Flow field control for 2-meter high-speed free-jet wind tunnel

Jiayi TIAN, Zhongwei LING, Weijie LIU, Jianhua Qin, Neng XIONG

China Aerodynamics Research and Development Center, Mianyang 621000, China

KEYWORDS

Abstract The 2-meter High-speed Free-jet Wind Tunnel (2 m HFWT) is China’s first large-scale open-jet trisonic wind tunnel.Compared to traditional closed high-speed wind tunnels, this wind tunnel is endowed with remarkable advantages of ample test chamber space,less interference from the tunnel wall, flexible model support mode, and adjustable continuous variation of the Mach number.Nevertheless, its unique structure makes traditional wind tunnel control methods difficult to apply and brings significant challenges to wind tunnel flow field control.In this paper,a flow field control system is designed for the 2 m HFWT by comprehensively using advanced control technologies such as neural network, gain scheduling, feedforward control, and adaptive control.Through practical application tests,it is proved that the proposed control system successfully solves the problem of high-precision flow field control under continual depletion of storage tank pressure,and realizes distinctive functions of adaptive static pressure matching and continuously varying Mach number at supersonic speed.In addition, due to the application of workflow technology, the flow field control system can flexibly adapt to the implementation of tests of different types and operation conditions,thus fully satisfying the needs of conducting various conventional and special tests in the 2 m HFWT.

1.Introduction

Accurate aerodynamic test data is not only an indispensable basis for the design,development,and performance assessment of various types of aviation and aerospace vehicles, but also a crucial guarantee for improving the level of aircraft design and development, shortening the development cycle, and reducing the development cost.1–5Acquiring accurate aerodynamic test data requires the realization of high-fidelity and refined simulation of the internal and external flow around the aircraft.However, the existing high-speed wind tunnels in China are all closed wind tunnels with the maximum cross-sectional area of the test section being only 2.4 m × 2.4 m (Mach number range of 0.3–1.4)6and 2 m × 2 m (Mach number range of 1.5–4.0).7Limited by the small size of the test section,the wall interference of the wind tunnel,8and the blockage of the test model,9it is difficult to carry out simulation tests in the existing high-speed wind tunnels for key aerodynamic problems that strangle the development of advanced aircraft, such as the aircraft stall characteristic at a large angle of attack,10the comprehensive coupling effect of internal and external flow on the inlet,11the aerodynamic/motion coupling characteristic of high maneuver flight,12,13the thrust vector and nozzle load characteristics,14the separation characteristic of embedded systems,15,16and the mode transition of Turbine-Based Combined Cycle (TBCC) engine.17,18To overcome the aforementioned momentous aerodynamic problems, the first largescale open-jet wind tunnel covering sub, trans and supersonic domains in China is designed and constructed at the China Aerodynamics Research and Development Center (CARDC),named the 2-meter High-speed Free-jet Wind Tunnel (2 m HFWT).

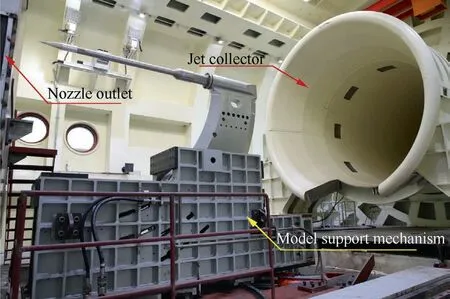

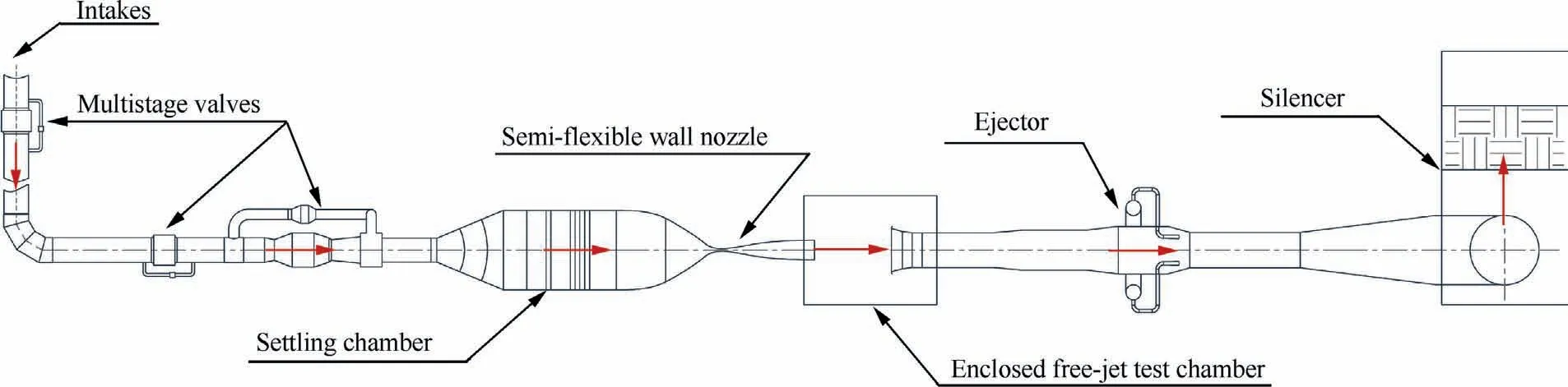

The 2 m HFWT is an injection-driven,blowdown,intermittent wind tunnel with the intakes, multistage valves, settling chamber,semi-flexible wall nozzle,test chamber,diffuser,ejector, and silencer arranged in sequence along the airflow direction.Fig.1 shows a sketch map of the 2 m HFWT.The enclosed free-jet test chamber, as shown in Fig.2, is rectangular in shape and has a semi-rounded roof.The front-end of the test chamber is a two-dimension semi-flexible wall nozzle with an outlet size of 2 m×2 m,and the rear-end is a jet collector,which can be moved along the airflow direction.A model support mechanism is installed in the middle of the test chamber that can realize the four-degree-of-freedom motion.The 2 m HFWT adopts blowdown operation mode with/without ejection working, the corresponding test range of Mach number can cover 0.3–3.5, and especially in the range of 2.0–3.5, the Mach number can continuously change under control.Compared to traditional closed high-speed wind tunnels, the 2 m HFWT is endowed with remarkable advantages of ample test chamber space, less interference from the tunnel wall, flexible model support mode, and adjustable continuous variation of the Mach number.All these merits enable the 2 m HFWT to carry out various types of special tests, including aircraft inlet/engine compatibility tests, separation safety tests of weapon systems, functional realization tests of structural systems, and virtual flight tests for aircraft models, to name but a few.

The open or enclosed free-jet test chambers are mainly used in low-speed and hypersonic wind tunnels in China, resulting in a great lack of experience in designing and operating a free-jet test facility in such a wide speed domain of sub, trans and supersonic speed.Thus, there is no reference example for the design of the 2 m HFWT flow field control system.The unique structure of the enclosed free-jet test chamber makes traditional wind tunnel control methods difficult to apply to it, bringing unprecedented challenges to the design of the 2 m HFWT flow field control system as follows:

Fig.2 Enclosed free-jet test chamber of 2 m HFWT.

(1) In contrast to traditional small-size closed wind tunnels,the 2 m HFWT not only has an apparent increase in the volume of the settling chamber,but also greatly extends the distance between the flow field parameter detection point and the corresponding control actuator, which makes the flow field characteristics of fast time-varying and large lag more striking.Also, the unique structure results in an irregular pressure fluctuation in test chamber, further aggravating the nonlinearity of the flow field.

No sooner had she reached her room than the Princess exclaimed, Now let us see what these fine plums can add to my beauty, and throwing off her hood52, she picked up a couple and ate them

For the 2 m HFWT, the high-speed jet entering the enclosed free-jet test chamber from the nozzle outlet is not restricted by the solid wall boundary, but strongly impacts, shears and entrains still air, forming a jet shear layer with an extremely complex structure.The vortex periodically shedding from the nozzle outlet develops, strengthens, and grows unstable in the shear layer, making the jet flow field carry strong instability.As the vortex travels, it finally collides with the downstream jet collector inlet to form a pressure disturbance wave, which propagates back to the nozzle outlet to induce new shedding vortices again.This further exacerbates the instability of the flow field in test chamber.As a result,the static pressure in the flow field significantly fluctuates,and the size of the jet uniform region is greatly decreased,which affects the performance index of the jet flow field and limits the practical application of the 2 m HFWT severely.

(3) The usage of the enclosed free jet test chamber leads to the fact that a jet shear layer with extremely complex structure occurs in the jet flow field of the test chamber.The vortex structure periodically shedding from the nozzle outlet develops, strengthens, propagates and grows unstable in the shear layer,thus making the jet flow field carry strong instability.As a consequence,the static pressure of the jet flow field fluctuates significantly,and correspondingly the size of the jet uniform region in test chamber greatly decreases.Therefore, it is imperative to improve the uniformity of the jet flow field and expand the space of the jet uniform region by flow field control,so as to guarantee satisfying performance index of the flow field and accommodate larger scale test model.

And so we did. As sweetly as Sonali s voice reached the heavens and so many hearts, so, too, our love rose into the moonlit sky. Alan s courage and spirituality are so strongly reflected in Sonali s ability to rise above her own heartbreak and loss and uplift people. Just as Alan didn t sit back in his seat with shaking knees but rose fearlessly to help save thousands of people s lives, so, too, Sonali chose not to bury herself in grief, but to sing her dad s vision of love and courage. I am grateful for them both!

An adaptive static pressure matching wind tunnel test of the Mach number 2.3 is carried out in the 2 m HFWT and the corresponding test result is shown in Fig.11.As shown in Fig.11(a), stagnation pressure approaches the stagnation pressure target of 364 kPa about 20 s after starting the wind tunnel, and then the adaptive static matching control comes into play.Under this three-loop flow field control system, it can be observed from Fig.11(b) that the stagnation pressure target is adaptively adjusted to force the static pressure in test chamber to approach the biased matching target (namely 98% of the static pressure of the nozzle outlet) whenever the static pressure in test chamber deviates from a predetermined matching boundary (±1.4% of the biased matching target).At the same time, the stagnation pressure is propelled to constantly track the adjusted stagnation pressure target and basically keeps stable within the 0.15% stability region during the entire test period as depicted in Fig.11(a), ensuring the stability of the flow field.It is worth noting that the reason for the static pressure in test chamber crossing the matching boundary during the test is that a measurement instrument mounted on the model support mechanism continuously moves and changes its position (as denoted by the green line in Fig.11(c)) to measure the characteristic parameters of the flow field.This further demonstrates that the proposed adaptive static pressure matching control is correct and effective, which can timely regulate the static pressure in test chamber to rebuild the static matching condition once the static pressure in test chamber crosses the matching boundary.In this way, the control objective of satisfying the required static matching relationship while stabilizing the stagnation pressure is achieved just by regulating a single actuator of the pressure regulator.

Fig.1 Sketch map of 2 m HFWT.

(4) In order to conduct special tests such as the mode transition of the TBCC engine,the 2 m HFWT is required to conduct supersonic continuously varying Mach number test, which puts forward a further requirement for the flow field control system of the 2 m HFWT.

(5) The 2 m HFWT mainly carries out special tests, and therefore the test process is always altered to satisfy different characteristics and requirements of various types of tests.Hence the flow field control system is required to be capable of flexibly adapting to different test types and different operating conditions, which further increases its design difficulty.

(1) Being able to determine the opening of the pressure regulator for non-calibrated Mach number makes it possible to conduct the supersonic continuously varying Mach number test in the 2 m HFWT.

To address the aforementioned problems, a flow field control system is designed for the 2 m HFWT in this paper by comprehensively using advanced control technologies, such as neural network, gain scheduling, feedforward control, and adaptive control.First, a valve characteristic neural network for the pressure regulator is presented to accurately describe the valve characteristic for arbitrary Mach numbers and arbitrary pressure ratios.Based on gain scheduling and feedforward control, a stagnation pressure composite control system of open-loop feedforward compensation and closed-loop feedback tracking is then designed, which forces the stagnation pressure to approach a predetermined target and remain stable during the test period, regardless of the continual pressure depletion of air storage tank and the variation of model position and attitude.This composite control system is further upgraded to a three-loop flow field control system based on adaptive control to actualize a distinctive function of adaptively matching the static pressures of the nozzle outlet and the test chamber at supersonic speed.In addition, the workflow technology is introduced into the software design of the flow field control system, so that the flow field control system can flexibly modify the test process to adapt to different types of tests and different operating conditions, thus satisfying the need of conducting various conventional and special tests in the 2 m HFWT.

The rest of this paper is organized as follows:the upcoming section elaborates the design of the 2 m HFWT flow control system in detail.Then,the application results in practical wind tunnel tests are presented and discussed in the subsequent section,thus fully demonstrating the effectiveness of the proposed flow control system.Finally, the paper ends with the conclusion.

2.Flow field control system design

2.1.Valve characteristic neural network

In principle, the opening of the pressure regulator S, the pressure of the air storage tank Pg,the stagnation pressure P0,and the Mach number Ma should satisfy the following nonlinear function1,21

CHINESE JOURNAL OF AERONAUTICS2023年10期

CHINESE JOURNAL OF AERONAUTICS2023年10期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Role of unsteady tip leakage flow in acoustic resonance inception of a multistage compressor

- Numerical and experimental investigation of quantitative relationship between secondary flow intensity and inviscid blade force in axial compressors

- Flamelet-like models applied in scramjet combustors: A state of art and prospect

- An improved nonlinear onboard adaptive model for aero-engine performance control

- High-fidelity simulation of blade vortex interaction of helicopter rotor based upon TENO scheme

- Numerical simulation and experimental research on oscillation performance of disc-type jet oscillator