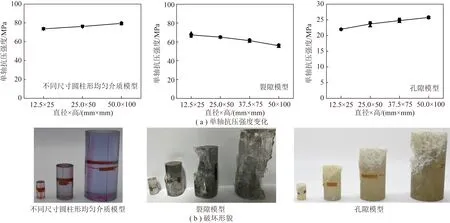

三維數字重構和3D打印技術為實現巖石RVE模型內部非連續結構的透明解析、發展考慮內部非連續結構特征的巖石力學理論提供了條件和基礎。利用RVE尺度模型研究巖石的應力、應變、滲流與災變等行為,建立反映內部非連續結構特征的巖石本構模型、強度準則和災變判據,首先需要厘清巖石內部非連續結構特征及其對巖石力學行為與災變行為的影響,并確定有代表性的RVE模型尺度。BELL和SIEGMUND開展了不同厚度3D打印模型的三點彎曲斷裂實驗,分析了1~5 mm內模型強度和斷裂韌性的尺寸效應;AKIYAMA等通過四點彎實驗研究了模型尺寸對基于FDM 技術的打印模型力學性能的影響。筆者測試了采用不同光敏打印材料制備的不同尺寸的含復雜孔隙和裂隙結構的3D打印模型的抗壓強度、抗拉強度、彈性模量、泊松比、屈服強度、斷裂韌性等,分析了巖石打印模型的尺寸效應(圖8),圖8(a)數據是根據至少3個重復試件實測結果計算獲得。實驗結果表明: 3D打印RVE模型體現出與天然巖石一致的尺寸效應,這為定量分析巖石內部非連續結構效應及其對巖石災變力學行為的影響,確定含不同類型非連續結構的RVE單元尺寸提供了基礎和依據。

5 巖石內部應力場的透明解析

5.1 二維模型應力場透明解析

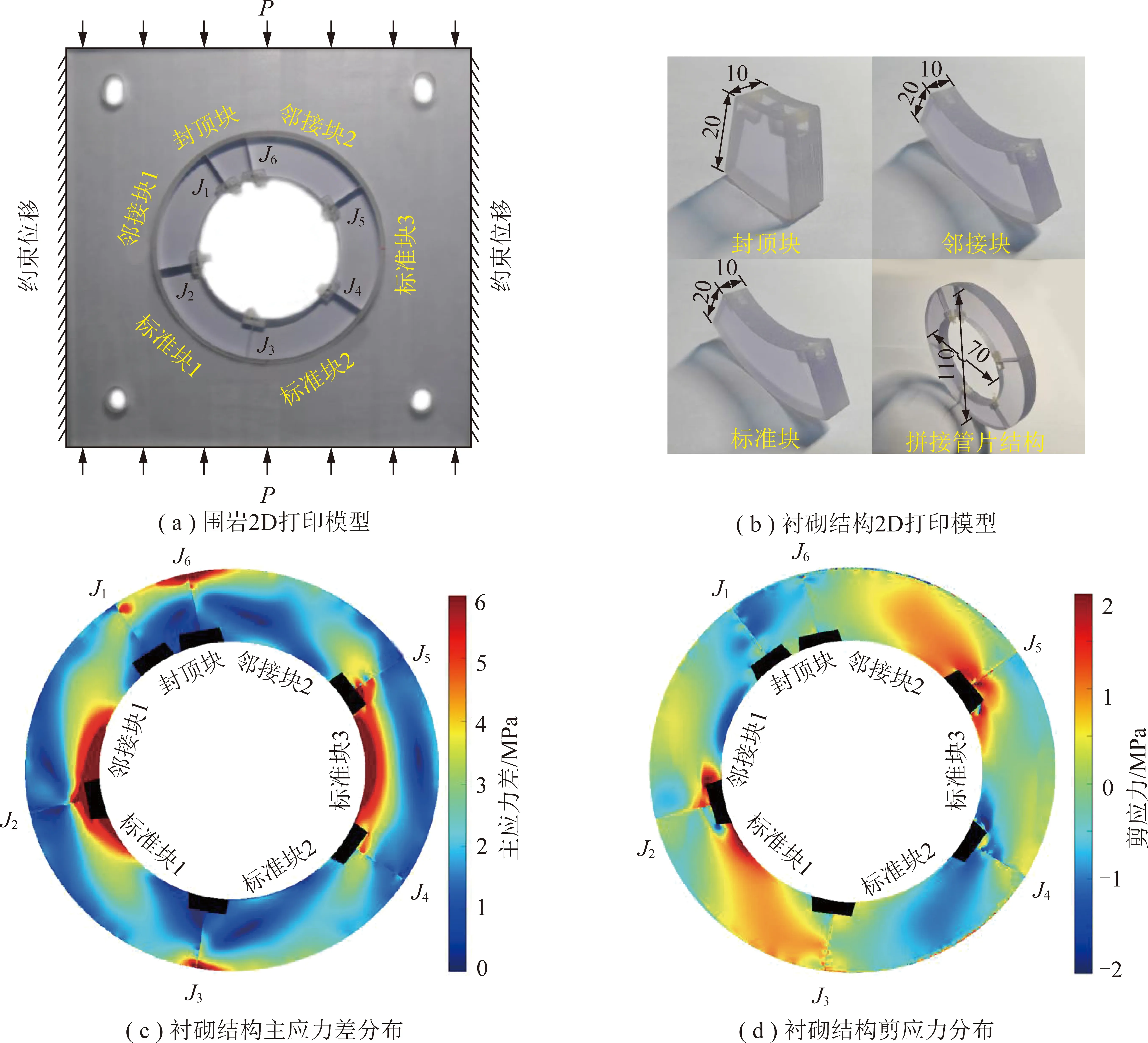

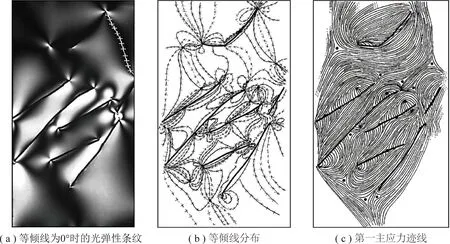

為了揭示復雜非連續結構對巖石災變行為的影響機制,筆者采用3D打印技術制備了天然巖石非連續結構的二維透明模型,采用光彈性實驗方法,通過改進相移和解包裹算法,定量解析了荷載作用下非連續結構全場應力分布特征與演化規律,為認知和解析巖石災變行為的內在物理機制創造了條件。例如,筆者基于巖石裂隙結構的CT圖像,制備了天然裂隙的二維透明RVE模型,發展改進了相移和解包裹算法,獲得了外部荷載作用下裂隙結構全場剪應力和主應力差(圖9)。此外,筆者還模擬巖石粗糙斷層結構,打印制備了粗糙斷層的二維透明RVE模型,設計了斷層剪切變形的光彈性實驗,開發了非連續結構光彈性應力場的定量提取算法,定量解析了斷層滑移時斷層區域全場主應力差和剪應力分布與演化規律(圖10),建立了粗糙面起伏角與斷層周邊應力場的定量關系。采用類似方法,作者打印制備了隧道襯砌與圍巖結構的二維平面模型,提出了圍巖襯砌結構全場應力的實驗提取與定量解析方法,獲得了外載作用下圍巖襯砌結構全場主應力差與剪應力分布及演化規律(圖11),為定量表征襯砌結構及管片界面應力分布、驗證數值模擬結果提供了方法和途徑。類似的,MISSERONI等通過可視化內含剛性顆粒模型周邊光彈性條紋的分布,分析了剛性顆粒模型周邊的應力集中和應力場分布特征;DANIELS和HAYMAN通過顆粒光彈模型,解析了不同節理結構特征對巖石內部應力場的影響;BIGONI和NOSELLI通過建立墻體結構的光彈模型,分析了承載梁壓縮引起的墻體內部壓應力分布的特征;GHISLAIN 等建立了地質斷層的光彈模型,利用光彈性條紋和主應力跡線,分析了斷層周圍應力場(圖12);SOLIVA 等和LUNINA等利用地質斷層的光彈性模型,定量解析了斷層周邊應力場的分布與演化。

圖8 巖石3D打印模型尺寸效應的實驗結果Fig.8 Experimental investigation on the size effects of 3D-printed rock models

圖9 巖石裂隙結構2D透明模型及不同軸向載荷作用下裂隙區域應力場演化的解析結果[62]Fig.9 2D transparent model of rock fractures and the evolution of stress fields under different uniaxial compressive loads[62]

圖10 巖石粗糙斷層2D透明模型及剪切位移變化時斷層周邊應力場分布演化的解析結果[64]Fig.10 2D transparent model of a rough fault and the distribution and evolution of stress fields under different shear deformations[64]

圖11 襯砌結構應力場的透明解析結果[65]Fig.11 Transparentized solutions to the stress fields of lining structures[65]

5.2 三維模型應力場透明解析

巖石非連續結構二維模型應力透明解析為認知和量化非連續結構對巖石災變行為的影響、構建非連續巖石力學理論提供了途徑和支撐。然而,天然巖石包含復雜的三維結構,透明顯示和定量解析外載作用下巖石內部三維應力場分布及演化對于闡釋巖石結構整體災變機理和預測工程災害發生的位置與量級具有重要意義。

圖12 斷層周邊應力場定量解析結果[70]Fig.12 Quantitative solutions to the stress fields near faults

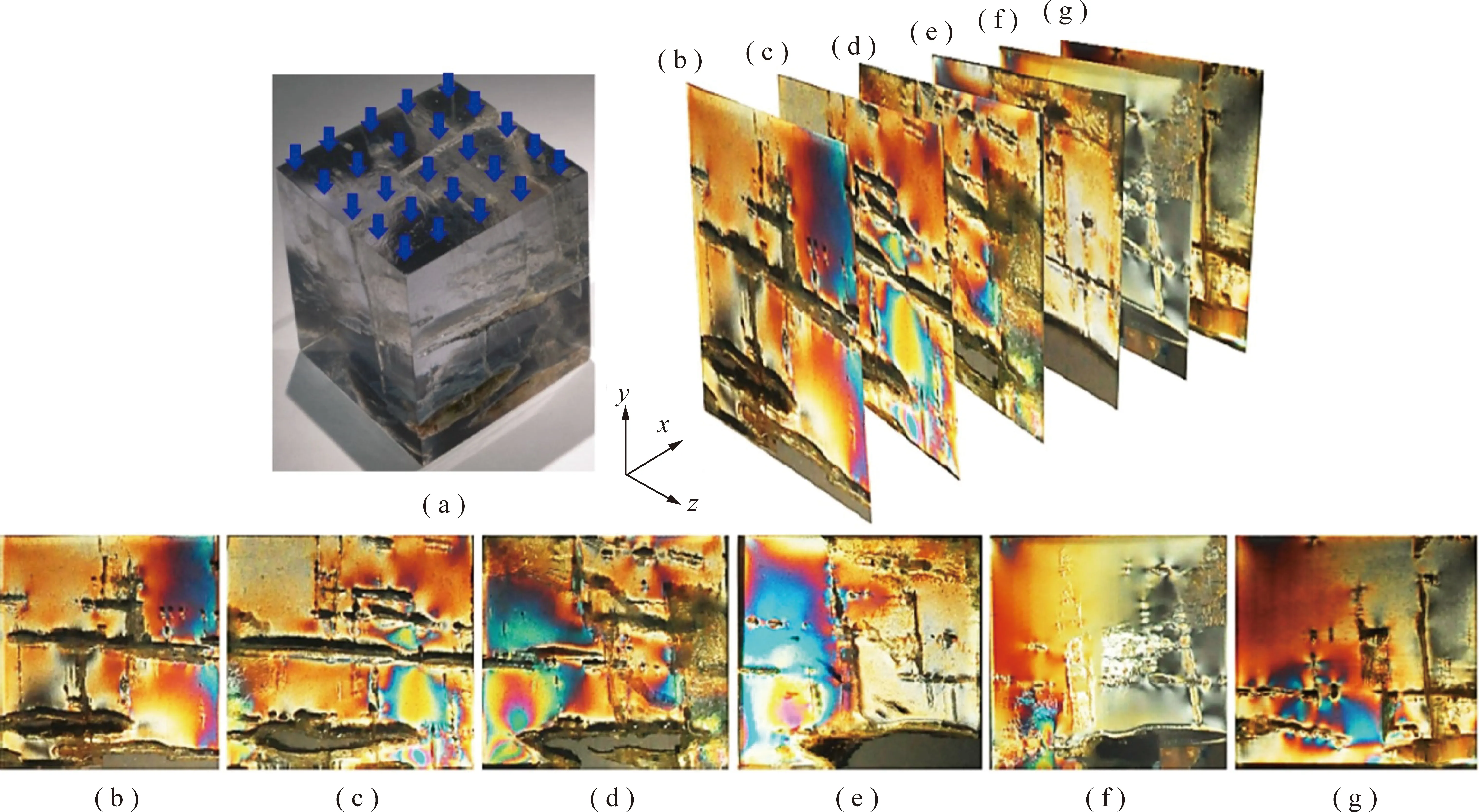

光彈性應力凍結是一種獲取和分析三維連續均質模型內部應力場的有效方法,該方法是在溫箱中對光彈性模型施加固定荷載,經歷溫度升降循環,光彈性材料在溫升過程中分別出現液態相和彈性相,降溫時液態相固化,模型內部應力被“凍結”下來。對“凍結”后模型進行不同位置的切片,通過觀測切片的光彈性條紋來解析三維模型內部全場應力分布。然而,天然巖石結構復雜,傳統的光彈性應力凍結法難以制備包含眾多跨尺度孔隙、裂隙、顆粒等不規則結構的三維模型,加之缺乏有效的針對非連續結構應力場的提取算法,實現非連續巖石內部三維應力場定量解析一直是個難題。

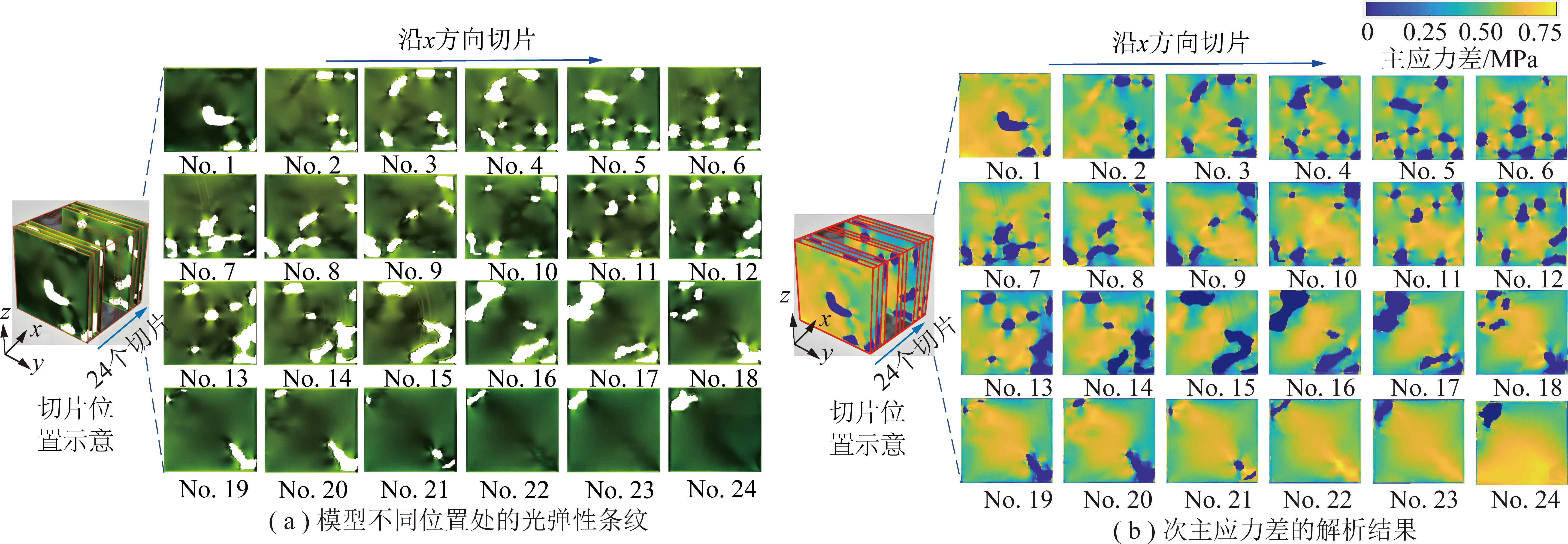

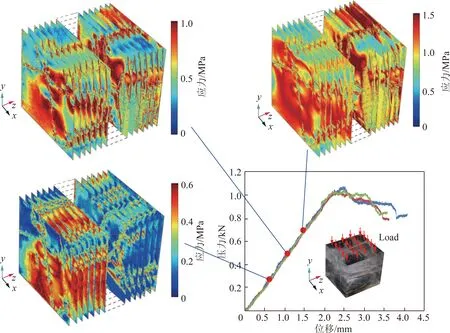

針對上述問題,筆者采用高精度CT成像、3D數字重構和3D打印技術,在二維模型應力解析方法的基礎上,通過研制高應力敏感3D打印材料、改進光彈性應力凍結法和發展針對復雜結構的應力場提取算法等措施,提出了非連續巖石內部三維應力場的透明定量解析方法,為實現巖石RVE模型內部復雜三維應力場的透明解析、構建基于RVE內部非連續結構效應的巖石力學理論提供了實驗基礎與理論支撐。例如,圖13展示了裂隙煤巖三維透明模型內部不同位置處的應力條紋;圖14給出了孔隙巖石三維透明模型內部不同位置處的應力條紋與定量解析結果;圖15為非均質砂礫巖三維透明模型內部不同位置處的應力分布解析結果,該結果直觀顯示和量化了相鄰顆粒間的高應力分布特征,為闡釋非均質砂礫巖變形破壞的內部非均質非均布顆粒效應及應力場演化提供了實驗證據及依據;圖16直觀顯示和定量表征了軸向壓縮荷載作用下不同荷載階段裂隙煤巖內部三維應力場的分布與演化特征。

圖13 裂隙煤巖三維透明模型內部不同位置處的應力分布特征[14]Fig.13 Stress distribution at various positions inside a 3D transparent model of fractured coals[14]

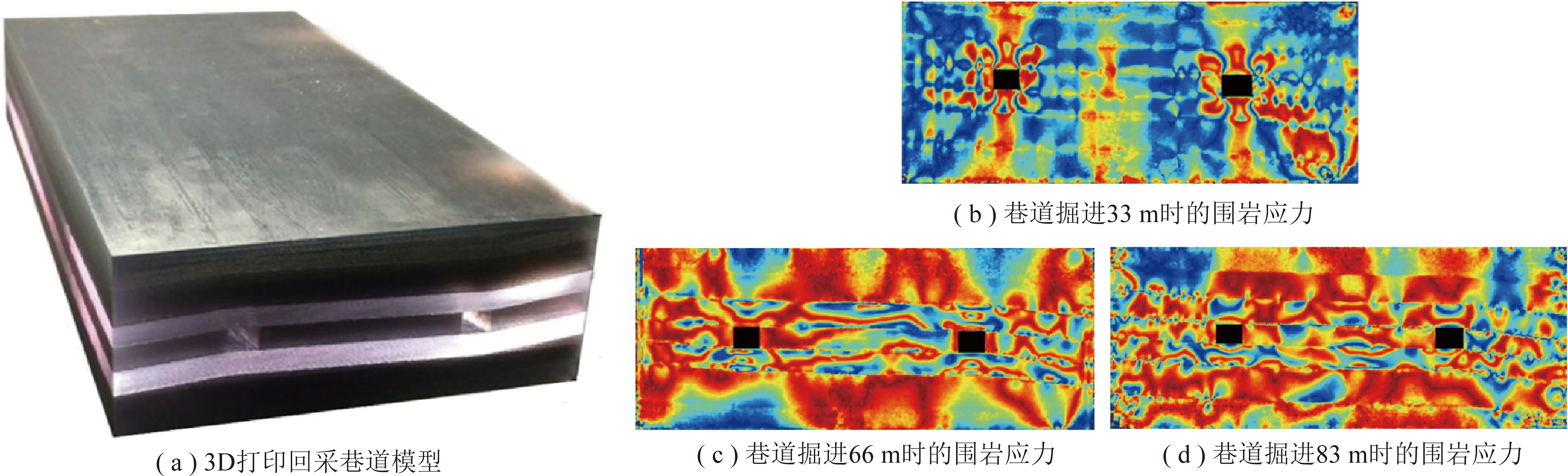

為了揭示開采過程誘發巷道圍巖災變機理和超前預測采動圍巖破壞的位置和量級,筆者基于礦區現場三維地質勘探信息,利用3D打印技術,制備了回采巷道和回采工作面的三維縮尺透明物理模型(圖17),模型中的煤層及覆巖采用與其物理力學性質相近的3D打印模型材料制備。采用上述應力解析方法,透明顯示和定量表征了不同掘進位置處回采巷道圍巖的應力分布大小與演化規律,為超前預警不同開采方式可能誘發的巷道與工作面圍巖災變提供了研究與定量分析手段。

圖14 孔隙巖石模型內部應力場的透明解析[42]Fig.14 Transparentized solutions to the stress fields inside porous rock models [42]

圖15 非均質砂礫巖模型內部應力場的透明解析[53]Fig.15 Transparentized solutions to the stress fields inside heterogeneous glutenite models[53]

5.3 動態應力場的透明解析

準確獲取和量化巖石全場應力連續動態演化與非連續結構效應對于揭示礦山巖爆、瓦斯突出、地震等動力災害的內稟物理機理至關重要。國內外眾多學者發展了動態光彈性實驗方法來獲取和分析巖石應力場的動態演化特征,例如,相移法、RGB法、載荷步法、載波法和焦散線法等。但由于巖石非連續結構模型制備困難以及動態應力場的連續高速變化特征,傳統的巖石動態應力場表征主要集中于簡單結構模型以及應力場演化的定性或半定量分析,難以直觀顯示和定量解析復雜巖石結構的動態應力場演化特征。

圖16 軸向壓縮荷載作用下不同階段裂隙煤巖內部應力場的分布與演化特征Fig.16 Distribution and evolution of the stress fields inside a fractured coal under different compressive loads

圖17 回采巷道圍巖應力場的定量解析與透明推演[79]Fig.17 Quantitative solution and transparentized interpretation of the stress field in mining roadways[79]

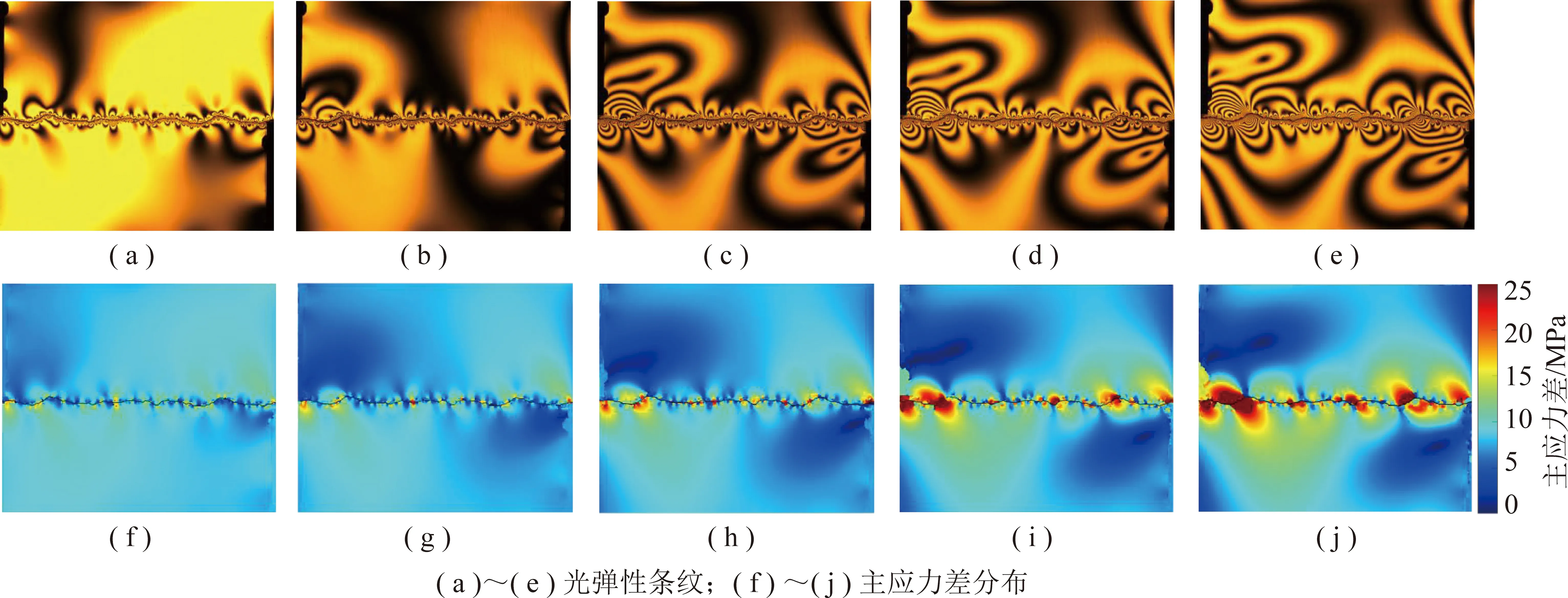

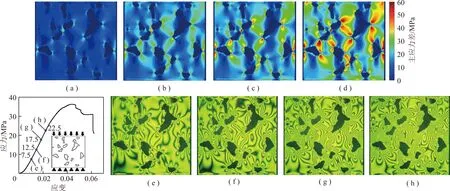

針對上述問題,筆者利用3D打印技術制備了內嵌梭形裂紋的透明圓盤模型,通過對徑壓縮光彈性實驗以及改進動態光彈條紋提取算法,獲取并定量解析了裂紋尖端應力場特征及其與裂紋擴展速度之間的對應關系;對于復雜非連續結構內部動態應力場定量解析難題,作者提出了一種定量解析連續載荷作用下復雜非連續結構模型內部全場應力演化的方法,獲得了連續加載下復雜孔隙模型內部的主應力差分布與演化規律(圖18),該方法適用于定量解析沖擊或爆炸載荷作用下復雜巖石結構模型內部應力場,但前提是能夠清晰地獲取快速連續變化的動態光彈條紋。

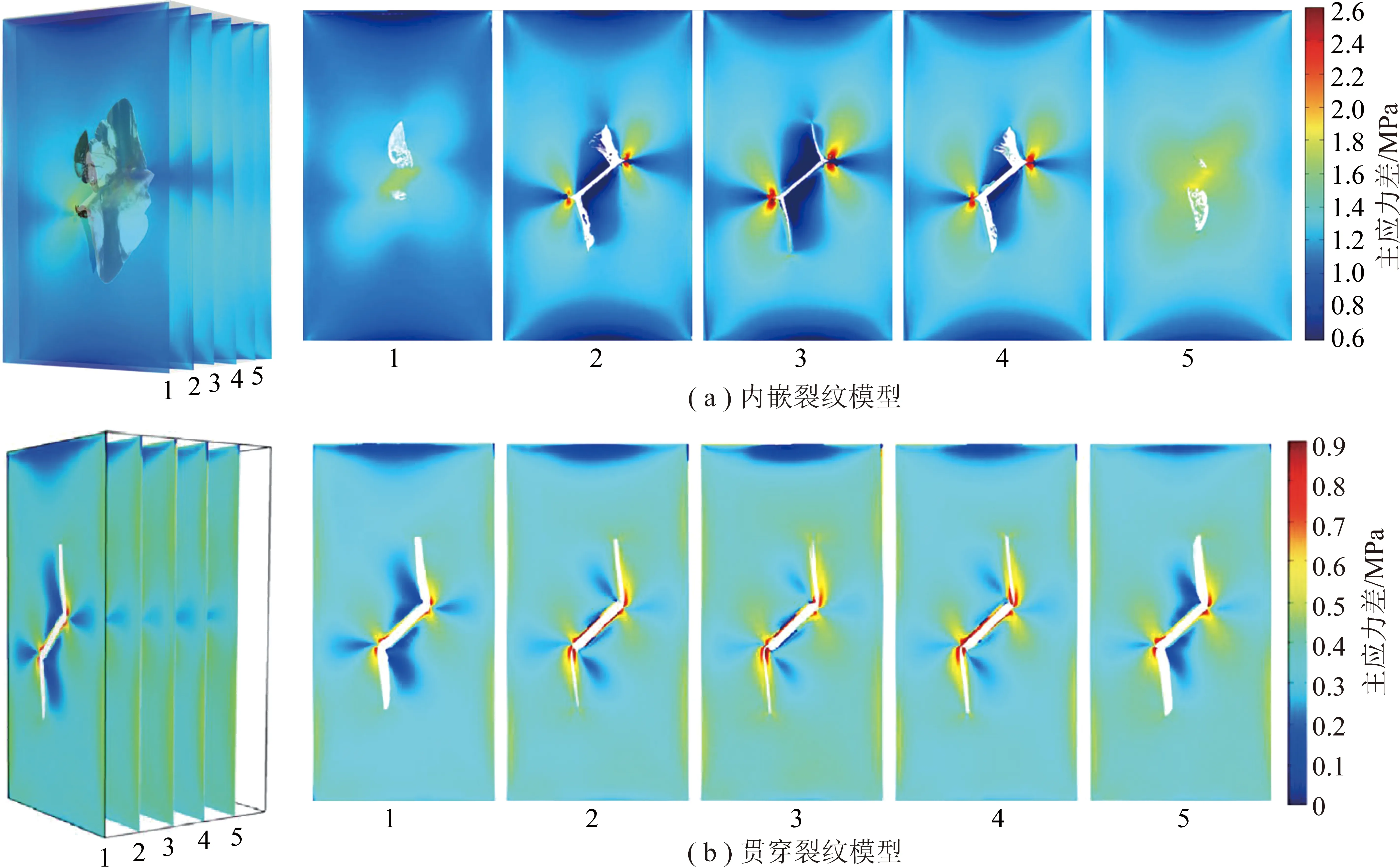

由于存在大量不規則天然裂隙,巖石內部裂隙三維擴展行為及起裂判據一直是巖石斷裂與災變理論研究的熱點和難點問題。巖石三維裂紋擴展過程中的應力場特征對于理解和定量分析裂紋起裂、擴展、轉向和匯聚行為、建立裂紋非穩定擴展失效判據至關重要。然而,傳統實驗方法在制備三維裂紋模型以及獲取裂紋三維擴展過程中的應力變化等方面存在困難,三維裂紋連續擴展過程中的應力場透明顯示與定量描述尚未得到解決。針對此問題,筆者采用3D打印技術和所研制的應力敏感3D打印材料,制備了含內嵌非貫穿型裂紋和貫穿型裂紋的透明模型,通過模型受壓的光彈性應力凍結實驗,利用改進的光彈條紋分析技術和應力場提取算法,獲得并定量解析了裂紋三維擴展過程中模型應力全場特別是裂紋尖端區域主應力差和剪應力的分布及演化特征(圖19)。

圖18 載荷連續作用下不同加載階段復雜孔隙結構模型內部主應力差全場分布與演化規律[54]Fig.18 Distribution and evolution of the principal stress difference inside a porous rock model under different continuous compressive loads[54]

圖19 三維內嵌裂隙和貫穿裂隙擴展過程中內部不同位置處主應力差的透明解析[101-102]Fig.19 Transparentized solutions to the principal stress differences at different positions inside the 3D models containing embedded and penetrated fractures[101-102]

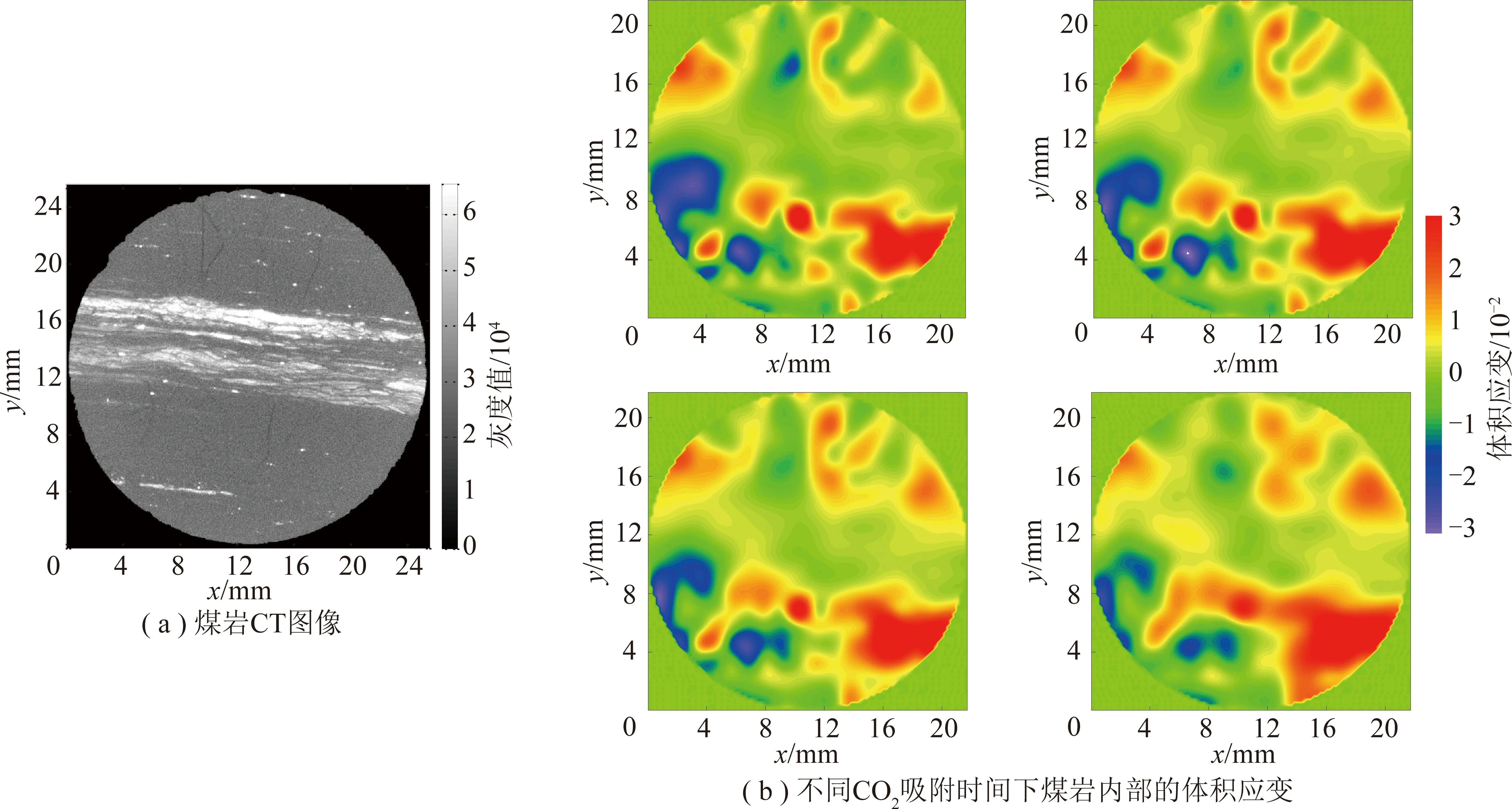

6 巖石內部應變場的透明解析

直觀顯示和定量表征巖石內部變形破壞程度和集中分布區域對于理解巖石整體變形破壞機理具有重要意義。然而,目前常用的數字圖像相關法(Digital Image Correlation,DIC)和表面三維DIC技術只能測量巖石表面和離面的變形,難以用于量測巖石內部變形,迫切需要發展內部三維變形場的直觀定量表征的方法。借助三維成像技術,如微焦點CT、共聚焦顯微鏡、磁共振成像等技術,可以獲得巖石樣品的三維圖像,基于此,BAY等提出了數字體圖像相關法(Digital Volume Correlation,DVC)來量測受壓骨骼內部應變場。近年來,DVC方法得到迅速發展和應用。但如何提高內部微小應變的測量與計算精度一直是DVC法面臨的主要挑戰。根據配準算法的不同,將DVC方法分為基于子集的局部DVC (Local DVC, L-DVC)和基于有限元的全局DVC (Global DVC,G-DVC)兩種主要方法。相比之下,L-DVC計算效率高,在計算參數相同的情況下,G-DVC的精度略高于L-DVC,尤其是當子集尺寸較小時。針對巖石內部非連續結構特征,筆者提出了多尺度子塊體搜索和亞體素平移方法MS-DVSP(Multi-scale and Shifting Digital Volumetric Speckle Photography),顯著提高了復雜結構內部三維變形的測量精度,透明顯示和定量解析了荷載作用下煤巖(圖20)、紅砂巖和混凝土等內部三維變形的分布與演化規律,為構建基于內部應力場和應變場透明解析的非連續巖石本構關系與災變準則提供了途徑和基礎。

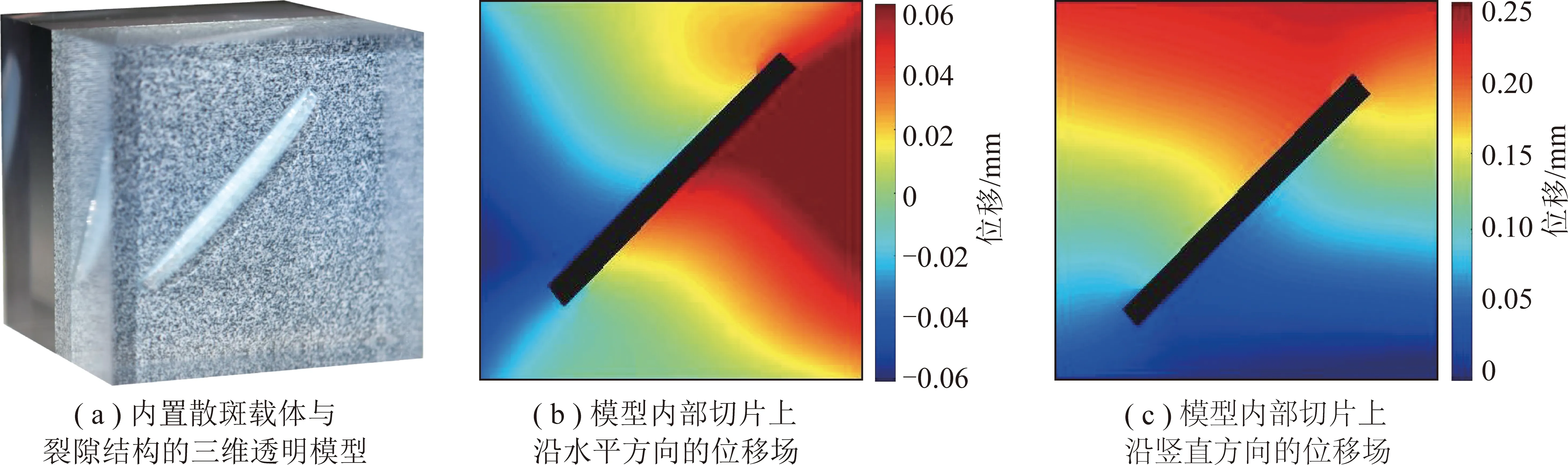

值得關注的是,DVC法雖然能夠應用于量測巖石內部變形場,但天然巖石結構復雜,每一個用于實驗量測的巖石樣品結構差異性很大,難以保證被測巖石RVE結構的一致性以及所獲得的應變場具有足夠代表性。同時, 由于DVC法要求被測巖石RVE內部必須有滿足計算要求的高質量散斑,而很多類別巖石內部并不存在這樣的散斑,這使得DVC法難以直接應用于測量此類巖石的內部變形場。為解決此難題,筆者采用多材料3D打印技術制備了內置散斑載體與裂隙結構的三維透明模型(圖21),發展了三維散斑數字圖像相關法,獲得并定量分析了含裂隙模型的內部變形場,為透明定量解析三維非連續結構內部變形分布演化特征與變形破壞機理提供了新方法和新途徑。

圖20 不同CO2吸附時間下煤巖內部的體積應變[116]Fig.20 Volumetric strain inside a coal at different CO2 sorption time [116]

圖21 內嵌裂紋模型位移場的透明解析Fig.21 Transparentized solution to the displacement field of a 3D fractured model

7 巖石內部滲流場的透明解析

準確認識和定量表征巖石內流體輸運行為對于研究和解決煤與瓦斯共采、油氣資源開發、土壤污染物運移、CO地質封存及核廢料處置等一系列工程問題具有重要意義。然而,目前常用的RVE尺度巖心驅替實驗重點關注流體宏觀輸運性質,如滲透率、相滲曲線和毛細壓力曲線等特征,缺乏對這些宏觀輸運性質演變起控制作用的孔尺度流體運移機理的深入分析和準確描述,導致宏觀輸運性質演化規律難以預測。同時,由于巖心驅替實驗中巖石內部流體流動過程不可見,且孔隙結構存在顯著非均質性,全場流動模式極為復雜,僅憑宏觀認識難以準確反映和描述真實流動規律。常用的微觀模型實驗在模型制備及施加溫度壓力條件等方面受限,且模型一般為小尺度二維模型,導致微觀模型實驗結果難以直接應用于實際工程。此外,常用的流體動力學計算方法(CFD)在處理復雜幾何結構及多相滲流行為受到較大限制,且受限于計算資源,模擬計算難以準確反映真實地層非均質性孔隙結構內的多相輸運行為。針對常規巖心實驗、微觀模型實驗及傳統數值分析存在的問題,筆者借助3D打印技術、自主設計研發的原位三軸加載CT成像系統(圖22)以及改進的并行格子玻爾茲曼方法(LBM),透明顯示和定量解析了復雜巖石復雜結構內流體輸運行為及非均質孔隙結構中的非混相界面不穩定性,探討了復雜孔隙系統內非混相水油驅替動力學特征、優勢路徑及其對孔隙結構幾何參數、流體黏度等物理參數的敏感性,通過直觀展示流場、識別和分析孔隙結構內流體流動路徑,闡釋了巖石復雜結構內流體輸運控制機理。這些研究為揭示巖石復雜結構內流體滲流機制及定量分析流體宏觀輸運特性、解決實際工程問題提供了基礎和手段。

圖22 自主設計研發的原位三軸加載CT成像系統Fig.22 Self-developed in-situ triaxial loading and CT imaging system

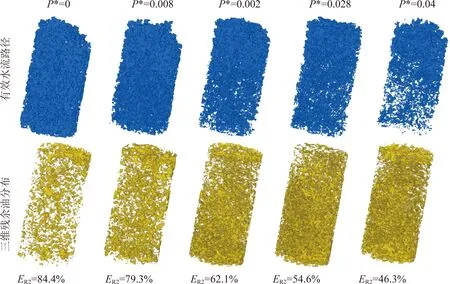

針對長期注水開發老油田含水率大幅上升、儲層水竄導致采收率下降、注水無效循環以及廢水處理成本升高等工程難題,筆者采用高精度微米CT成像方法,獲得了真實儲層不同水驅條帶代表性三維孔隙結構,依據天然巖石真實結構信息,采用3D打印技術制備了巖石孔隙結構的透明模型,利用透明模型的多相驅替實驗,直觀展示和定量解析了油、水、堵劑、聚合物、表面活性劑驅替過程(圖23),揭示了條帶結構滲透率級差及注入黏度差異是高滲透條帶形成水竄通道主要原因,堵劑運移路徑及原位成膠是保證后續注入轉向進入驅替高含油區域、進而提高剩余油采收率的重要因素。

油氣注液驅替開采會造成儲層地應力重分布,引發巖石結構變形,進而改變巖石內流體的驅替特性。然而,儲層巖石深埋地下,驅替開采引發的巖石孔隙結構三維形變及驅替行為“看不見、摸不著”,難以直觀顯示和定量描述,同時也缺乏三維孔隙變形過程中孔尺度非混相驅替動力學行為與機理的科學認知與理論解析模型,傳統實驗方法無法觀測孔隙變形時的三維非混相驅替行為演化,難以揭示驅替過程的主控因素。為解決該問題,筆者在天然巖石三維孔隙結構CT圖像的基礎上,采用3D打印技術,制備了與天然巖石相同孔隙結構的三維物理模型(圖24,其中,為歸一化的圍壓;為驅替效率),采用自主研發的原位三軸加載CT成像系統,開展了不同圍壓條件下三維孔隙結構變形與變形孔隙結構內三維油水驅替演化的原位CT掃描實驗,透明顯示并定量分析了不同圍壓條件下油水驅替過程中驅替前緣運移行為及指進現象、優勢路徑以及殘余油空間分布的動態演化(圖23),建立了有效應力、孔隙變形特征以及油水驅替效率之間的定量關系,為科學認知和定量描述油氣資源開采引起的儲層巖石孔隙結構形變與水油驅替機理提供了新手段、新方法,取得了新發現。

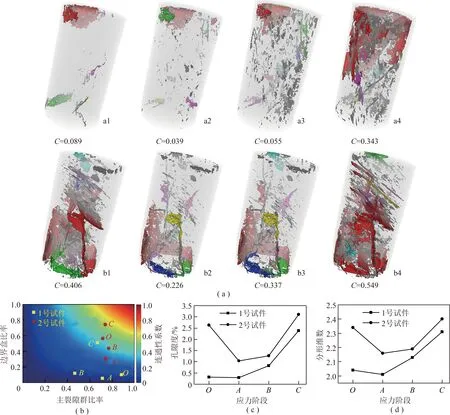

直接觀測與定量表征煤層開采過程中煤巖內部三維裂隙網絡演化以及裂隙網絡內部流體流動是預測導水裂隙帶演化和防治礦井水污染的重要基礎。然而,采動應力作用下煤巖內部三維裂隙網絡發育演化以及流體流動難以直接觀測,現有理論模型和數值模擬方法難以計算和預測這一復雜過程。近年來,國內外學者嘗試使用CT成像技術來研究巖石內部三維裂隙演化與流體流動規律,但受限于實驗設備和測試方法,目前研究大多采用對變形破壞后的巖石樣品進行CT掃描來觀測巖石內部的三維裂隙網絡及流體分布。然而,這種方法難以觀測樣品在承載條件下的內部結構變形與流動行為,相較于原位應力狀態下三維裂隙結構和流體流動行為會產生較大誤差。針對上述挑戰,筆者利用所研發的原位三軸加載CT成像系統,開展了不同開采應力路徑下煤巖三維裂隙網絡演化與水流特征的原位CT觀測實驗,直觀展現并定量表征了不同應力階段煤巖內部三維裂隙網絡的拓撲結構、連通性和裂隙生長閉合,并分析了其對裂隙煤巖滲透率的影響(圖25,為連通性系數),該研究提供了一種直接觀測和定量表征采動應力下煤巖三維裂隙網絡演化和滲透率改變的實驗方法,為預測煤礦開采過程中導水裂隙帶的分布與演化以及礦井水污染防治提供了基礎和參考。

圖23 高中低滲非均質孔隙結構內調剖堵水透明可視化實驗[126]Fig.23 Visualization of water flooding,polymer gel injection,antidilution polymer flooding,and surfactant agent flooding processes in a 3D printed heterogeneous porous model[126]

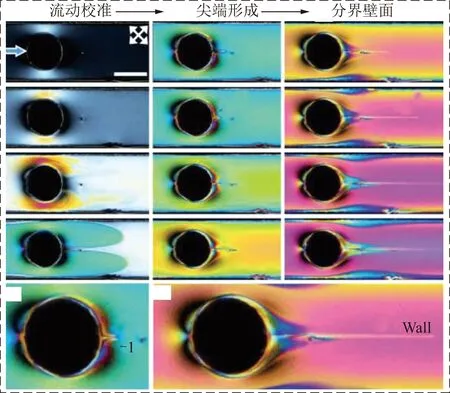

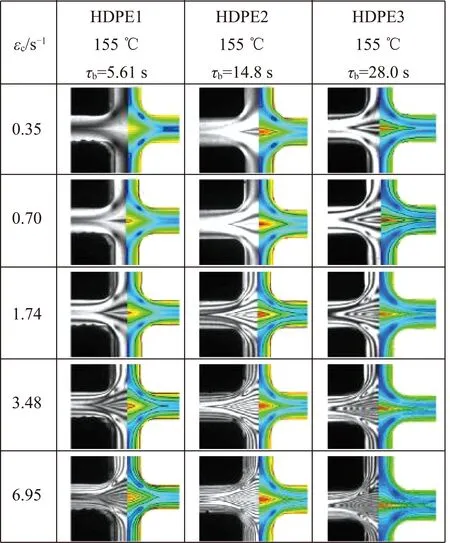

值得關注的是,煤炭資源開發過程誘發的巖石災變常常是固體變形與流體流動耦合作用的結果,如何透明顯示和定量解析巖石災變中的流固耦合效應一直是巖石力學研究的前沿課題。基于作者建立的固體應力場透明解析方法以及流體雙折射法,筆者制備了內含流體介質的巖石復雜結構的3D打印模型(圖6(b)),提出災變過程中巖石固體與流體應力場耦合作用的透明解析方法。該方法同時捕捉外載作用下巖石模型固體和流體內部的應力光彈條紋(圖26),利用作者改進的光彈條紋解析方法,提取固體和流體介質的應力場,實現巖石變形過程中內部固體與流體應力場耦合作用及致災機理的透明解析。其中流體雙折射法(Flow-Induced Birefringence,FIB)是指利用具有雙折射效應的流體來直觀顯示流場應力分布的方法,例如,PHILIPPOFF,PRADOS和PEEBLES等學者研究發現了流體的應力雙折射效應;MULLER和VERGNES研究了流體應力雙折射條紋與流體內部應力場的對應關系;SENGUPTA等利用流體應力雙折射條紋研究了圓柱繞流條件下流體內部的應力場演化(圖27);AUHL等借助流體雙折射條紋分析了不同應變率條件下流體流動過程中的應力場,并與數值計算結果進行了對比(圖28,其中,為應變率;為時間)。上述研究為透明解析巖石內部流體介質與固體結構內部應力場耦合效應提供了途徑和方法。

圖24 不同圍壓條件下水驅路徑與殘余油空間分布[131]Fig.24 Water flow paths and 3D oil trapping under various confining pressures[131]

圖25 不同開采應力路徑下煤巖內部三維裂隙演化特征[135]Fig.25 Evolution of 3D fractures inside a coal under various mining-induced stresses[135]

圖26 豎向壓縮時內含流體介質的三維孔隙結構固體與流體應力條紋Fig.26 Stess patterns of the solid and liquid in a 3D porous model under vertical compressive loads

圖27 流體繞過圓柱障礙物時的流動情況[139]Fig.27 Fluid birefringence fringe during fluid flow through one cylinder[139]

圖28 不同應變率下流體內部應力實測值與數值結果的對比[140]Fig.28 Comparison of fluid birefringence fringes and numerical solutions under different strain rates[140]

8 結論與展望

(1)三維數字重構方法可以經濟有效地獲取和透明顯示巖石內部非連續結構,但目前研究主要集中在利用有限微觀結構信息進行巖石RVE模型重構,在重構模型尺度、重構效率和模型精度方面仍需要進一步提升。

(2)3D打印技術為制備巖石復雜非連續結構物理模型并量化非連續結構對巖石災變力學行為的影響提供了新途徑。但研制反映天然巖石物性并能夠透明量化巖石多物理場行為的3D打印材料仍面臨諸多挑戰,尚需從多方面進一步研究和改性現有的打印材料。

(3)基于具有自主知識產權的原位三軸加載CT成像系統、三維數字重構方法及研制的透明3D打印材料,制備了具有與天然巖石一致非連續裂隙、孔隙結構及相近物理力學性質的巖石透明物理模型,為通過RVE物理模型揭示并量化巖石災變的內部非連續結構及多物理場耦合效應創造了條件。

(4)初步形成了巖石非連續結構應力場、應變場、滲流場等多物理場定量透明解析理論與方法,為破解開采誘發的巖石災變“黑箱”機理、建立基于RVE尺度多物理場透明解析的非連續巖石力學與災變分析理論、實現開采災害的透明推演、超前預警和科學防控提供了途徑和研究基礎。

需要指出的是,巖石災變內部非連續結構及多物理場效應的透明解析與透明推演研究尚屬剛剛起步,當前研究面臨諸多挑戰。例如,除需進一步研發反映天然巖石物性并能夠透明量化巖石多物理場行為的3D打印材料外,在透明解析巖石內部塑性變形與應力場特征、建立內部塑性變形解析量與宏觀塑性力學響應之間的定量關系、透明解析多物理場之間的耦合效應、分析和量化多相(固、液、氣)多物理場之間的相互作用仍存在困難,迫切需要通過多學科交叉融合開展更深入的研究。

[1] 2050世界與中國能源展望(2020版)[R]. 中國石油經濟技術研究院,2020.

[2] 中國政府網. 中央經濟工作會議[EB/OL]. http://www. gov. cn/xinwen/2021-12/10/content_5659796. html,2021-12-10.

[3] 新華社. 習近平在第七十五屆聯合國大會一般性辯論上的講話[EB/OL]. http://www. xinhuanet. com/politics/leaders/2020-09/22/c_1126527652. htm,2020-09-22.

[4] 潘一山,代連朋,李國臻,等. 煤礦沖擊地壓與冒頂復合災害研究[J]. 煤炭學報,2021,46(1):112-122.

PAN Yishan,DAI Lianpeng,LI Guozhen,et al. Study on compound disaster of rock burst and roof falling in coal mines[J]. Journal of China Coal Society,2021,46(1):112-122.

[5] 袁亮. 深部采動響應與災害防控研究進展[J]. 煤炭學報,2021,46(3):716-725.

YUAN Liang. Research progress of mining response and disaster prevention and control in deep coal mines[J]. Journal of China Coal Society,2021,46(3):716-725.

[6] 齊慶新,潘一山,李海濤,等. 煤礦深部開采煤巖動力災害防控理論基礎與關鍵技術[J]. 煤炭學報,2020,45(5):1567-1584.

QI Qingxin,PAN Yishan,LI Haitao,et al. Theoretical basis and key technology of prevention and control of coal-rock dynamic disasters in deep coal mining[J]. Journal of China Coal Society,2020,45(5):1567-1584.

[7] 李鐵,蔡美峰,蔡明. 采礦誘發地震分類的探討[J]. 巖石力學與工程學報,2006,25(S2):3679-3686.

LI Tie,CAI Meifeng,CAI Ming. A discussion on classification of mining-induced seismicity[J]. Chinese Journal of Mechanics and Engineering,2006,25(S2):3679-3686.

[8] DEKOCK Tim,BOONE Marijn A,DE Schryver Thomas,et al. A pore-scale study of fracture dynamics in rock using X-ray micro-CT under ambient freeze-thaw cycling[J]. 2015,49(5):2867-2874.

[9] JIANG Zeyun,VAN Dijke Marinusizaak Jan,GEIGER Sebastian,et al. Pore network extraction for fractured porous media[J]. Advances in Water Resources,2017,107:280-289.

[10] JU Yang,REN Zhangyu,ZHENG Jiangtao,et al. Quantitative visualization methods for continuous evolution of three-dimensional discontinuous structures and stress field in subsurface rock mass induced by excavation and construction-An overview[J]. Engineering Geology,2020,265:105443.

[11] MING C,HORII H. A constitutive model of highly jointed rock masses[J]. Mechanics of Materials,1992,13(3):217-246.

[12] LI Shihai,ZHOU Dong. Progressive failure constitutive model of fracture plane in geomaterial based on strain strength distribution[J]. International Journal of Solids and Structures,2013,50(3):570-577.

[13] 謝和平. 深部巖體力學與開采理論研究進展[J]. 煤炭學報,2019,44(5):1283-1305.

XIE Heping. Research review of the state key research development program of China:Deep rock mechanics and mining theory[J]. Journal of China Coal Society,2019,44(5):1283-1305.

[14] JU Yang,XIE Heping,ZHENG Zemin,et al. Visualization of the complex structure and stress field inside rock by means of 3D printing technology[J]. Chinese Science Bulletin,2014,59(36):5354-5365.

[15] KETCHAMRICHARD A,CARLSON William D. Acquisition,optimization and interpretation of X-ray computed tomographic imagery:Applications to the geosciences[J]. Computers and Geosciences,2001,27(4):381-400.

[16] BLUNTMARTIN J,BIJELJIC Branko,DONG Hu,et al. Pore-scale imaging and modelling[J]. Advances in Water Resources,2013,51:197-216.

[17] WILDENSCHILD Dorthe,SHEPPARD Adrian P. X-ray imaging and analysis techniques for quantifying pore-scale structure and processes in subsurface porous medium systems[J]. Advances in Water Resources,2013,51(1):217S246.

[18] CNUDDE V,BOONE M N. High-resolution X-ray computed tomography in geosciences:A review of the current technology and applications[J]. Earth-Science Reviews,2013,123(4):1-17.

[19] WERTHCHARLES J,ZHANG Changyong,BRUSSEAU Mark L,et al. A review of non-invasive imaging methods and applications in contaminant hydrogeology research[J]. Journal of Contaminant Hydrology,2010,113(1-4):1-24.

[20] XIONG Q R,BAYCHEV T G,JIVKOV A P. Review of pore network modelling of porous media:Experimental characteris-ations,network constructions and applications to reactive transport[J]. Journal of Contaminant Hydrology,2016,192:101-117.

[21] NIASHAHRAM Farhadi,DASANI Devang,TSOTSIS Theodore T,et al. An integrated approach for the characterization of shales and other unconventional resource materials[J]. Industrial and Engineering Chemistry Research,2016,55(12):3718-3728.

[22] WANG Moran,PAN Ning. Modeling and prediction of the effective thermal conductivity of random open-cell porous foams[J]. International Journal of Heat and Mass Transfer,2008,51(5-6):1325-1331.

[23] ZHENG Jiangtao,WANG Ziyan,GONG Wenbo,et al. Characterization of nanopore morphology of shale and its effects on gas permeability[J]. Journal of Natural Gas Science and Engineering,2017,47:83-90.

[24] JU Yang,ZHANG Qinggang,YANG Yongming,et al. An experimental investigation on the mechanism of fluid flow through single rough fracture of rock[J]. Science China-Technological Sciences,2013,56(8):2070-2080.

[25] JU Yang,ZHANG Qingang,ZHENG Jiangtao,et al. Fractal model and lattice Boltzmann method for characterization of non-Darcy flow in rough fractures[J]. Scientific Reports,2017,7:1-9.

[26] OKABE H,BLUNT M J. Pore space reconstruction using multiple-point statistics[J]. Journal of Petroleum Science and Engineering,2005,46(1):121-137.

[27] JU Yang,ZHENG Jiangtao,EPSTEIN Marcelo,et al. 3D numerical reconstruction of well-connected porous structure of rock using fractal algorithms[J]. Computer Methods in Applied Mechanics and Engineering,2014,279(9):212-226.

[28] JIAO Y,STILLINGER F,TORQUATO S. A superior descriptor of random textures and its predictive capacity[J]. Proceedings of the National Academy of Sciences,2009,106(42):17634-17639.

[29] JU Yang,HUANG Yaohui,GONG Wenbo,et al. 3-D reconstruction method for complex pore structures of rocks using a small number of 2-D X-ray computed tomography images[J]. IEEE Transactions on Geoscience and Remote Sensing,2018,57(4):1873-1182.

[30] GERKEKIRILL M,KARSANINA Marina V. Improving stochastic reconstructions by weighting correlation functions in an objective function[J]. Europhysics Letters,2015,111(5):1-5.

[31] KARSANINA Marina,GERKE Kirill. Hierarchical optimization:fast

and robust multiscale stochastic reconstructions with rescaled correlation functions[J]. Physical Review Letters,2018,121(26):1-6.

[32] JU Yang,HUANG Yaohui,ZHENG Jiangtao,et al. Multi-thread parallel algorithm for reconstructing 3D large-scale porous structures[J]. Computers and Geosciences,2017,101:10-20.

[33] ?REN P E,BAKKE S. Process based reconstruction of sandstones and prediction of transport properties[J]. Transport in Porous Media,2002,46(2):311-343.

[34] MOSSER Lukas,DUBRULE Olivier,BLUNT MARTIN J. Reconstruction of three-dimensional porous media using generative adversarial neural networks[J]. Physical Review E,2017,96(4):1-17.

[35] PERRASMATTHEW A,VOGLER Daniel. Compressive and tensile behavior of 3D-printed and natural sandstones[J]. Transport in Porous Media,2018,129(2):559-581.

[36] ZHOU Tao,ZHU Jianbo. Identification of a suitable 3D printing mate-rial for mimicking brittle and hard rocks and its brittleness enhancements[J]. Rock Mechanics and Rock Engineering,2018,51(3):765-777.

[37] ZHOU Tao,ZHU Jianbo. An experimental investigation of tensile fracturing behavior of natural and artificial rocks in static and dynamic brazilian disc tests[J]. Procedia Engineering,2017,191:992-998.

[38] GELLE Leanor M,WALLEY Stephen M,BRAITHWAITE christo-

pher H. Review of the validity of the use of artificial specimens for characterizing the mechanical properties of rocks[J]. Rock Mechanics and Rock Engineering,2019,52(9):2949-2961.

[39] WANG Li,JU Yang,XIE Heping,et al. The mechanical and photoelastic properties of 3D printable stress-visualized materials[J]. Scientific Reports,2017,7(1):10918.

[40] JU Yang,GUO Wang,REN Zhangyu,et al. Experimental study on

mechanical and optical properties of printable photopolymer used for visualising hidden structures and stresses in rocks[J]. Optical Materials,2021,111:110691.

[41] JU Yang,REN Zhangyu,HU Xuan,et al. Critical phase-transition temperature for freezing stress in thermo-sensitive photopolymers used for visualizing stress fields in solids[J]. Optics and Lasers in Engineering,2021,139:106458.

[42] JU Yang,REN Zhangyu,LI Xiaolan,et al. Quantification of hidden whole-field stress inside porous geomaterials via three-dimensional printing and photoelastic testing methods[J]. Journal of Geophysical Research Solid Earth,2019,124(6):5408-5426.

[43] JING L. A review of techniques,advances and outstanding issues in numerical modelling for rock mechanics and rock engineering[J]. International Journal of Rock Mechanics and Mining Sciences,2003,40(3):283-353.

[44] KATO Naoyuki. Interaction of slip on asperities:Numerical simulation of seismic cycles on a two-dimensional planar fault with nonuniform frictional property[J]. Journal of Geophysical Research:Solid Earth,2004,109(B12):1-17.

[45] ISHUTOV Sergey,HASIUK Franciszek J,HARDING Chris,et al. 3D printing sandstone porosity models[J]. Interpretation,2015,3(3):SX49-SX61.

[46] ISHUTOV Sergey,HASIUK Franciszek J,FULLMER Shawn M,et al. Resurrection of a reservoir sandstone from tomographic data using three-dimensional printing[J]. AAPG Bulletin,2017,101(9):1425-1443.

[47] ISHUTOV S,HASIUK F J,JOBE D,et al. Using resin-based 3D printing to build geometrically accurate proxies of porous sedimentary rocks[J]. Ground Water,2018,56(3):482-490.

[48] JIANG Quan,FENG Xiating,GONG Yanhua,et al. Reverse modelling of natural rock joints using 3D scanning and 3D printing[J]. Computers and Geotechnics,2016,73:210-220.

[49] JU Yang,WANG Jianqiang,PENG Ruidong,et al. Industrial CT scanning test system[P]. US Patent:15539835,2018-02-13.

[50] JU Yang,WANG Jianqiang,PENG Ruidong,et al. Industrial CT scanning test system and fluid pressure loading apparatus[P]. US Patent:15539835,2018-01-30.

[51] 鞠楊,王建強,彭瑞東,等. 一種工業CT掃描試驗方法及試驗系統[P]. 中國專利:CN106706676B,2019-07-26.

[52] JU Yang,WANG Li,XIE Heping,et al. Visualization and transparentization of the structure and stress field of aggregated geomaterials through 3D printing and photoelastic techniques[J]. Rock Mechanics and Rock Engineering,2017,50(6):1383-1407.

[53] JU Yang,WANG Li,XIE Heping,et al. Visualization of the three-

dimensional structure and stress field of aggregated concrete materials through 3D printing and frozen-stress techniques[J]. Construction and Building Materials,2017,143:121-137.

[54] JU Yang,REN Zhangyu,MAO Lingtao,et al. Quantitative visualisation of the continuous whole-field stress evolution in complex pore structures using photoelastic testing and 3D printing methods[J]. Optics Express,2018,26(5):6182-6201.

[55] HILLER Jonathan,LIPSON Hod. Design and analysis of digital materials for physical 3D voxel printing[J]. Rapid Prototyping Journal,2009,15(2):137-149.

[56] SOSSOU Germain,DEMOLY Frédéric,BELKEBIR Hadrien,et al. Design for 4D printing:A voxel-based modeling and simulation of smart materials[J]. Materials & Design,2019,175:107798.

[57] BELL Darren,SIEGMUND Thomas. 3D-printed polymers exhibit a strength size effect[J]. Additive Manufacturing,2018,21:658-665.

[58] AKIYAMA Hiroyuki,UCHIDA Makoto,KANEKO Yoshihisa. Evaluation of effect of sample size and layer direction on mechanical property of specimen manufactured by FDM-type 3D printer[J]. Key Engineering Materials,2019,794:324-332.

[59] THEOCARISPERICLES S,GDOUTOS Emmanuel E. Matrix theory of photoelasticity[M]. Berlin:Springer,2013.

[60] FROCHTMAX Mark. Photoelasticity:The selected scientific papers of MM Frocht[M]. Pergamon:1969.

[61] JU Yang,REN Zhangyu,WANG Li,et al. Photoelastic method to quantitatively visualise the evolution of whole-field stress in 3D printed models subject to continuous loading processes[J]. Optics and Lasers in Engineering,2018,100:248-258.

[62] JU Yang,WANG Yating,REN Zhangyu,et al. Optical method to quantify the evolution of whole-field stress in fractured coal subjected to uniaxial compressive loads[J]. Optics and Lasers in Engineering,2020,128:106013.

[63] YIN Peijie,ZHAO Can,MA Jianjun,et al. Experimental study of non-linear fluid flow through rough fracture based on fractal theory and 3D printing technique[J]. International Journal of Rock Mechanics and Mining Sciences,2020,129:104293.

[64] JU Yang,WAN Changbing,REN Zhangyu,et al. Quantification of

continuous evolution of full-field stress associated with shear deformation of faults using three-dimensional printing and phase-shifting methods[J]. International Journal of Rock Mechanics Mining Sciences,2020,126:104187.

[65] JU Yang,WAN Changbing,FU Guoming,et al. Optical method for identification and quantification of full-field stress distributions and evolution in assembled lining structures based on additively printed models and phase-shifting methods[J]. Tunnelling and Underground Space Technology,2022,119:104228.

[66] MISSERONI D,DAL CORSO F,SHAHZAD S,et al. Stress concentration near stiff inclusions:Validation of rigid inclusion model and boundary layers by means of photoelasticity[J]. Engineering Fracture Mechanics,2014,121-122:87-97.

[67] DANIELSKAREN E,HAYMAN Nicholas W. Force chains in seismogenic faults visualized with photoelastic granular shear experiments[J]. Journal of Geophysical Research:Solid Earth,2008,113(B11):B11411.

[68] BIGONI Davide,NOSELLI Giovanni. Localized stress percolation

through dry masonry walls. Part I - Experiments[J]. European Journal of Mechanics-A/Solids,2010,29(3):291-298.

[69] BIGONI Davide,NOSELLI Giovanni. Localized stress percolation thr-

ough dry masonry walls. Part II-Modelling[J]. European Journal of Mechanics-A/Solids,2010,29(3):299-307.

[70] GHISLAIN de Joussineau,PETIT JeanPierre,GAUTHIERBERTRAND D M. Photoelastic and numerical investigation of stress distributions around fault models under biaxial compressive loading conditions[J]. Tectonophysics,2003,363(1-2):19-43.

[71] SOLIVA Roger,MAERTEN Frantz,PETIT JeanPierre,et al. Field evidences for the role of static friction on fracture orientation in extensional relays along strike-slip faults:Comparison with photoelasticity and 3-D numerical modeling[J]. Journal of Structural Geology,2010,32(11):1721-1731.

[72] LUNINA O V,GLADKOV A S,AFONKIN A M,et al. Deformation style in the damage zone of the Mondy fault:GPR evidence(Tunka basin,southern East Siberia)[J]. Russian Geology and Geophysics,2016,57(9):1269-1282.

[73] CERNOSEK Jan. Three-dimensional photoelasticity by stress freezing

[J]. Experimental Mechanics,1980,20(12):417-426.

[74] KUSKE Albrecht,ROBERTSON George Stewart. Photoelastic stress analysis[M]. New Jersey :Wiley-Interscience,1974.

[75] FROCHTMAX Mark,GUERNSEY JR R. A special investigation to develop a general method for three-dimensional photoelastic stress analysis[J]. National Advisory Committee for Aeronautics,1952.

[76] GUERNSEY R. A special investigation to develop a general method for three-dimensional photoelastic stress analysis[M]. Oxford:Pergamon,1969,233-269.

[77] SWAIN Digendranath,PHILIP Jeby,PILLAI Annamala,et al. A revisit to the frozen stress phenomena in photoelasticity[J]. Experimental Mechanics,2016,56:903-917.

[78] HEYWOOD R B. Photoelasticity for Designers [M]. Oxford :Pergamon,1969.

[79] 謝和平,高峰,鞠楊,等. 深地煤炭資源流態化開采理論與技術構想[J]. 煤炭學報,2017,42(3):547-556.

XIE Heping,GAO Feng,JU Yang,et al. Theoretical and technological conception of the fluidization mining for deep coal resources[J]. Journal of China Coal Society,2017,42(3):547-556.

[80] LEE S,RAVICHANDRAN G. An investigation of cracking in brittle solids under dynamic compression using photoelasticity[J]. Optics and Lasers in Engineering,2003,40(4):341-352.

[81] JU Yang,XIE Heping,ZHAO Xi,et al. Visualization method for stress-field evolution during rapid crack propagation using 3D printing and photoelastic testing techniques[J]. Scientific Reports,2018,8(1):1-10.

[82] XIA Kaiwen,ROSAKISARES J,HIROO Kanamori. Laboratory ear-

thquakes:The sub-Rayleigh-to-supershear rupture transition[J]. Science,2004,303(5665):1859-1861.

[83] XIA Kaiwen,ROSAKISARES J. Laboratory earthquakes along faults

with a low velocity zone:Directionality and pulse-like ruptures[J]. Extreme Mechanics Letters,2021,46:101321.

[84] GABUCHIAN Vahe,ROSAKIS Ares,BHAT Harsha S,et al. Experimental evidence that thrust earthquake ruptures might open faults[J]. Nature,2017,545:336-340.

[85] GABUCHIAN Vahe,ROSAKIS Ares J,LAPUSTA Nadia,et al. Experimental investigation of strong ground motion due to thrust-fault earthquakes[J]. Journal of Geophysical Research Solid Earth,2014,119(2):133-143.

[86] ASUNDI Anand,TONG Liu,BOAY Chai Gin. Dynamic phase-shifting photoelasticity[J]. Applied Optics,2001,40(22):3654-3658.

[87] ASUNDI Anand,SAJAN M R,LIU Tong. Dynamic photoelasticity using TDI imaging[J]. Optics & Lasers in Engineering,2002,38(1-2):3-16.

[88] AJOVALASIT A,PETRUCCI G,SCAFIDI M. Review of RGB photoelasticity[J]. Optics & Lasers in Engineering,2015,68:58-73.

[90] AJOVALASIT A,PETRUCCI G. Developments in RGB Photoelasticity[J]. Applied Mechanics & Materials,2005,3-4:205-210.

[91] RAMAKRISHNAN Vivek,RAMESH K. Scanning schemes in white light Photoelasticity-Part I:Critical assessment of existing schemes[J]. Optics and Lasers in Engineering,2017,92:129-140.

[92] RAMAKRISHNAN Vivek,RAMESH K. Scanning schemes in white light photoelasticity-Part II:Novel fringe resolution guided scanning scheme[J]. Optics and Lasers in Engineering,2017,92:141-149.

[93] NG T W. Photoelastic stress analysis using an object step-loading method[J]. Experimental Mechanics,1997,37(2):137-141.

[94] ZUCCARELLO B,TRIPOLI G. Photoelastic stress pattern analysis using Fourier transform with carrier fringes:Influence of quarter-wave plate error[J]. Optics & Lasers in Engineering,2002,37(4):401-416.

[95] RAMESH K,KASIMAYAN T,NEETHI Simon B. Digital photoelasticity - A comprehensive review[J]. The Journal of Strain Analysis for Engineering Design,2011,46:245-266.

[96] MANOGG Peter. Investigation of the rupture of a plexiglas plate by means of an optical method involving high-speed filming of the shadows originating around holes drilled in the plate[J]. International Journal of Fracture Mechanics,1966,2(4):604-613.

[97] QIU Peng,YUE Zhongwen,YANG Renshu. Mode I stress intensity factors measurements in PMMA by caustics method:A comparison between low and high loading rate conditions[J]. Polymer Testing,2019,76:273-285.

[98] GAO Guiyun,LI Zheng,NEGAHBAN Mehrdad. Dynamic fracture analysis of polycarbonate by the optical method of caustics[J]. Procedia Materials Science,2014,3:165-176.

[99] PAPADOPOULOS G A. New formula of experimental stress intensity factor evaluation by caustics[J]. International Journal of Fracture,2011,171(1):79.

[100] REN Zhangyu,XIE Huimin,JU Yang. Quantification of photoela-stic fringe orders using polarized light camera and continuous loading[J]. Optics and Lasers in Engineering,2020,134:106263.

[101] JU Yang,LIU Peng,REN Zhangyu,et al. Characterization of stress field evolution during 3D internal fracture propagation using additively printed models and frozen stress techniques[J]. Theoretical and Applied Fracture Mechanics,2021,111:102870.

[102] LIU Peng,JU Yang,FU Guoming,et al. Visualization of full-field stress evolution during 3D penetrated crack propagation through 3D printing and frozen stress techniques[J]. Engineering Fracture Mechanics,2020,236:107222.

[103] BAYBRIAN K,Smith TAIT S,Fyhrie DAVID P,et al. Digital volume correlation:Three-dimensional strain mapping using X-ray tomography[J]. Experimental Mechanics,1999,39(3):217-226.

[104] SMITHTAIT S,BAY BRIAN K,RASHID Mark M. Digital volume correlation including rotational degrees of freedom during minimization[J]. Experimental Mechanics,2002,42(3):272-278.

[105] LIU Li,MORGAN Elise. Accuracy and precision of digital volume correlation in quantifying displacements and strains in trabecular bone[J]. Journal of Biomechanics,2007,40(15):3516-3520.

[106] OBATA Yoshihiro,BALE HRISHIKESH A,BARNARD HAROLD S,et al. Quantitative and qualitative bone imaging:A review of synchrotron radiation microtomography analysis in bone research[J]. 2020,110:103887.

[107] WANG Long,ZHANG Wei,LI Haibo,et al. 3D in-situ characterizations of damage evolution in c/sic composite under monotonic tensile loading by using X-Ray computed tomography[J]. Applied Composite Materials,2020,27(1):1-12.

[108] RETHORE J,LIMODIN N,BUFFIERE J Y,et al. Digital volume correlation analyses of synchrotron tomographic images[J]. Journal of Strain Analysis for Engineering Design,2011,46(7):683-695.

[109] BULJAC A,JAILIN C,MENDOZA A,et al. Digital volume correlation:Review of progress and challenges[J]. Experimental Mechanics,2018,58(5):1-48.

[110] XU Feng. Quantitative characterization of deformation and damage process by digital volume correlation:A review[J]. Theoretical and Applied Mechanics Letters,2018,8(2):83-96.

[111] XU Feng. Quantitative characterization of deformation and damage process by digital volume correlation:A review[J]. Theoretical and Applied Mechanics Letters,2018,8(2):83-96.

[112] BULJAC A,JAILIN C,MENDOZA A,et al. Digital volume correlation:Review of progress and challenges[J]. Experimental Mechanics,2018,58(5):661-708.

[113] PAN Bing,WANG Bo. Some recent advances in digital volume correlation[J]. Optics and Lasers in Engineering,2020,135:106189.

[114] MAO Lingtao,LIU Haizhou,ZHU Ying,et al. 3D strain mapping of opaque materials using an improved digital volumetric speckle photography technique with X-ray microtomography[J]. Applied Sciences,2019,9(7):1418.

[115] MAO Lingtao,ZHU Ying,WANG Yuwei,et al. An improved digital volumetric speckle photography technique with X-ray microtomography and its applications to investigating strain localization in red sandstone[J]. Applied Sciences,2020,53(3):1457-1466.

[116] MAO Lingtao,HAO Nai,AN Liqian,et al. 3D mapping of carbon dioxide-induced strain in coal using digital volumetric speckle photography technique and X-ray computer tomography[J]. International Journal of Coal Geology,2015,147-148:115-125.

[117] MAO Lingtao,CHIANG Fupen. 3D strain mapping in rocks using digital volumetric speckle photography technique[J]. Acta Mechanica,2016,227(11):3069-3085.

[118] MAO Lingtao,YUAN Zexun,YANG Min,et al. 3D strain evolution in concrete using in situ X-ray computed tomography testing and digital volumetric speckle photography[J]. Measurement,2019,133:456-467.

[119] LENOIR N,BORNERT M,DESRUES J,et al. Volumetric digital image correlation applied to X-ray microtomography images from triaxial compression tests on argillaceous rock[J]. Strain,2007,43(3):193-205.

[120] GANDOMKAR Asghar,RAHIMPOUR Mohammad Reza. Investigation of low-salinity waterflooding in secondary and tertiary enhanced oil recovery in limestone reservoirs[J]. Energy and Fuels,2015,29:7781-7792.

[121] HerringANNA L,ANDERSSON Linnéa,NEWELL D L,et al. Pore-

scale observations of supercritical COdrainage in Bentheimer sandstone by synchrotron X-ray imaging[J]. International Journal of Greenhouse Gas Control,2014,25:93-101.

[122] SKAUGE Arne,ZAMANI Nematollah,GAUSDAL Jacobsen J?rgen,et al. Polymer flow in porous media:Relevance to enhanced oil recovery[J]. Colloids and Interfaces,2018,2:27.

[123] JU Yang,GONG Wenbo,ZHENG Jiangtao. Characterization of immiscible phase displacement in heterogeneous pore structures:Parallel multicomponent lattice Boltzmann simulation and experimental validation using three-dimensional printing technology[J]. International Journal of Multiphase Flow,2019,114:50-65.

[124] JU Yang,GONG Wenbo,CHANG Wei,et al. Effects of pore characteristics on water-oil two-phase displacement in non-homogeneous pore structures:A pore-scale lattice Boltzmann model considering various fluid density ratios[J]. International Journal of Engineering Science,2020,154:103343.

[125] LIU Jinhui,JU Yang,ZHANG Yingqi,et al. Preferential paths of air-water two-phase flow in porous structures with special consideration of channel thickness effects[J]. Scientific Reports,2019,9(1):16204.

[126] ZHENG Jiangtao,WANG Zenglin,JU Yang,et al. Visualization of water channeling and displacement diversion by polymer gel treatment in 3D printed heterogeneous porous media[J]. Journal of Petroleum Science and Engineering,2021,198:108238.

[127] CNUDDE V,BOONE M N. High-resolution X-ray computed tomography in geosciences:A review of the current technology and applications[J]. Earth-Science Reviews,2013,123:1-17.

[128] CONNOLLY Paul R J,VOGT Sarah J,IGLAUER Stefan,et al. Capillary trapping quantification in sandstones using NMR relaxometry[J]. Water Resources Research,2017,53:7917-7932.

[129] ISHAKOGLU Ali,BAYTAS A Filiz.The influence of contact angle on

capillary pressure-saturation relations in a porous medium including various liquids[J]. International Journal of Engineering Science,2005,43:744-755.

[130] ISHIBASHI Takuya,MCGUIRE Thomas P,WATANABE Noriaki,et al. Permeability evolution in carbonate fractures:Competing roles of confining stress and fluid pH[J]. Water Resources Research,2013,49:2828-2842.

[131] JU Yang,XI Chaodong,ZHENG Jiangtao,et al. Study on three-dimensional immiscible water-oil two-phase displacement and trapping in deformed pore structures subjected to varying geostress via in situ computed tomography scanning and additively printed models[J]. International Journal of Engineering Science,2022,171:103615.

[132] ALHAMMADIAMER M,GAO Ying,AKAI Takashi,et al. Pore-scale X-ray imaging with measurement of relative perm-eability,capillary pressure and oil recovery in a mixed-wet micro-porous carbonate reservoir rock[J]. Fuel,2020,268:117018.

[133] GAO Ying,QASEMINEJAD Raeini Ali,BLUNT Martin J,et al. Pore occupancy,relative permeability and flow intermittency measurements using X-ray micro-tomography in a complex carbonate[J]. Advances in Water Resources,2019,129:56-69.

[134] HERRING Anna L,ANDERSSON Linnéa,SCHLüTER Steffen,et al. Efficiently engineering pore-scale processes:The role of force dominance and topology during nonwetting phase trapping in porous media[J]. Advances in Water Resources,2015,79:91-102.

[135] JU Yang,XI Chaodong,WANG Shaojie,et al. 3-D fracture evolution and water migration in fractured coal under variable stresses induced by fluidized mining:In situ triaxial loading and CT imaging analysis[J]. Energy Reports,2021,7:3060-3073.

[136] PHILIPPOFF Wladimir. Flow-Birefringence and Stress[J].Nature,

1956,178:811-812.

[137] PRADOS J W,PEEBLES F N. Two-dimensional laminar-flow anal-

ysis,utilizing a doubly refracting liquid[J]. 1959,5(2):225-234.

[138] MULLER R,VERGNES B. Validity of the stress optical law and application of birefringence to polymer complex flows[M]. Amsterdam:Elsevier,1996,257-284.

[139] SENGUPTA Anupam,PIEPER Christoph,ENDERLEIN J?rg,et al. Flow of a nematogen past a cylindrical micro-pillar[J]. Soft Matter,2013,9(6):1937-1946.

[140] AUHL D,HOYLE D M,HASSELL D,et al. Cross-slot extensional rheometry and the steady-state extensional response of long chain branched polymer melts[J]. Journal of Rheology,2011,55(4):875-900.