Dyeability of Polylactide Fabric with Hydrophobic Anthraquinone Dyes*

HE Liang (何亮), ZHANG Shufen (張淑芬)**, TANG Bingtao (唐炳濤), WANG Lili (王麗麗) and YANG Jinzong (楊錦宗)

?

Dyeability of Polylactide Fabric with Hydrophobic Anthraquinone Dyes*

HE Liang (何亮), ZHANG Shufen (張淑芬)**, TANG Bingtao (唐炳濤), WANG Lili (王麗麗) and YANG Jinzong (楊錦宗)

State Key Laboratory of Fine Chemicals, Dalian University of Technology, Dalian 116012, China

The dyeability of polylactide fabric has been investigated with the substituted aminoanthraquinone hydrophobic dyes. Their application to the polylactide fabric led to good exhaustion values and good wash fastness between 4 and 5. Microscopic assessment of cross-sections of the dyed polylactide fibres confirmed that these dyes could penetrate into the fibres. The nature of the substituted amino groups showed little influence on the wash fastness, but clearly influenced the exhaustion and light fastness.

hydrophobic dye, dyeability, polylactide, microscopic analysis

1 INTRODUCTION

Polylactide (PLA) is an aliphatic polyester based on renewable materials, which has been widely noticed in the industrial fields [1, 2]. The most excellent characteristic of PLA is its biodegradability. PLA can be degraded to carbon dioxide and water completely in natural environment without pollution. This means that the biodegradable PLA fibers are environmentally benign. Another attractive characteristic is its abundance and availability. PLA can be conveniently produced from the polymerization of lactic acid [3], which is obtained from the fermentation of corn, sugar, and vegetables, and does not need any fossil fuels. At present, the percentage consumption of food for PLA synthesis is very low in the world [4]. These two characteristics make synthetic PLA fibre very suitable for meeting the increasing demand on environmental benignancy and protection of limited natural resources.

On the other hand, some properties of PLA cause difficulties in textile application. First of all, PLA hydrolyzes more easily than other synthetic polyesters, leading to strength and elongation losses [5]. Secondly, so far, dye selections for PLA are only limited in popularity or energy levels of commercial disperse dyes [3, 6]. Furthermore, dark shades on PLA make dye selections very difficult, because the dyeing behavior is usually different on PLAother polyesters. In fact, few commercial disperse dyes have exhaustions higher than 80% on PLA [6, 7]. Considering these two disadvantages of PLA, some renovations need to be carried out. For the former case, the production of PLA composite with other synthetic fibers, such as poly(ethylene terephthalate) (PET), may be a choice in future. As a result, the selected dyes need to dye not only PLA, but also the synthetic fibers. For the latter case, other kinds of dyes can be selected, such as indigo dye [4]. However, there is almost no report about the dyeing performance of PLA fibers with strong hydrophobic anthraquinone dyes.

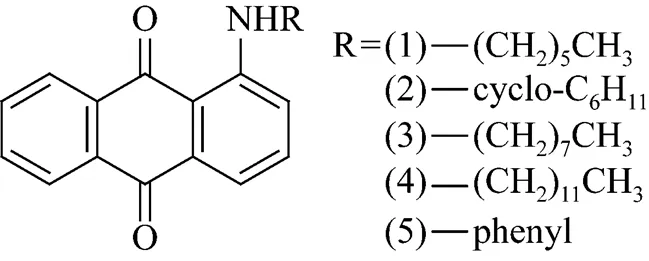

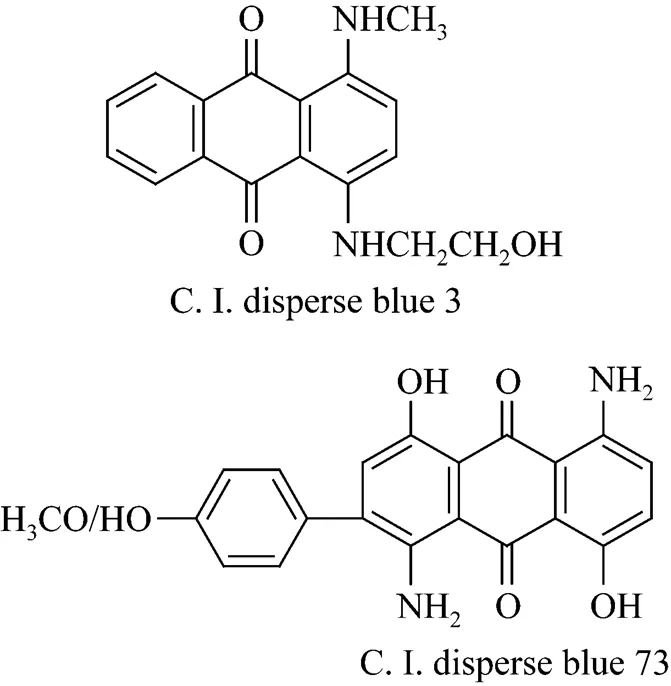

This article presents a research on the dyeability of PLA with strong hydrophobic anthraquinone dyes (Fig. 1). With a view to the future production of PLA composite with other synthetic fibers, the possibility of simultaneous dyeing PLA and PET is also discussed in the article.

Figure 1 Structure of the model hydrophobic dyes (dye 1 through 5)

2 EXPERIMENTAL

2.1 Materials

Polylactide was knitted fabric (250 g·m-2) with spun staple and was scoured in boiled water containing 5‰ of sodium dodecyl benzene sulphonate for 10 min before use. Bis-(5,5′-disulphonate)-naphthylmethane disodium salt (NNO, 100% diffusibility) was from Jinhua Shuanghong Chemical Co. (China), and octyl phenol ethoxylate (OP-10, >98.5%) was from Shanghai Jiachen Chemical Co. (China). The hydrophobic dyes were synthesized according to Ref. [8] and confirmed by Mass Spectrometry (MS), Infrared Spectroscopy (IR), and1H Nuclear Magnetic Resonance (NMR) spectra.

The dye dispersions were obtained by milling dye, NNO, and OP-10 with glass beads for 6 h. The mass ratio of OP-10 and NNO to dye was 1︰10︰10. The average size of the dye particles was examined with SA-CP3 Centrifugal Particle Size Analyzer (Shimadzu, Japan) and proved less than 0.5 μm.

2.2 Process

1-Hexylaminoanthraquinone (dye 1) was used to investigate the dyeability of polylactide fabric with hydrophobic dyes. All dyeing experiments were performed with 1.0 g pieces of PLA fabric and at a goods- to-liquor ratio of 1︰30. The pH of dye bath was adjusted with AcOH/NaOAc (pH 4 and 5), NH4OAc (pH 7), and NH4Cl/NH3?H2O (pH 8 and pH 9). The dyeing of other dyes was based on the optimal conditions of dye 1.

The dyeing was performed in a two bath laboratory dyeing apparatus, started at 50°C, and then ramped to the dyeing temperature at 2°C·min-1, and held for some time. After dyeing, the fabric samples were taken out from the dyeing vessel and rinsed with water until the washing water was colorless.

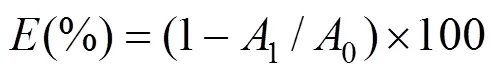

2.3 Exhaustion measurement

All dye bath samples from the studies were dissolved in 1︰1 acetone/water to eliminate solvent effects. The absorbance of the dye in the bath was then measured before and after dyeing using a HP 8453 UV-Vis Spectrophotometer in order to determine the exhaustion of each dye on the PLA fabric [1]. The dye exhaustion () on PLA was calculated according to:

where0and1are the absorbance values of the dyebath before and after dyeing, respectively.

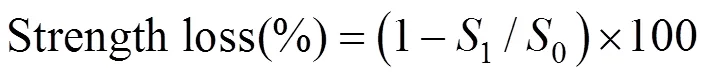

2.4 Measurement of strength loss

Undyed and dyed fabrics (10 cm×6.3 cm) were tested for tearing strength using a YG(B) 033A tearing meter (Darong Textile, Wenzhou). Each sample was tested five times and the average values were reported. The strength loss of the dyed fabric was calculated according to:

where0and1are the tearing strength values (N) of the undyed and dyed fabrics, respectively.

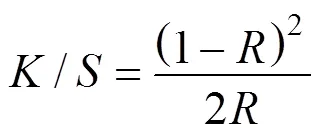

2.5 Measurement of shade depth

The dried samples were evaluated for shade depth (/value) atmaxusing a U3283 Hunter color spectrophotometer (USA). The/value is a function of the reflectance, as expressed by

Each sample was read in four different areas and the average value was recorded.

2.6 Microscopic examination of cross-sections

Cross-sections of dyed PLA at a thickness of 1 μm were prepared using an LKB-V ultramicrotome. Images of the cross-sections at 800×magnification were obtained using a BX51TR-32000 light microscope (Olympus, Japan).

2.7 Fastness test

Wash fastness and light fastness were tested according to ISO 105-C01 (1989) and ISO 105-B02 (1994), respectively.

3 RESULTS AND DISCUSSION

3.1 Effect of dyeing temperature

The representative variations of the dye on PLA as a function of dyeing temperature are shown in Fig. 2. It can be seen that the dye exhaustions almost leveled off from 90°C and then decreased from 120°C, while the strength loss of PLA increased with the increase of the dyeing temperature. The dye had high exhaustions on PLA under a wide range of temperatures, which indicated that it had high affinity for PLA. However, at higher temperatures, not only the dye affinity for PLA decreased, but also PLA experienced substantial degradation as shown in the figure. These factors probably resulted in the decreased exhaustion. On the other hand, it is noticeable that PLA was able to shrink below 110°C besides its strength loss [5]. From these results, it is seen that the ideal dyeing temperature of PLA fabric with the disperse dyes should be based on the end-product characteristics.

Figure 2 Effect of dyeing temperature on the dyeability on PLA

[dye 1: 2% (on the mass of fabric), pH: 5.0, time: 30 min]

□?dye exhaustion; ●?strength loss

3.2 Effect of dyeing time

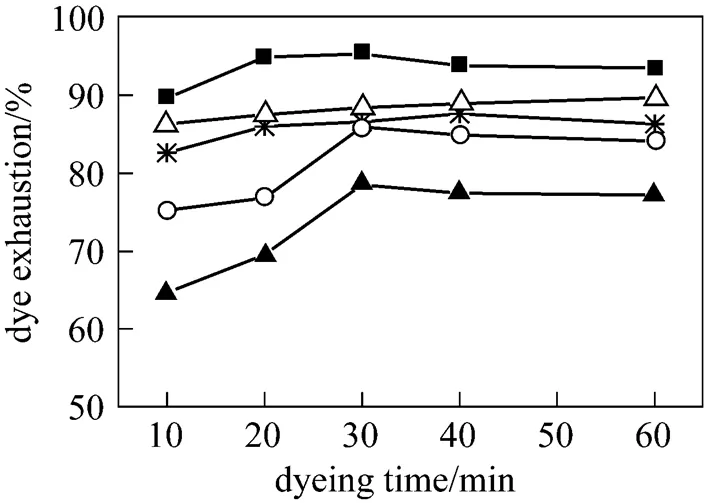

Figure 3 shows the effects of dyeing time on dye exhaustion at 110°C. For dye 1, dye 3, and dye 4, dye exhaustions on PLA leveled off from 20 min, and then their changes were small. Obviously, the dyeing equilibrium was attained at that time. Also, as seen in Fig. 3, the dye exhaustions decreased with increasing the length of the alkyl chains of the dyes. For dye 2 and dye 5, their times of dyeing equilibrium were longer, up to 30 min, but their exhaustions were still lower than those of dyes 1, 3, and 4, whose side chains were aliphatic alkyl. Based on the dyeing curves, it was seen that a dyeing time of 20-30 min was sufficient for dyes 1, 3, and 4, whereas dyes 2 and 5 needed about 30 min.

Figure 3 Dye exhaustion on PLA as a function of dyeing time

[dyes: 2% (on the mass of fabric), pH: 5.0, temperature: 110°C]

3.3 Effect of dye bath pH

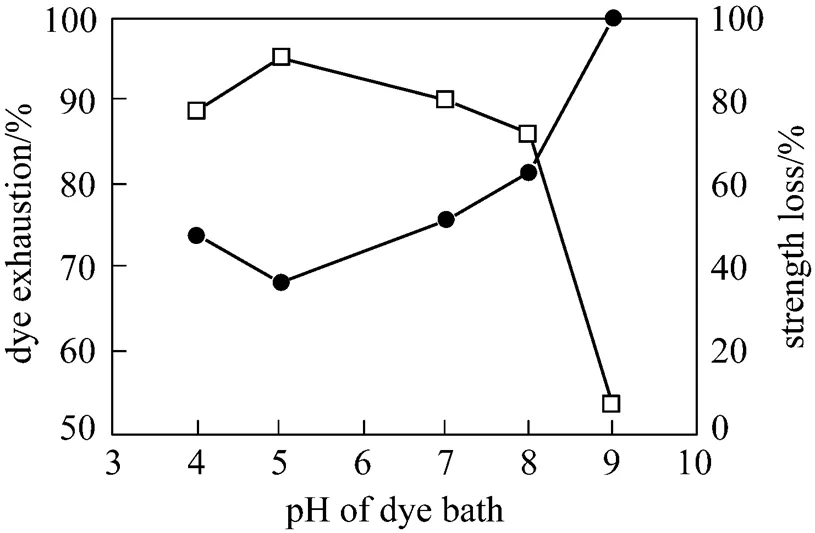

The influence of dye bath pH on dye exhaustion is shown in Fig. 4. The dye exhaustion initially increased from pH 4 to pH 5, and then decreased from pH 5 to Ph 9. This variation was likely caused by the degradation of PLA because the strength loss of PLA displayed a reverse change process under the dyeing conditions. In fact, PLA easily hydrolyzed under the dyeing conditions. The mild hydrolysis of PLA may provide an increase in the dye accessible area [5]. However, the severe hydrolysis of PLA in strong acidic or alkaline environment can affect the integrality of PLA, leading to the decrease of dye exhaustion. According to Fig. 4, the pH with the highest dye exhaustion and the least effect on the PLA strength is about 5.0.

Figure 4 Effect of dye bath pH on the dyeability on PLA

[dye 1: 2% (on the mass of fabric), temperature: 110°C, time: 30 min]

□?dye exhaustion;●?strength loss

3.4 Effect of dye concentration

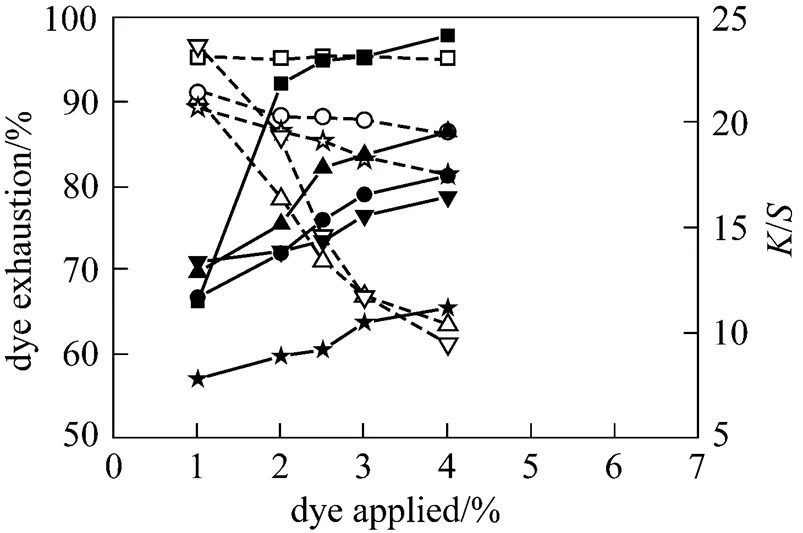

Figure 5 shows the relationship between the dyeability on PLA with the dye concentration. As seen in Fig. 5, the exhaustion of dye 1 remained about 96% in all the dye concentrations studied; however, the exhaustions of the other four dyes decreased with the increase of the dye concentration, especially for dye 2 and dye 5. The exhaustion results of dye 1 as a function of the dye concentration are quite different from the dyeing behaviors of conventional dyeing processes. Generally, dye exhaustion decreases with the increase of the dye concentration. The invariability in the dye exhaustion on PLA obtained in this study may be relevant to the dye affinity for PLA. An appropriate hydrophobic alkyl chain introduced to the dye molecule can enhance the dye-fibre affinity. Therefore, dye molecules can be adsorbed adequately by PLA, resulting in the high exhaustion. On the other hand, the/values of the dyed samples increased with the increase of dye concentration, but decreased with the increase of the length of alkyl chains at the same dye concentration. This was because the efficiency of the chromophore decreased with the increase of the length of alkyl chains.

Figure 5 Relationship between dyeability of dyes on PLA and dye concentration

[pH: 5.0, temperature: 110°C, time: 30 min. Ex. (1) and/(1) indicate the dye exhaustion and/value of dye 1, and so forth]

□?Ex. (1); △?Ex. (2); ○?Ex. (3); ☆?Ex. (4); ▽?Ex. (5); ■/(1);▲/(2); ●/(3); ★/(4); ▼/(5)

3.5 Microscopic analysis

Microscopic assessment of the cross-sections of dyed PLA fibres was carried out under a microscope. According to the optimal dyeing conditions above- mentioned, dye 4 was used to assess the cross-sections because it had a longer alkyl chain in these dyes. In Fig. 6, it is demonstrated that the inside of the fibre cells were colored, which indicated that dye 4 had penetrated into the PLA fibre.

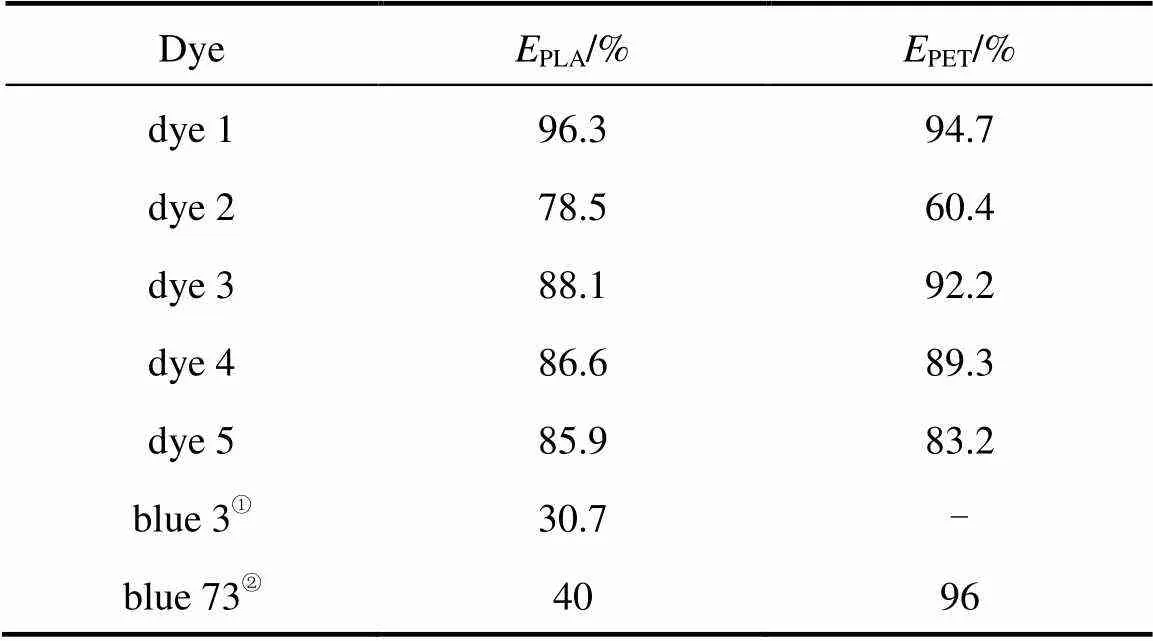

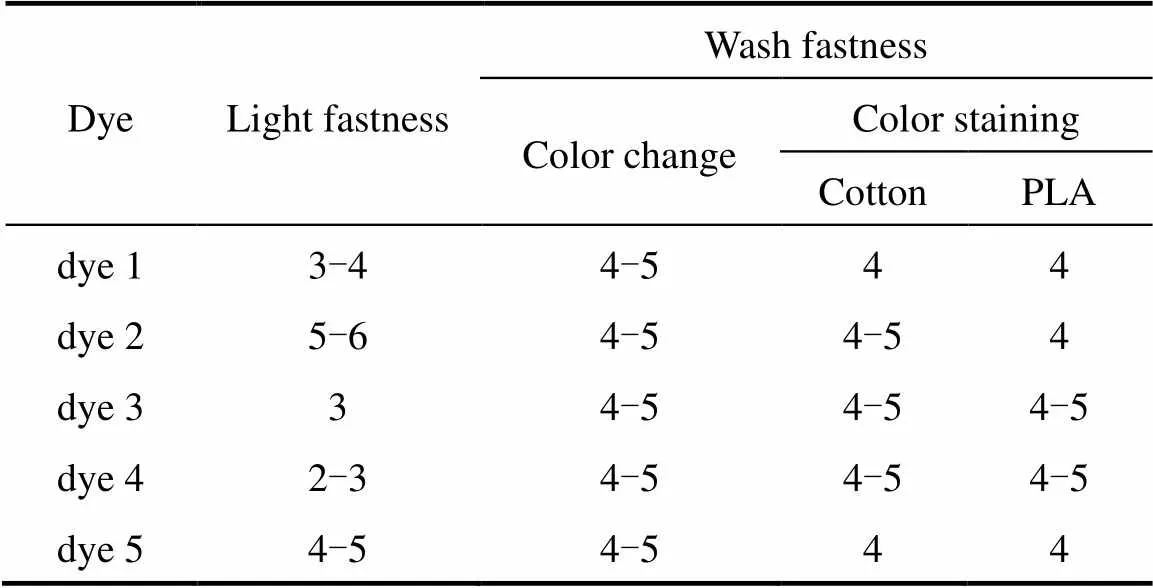

3.6 Dyeing properties

As seen in Table 1, the dyes except dye 2 had exhaustions greater than 85.0% on PLA, which were considerably higher than those of some commercial disperse dyes with similar structures (Fig. 7). However, for dyes 1, 3, and 4, the exhaustions decreased with increasing the length of alkyl chains attached to the anthraquinone ring. This possibly resulted from the decreased dye penetration. Besides dye 2, these dyes also had high exhaustions on PET under the same dyeing conditions. From these results, it is promising that PLA can be dyed with PET simultaneously, whereas most of the commercial disperse dyes had higher exhaustions on PET, but lower exhaustions on PLA [6], therefore, dyeing PET and PLA in one bath may be difficult with these commercial dyes.

Figure 6 Cross-sections of PLA dyed with dye 4

Table 1 Exhaustion (E) of hydrophobic and commercial disperse dyes on PLA and PET

① Ref. [7].② Ref. [6].

Figure 7 Structures of C.I. disperse dyes

For PLA, light fastness of dyes with aromatic amino or cyclo-fatty amino groups was higher than that of dyes with fatty amino group. Obviously, dye exhaustion is not the only reason for lower light fastness. The interaction between the dye and fiber, the distribution of the dye in the fiber, and the dye crystallization and agglomeration all play important roles in light fastness. Wash fastness of the dyes on PLA was 4 or 4-5 grades (see Table 2).

Table 2 Fastness properties of the hydrophobic dyes on PLA

4 CONCLUSIONS

The dyeability of PLA with hydrophobic anthraquinone dyes was investigated. Owing to the easier hydrolysis of PLA, its dyeing conditions should be controlled carefully. Under the optimal conditions, the dyes could penetrate into PLA. Moreover, their dye exhaustions were able to exceed 85%, and their wash fastness was good rating between 4 and 5.

Under the same condition, PET could also be dyed with high exhaustions. Thus, it is promising to dye PLA composite with other synthetic fibers in one bath.

1 Phillips, D., Suesat, J., Wilding, M., Farrington, D., Sandukas, S., Bone, J., Dervan, S., “Effect of heat setting on dimensional stability and dyeing properties of poly(lactic acid) fibres”,.., 119, 128-133 (2003).

2 Zini, E., Baiardo, M., Armelao, L., Scandola, M., “Biodegradable polyesters reinforced with surface-modified vegetable fibers”,.., 4, 286-295 (2004).

3 Lunt, J., Bone, J., “Properties and dyeability of fibers and fabrics produced from polylactide (PLA) polymers”,., 1, 20-23 (2001).

4 Sawada, K., Ueda, M., “Optimization of dyeing poly(lactic acid) fibers with vat dyes”,, 74, 81-84 (2007).

5 Yang, Y., Huda, S., “Dyeing conditions and their effects on mechanical properties of polylactide fabric”,., 3, 56-61 (2003).

6 Yang, Y., Huda, S., “Comparison of disperse dye exhaustion, color yield, and colorfastness between polylactide and poly(ethylene terephthalate)”,...., 90, 3285-3290 (2003).

7 Scheyer, L.E., Cheweshe, A., “Application and performance of disperse dyes on polylactic acid (PLA) fabric”,., 1, 44-48 (2001).

8 Lord, W.M., Peters, A.T., “Alkylaminoanthraquinone as dyes for polypropylene fibers”,...., 27, 362-368 (1977).

2007-12-24,

2008-08-11.

the National Science Foundation for Distinguished Young Scholars of China (20525620) and Dalian University of Technology Youth Teacher Foundation (893227).

** To whom correspondence should be addressed. E-mail: zhangshf@chem.dlut.edu.cn

Chinese Journal of Chemical Engineering2009年1期

Chinese Journal of Chemical Engineering2009年1期

- Chinese Journal of Chemical Engineering的其它文章

- An Improved Fuzzy Predictive Control Algorithm and Its Application to an Industrial CSTR Process*

- Preparation, Characterization and Catalytic Behavior of 12-Molybdophosphoric Acid Encapsulated in the Supercage of Cs+-exchanged Y Zeolite*

- Purification of Sulfuric and Hydriodic Acids Phases in the Iodine-sulfur Process*

- Synthesis and Characterization of Novel Temperature and pH Responsive Hydroxylpropyl Cellulose-based Graft Copolymers

- The Separation of Catechol from Carbofuran Phenol by Extractive Distillation*

- Electrochemical Performance of Nickel Hydroxide/Activated Carbon Supercapacitors Using a Modified Polyvinyl Alcohol Based Alkaline Polymer Electrolyte*