Multimodal Control Method Based on Intelligence Strategy in Complex Large-scale Process

TAN Xiankun,LI Lei

1.International School,Chongqing Jiaotong University,Chongqing 400074,China;2.College of Automation,Chongqing University,Chongqing 400044,China

1.Introduction

Modern manufacturing industry is developing towards to green manufacturing of newly sustainable direction.The green manufacturing means that it must be in low-carbon,environmental protection,economizing resource and harmoniousness with natural ecology,and therefore the higher expectations and requirements have been presented in the control engineering of manufacturing industry,for instance,how to implement the optimization control of multiple target in complex industry process.The target of green manufacturing is to seek the global coordination and optimization for whole control process,and it not only includes itself performance of control system such as dynamic and steady performance specification,but also it comes down to the social and economic benefit of products.Therefore the green manufacturing is a complex systems engineering[1],and it has to make overall plans take all factors into consideration in the whole control process so as to obtain the global coordination and optimization.Generally it always adopts the structure form of multi-layer classification to decompose the complex system as a plurality of control sub-process,according to the principle of decomposition and coordination and in accordance with the general decentralized and centralized management principles,it makes global optimization and coordination for complex process,and then it adopts intelligent control strategy to actualize the control for the complex process of the underlying.

2.Decomposition and coordination of complex system

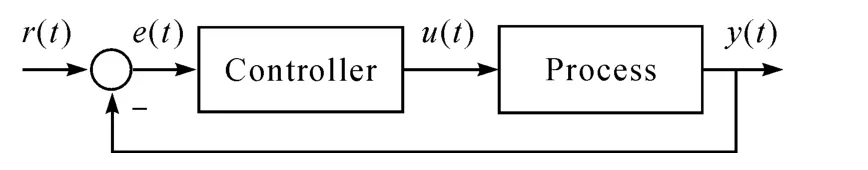

The decomposition of complex system bottom owns lots of methods,and here it only discusses the functional module method to decompose the complex system bottom as a lot of subsystem shown as in Fig.1.

Fig.1 Sketch map of decomposition and coordination

The control specification index of each subsystem is determined by coordination decision unit of upper hierarchy.Since there is no direct information exchange among the subsystems,and the performance coordination among the subsystems can reasonably be executed through performance index decomposition of system.It means that each subsystem is an independent system,and the performance in input and output of the subsystem is determined by coordination decision unit.In the Fig.1,c1,c2,…,cn,f1,f2,…,fnrepresents respectively the control and feedback information,the subsystem 1,subsystem 2,…and subsystem n are located in the process control field.The decision unit coordinates the parameters of each subsystem performance according to the user requirement.

3.Intelligent control and its basic features

Intelligent control is an automatic control technology that under the condition of no intervention it can autonomously drive the intelligent machine to actualize the control objective.It covered lots of technologies and contents of intelligent control and intelligent optimization method and so on,and each of them creates a system of one’s own and they are interrelated and interacted.But each is limited to an application of certain areas.Here it takes Human-Simulated Intelligent Control(HSIC)as an example so as to summarize its basic features.HSIC sums up the experience of human control,and describes its inference of inspiration and intuition as well as control behavior.In structure and function,HSIC owns the following basic features[2-3].

1)Hierarchical information processing layer and decision-making body(high order production system structure).

2)The feature identification and characteristics of memory online.

3)Multi-modal control of combining open with closed loop control and combined qualitative decision with quantitative control.

4)Application of heuristic and intuitionistic logic.

From the point of view of control theory,a series of new concepts and new methods are appeared in HSIC theory.①Intuitive reasoning logic of human is described by production rule of artificial intelligence.②Based on the system dynamic characteristic model,it makes the feature identification and characteristics of memory online.③Establishment of characteristics model is closely linked with the pattern recognition of artificial intelligence and the knowledge representation technique.④Based on the classical control theory,it adopted the multimodal control pattern of combining open with closed loop control and combined qualitative decision with quantitative control,and it makes full use of advanced scientific and technological achievements from control theory.⑤Hierarchical information processing layer and decisionmaking body takes computer hardware system as the carrier,and the implementation of the above principle fully reflects that intelligent control is the organic combination of cross among control theory,artificial intelligence and computer science.

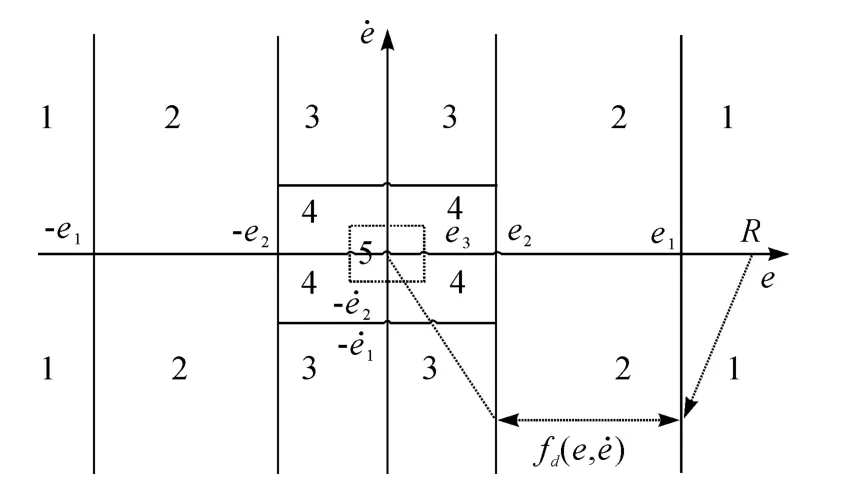

4.Generalized control model and dynamic characteristic model

The sub-process of complex large-scale process after decomposition is also difficult to build the math model,and generally it adopts the generalized control model based on knowledge,shown as in Fig.2.e(t),˙e(t),tshows respectively the process deviation and its change rate as well as time,and they form to solve the information space.The trajectory of process motion in information space not only reflects all dynamic information of process,but also reflects the influence on system control action.All the dynamic characteristic information form the characteristic model,and it is the base of characteristic identification which belongs to the priori knowledge of controller[4-5].

Fig.2 Generalized control model based on knowledge

Characteristic model is that it is the model combined quantitative and qualitative description for dy-namic characteristic of intelligent control system.Aimed at the difference of the control problem solving and the requirements of the control index,it is a sort ofpartition for spatialdynamic information of process.Each region of the partitioned respectively shows a sort of characteristic state of process.Therefore the characteristic model is a set of all characteristic states.

Characteristic identification is a process,and it shows that according to the characteristic model,the HSIC makes online process for sampling information,through pattern recognition it can determine what the characteristic state of process is located currently.

Characteristics of memory is a sort of memory,and it shows the memory of HSIC for some characteristic quantities in reflecting early decision and control effect and the requirements of the control task as well as the controlled process properties.

Control(decision)mode set means that it is a certain sort of the set of qualitative or quantitative mapping among control output,deviation informationEand characteristic memory information.

Rule set of inspiration and intuition reasoning is a kind ofimitation forcontrolexpertdecision process,according to the result of characteristics identification it determines the control strategy,and the description.It is given using the condition state“if conditions then action”form of production rule.

Hierarchical information processing and decision-making mechanism is a sort of high order production system structure for solving the control problem.According to the level of being high and low,it can be divided as the central command level,the organization coordination level and the unit control level.

5.Basic control algorithm and controller design

5.1.Basic control algorithm

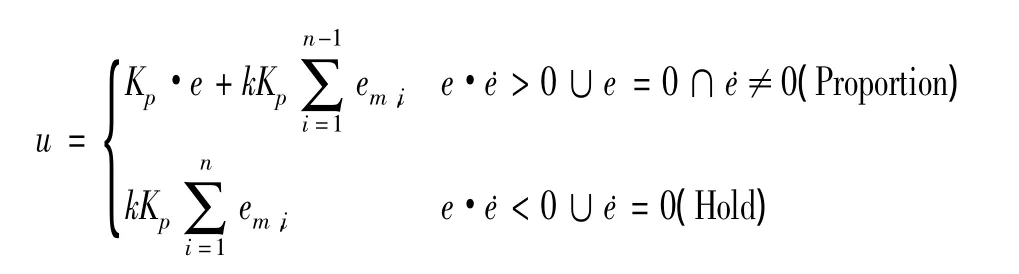

According to the static characteristic of prototype algorithm of HSIC shown as in Fig.2,the basic control algorithm is as below.

In which,uis the output of controller,e(t),˙e(t)is respectively the process deviation and its change rate,em,iispeak value of deviation,Kpis a proportional coefficient,andkis a constraint coefficient.

In the Fig.3,Pshows the output of controller.If the balance state of process deviates towards to positive direction,then the deviation would be gradually increased and then it can adopt proportional control pattern until the deviation up to the maximum.Accordingly the control quantity is also to achieve the maximum.After that,the deviation begins to have a trend of decrease,and here it adopts the hold control pattern,namely the outputPof controller holds invariant,and then it makes“wait behind”and“observation”for deviation change.Once the deviation passes to zero and increases towards to negative direction,then it still adopts proportional control,and repeats the control process that is roughly the same as mentioned above.After through one or two times of process switching like“Proportion-Hold-Proportion-Hold”,the process would quickly be stabilized at new balance point.At the same time of control pattern switching between“Hold“and“Proportion”,it continuously modifies control quantity.After the control quantity stabilizing to the control objective,the process is stabilized to process setting value.The setting difference ofKpandkwould directly result in difference of solving process.As long as the setting is proper,then the solving process would be convergent,and it can obtain the control objective quantity quickly.

Fig.3 Static characteristic of prototype algorithm

5.2.controller design

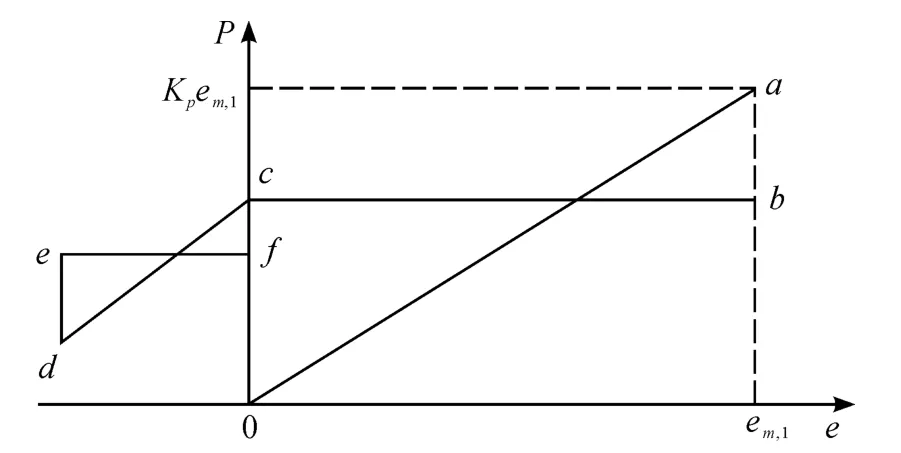

1)Characteristic model

The basic control algorithm not only reflects the qualitative decision process according to the running state recognition and the corresponding control mode selection,and at the same time it also gives the quantitative control of the specific control mode output.The control characteristic model is shown as in Fig.4.

Fig.4 Control characteristic model

From the analysis of Fig.4,it can be seen that

① Corresponding to region 1,it should takes Bang-Bang control because of the deviation being large,namely the control action should take as large as possible.

② Corresponding to region 2,it should take proportional mode and introduce the weak differential control because of the relative deviation being larger,and the aim is to ensure the deviation change speed does not change too large.

③ Corresponding to region 3,it takes proportional mode and introduce the strong differential control so as to make the deviation change speed reduce as soon as possible.

④ Corresponding to region 4,if the deviation change speed is lower than the preset speed then it adopts proportional mode plus differential mode control.

⑤ Corresponding to region 5,in order to eliminate the deviation,it adopts PID control because of the both deviation and its change rate are very small.

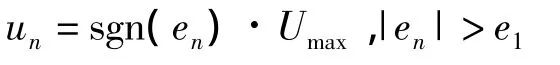

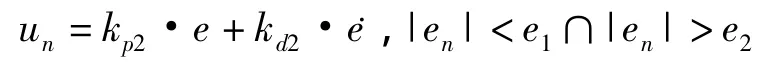

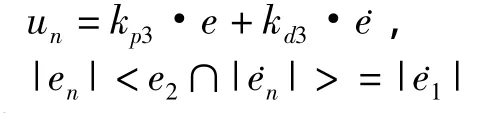

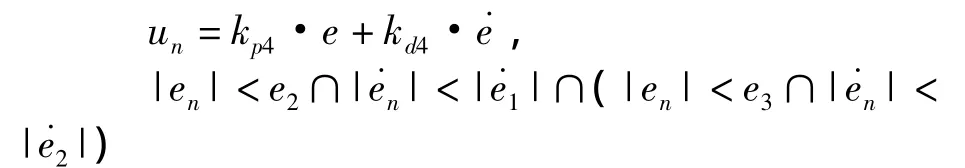

Therefore,according to the deviationeand˙e,on the basis of characteristic model,the control mode can be divided into fife sorts,and it can be expressed as the following.

①Bang-Bang control mode

②Proportional control mode

③Proportional control mode

④Proportional control mode

⑤Proportional integral control mode

6.Simulation experiment

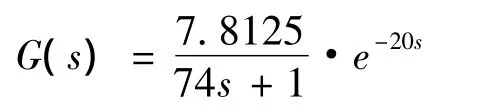

For convenience of comparison,here it takes an inertia with lag process as an example,and respectively adopts PID(control algorithm 1)and multimodal control(control algorithm 2)to make the simulation for the same process under the environment of Matlab.The process model is as below.

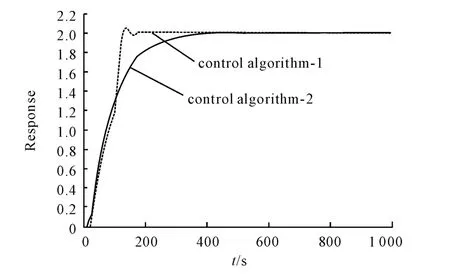

Under the condition of step input being 2,the response curve of process is shown as in Fig.5.It can be seen from the response curve that the curve of control algorithm 1 has faster response time and larger oscillation,and it appears the overshooting phenomena,but for the curve of control algorithm 2 it owns the smooth and steady response curve,and there is not any overshooting.The comparative result of simulation demonstrates that the control algorithm 2 has better control quality than the control algorithm1.

Fig.5 Response comparison for different algorithm

In order to inspect the robustness of control algorithm,a first-order inertial linkG(S)=1/(5S+1)is added into the original process model,under the condition of the same input,the process response is shown as in Fig.6.From the response curve it can be seen that the control algorithm 2 has better robustness than the control algorithm 1.

Fig.6 Response curve adding a first-order inertial link

The above simulation experiments show that the multimodal strategy should be listed as the preferred control strategy for the bottom control of complex large-scale process.

7.Conclusions

From the analysis of simulation experiment,it can obtain the conclusion that it is not sensitive for process parameter change,namely its robustness is stronger,and achieves more smooth and steady effect of dynamic control by means of multimodal control.

[1]PENG Li,LIN Ying,YANG Yi.Exploring on Related Technique in the Control of Complicated System[J].Journal of Southwest China Normal University:Natural Science Edition,2004,29(6) :1066-1068.

[2]CHENG Zhong,YAN Wei,LI Zushu,et al.NPID controller based on HSIC[J].Control and Decision,2003,18(6):694-698.

[3]LI Shiyong.Fuzzy Control?Neural Control and Intelligence Cybernetics[M].Harbin:Harbin Institute of Technology Press,2003.

[4]LI Zushu,TU Yaqing.Human Simulated Intelligent Controller[M].Beijing:National Defense Industry Press,2003.

[5]CAI Zixing,ZHOU Xiang,LI Meiyi.A Novel Intelligent Control Method Evolutionary Control[C]//Proceedings of the 3’d World Congress on Intelligent Control and Automation.2000:387-390.

- 機床與液壓的其它文章

- Detection of Bearing Fault Signal Based on the Wavelet and Chaos Theory

- Development of Vibration Signal Acquisition and Analysis System for Machine Tools Based on LabVIEW

- Vibration Analysis of a Large-size Reduction Gearbox Test System Based on Its Dynamic Characteristics

- Fusion Control Strategy Based on I-Fuzzy-Smith Algorithm for Complex Process with Large Lag

- Simulation Analysis of PID Optimization of Hydraulic Pressure System Based on Genetic Algorithm

- Design of a State Monitoring and Alarm Device for Escalator