Carbon nanotube composites in aerospace applications

Tang Jianmao

(Chinese Materials Research Society , Beijing 100048, China)

0 Introduction

Composite materials have become one of the most important trends in the development of new materials.A great progress has been made in high performance composites, especially in carbon fiber reinforced plastics(CFRP).Composite structural parts mainly made of carbon fibers and epoxy resins take a larger and larger share in the aerospace structures.In the recently launched B787 Dreamliner, CFRP parts constitute 50% of the total structural weight, including such primary structures as fuselage, wing and horizontal stabilizer;in the air giant A380 airplane, CFRP parts constitute 25% of the total structural weight.In aerospace applications, the structural materials of light weight and high strength are the everlasting goals, and carbon nanotube reinforced polymer composites become very attractive as a kind of new generation materials.

Since their first study carried out nearly 20 years ago by Iijima[1], much research work has been done for carbon nanotubes and their applications.The remarkable physical and mechanical properties of carbon nanotubes have been extensively reported, from unique electronic properties, high thermal conductivity to superior mechanical properties where the stiffness, strength and resilience are better than any current materials.Carbon nanotubes offer tremendous opportunities for the development of fundamentally new materials systems.In particular, the nano-composites reinforced with carbon tubes can offer extraordinary specific stiffness and strength, and are very promising for aerospace applications in the 21st century.In this paper, a concise review is made for carbon nanotubes, including the basic molecular structures, unique properties, potential applications, as well as the recent advances in carbon nanotubes composites, and some special technical issues for carbon nanotubes reinforced polymer composites for aerospace applications.

1 What are carbon nanotubes (CNTs)?

Carbon nanotubes (CNTs) are members of the fullerene structural family, as a tube-shaped material, made of carbon, with a diameter of the nanometer scale, typically ranging from less than 1 nm up to 50 nm.A nanometer is one-billionth of a meter, or about one ten-thousandth of the thickness of a human hair.Now nanotubes can be constructed with a very large ratio of length-to-diameter up to 132 000 000∶1, significantly larger than any other material at present.That is, the diameter of a nanotube is of the order of a few nanometers, while the length can be up to 18 cm[1].For a carbon nanotube, the graphite layer appears somewhat like a rolled-up cylindrical nanostructure with a continuous unbroken hexagonal mesh and carbon atoms at the apexes of the hexagons.

CNTs have many structures, differing in length, thickness, and in the type of helicity and number of layers, which can typically be classified into single-wall nanotubes (SWNTs) and multi-wall nanotubes (MWNTs).

1.1 Single-wall nanotubes (SWNTs)

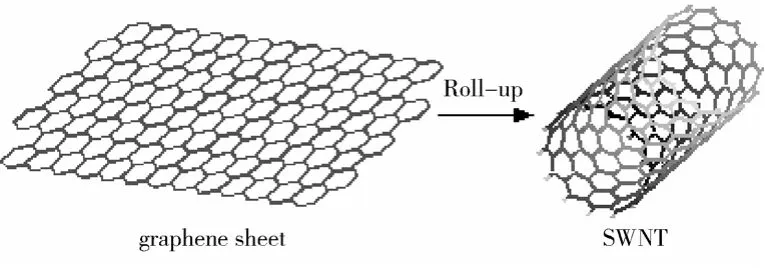

Single-wall nanotubes (SWNTs) are tube-like nanostructures of graphite, normally capped at the ends, and with a single cylindrical wall.The structure of an SWNT can be visualized as a layer of graphite, a single atom thick, called graphene, which is rolled into a seamless cylinder as shown in Fig.1.

Most SWNTs typically have a diameter of nearly 1 nm.The tube, however, can be many thousands of times longer.

SWNTs are more flexible but harder to make than MWNTs.They can be twisted, flattened, and bent into small circles or around sharp bends without breaking.

SWNTs have remarkable electronic and mechanical properties, which can be used in numerous applications, such as field-emission displays, nano-composite materials, nanosensors, and logic elements.These materials are on the leading-edge of electronic fabrication, and are expected to play a major role inthe next generation of miniaturized electronics.

Fig.1 Schematic diagram of SWNT forming

1.2 Multi-wall Nanotubes (MWNTs)

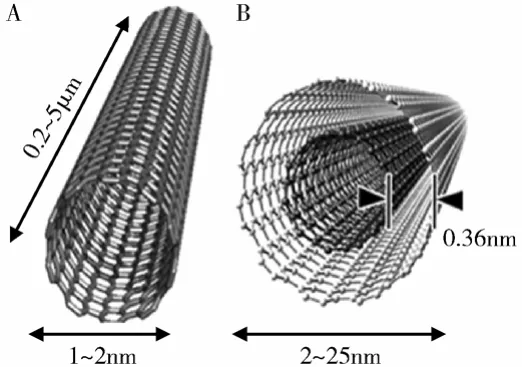

Multi-wall nanotubes can be either in the form of a coaxial assembly of SWNTs similar to a coaxial cable, or as a single sheet of graphite rolled into the shape of a scroll as shown in Fig.2.

The diameters of MWNTs are typically in the range of 5~50 nm.The interlayer distance in MWNTs is close to the distance between graphene layers in graphite.

MWNTs are easier to produce in high volume quantities than SWNTs.However, the structure of MWNTs is less well understood because of its greater complexity and variety.Regions of structural imperfection may degrade its desirable material properties.

The challenge in the production of SWNTs on a large scale as compared to that of MWNTs is reflected in the prices of SWNTs, which currently are higher than those of MWNTs.

SWNTs, however, enjoy a performance of up to ten times better, which is a very important factor for some specific applications.

Fig.2 Computer modeling of MWNT

Both single-wall carbon nanotubes (SWCNTs) and multi-wall carbon nanotubes (MWCNTs) can be produced by a variety of different processes, which can broadly be divided into two categories∶high-temperature evaporation using arc-discharge[2]or laser ablation[3], and various chemical vapour deposition (CVD) or catalytic growth processes[3].In the high-temperature methods, MWCNTs can be produced from the evaporation of pure carbon, but the synthesis of SWCNTs requires the presence of a metallic catalyst.The CVD approach requires a catalyst for both types of CNTs but also allows the production of carbon nanofibers (CNFs).

2 Properties of carbon nanotubes

CNTs were much studied with respect to their mechanical and transport properties.For example, the extremely high elastic modulus, greater than 1 TPa (the elastic modulus of diamond is 1.2 TPa) and reported strengths 10~100 times higher than the strongest steel at a fraction of the weight[4].This means that carbon nanotubes may bring about an entirely new class of advanced materials.

In addition to the exceptional mechanical properties, carbon nanotubes also offer superior thermal and electrical properties∶thermal stability up to 2 800 ℃ in vacuum, thermal conductivity about twice as high as diamond, electrical current carrying capacity 1 000 times higher than copper wires[5].

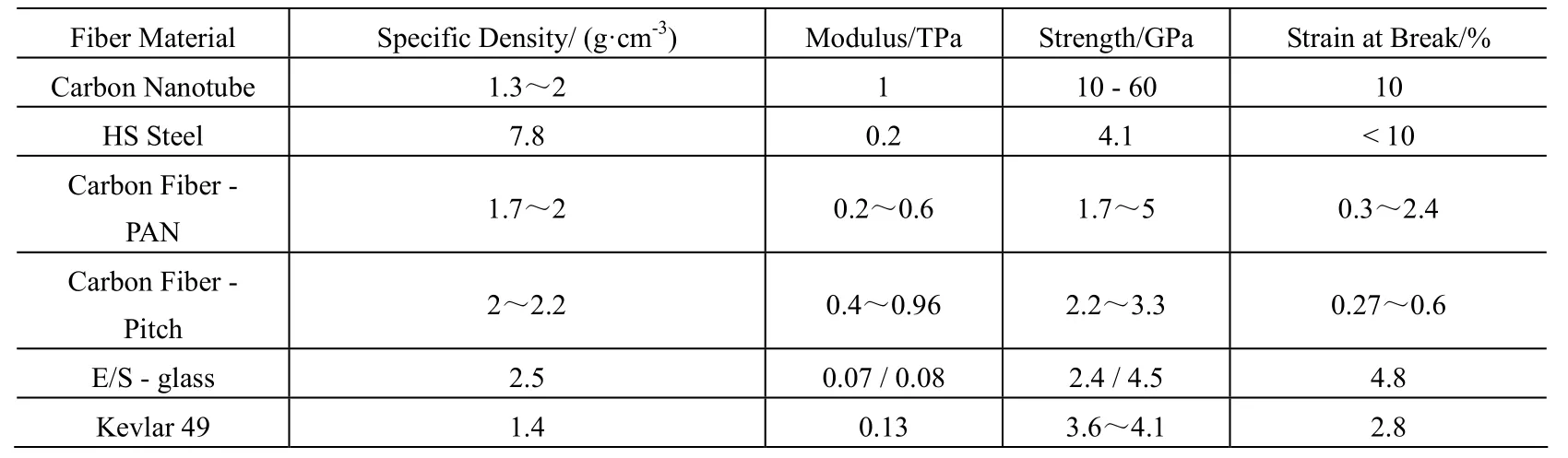

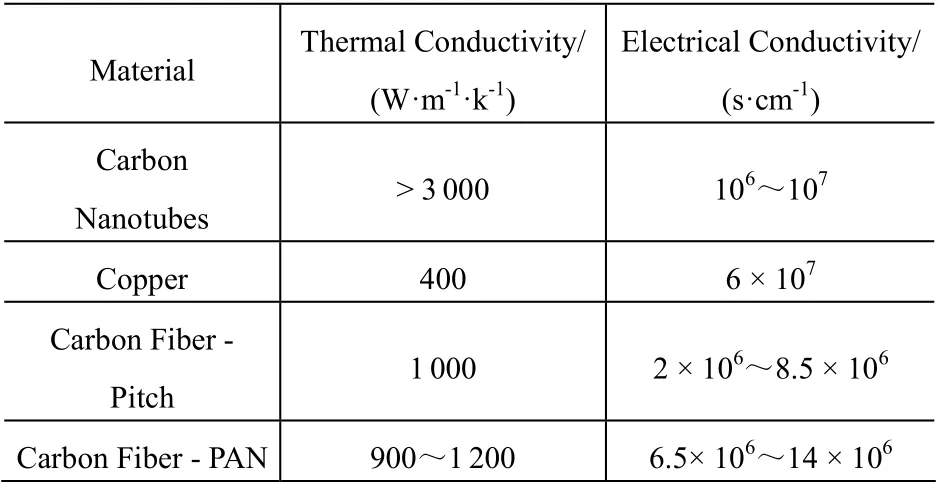

The following tables (Table 1 and Table 2) compare these properties with other engineering materials.

Overall, carbon nanotubes show a unique combination of stiffness, strength, and tenacity as compared to other fiber materials which are usually inferior in one or more of these properties.Thermal and electrical conductivities are also very high, comparable to other conductive materials.

Table 1 Mechanical properties of engineering fibers

Table 2 Transport properties of conductive materials

3 Potential applications for carbon nanotubes

Carbon nanotube technology can be used for a wide range of applications∶

· Conductive plastics;

· Structural composite materials;

· Flat-panel displays;

· Gas storage;

· Antifouling paint;

· Micro- and nano-electronics;

· Radar-absorbing coating;

· Technical textiles;

我急了,它待在這里,遲早要被餓死。好在它所處的位置,嚴嚴實實地替它擋住了寒風。將它救出來,雨可能會淋死它,風可能會凍死它……難道它只有死路一條嗎?我不知道如何是好。

· Ultra-capacitors;

· Atomic force microscope (AFM) tips;

· Batteries with improved lifetime;

· Biosensors for harmful gases;

· Extra strong fibers.

As a very important field, CNT composites are very promising in aerospace applications because of their superior mechanical properties combined with the low density, fiber- like structure and high aspect ratio.Many studies were carried out in improving mechanical properties of composites by adding CNTs.For example, the tensile modulus and yield strength are increased with the addition of SWNT into a polyimide SWNT composite, a much bigger increase than that for film samples (cast without preferred SWCNT orientation), but much less increase than what would be expected from an oriented discontinuous fiber reinforced polymer composite, which is likely due to inefficient and incomplete dispersion.With an improved dispersion, significant reinforcing effects of the aligned fibers on the mechanical properties are anticipated[6].

If the composites made of carbon-nanotube/polystyrene were added by 1% of MWNT in weight (about 0.5% in volume), the elastic stiffness was shown to increase by up to 36%~42%, and the tensile strength by 25%[7].

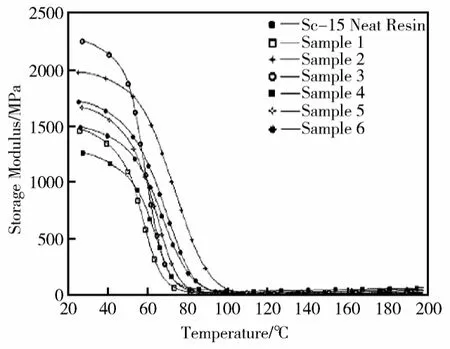

Significant improvements in the mechanical properties of the epoxy/SWNT nano-composites were reported with a 50.8% increase in the storage modulus as illustrated in Fig.3[8].

Fig.3 Storage modulus of CNTs/epoxy composite

Nano-composites consisting of double-wall carbon nanotubes (DWCNT) and an epoxy matrix were shown to have a significant increase of strength, Young’s modulus and strain to failure at a nanotube content of only 0.1%(wt.)[9].

4 Technical issues limiting the advancement of nanotube-reinforced composites

The extraordinary stiffness and specific tensile strength of CNTs makes them well-suited for use as reinforcing elements in polymer composites.The incorporation of carbon nanotubes can greatly increase the strength and stiffness of a polymer matrix with minimal increases in weight.One may also expect its ability in protecting against vibration and flame.There are a number of technical difficulties that must be overcome before carbon nanotube reinforced-polymer composites can become commercially available.

Perhaps the most obvious obstacle is that of cost.Pure, high quality carbon nanotubes are definitely very expensive.However, the price of nanotubes has dropped dramatically over the past several years as a result of several efforts focused on realizing the mass production of CNTs.This trend is expected to continue as nanotube synthesis techniques are refined and more manufacturing facilities are brought online.

For CNTs reinforced polymer composites, four critical technical issues will be dealt for effective fiber reinforcement of composite materials∶large aspect ratio, interfacial stress transfer, good dispersion, and alignment[10].

While carbon nanotubes typically have very high aspect ratios, their absolute lengths still remain short, which makes them difficult to be controlled and processed.Most CNTs are only of an order of microns in length, although individual CNTs of some centimeters in length have been synthesized.However, long nanotubes cannot be synthesized in bulk quantities at present.

In order to increase the length of nanotube-based reinforcing fibers, a number of methods for producing longer fibers from shorter nanotubes have been developed.Woven CNT composite fibers up to 100 meters in length have been demonstrated in a thin, continuous, transparent sheet of nanotubes[11].While its focus is on the development of conductive fibers for wearable electronics, these materials also are well-suited for inclusions within composite materials.

Nanotube sheets, in particular, have been used to fuse together thermally two polymer sheets in a transparent and seamless fashion[11].

Due to their unique electrical and structural properties, carbon nanotubes tend not to bond strongly with their host matrix or with one another.As a result, the potential increases and improvements in the mechanical properties of a nanotube composite are limited by the degree of interfacial stress transfer that can be achieved.A great deal of study shows that it can be done through chemical functionalization and surface modification of carbon nanotubes[12].Ion beam irradiation has also been shown to promote crosslinking and improve binding within bundles of nanotubes[13].

CNT dispersion within a matrix is important to achieve efficient and effective load transfer to the nanotubes.This helps to ensure uniform stress distributions and to minimize the effect of stress concentration.The two primary difficulties associated with dispersion are to separate individual CNTs from each other and then to uniformly mix them with the polymer matrix.Sonication of CNTs within a solvent is one of the most common methods and can deal with both difficulties simultaneously.Shear mixing and magnetic stirring are also commonly used to mix nanotubes within a polymer[10].

The alignment of CNTs within a matrix is probably the least critical of the four issues for nanotube composites, as the alignment requirements are often dictated by the intended application.Highly-oriented fibers will provide the greatest increase in strength in the fiber direction, but little to no improvement in the transverse direction.In comparison, randomly-oriented fibers will result in isotropic mechanical properties, but at reduced levels of improvement[10].

5 Summary and conclusions

The exceptional mechanical and physical properties of carbon nanotubes, combined with their low density, make this new form of carbon materials an excellent candidate for the next generation of composite reinforcement.However, there are many economic and technical issues currently to prevent carbon nanotube-reinforced polymers from being applied to large-scale composite structures, especially in high-tech aerospace applications.

The high cost and relatively short lengths of CNTs, combined with the inability to effectively disperse and align them within a host matrix, become the main limits to develop composite structures that could supplement or replace conventional aerospace materials.

However, a great number of studies focus on these issues.Investigations worldwide aim to develop advanced synthesis processes capable of large-scale production of CNTs in macroscopic lengths, and to combine shorter CNTs into longer and more useable composite fibers.

Functionalization and irradiation of polymer-embedded nanotubes and nanotube fibers also have been shown to be able to enhance dispersion and strengthen nanotube-matrix interactions, therefore to improve further the mechanical properties of CNT-reinforced composites.

Despite these studies, much further R&D work is still needed before the full potential of CNTs reinforcing composites can be realized and implemented.

[1]Iijima S.Helical microtubules of graphitic carbon[J].Nature, 1991, 354∶56-58

[2]Journet C, Maser W K, Bernier P, et al.Large-scale production of single-walled carbon nanotubes by the electric-arc technique[J].Nature, 1997, 388∶756-758

[3]Rinzler A G, Liu J, Dai H, et al.Large-scale purification of single-wall carbon nanotubes∶process, product and characterization[J].Applied Physics A,1998, 67(1)∶29-37

[4]Thostenson E T, Ren Zhifeng, Chou Tsu-Wei.Advances in the science and technology of carbon nanotubes and their composites∶a review[J].Composites Science and Technology, 2001, 61(13)∶1899-1912

[5]Collins P G, Avouris P.Nanotubes for electronics[J].Scientific American 2000, 283(6)∶62-69

[6]Siochia E J, Working D C, Park C.Melt processing of SWCNT-polyimide nanocomposite fibers[J].Composites Part B∶Engineering, 2004, 35(5)∶439-446

[7]Qian D, Dickey E C, Andrews R, Rantell T.Load transfer and deformation mechanisms in carbon nanotube-polystyrene composites[J].Applied Physics Letters, 2000, 76(20)∶2868-2870

[8]Salvetat J P, Briggs G A D, Bonard J M.Elastic and shear moduli of single-walled carbon nanotube ropes[J].Physical Review Letters, 1999, 82(5)∶944-947

[9]Gojny F H, Wichmann M H G, Kopke U, et al.Deformation and fracture behavior of nanpcomposites[J].Composites Science and Technology, 2004, 64(15)∶2363-2371

[10]Coleman J N, Khan U, Gun’ko Y K, et al.Mechanical reinforcement of polymers using carbon nanotubes[J].Advanced Materials, 2006, 18(6)∶689-706

[11]Zhang M, Nakayama Y, Harada J, et al.Strong, transparent, multifunctional, carbon nanotube sheet[J].Science, 2005, 309∶1215-1219

[12]Piner R D, Xu T T, Fisher F T, et al.Improvement of thermal and mechanical properties of carbon nanotube composites through chemical functionalization[J].Chemistry of Materials, 2003,15(23)∶4470-4475

[13]Kis A, Csanyi G, Salvetat J P, et al.Reinforcement of single-walled carbon nanotube bundles by intertube bridging[J].Nature Materials, 2004, 3(3)∶153-157