泵站正向進水前池擴散角對池內流場結構的影響

樊新建,董春海,王之君,陸亞楠,姚 薇

泵站正向進水前池擴散角對池內流場結構的影響

樊新建,董春海,王之君,陸亞楠,姚 薇

(蘭州理工大學能源與動力工程學院,蘭州 730050)

針對從多沙河流取水的大型泵站進水前池內水流流態較差,易在池內產生大尺度回流區域,導致泥沙嚴重淤積等問題,該研究以甘肅省景泰川電力提灌工程典型泵站的正向進水前池為研究對象,構建不同擴散角體型結構的正向進水前池三維模型,基于Mixture多相流模型和Realizable模型開展數值模擬計算,闡明了正向進水前池流場結構特征,提出了有效改善正向進水前池流場結構的擴散角范圍。結果表明:泵站機組全開時,正向進水前池內流場結構對稱分布,在進水前池中央形成主流區,兩側形成回流區,中央主流區域水流流速遠大于兩側回流區,主流效應顯著;隨著擴散角的減小,兩側低流速區面積減小,主流區域流速呈下降的趨勢,區域寬度呈現增加的趨勢,進入前池的水流擴散效應增加明顯;擴散角在25°~30°之間時,入池的水流沿流程發展和擴散較為充分,有效改善多泥沙河流引水泵站前池的泥沙淤積,研究成果可為同類泵站的設計和更新改造提供指導和參考。

泵站;數值模擬;正向進水前池;擴散角;流場結構;泥沙淤積

0 引 言

前池作為泵站進水建筑物中不可或缺的部分,具有平順、均勻擴散水流的作用,為水泵取水提供良好的進水條件[1-2]。對于從多泥沙河流提水的泵站,極易因進水前池體型結構不佳,在池內形成漩渦、回流等不良流態,導致泥沙嚴重淤積[3-4]。究其原因,進水前池的體型結構決定池內流場結構,流場結構紊亂不僅會在進水前池內產生泥沙淤積,還會惡化機組進水條件、降低泵站運行效率,嚴重制約灌區工程效益的發揮[5-8]。

隨著計算流體力學(computational fluid dynamics)理論與技術的發展,數值模擬和理論分析為研究泵站前池水流流態和泥沙淤積的主要方法,現階段該領域的專家學者已開展了大量研究工作。CONSTANTINESCU等[9]分別采用模型和模型模擬了泵站前池的漩渦分布特征,得出了選取合適的湍流模型對前池內的旋渦分布有著重大影響的結論。資丹等[10]針對正向泵站進水前池,采用CFD技術開展大型泵站組合式導流墩整流研究,結果表明“八字型導流墩+川字型導流墩+十字型消渦板”的組合式導流墩,可有效改善前池流態,提高水泵運行穩定性。李顏雁等[11]采用數值模擬的方法,基于3種不同增設立柱方案對前池進行整流,結果表明:增設非等間距雙排立柱可使前池流速分布較為均勻,改善前池水流流態。周濟人等[12]針對側向進水泵站,采用CFD軟件,基于N-S方程和Standard湍流模型對前池流態進行了數值模擬,結果表明加設“Y”型導流墩流速分布有所改善;加設底坎后,位于翼墻前方的旋渦消失,流場發生變化;加設導流墻有效優化了前池的水流流態。雷鎮等[13-14]均對泵站前池內的導流底坎進行了研究,分別提出了組合底坎整流的合適參數及底坎的相對高度、相對距離參數,從而改善前池內水流流態。蔻元之等[15]通過物理模型試驗,分析了泵站的正向進水前池在不同的泥沙含量和不同工況下的流態分布特征和泥沙淤積特點。高傳昌等[16]應用數值計算方法,提出了在進水池設置導流臺、水下消渦板和W型后墻導流墩的組合整流措施,結果表明,組合整流措施有效的改善了進水池的水流流態和速度分布。徐存東等[17]對多沙水源提水泵站引入逆向工程技術,建立淤積狀態下和非淤狀態下的三維泵站前池模型進行了水沙兩相流數值模擬,分析了開機組合對前池流場特性的影響,結果表明泵站機組對稱開啟時,主流擴散效果有所提高,泥沙淤積情況略有改善。上述研究表明,目前針對在前池內設置導流墩、導流墻、底坎、立柱、壓水板等局部整流設施,改善開機組合來優化前池內含沙水流流態的方法居多,但對前池體型結構,尤其是前池邊墻擴散角度對池內水流流場結構影響的研究還相對匱乏。

基于此,本文以甘肅省景泰川電力提灌工程(簡稱“景電工程”)典型泵站的正向進水前池作為研究對象,采用數值模擬與現場測試相結合的手段,開展大型泵站正向進水前池邊墻擴散角對池內流場結構的影響研究,以獲得前池水流流場結構特征,提出有效改善多泥沙河流引水泵站正向進水前池泥沙淤積的邊墻擴散角范圍,擬為同類泵站的設計和更新改造提供參考。

1 計算方法

1.1 研究對象

1.1.1 泵站參數

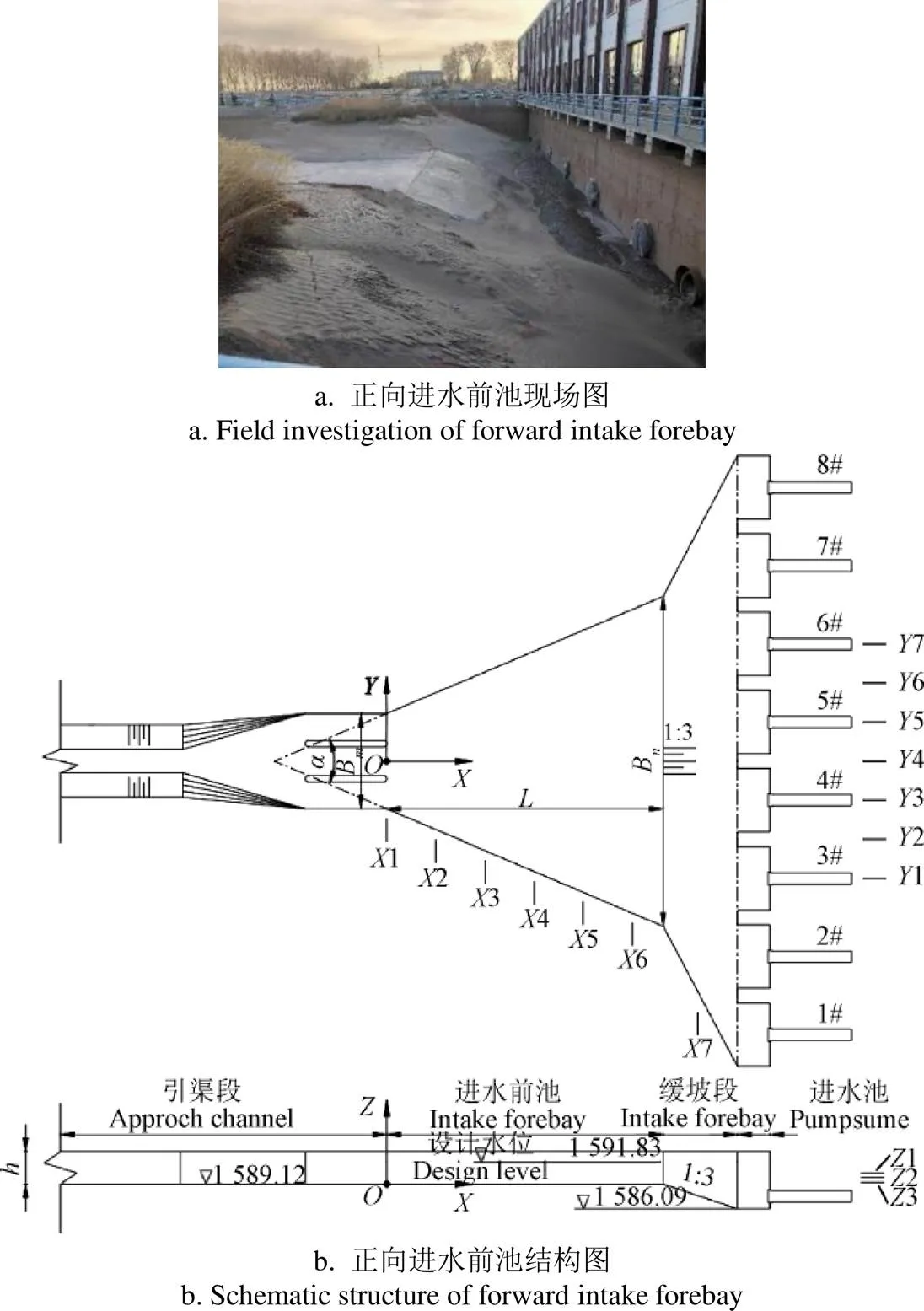

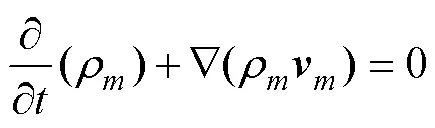

“景電工程”是一項高揚程、大流量、多梯級的大Ⅱ型電力提水灌溉工程,工程自黃河提水,共建有泵站40余座。典型泵站是該提水工程中前池泥沙淤積問題較為突出的泵站,如圖1a所示,其前池結構形式為正向直線擴散型,包括引渠段、前池段、進水池、出水管等,其中進水前池長度=33.83 m,入口端寬度B=11.7 m,末端寬度B=31.25 m,池深=3.97 m,邊墻擴散角=46°,泵站設計提水流量23 m3/s,設計前池水位1 591.83 m,共布置裝備8臺機組,其中2#~7#機組為常開機組,1#、8#機組為備用機組,吸水管管徑為1.4 m,池底緩坡段坡度為1∶3,正向進水前池結構形式見圖1b。

注:α為進水前池擴散角度,(°);L為進水前池長度,m;Bm為進水前池入口端寬度,m;Bn為進水前池末端寬度,m;h為進水前池池深,m;1#~8#為機組編號;X1~X7、Y1~Y7、Z1~Z3為觀測斷面。

1.1.2 泥沙特征

典型泵站正向進水前池內泥沙淤積形態基本呈對稱分布,中央區域泥沙淤積量少,兩側區域泥沙淤積較為集中,且越靠近邊墻,泥沙淤積量越多,淤積坡面平滑,形成了新的過流通道,嚴重影響泵站的正常取水。

對泵站引水泥沙含量及粒徑取樣分析,結果表明:泵站引水年均泥沙含量約為30 kg/m3,汛期最大泥沙含量達326 kg/m3,前池內懸浮泥沙顆粒粒徑分布在0.02~1 mm之間,其中小于0.063 mm的泥沙粒徑占比達到90%以上,屬于極細顆粒沙土。可見,該泵站提水水流具有含沙量高、泥沙粒徑小的特征,這也是導致進水前池內流場結構紊亂,泥沙淤積問題突出的根本原因。

1.2 控制方程

由于前池水流中既存在流體介質,還存有懸浮泥沙等固體物質,在探析前池內的流場結構時不應忽視多場耦合狀態,故采用ANSYS 10.0-Fluent分析軟件,基于Mixture多相耦合控制方程[18-19]展開固液兩相流模擬。

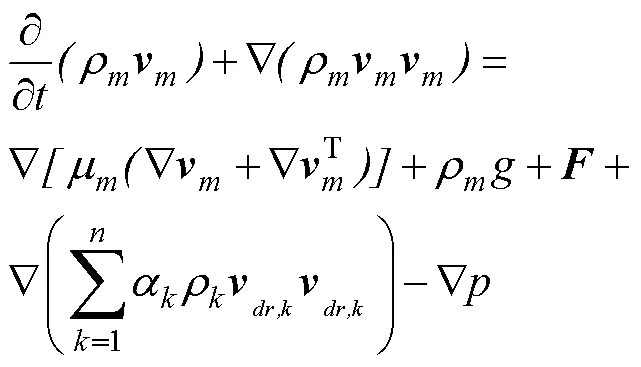

Mixture模型連續性方程:

Mixture模型運動方程:

式中為混合流體密度,kg/m3;為第相的密度,kg/m3;為第相的體積分數;為質量平均速度,m/s;為流場壓力;為相數;為混合流體黏滯性系數,Pa·s;為第相湍流運動粘性系數,Pa·s;為重力加速度,N/kg;為體積力,N;為次相等相的流速,m/s。

1.3 湍流模型與網格劃分

由于前池尺寸較大,池內水流流動較為復雜,常常會發生回流及水流脫壁現象,故選擇Realizable[20-21]湍流模型進行水沙運動數值模擬與實際更為接近。借助ICEM-CFD軟件對所建立的正向前池三維概化模型進行非結構化網格[22-23]劃分,對比5種網格劃分方案(全局最大單元尺寸分別為0.25、0.30、0.35、0.40、0.45 m),經網格無關性檢驗,發現當全局最大單元尺寸為0.35 m、計算域內網格數為250.5萬時,網格質量均達到0.3以上,保證了求解過程中的計算效率和精度。正向進水前池網格劃分結果如圖2所示。

圖2 前池網格劃分結果

1.4 邊界條件與計算方法

前池進口采用velocity-inlet(速度入口)[24]作為入口邊界條件;出口斷面設置在泵站壓力管道處,邊界條件設置為outflow(自由出流);前池自由液面浮動變化較少采用剛蓋假定法來模擬計算自由液面;計算域其余壁面皆為固體邊界,采用wall-function method(壁面函數)進行處理。將水沙兩相流體設為本次計算介質,主相為水,密度水=998.2 kg/m3,次相為沙,密度水=2 500 kg/m3,泥沙粒徑為0.025 mm,體積分數為1.2%,入口平均流速為1.71 m/s。在對前池內的水沙運動進行數值模擬計算過程中,采用二階迎風格式的隱式求解以確保計算精度[25-26],選用基于分離求解器的SIMPLEC算法進行流場耦合[27],迭代殘差精度不低于10-4,并對模擬結果做可視化處理。

1.5 模擬設計方案

為研究正向進水前池邊墻擴散角的改變對前池流場結構的影響,保持進水前池入口端寬度B、長度以及進水池和吸水管等結構和放置方式不變,分別建立前池邊墻擴散角為20°、25°、30°、35°、40°、46°6種體型的前池,其中=46°為工程原型前池邊墻擴散角,模擬機組設計運行工況為2#~7#機組開啟,1#、8#備用機組關閉,前池結構示意圖詳見圖1。

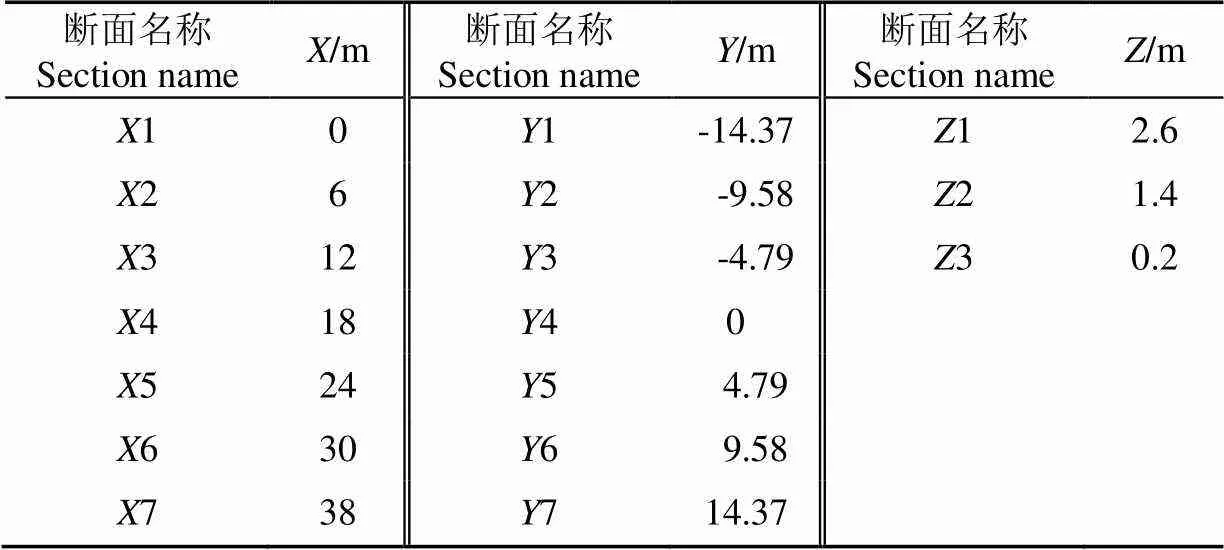

為便于更直觀地分析前池內流場結構特征及水流流速分布規律,定義沿水流方向為方向,垂直水流方向為方向,沿水深方向為方向,確定觀測斷面,將面與面的相交線確定為觀測特征線,表述為+斷面名稱(如1與1觀測特征線為l1-Y1),觀測斷面位置如圖1所示,斷面相關參數見表1。設進水前池入口斷面平均流速為0,池內水流流速為,將池內水流流速與入口斷面平均流速0相除作無量綱處理,繪制沿池內相應斷面的流速分布圖。

1.6 模型驗證

采用HXH03-1S型超聲波多普勒流速流向儀對景電灌區典型泵站正向進水前池內均勻布置的98個流速測點進行現場測量。選取2斷面與3斷面相交的特征線l3-Z2與實測值進行對比,并采用相對誤差、標準差[28]2個值進行誤差分析,以驗證數值模擬的準確性。圖3b給出了特征直線l3-Z2上流速實測值與模擬值,由圖3b可知,l3-Z2上流速實測值與模擬值的整體變化趨勢基本一致,兩者相對誤差最大為0.226,標準差誤差為0.026,實測結果與模擬結果相近,表明采用數學模型對正向進水前池內流場的計算結果準確可靠。

表1 觀測斷面參數

注:1~7為沿垂直水流方向觀測斷面,是觀測斷面距前池入口斷面的距離;1~7為沿水流方向的觀測斷面,是觀測斷面距前池中心線的距離;1~3為沿水深方向的觀測斷面,是觀測斷面距進水前池池底的距離。

Note:1-7represents observation sections vertical the flow direction,represents the distance between the observation section to the inlet section of the forebay;1-7represents observation sections along the flow direction,represents the distance between the observation section and to the center line of the forebay;1-3represents observation sections along the water depth direction,represents the distance between the observation section and the bottom of the intake forebay.

2 結果與分析

2.1 擴散角對前池內流場結構的影響

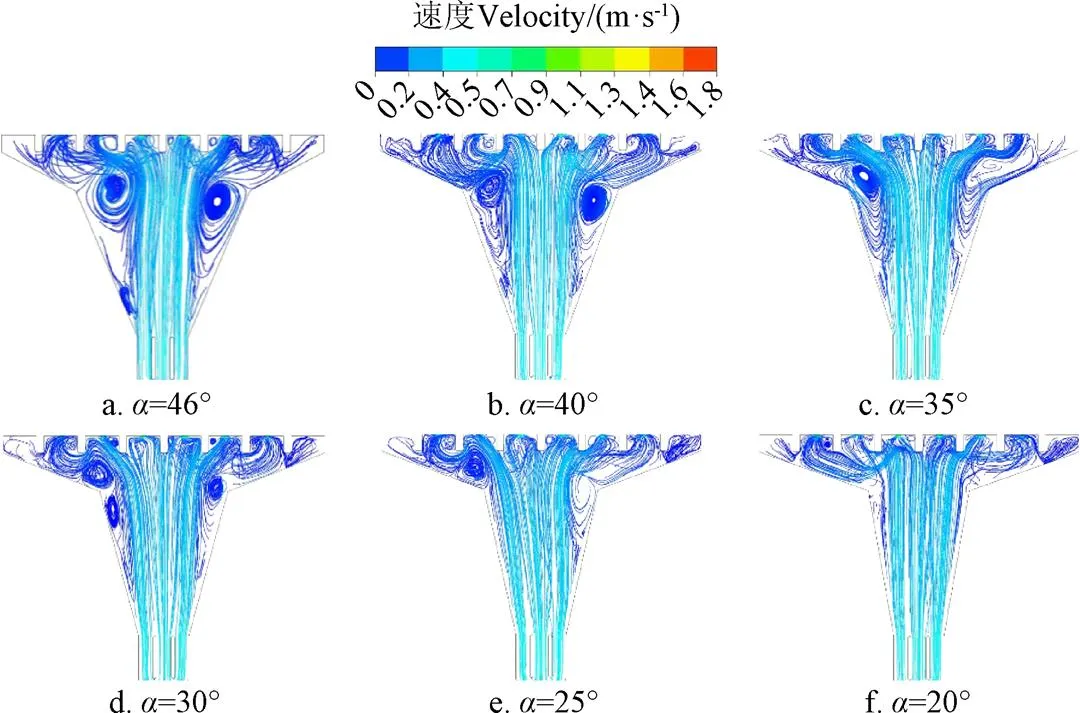

圖4給出了不同擴散角下正向進水前池2斷面流場分布。由圖4可見,泵站機組全開時(2#~7#機組開啟),正向進水前池內流場結構對稱分布,水流自引水渠進入前池后逐漸擴散,在進水前池中央形成主流區,兩側形成回流區。主流區內水流流態均勻,水流流速高,入池水流表現出的攜沙運動能力突出,區域內泥沙濃度低,沿水流方向主流區寬度在擴散型池身的作用下不斷增大;兩側回流區內產生兩個近似對稱的立軸漩渦,呈橢圓形形態分布,渦心位于進水前池末端,漩渦的存在一方面限制了主流的擴散,導致入池水流擴散效果不理想,另一方面降低了區域內水流流速,削弱了水流的攜沙運動能力,泥沙出現懸浮、停滯現象,泥沙濃度上升,同時懸浮、停滯的泥沙在自身重力的作用下向下層沉降輸移,致使泥沙在進水前池兩側產生淤積。

圖4 不同擴散角下Z2斷面流速分布流線圖

由圖4a可見,工程原型前池(=46°)主流區最大寬度為1.46B,僅為前池對應斷面寬度的31.98%,漩渦回流區面積約為進水前池面積的45%,進水前池內流場結構較為紊亂。擴散角為40°、35°、30°、25°、20°時,主流區最大寬度分別為1.50B、1.66B、1.71B、1.75B、1.70B,為前池對應斷面寬度的33.07%、39.65%、41.13%、42.76%、42.55%,漩渦回流區面積相對于工程原型前池分別減少了27.75%、42.69%、50.47%、62.49%、86.25%。可見,大擴散角進水前池邊墻對水流的約束能力較弱,水流產生嚴重的脫壁現象,在主流區兩側產生大尺度的旋渦回流區,在兩側大面積立軸漩渦的擠壓作用下,主流區寬度和其占前池對應寬度比值均較小;而減小前池擴散角后主流區寬度和其占前池對應寬度比值均有所增大,漩渦回流區面積被大大削減,入池水流得到充分擴散。

經對不同擴散角體型下的正向進水前池內水流流態分析,發現不能通過不斷減小進水前池擴散角的方式來改善進水前池內流場結構,過小擴散角的進水前池會受自身較小體型結構的約束,限制主流的擴散,導致水泵機組進水條件的惡化。計算結果表明,擴散角在25°~30°時,前池主流區最大寬度和其占前池對應斷面寬度比值較大,回流區面積占比進水前池面積較小,入池水流擴散效果較佳、流場結構穩定,可以有效地改善前池內泥沙淤積狀況,提升泵站的運行效率。

2.2 擴散角對前池內水流流速分布的影響

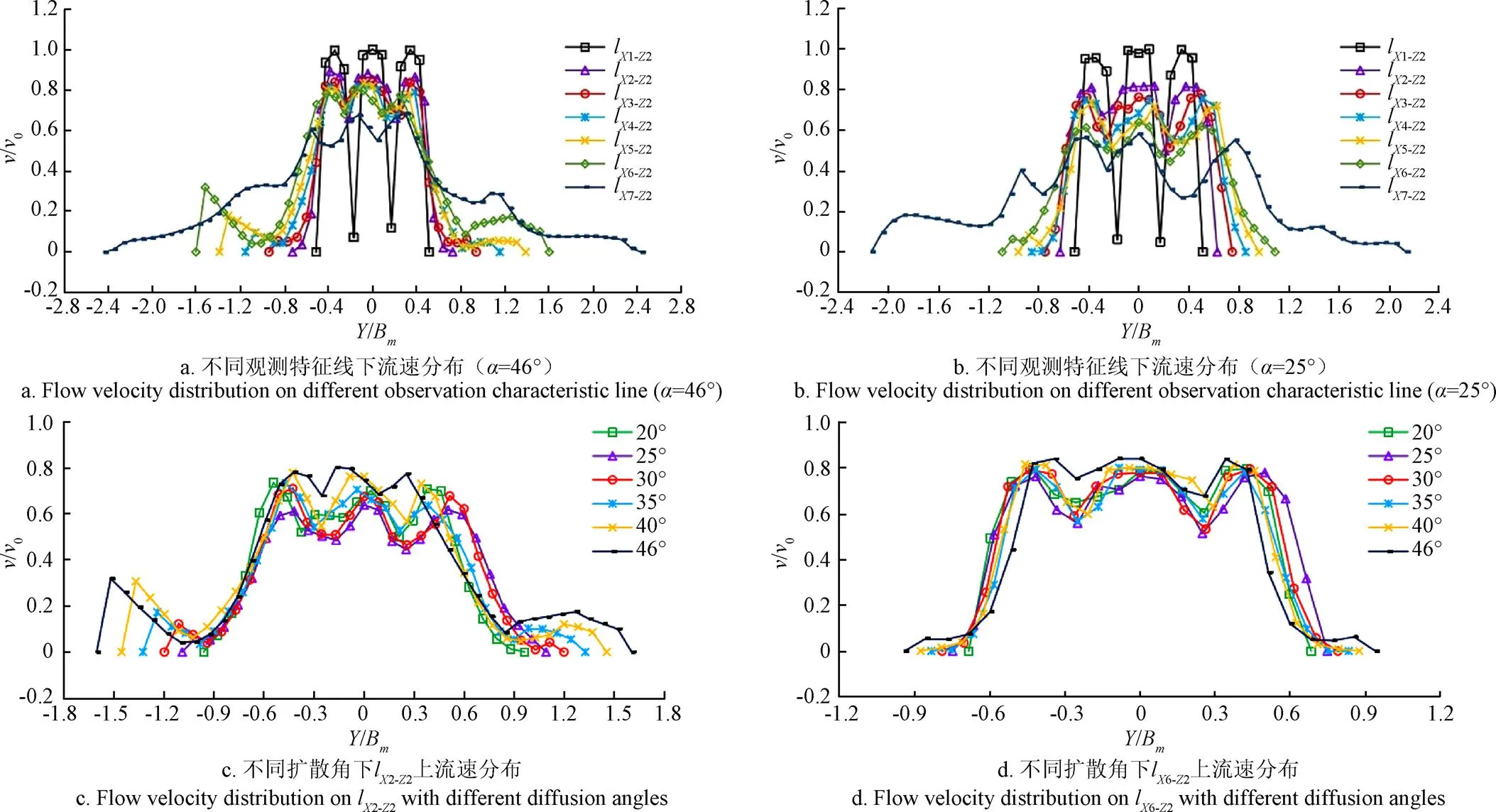

2.2.1 水流流速沿垂直水流方向分布規律

圖5給出了泵站進水前池內水流流速沿垂直水流方向典型分布。由圖可見,正向進水前池內水流流速沿垂直水流方向呈中間大兩側小的分布,兩側存在低流速區,且在池前導流墩的作用下中央主流區域流速出現一定幅度的波動;入池水流的主流區兩側明顯存在一個流速驟降區,在靠近邊墻附近略有回升。沿水流流動方向,入池水流得到有效擴散,水流流速不斷減小,導流墩的作用被削弱,中央主流區域流速波動幅度自斷面1至斷面6逐漸減小,同時低流速區內漩渦對水流的影響增強,主流區域兩側流速曲線驟降區與回升區域面積增加。

圖5 水流流速沿垂直水流方向分布

由圖5a、圖5b可見,正向進水前池中央主流區域流速平均值約前池進口平均流速的70%~95%,兩側回流區內流速平均值約為前池進口平均流速的15%~30%,中央主流區域水流流速遠大于兩側回流區,中央區域主流效應顯著;進水前池內的流速分布不均勻導致池內泥沙濃度呈中間低、兩側高的分布,自前池中央向兩側泥沙濃度遞增。由圖5c、圖5d可見,不同擴散角下前池內水流流速沿垂直水流方向分布特征相似,中央區域為主流區,兩側為低流速區;當前池邊墻擴散角較大時,主流區兩側回流區域面積大,進水前池內產生的漩渦尺度及強度較大,對中央主流區域產生的擠壓效應嚴重,水流有效過流面積減小;隨著擴散角的減小,主流區域兩側流速曲線驟降區與回升區域面積減小,主流區域流速下降,區域寬度增加,表明進入前池的水流擴散效應增加明顯。

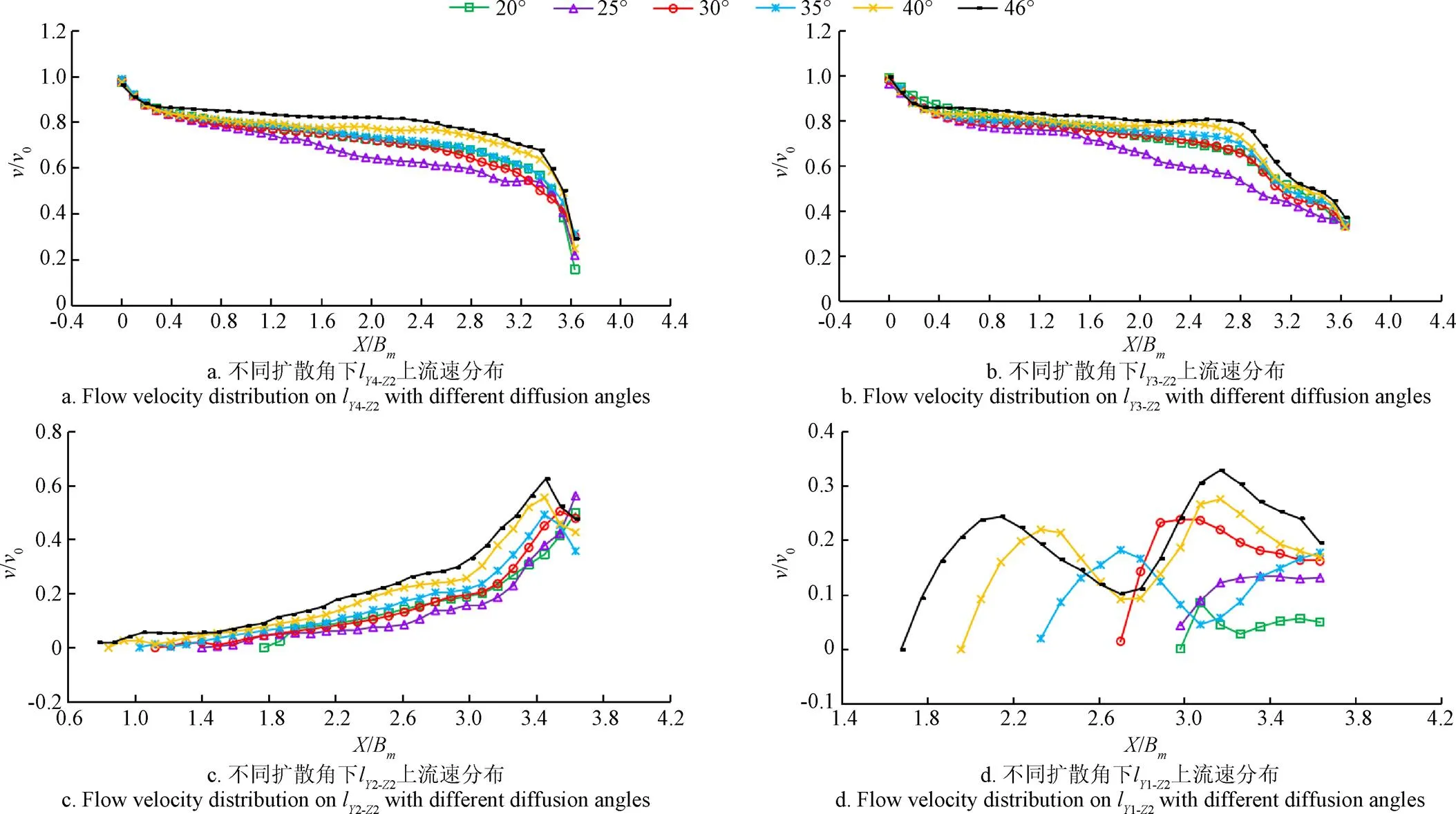

2.2.2 水流流速沿水流方向分布規律

圖6給出了不同擴散角下前池內水流流速沿水流方向典型分布。圖6a、圖6b為主流區域水流流速沿水流方向分布,區域內的水流流速沿流程逐漸減小。擴散角在25°~46°之間時,主流區沿縱向流速隨擴散角的減小而逐漸降低;擴散角為20°時,主流區的縱向流速比擴散角比25°、30°的大,在5斷面與直線l4-Z2交匯處,=20°時的流速分別約為=25°、=30°的1.20、1.10倍,這表明當擴散角過小時,入池水流受前池較小體型結構的約束而未能得到有效的擴散,擴散角為25°~30°間的前池入池水流沿流程發展和擴散較為充分,有利于形成穩定的前池流場結構,減少因進水前池泥沙淤積而導致泵站運行效率下降的問題。

圖6c為主流區與回流區之間過渡區域水流流速沿水流方向分布,區域內水流流速自邊墻起在主流的擴散和帶動作用下,沿流程逐漸增大;水流行進至進水前池末端和進水池段時,過水斷面突增,同時受泵站機組吸水作用,水流迅速向兩端擴散,使得水流流速快速增加,在/m=3.5附近達到最大值。圖6d為低流速區域水流流速沿水流方向分布,可見,回流區內流速較低,渦心處流速接近為0,最大逆向流速出現在擴散角為46°前池回流區內/B=3.12位置,其流速值為-0.330;隨著擴散角的減小,前池內逆向流速值減小,最小逆向流速出現在擴散角為30°前池回流區內/B=3.35位置,其流速值為?0.230;當擴散角小于25°時,該特征直線所在的斷面回升區位于邊墻附近,逆向流速基本消失。

圖6 水流流速沿水流方向分布

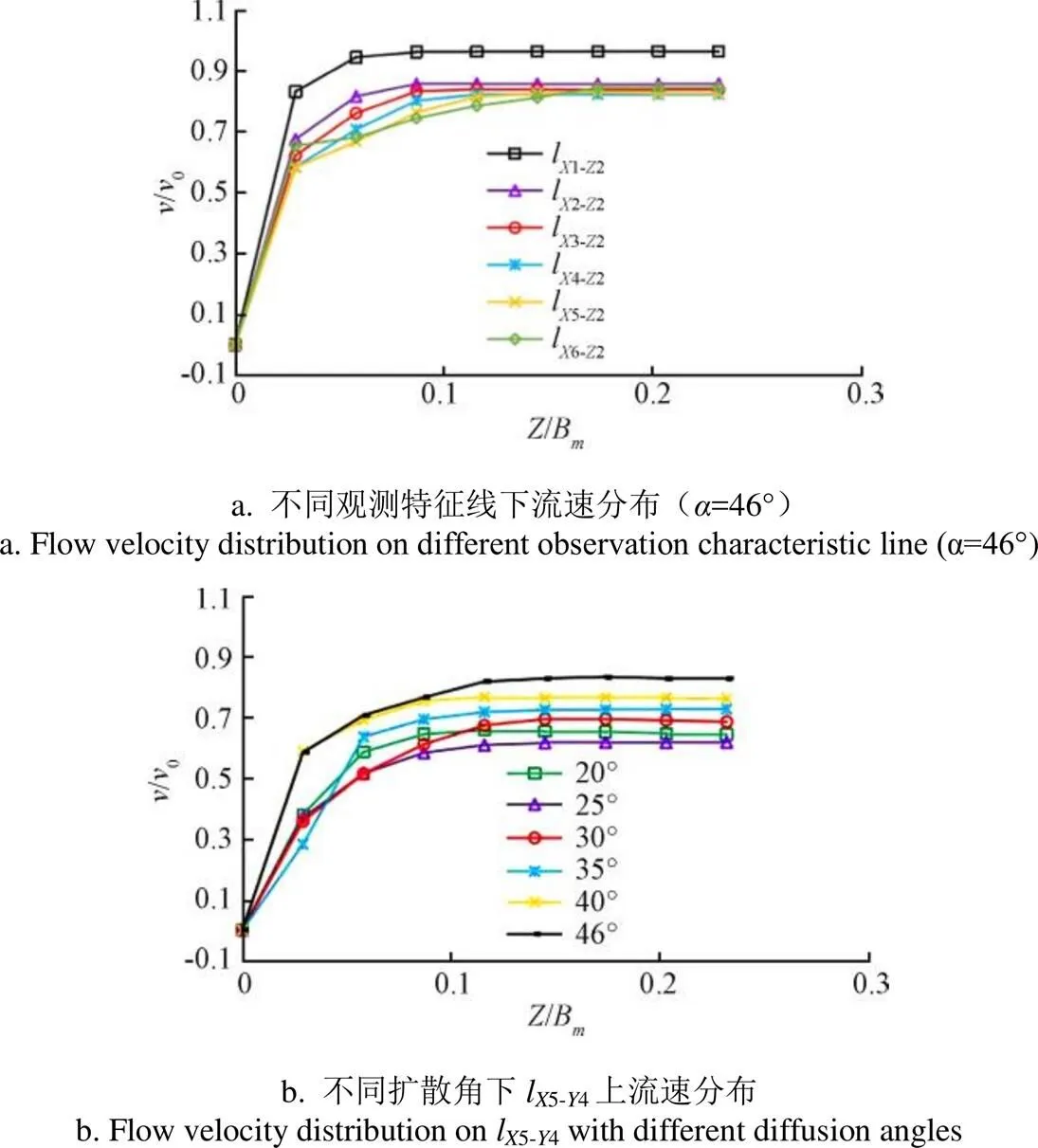

2.2.3 水流流速沿水深方向分布規律

圖7給出了泵站進水前池內水流流速沿水深方向典型分布。由圖7a可見,正向進水前池水流流速沿水深方向分布形式為常見的指數型,在水深00.09B內水流流速呈突增的趨勢,自水深0.09B斷面處至水流表層流速增長率迅速減小至接近于零,流速達到最大值后趨于穩定,穩定的水流流速保證了進水前池內上層水體的良好入池流態;受水流流速對泥沙輸運的影響,表層水流泥沙濃度低,下層水體泥沙濃度高,自水流表層至池底處泥沙濃度逐漸增加,使得泥沙在回流區影響范圍內出現淤積現象。沿水流流動方向,進水前池內沿水深方向水流流速不斷減小,進一步展現了水流在流動過程中的擴散成效。

圖7b給出了正向進水前池不同擴散角下典型特征線上水流流速沿水深方向分布。可見,不同擴散角下前池內水流流速沿水深方向分布特征基本保持不變,均為指數型分布;原型前池擴散角較大為46°,沿水深方向水流趨于穩定后的流速值最大,隨著擴散角的減小,趨于穩定的流速呈不斷遞減趨勢,說明水流得到良好的擴散。

圖7 水流流速沿水深方向分布

3 結 論

采用數值模擬和現場實測相結合的方法,研究了大型泵站正向進水前池不同擴散角體型結構下池內的流場結構及水流流速特征,主要結論如下:

1)泵站機組全開時,正向進水前池內流場結構對稱分布,在進水前池中央形成主流區,兩側形成回流區,回流區內產生漩渦;前池擴散角較大時,兩側回流區對主流區的擠壓作用明顯;縮小前池擴散角能夠有效減小兩側回流區的擠壓作用,進入前池的水流擴散效應增加明顯,縮小回流區和漩渦的尺度,優化池內水流流態,提升了池內流場結構的穩定性。

2)泵站正向進水前池內水流流速沿垂直水流方向呈中間大兩側小的分布,入池水流的主流區兩側明顯存在一個流速驟降區,在靠近邊墻附近略有回升;中央主流區域流速平均值約為前池進口平均流速的70%~95%,兩側回流區內流速平均值約為前池進口平均流速的15%~30%,中央區域主流效應顯著。沿水流流動方向主流區水流流速由于水流的擴散作用沿流程逐漸減小,擴散角在25°~46°之間時,主流區沿水流方向流速隨擴散角的減小而逐漸降低;擴散角過小時,入池水流受前池較小體型結構的約束而未能得到有效的擴散。沿水深方向水流流速呈指數型分布,在水深0~0.09B范圍內流速增加速度快,隨后變化梯度小。

3)泵站正向進水前池擴散角在25°~30°之間時,入池的水流沿流程發展和擴散較為充分,可以有效改善多泥沙河流引水泵站前池的泥沙淤積,提升泵站的運行效率。

[1] 張校文,劉超,榮迎春,等. 多機組泵站正向進水陣列式隔板整流模擬及試驗驗證[J]. 排灌機械工程學報,2022,40(4):378-384.

ZHANG Xiaowen, LIU Chao, RONG Yingchun, et al. Numerical simulation and experimental verification of forward feed array diaphragm rectifier for multi-unit pumping station[J]. Journal of Drainage and Irrigation Machinery Engineering, 2022, 40(4) : 378-384. (in Chinese with English abstract)

[2] 付輝,牛華寺,毛雨佳,等. 超窄聯合泵房前池水力性能優化:實例研究[J]. 水利學報,2020,51(7):788-795,804.

FU Hui, NIU Huasi, MAO Yujia, et al. Hydraulic performance optimization of the ultra narrow union pumping forebay: A case study[J]. Journal of Hydraulic Engineering, 2020, 51(7): 788-795, 804. (in Chinese with English abstract)

[3] 營佳瑋,俞曉東,賀蔚,等. 基于流體體積模型的泵站前池流態及組合式整流方案[J]. 排灌機械工程學報,2020,38(5):476-480,493.

YING Jiawei, YU Xiaodong, HE Wei, et al. Volume of fluid model-based flow pattern in forebay of pump station and combined rectification scheme[J]. Journal of Drainage And Irrigation Machinery Engineering, 2020, 38(5): 476-480, 493. (in Chinese with English abstract)

[4] 資丹,王本宏,王福軍,等. 開機組合對泵站進水系統泥沙濃度分布的影響[J].農業工程學報,2022,38(7):59-68.

ZI Dan, WANG Benhong, WANG Fujun, et al. Influences of start-up pump units on the sediment concentration for the intake system of a pumping station[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(7): 59-68. (in Chinese with English abstract)

[5] 田俊姣. 多梯級揚水工程更新改造效果評價研究[D]. 鄭州:華北水利水電大學,2019.

TIAN Junjiao. Study on Evaluation of Renewal and Reconstruction Effect of Multi-Cascade Water-Lifting Project[D]. Zhengzhou: North China University of Water Resources and Electric Power, 2019. (in Chinese with English abstract)

[6] 徐存東,王國霞,劉輝,等. 大型泵站正向前池防淤優化模擬研究[J]. 武漢大學學報(工學版),2018,51(7):577-588.

XU Cundong, WANG Guoxia, LIU Hui, et al. Simulation study of preventing sedimentation in front intake forebay at large-scale pumping station[J]. Engineering Journal of Wuhan University, 2018, 51(7): 577-588. (in Chinese with English abstract)

[7] 王福軍,唐學林,陳鑫,等. 泵站內部流動分析方法研究進展[J]. 水利學報,2018,49(1):47-61,71.

WANG Fujun, TANG Xuelin, CHEN Xin, et al. A review on flow analysis method for pumping stations[J]. Journal of Hydraulic Engineering, 2018, 49(1): 47-61, 71. (in Chinese with English abstract)

[8] 李明,王勇,熊偉,等. 泵站側向進水前池幾何參數優化[J]. 農業工程學報,2022,38(19):69-77.

LI Ming, WANG Yong, XIONG Wei, et al. Optimizing the geometric parameters for the lateral inflow forebay of the pump sump[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(19): 69-77. (in Chinese with English abstract)

[9] CONSTANTINESCU S G, PATE V C. Role of turbulence model in prediction of pump-bay vortices[J]. Journal of Hydraulic Engineering, 2000, 126(5): 387-391.

[10] 資丹,王福軍,姚志峰,等. 大型泵站進水流場組合式導流墩整流效果分析[J]. 農業工程學報,2015,31(16):71-77.

ZI Dan, WANG Fujun, YAO Zhifeng, et al. Effects analysis on rectifying intake flow field for large scale pumping station with combined diversion piers[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(16): 71-77. (in Chinese with English abstract)

[11] 李顏雁,郭鵬程,孫龍剛,等. 立柱對大型泵站前池和進水池流態影響的數值分析[J]. 排灌機械工程學報,2021,39(9):929-936.

LI Yanyan, GUO Pengcheng, SUN Longgang, et al. Numerical analysis on influence of vertical column on flow pattern in forebay and intake of large pumping station[J]. Journal of Drainage and Irrigation Machinery Engineering, 2021, 39(9): 929-936. (in Chinese with English abstract)

[12] 周濟人,仲召偉,梁金棟,等. 側向進水泵站前池整流三維數值計算[J]. 灌溉排水學報,2015,34(10):52-55,80.

ZHOU Jiren, ZHONG Zhaowei, LIANG Jindong, et al. Three-dimensional numerical simulation of side-intake forebay of pumping station[J]. Journal of Irrigation and Drainage, 2015, 34(10): 52-55, 80. (in Chinese with English abstract)

[13] 雷鎮. 多機組泵站前池流動特征和組合整流[D]. 揚州:揚州大學,2020.

LEI Zhen. Study on the Influence of the Start-Up Combinations on the Characteristics of the Water-Sediment Flow Field in Forebay of Pumping Station[D]. Yangzhou: Yangzhou University, 2020. (in Chinese with English abstract)

[14] 李志祥,馮建剛,錢尚拓,等. 排水泵站整流底坎參數優化[J]. 農業工程學報,2021,37(3):56-63.

LI Zhixiang, FENG Jiangang, QIAN Shangtuo, et al. Optimization of rectification bottom sill parameters in drainage pumping stations[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(3): 56-63. (in Chinese with English abstract)

[15] 竇元之,顧靖超,陸立國,等. 高含沙水泵站前池擴散角試驗與分析[J]. 中國農村水利水電,2020(5):114-119,127.

KOU Yuanzhi, GU Jingchao, LU Liguo, et al. Test and analysis of diffusion angle of front pool of high sand water pumping station[J]. China Rural Water and Hydropower, 2020(5): 114-119, 127. (in Chinese with English abstract)

[16] 高傳昌,曾新樂,解克宇,等. 泵站進水池超低水位下組合整流方案與驗證[J]. 農業工程學報,2017,33(23):101-108.

GAO Chuanchang, ZENG Xinle, XIE Keyu, et al. Combined rectification scheme of pump intake sump in ultra-low water level and its verification[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(23): 101-108. (in Chinese with English abstract)

[17] 徐存東,李嘉明,王榮榮,等. 開機組合對泵站前池水沙流場特性的影響[J]. 河海大學學報(自然科學版),2022,50(2):11-16,91.

XU Cundong, LI Jiaming, WANG Rongrong, et al. Study on the influence of the start-up combinations on the characteristics of the water-sediment flow field in forebay of pumping station[J]. Journal of Hohai University (Natural Sciences), 2022, 50(2): 11-16, 91. (in Chinese with English abstract)

[18] 趙斌娟,袁壽其,劉厚林,等. 基于Mixture多相流模型計算雙流道泵全流道內固液兩相湍流[J]. 農業工程學報,2008,24(1):7-12.

ZHAO Binjuan, YUAN Shouqi, LIU Houlin, et al. Simulation of solid-liquid two-phase turbulent flow in double-channel pump based on mixture model[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(1): 7-12. (in Chinese with English abstract)

[19] 徐磊,夏斌,施偉,等. 中隔墩長度對斜式軸伸泵裝置出水流道水力特性的影響[J].農業工程學報,2020,36(1):74-81.

XU Lei, XIA Bin, SHI Wei, et al. Influence of middle pier lengths on hydraulic characteristic of outlet conduit in pump system with slanted extension shaft[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(1): 74-81. (in Chinese with English abstract)

[20] TOMAS C R, ROGER L. Mathematical and Numerical Foundations of Turbulence Models and Applications[M]. New York: Birkh?user, 2014.

[21] CHIPONGO Kudzai, KHIADANI Mehdi, Sookhak Lari Kaveh. Comparison and verification of turbulence Reynolds- averaged Navier-Stokes closures to model spatially varied flows[J]. Scientific Reports, 2020, 10(1): 19059-19059.

[22] 唐學林,王武昌,王福軍,等. 泵站前池水沙流的數值模擬[J]. 排灌機械工程學報,2011,29(5):411-417.

TANG Xuelin, WANG Wuchang, WANG Fujun, et al. Numerical simulation of slit-laden flows in pumping station forebay[J]. Journal of Drainage and Irrigation Machinery Engineering, 2011, 29(5): 411-417. (in Chinese with English abstract)

[23] 司喬瑞,唐亞靜,甘星城,等. 立式管道泵進水彎管和葉輪的參數化分析與驗證[J].農業工程學報,2020,36(17):54-63.

SI Qiaorui, TANG Yajing, GAN Xingcheng, et al. Parametric analysis and verification of curved inlet pipe and impeller of

vertical inline pump[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(17): 54-63. (in Chinese with English abstract)

[24] 王苗,李琳,楊海華,等. 梭錐管混濁流體分離裝置水沙兩相流數值模擬[J]. 水動力學研究與進展(A輯),2013,28(3):291-298.

WANG Miao, LI Lin, YANG Haihua, et al. Numerical simulation of the water-sediment two phase in turbid fluid separation device of shuttle-conical tube[J]. Chinese Journal of Hydrodynamics(Part A), 2013, 28(3): 291-298. (in Chinese with English abstract)

[25] VERSTEEG H, MALALASEKERA W. An introduction to Computational Fluid Dynamics:The Finite Volume Method[M]. 2nd edition . Upper Saddle Rive: Prentice Hall, 2007 .

[26] 高傳昌,劉新陽,石禮文,等. 泵站前池與進水池整流方案數值模擬[J]. 水力發電學報,2011,30(2):54-59.

GAO Chuanchang, LIU Xinyang, SHI Wenli, et al. Numerical simulation of flow pattern modification schemes for the forebay and suction sump of pumping station[J]. Journal of Hydroelectric Engineering, 2011, 30(2): 54-59. (in Chinese with English abstract)

[27] 吳修廣,沈永明,鄭永紅,等. 非正交曲線坐標下二維水流計算的SIMPLEC算法[J]. 水利學報,2003(2):25-30,37.

WU Xiuguang, SHEN Yongming, ZHENG Yonghong, et al.

2-D flow SIMPIC algorithm in non-orthogonal curvilinear coordinates[J]. Journal of Hydraulic Engineering, 2003(2): 25-30, 37. (in Chinese with English abstract)

[28] SCHUBERT A L, HAGEMANN D, VOSS A, et al . Evaluating the model fit of diffusion models with the root mean square error of approximation[J]. Journal of Mathematical Psychology, 2017, 77: 29-45.

Influence of diffusion angle on flow field structure in forward intake forebay of pumping station

FAN Xinjian, DONG Chunhai, WANG Zhijun, LU Ya’nan, YAO Wei

(730050,)

A pumping station is widely used in a water distribution system for the efficient and reliable transportation. However, the sediment deposition can pose an outstanding decrease in the operating efficiency of pump station. Particularly, the water is taken from the river with the high content of sand, such as in the Yellow River Basin. More importantly, the low flow pattern and large-scale backflow area can often occur in the forward intake forebay of a large-scale pumping station. The current anti-siltation measures cannot effectively improve the intake field structure in large-scale pumping station, due to the multiple dimensions, and single rectification. In this study, a systematic investigation was made to clarify the influence of diffusion angle on the flow field structure in the forward intake forebay of a pumping station. The typical research object was taken as the forward intake forebay of large-scale pumping station in Jingtaichuan Electric Power Irrigation Project in Gansu Province of China. A field investigation was firstly performed on the sediment deposition in the forward intake forebay of pumping station. The sampling was then implemented to analyzed the variation characteristics of sediment concentration and sediment particle size in the water flow from pumping station. A three-dimensional model was also established for the forward intake forebay with the different diffusion angle. Numerical simulation was carried out using the Mixture multiphase, and Realizable-model. The actual flow measurement was utilized to verify the accuracy of the numerical calculation. The characteristics of flow field structure were clarified in the forward intake forebay, together with the variation under the diffusion angle of the forebay. The mechanism of sediment deposition was revealed to propose the diffusion angle range for the optimal flow field structure in the forward intake forebay. The results show that the flow field structure was symmetrically distributed in the forward intake forebay of pumping station under the design operation conditions of the unit. The mainstream area was formed in the center of the intake forebay, whereas, the backflow area was formed on both sides. The flow velocity and the ability of current to carry sediment in the central mainstream area were much higher and stronger than those in the backflow area on both sides. The sediment deposition decreased significantly from the both sides to the center, indicating the significant mainstream effect. Furthermore, the squeezing effect of vortices was weakened in the backflow areas on both sides of the intake forebay on the mainstream area, as the diffusion angle of forebay decreased, while the area of low flow velocity on both sides also decreased significantly. At the same time, there was an increasing trend in the width of the central mainstream area, whereas, a downward trend was found in the flow velocity in the mainstream area. The ability of current to carry sediment increased to promote the performance of the flow diffusion entering the forebay. Once the diffusion angle was between 25°and 30°, the flow entering the pool was well developed to diffuse sufficiently along the pipeline, indicating the better flow pattern with the much more stable structure of flow field . The sediment deposition was effectively reduced in the forebay of the diversion pumping station on the sandy river. As such, the operating efficiency of pumping units was improved to guarantee the realistic benefit of irrigation project. The research findings can also provide the strong reference to design and update the large-scale pumping stations.

pumping station; numerical simulation; forward intake forebay; diffusion angle; flow field structure; sediment deposition

10.11975/j.issn.1002-6819.202208112

TV675

A

1002-6819(2023)-01-0092-08

樊新建,董春海,王之君,等. 泵站正向進水前池擴散角對池內流場結構的影響[J]. 農業工程學報,2023,39(1):92-99.doi:10.11975/j.issn.1002-6819.202208112 http://www.tcsae.org

FAN Xinjian, DONG Chunhai, WANG Zhijun, et al. Influence of diffusion angle on flow field structure in forward intake forebay of pumping station[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(1): 92-99. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.202208112 http://www.tcsae.org

2022-08-15

2022-11-23

國家自然科學基金(42167043);甘肅省自然科學基金(21JR7RA238);甘肅省水利科學試驗研究及技術推廣項目(甘水建管發[2020]46號第70)

樊新建,博士,副教授,研究方向為水力學及河流動力學。Emaill:fanxj008@163.com