Research of Production Configuration Management Based on the Internet of Things-mixed Cloud Enterprise

LI Guangrong,LIU Caixia, LU Yong, WANG Yunxia,WANG Zhiliang,HU Shengping

1.School of Mechanical Engineering,Nanjing Institute of Technology,Nanjing 211167,China;2.Xinxiang Vocational Education Center,Xinxiang 453001,China;3.Nanjing Bilin Software Company, LTD, Nanjing 210008,China

ResearchofProductionConfigurationManagementBasedontheInternetofThings-mixedCloudEnterprise

LI Guangrong1*,LIU Caixia2, LU Yong1, WANG Yunxia1,WANG Zhiliang1,HU Shengping3

1.SchoolofMechanicalEngineering,NanjingInstituteofTechnology,Nanjing211167,China;2.XinxiangVocationalEducationCenter,Xinxiang453001,China;3.NanjingBilinSoftwareCompany,LTD,Nanjing210008,China

Configurationrequirementofthemixedcloudproductionenterpriseisanalyzedandtheproductionconfigurationfunctionissummarized.Productionallocationcontentisinductedbasedontheinternetofthings-mixedcloudenterprise.Theworkshopproductionofconfigurationmanagementisdesignedindetail.Thoseareelaboratedonthespecificcontentandmodeofoperationofmaterialconfiguration.Itisobtainedthattheconfigurationofthemodelandrelationmodeldiagram.Productionresourceallocationmethodisstudiedbasedonmulti-treetheoryofinternetofthings-mixedcloudenterprise.Productionresourceallocationmodelbasedonthetreeisestablished.Ithaslaidatheoreticalbasisforoptimalapplicationandreasonableallocationofresources.

multi-tree,contentnetworking,mixedcloudenterprise,configuration

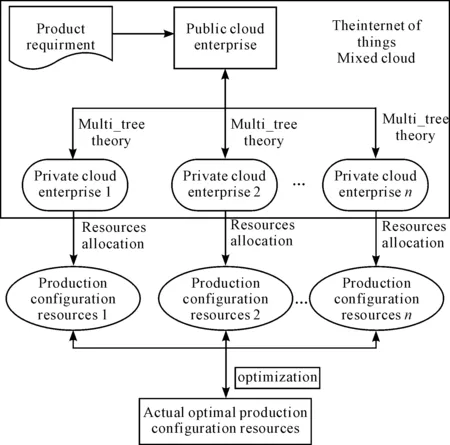

Production management of mixed-cloud enterprise can be classified according to project management mode, combined with resources allocation of public clouds and private cloud enterprise and suitable organization form for cloud enterprise project due to the decomposition of project to manage project. Through the project management pattern, the introduction of the project management classification is capable to distinguish all kinds of enterprise project. All kinds of resources of cloud enterprise have reasonable allocation according to the important priority of the project and resources. Allocation of resources is optimized to improve the effectiveness and utilization rate of cloud enterprise[1-3]. Therefore, researches about manufacturing enterprise production configuration management based on mixed clouds have important theoretical significance and practical application value.

1.Production configuration based on the internet of things-mixed cloud enterprise

1.1.Productionconfigurationrequirementsofmixcloudmanufacturingenterprise

Based on the production of mixed cloud manufacture, enterprise is completely produced according to the business model of production list. With the expansion of production scale, the accuracy of production scheduling and timelines of the delivery for a mixed cloud enterprise could be improved. At the same time, the problems could be found to improve the quality control of manufacturing process and production efficiency, as well as the product back problems of production workshop. In view of knowledge reuse of product design phase, matching the demand of purchase experience stage reference, mixed cloud enterprise record and compare history of product configuration to facilitate management new product design and alteration work related data and process.

1.2.Productionconfigurationfunctionofmixcloudmanufacturingenterprise

Production orders of mixed cloud enterprise are adopted by the manufacturing unit and create the production orders according to decomposition of the sales order by ERP and the information received from the MES (Manufacturing Execute System). At the same time, MES also support business functions of manually creation production orders. Production order management include three aspects of the data management, which are production order itself, process route of production orders, and material configuration of production orders (the order BOM). Detailed job program is for procedure workshop, and workshop ticket plan is split and created according to product configuration of working procedure and box number of product standard workshop. Production homework is scheduled for machining center of workshop, namely the production scheduling to each processing center of the production tasks of each working day order.

2.Production configuration management based on the internet of things—mixed cloud enterprise

2.1.Thecontentandmanagementofproductionconfigurationbasedontheinternetofthings-mixcloudenterprise

Mixed clouds create the enterprise system configuration. Public cloud enterprise and private enterprise maintain the staff and department of clouds, and register the system users, authority distribution and query. Information is maintained such as query operation log and data dictionary. In order to maintenance workshop foundation data, manufacturing enterprise configuration management include processing workshops, processing center, location, workshop section and basic working procedure, processing center route, processing center working team, etc. The maintenance of product based data include products, raw materials, and their BOM configuration, the product processing route, and the processing workshop configuration, theory working hours, product drawings, procedures and instructions, fault code, factory calendar, work divisions and other basic configuration[4-5].

Production configuration process of mixed clouds is as shown in Fig.1.

2.2.Workshopconfigurationmanagementbasedontheinternetofthings-mixedcloudenterprise

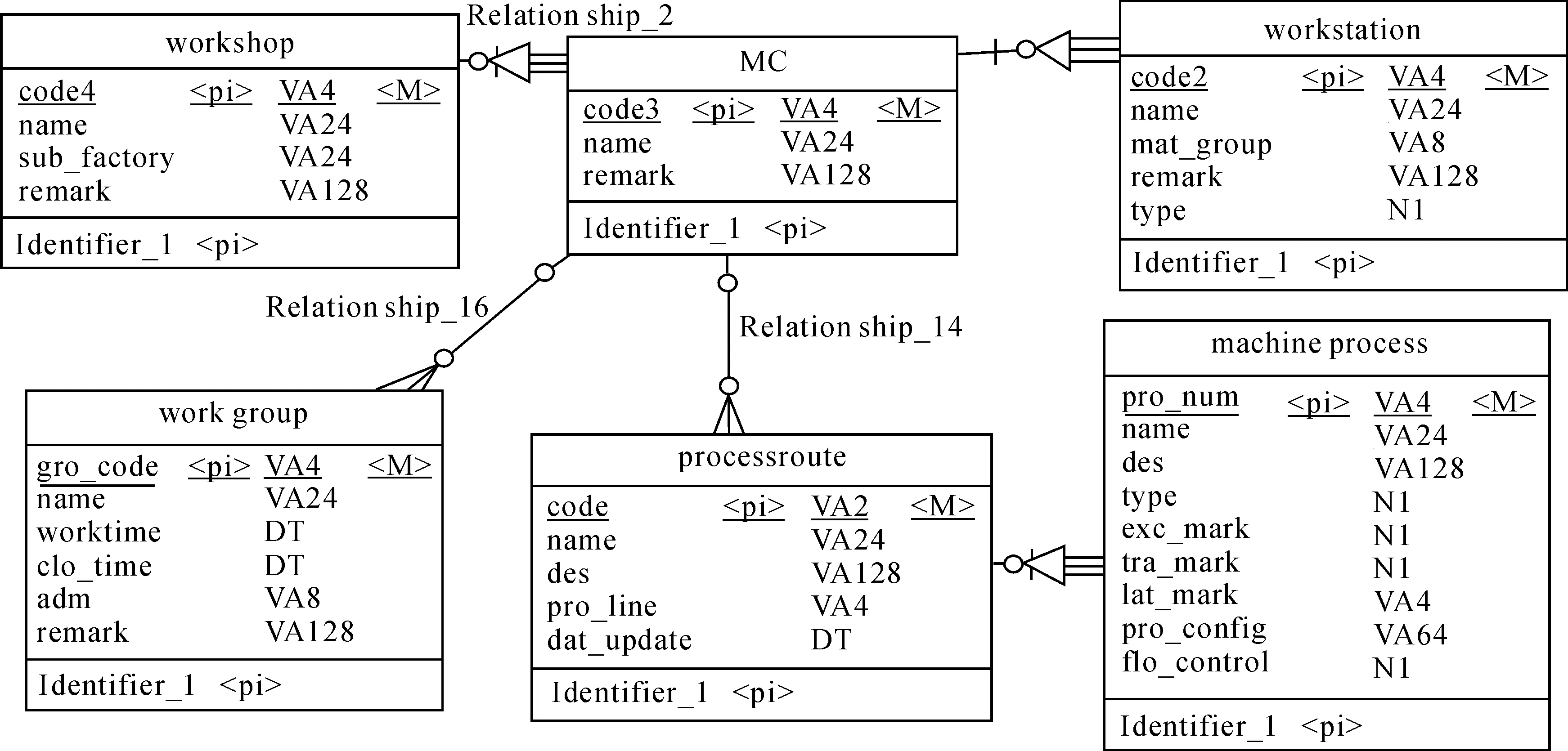

Workshop configuration and the model picture of mixed cloud enterprise are as follows: the division of physical places for workshop→processing center→work station. The workshop corresponds to the mass production process (such as extrusion and time). Processing center correspond to production machines (such as #1 and #2 machines) under the workshop. Location corresponds to storage location of products in each processing center, which points on the location and finished goods location. These are stored of products of the transfer process and finished goods of the procedure. The working team is set up under the processing center. The working team is a fixed group of work for processing center, different from their work. The process route is set up under the processing center, and the basic process route for this processing center is “line collection→inspection collection”.

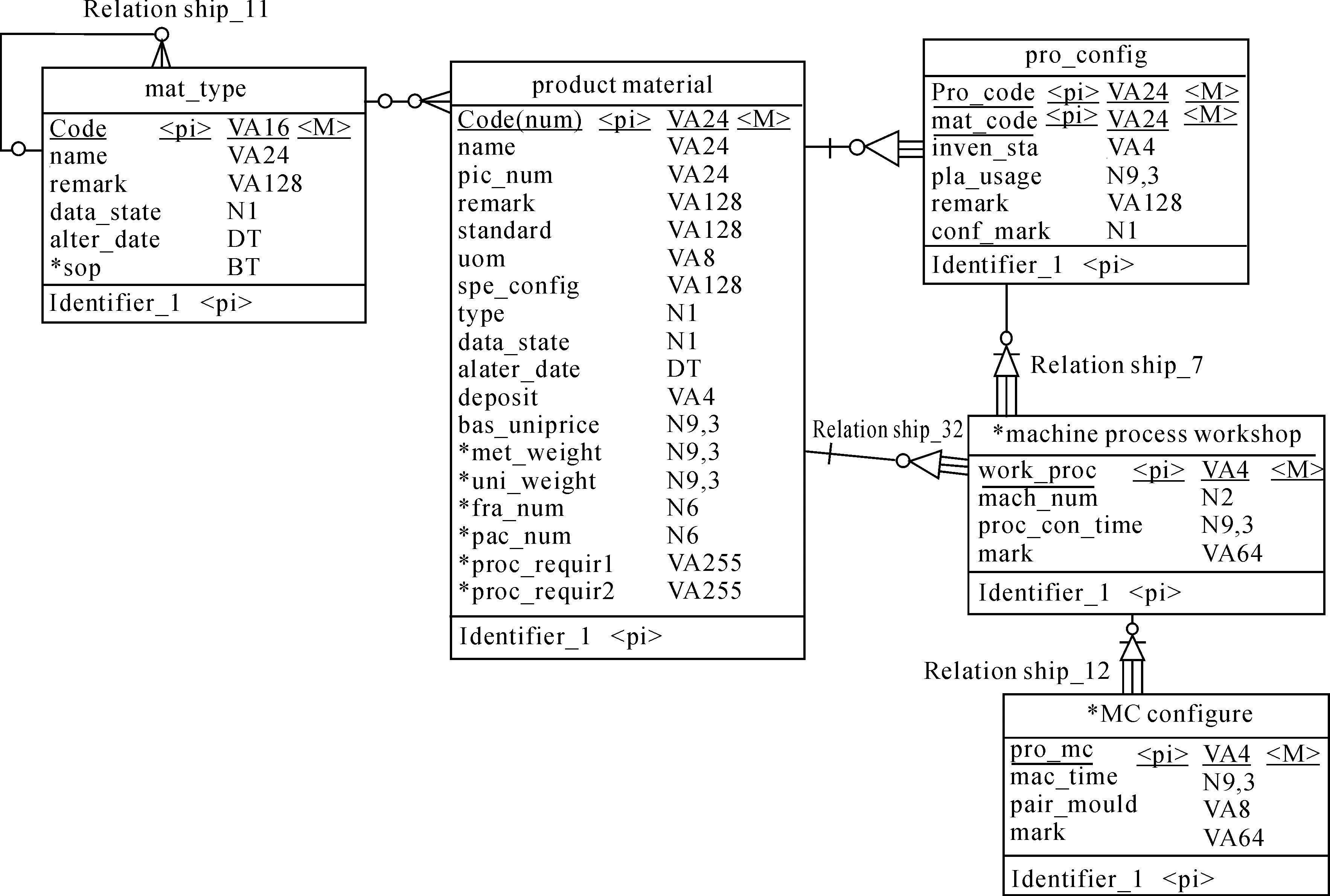

In the model, the factory products are divided into three levels for definition, material types→product and material→product BOM configuration. Material type support tree structure. According to client needs, tree structure is defined by multistage material classification. Only in the bottom of the material class, it can be configured belong to this type configuration material and products. The bottom level material can upload work instructions and drawings of the material classification. Work instructions are uploaded respectively based on each working procedure workshop. In the process of production process collection interface window, work instructions in this process workshop can be always read about the current production products[6]. For a model product type, work instructions need to be edited into only a file according to production workshop working procedure. It is convenient to read work instructions of the corresponding process of process workshop only positioning. The client computer related to read must be installed browser of the relevant types work instruction file (such as DOC file, need to install Word; PDF files, need to install Adobe Reader). Product and material is the only logo of concrete factory goods. The product can configure BOM structure. At the same time the manufacturing process workshop of every product configuration is configured. Processing center of manufacturing process workshop is configured. Function is set on process documents management and read. Using the Long binary data type of the database, file will be introduced into the database. The database will become bigger to be a bitmap for preventing vector diagram to be distortion. Theory processing time is set of the product manufacturing process workshop route, processing center configuration and in different processing center. Process workshop route is different of the process route in different processing center, which is higher level workshop level line. The product BOM can be used and also can be directly received in BOM from ERP.

3.Product configuration resources management based on the internet of things-mixed cloud enterprise

3.1.Multi-treetheory

If the tree is setSwhich consists of a limited data element ofn(n>0), It meets: ① only a root node, the root node is an invincible node. ② whenn>1, grubbing node outside of the other elements are divided intoK(K>0), a mutual intersection subset ofS1S2…Sk, eachSi(1 Fig.1 Configuration management process of mixed cloud enterprise Fig.2 Mode of material configuration Fig.3 Parts relation model figure 3.2.Productresourcesconfigurationbasedonmulti-treetheory Production configuration resources management of the Internet of things-mixed cloud virtual enterprise, according to production needs, are combined with configuration requirements and characteristics of public cloud enterprise and private cloud enterprise. Based on technology of networking and cloud enterprise, resources needed in the production configuration process are as a tree and different subresources are corresponding to the different subtrees. Production resources which are needed in manufacturing of public cloud enterprise are matched to attain different production conditions of different private cloud enterprise by multi-tree theory. And then multiple results of resource allocation and optimization are compared. The actual optimal production resource allocation scheme is finally drawn[9-10], production resource allocation model based on many fork tree are as shown in Fig.4. If production resource demand of mixed cloud virtual enterprise can be expressed as the treeS,n(n> 0) is the amount of production resources demand. Each child production resources demand could be expressed bySi(i>2). Each value ofSiwill be judged and matched by traversing method in the different private cloud enterprise. The similar values are confirmed and are carried out in turn arrangement, and the optimalSicould be finally determined. Optimal combinations are obtained from different private cloud enterprise. And the production resources are realized optimization management and application. It is the foundation to improve the production efficiency. Fig.4 Based on binary tree production configuration resources In the gradual and wider application background of cloud enterprise, technology of the internet of things is rapidly applied, and the function and content of the production configuration are summarized on the analysis of production configuration demands of mixed cloud enterprise. The process management of workshop production configuration is designed in detail. That are gotten the content of material configuration and its specific operating mode on the basis of process, which are expressed by the model diagram of material configuration and relational model graph. The methods have been discussed that multiple fork tree theory are applied to production allocation of resources of the internet of things-mixed cloud enterprise. The model of production resource allocation is concluded based on many fork trees. It is the theoretical foundation to obtain the optimum application production resources. [1] Sandeep Tayal.Tasks Scheduling optimization for the Cloud Computing Systems[J].International Journal of Advanced Engineering Sciences and Technology,2011,2(5):111-115. [2] WU Shaoyan.Workflow model of construction projects based on Petri net[J].Computer Engineering and Applications,2009,45 (30):10-12. [3] WANG Junbiao,DENG Hu,JIANG Jianjun,et al.EAI-oriented information classification code system in manufacturing enterprises[J].Front Mech Eng China,2008,3(1):81-85. [4] DIMITRIS K.Closed-loop PLM for intelligent products in the era of the Internet of things[J].Computer-Aided Design,2010,3(2):1-23. [5] Sobah Abbas Petersen.Virtual enterprise formation and partner selection:an analysis using case studies[J].Int.J.Networking and Virtual Organisations,2008,1(2):1-15. [6] Hashamdar H,Ibrahim Z.Analysing of Space Structures by UsingNumerical Integration[J].European Journal of Scientific Research,2009,38(4):583-589. [7] SHI Dongcai,CHENG Genwei.Traversal algorithm based on multi-subtrees and its application on the topological relationship in digital drainage network[J].Resources and Environment in the Yangtze Basin,2006,15(6):733-739. [8] YUAN Ling,DENG Xiaoyan.A multi-tree based search technology and its application[J].Computing Technology and Automation,2 0 l 1,30(3):139-141. [9] GAO Fang.Research on intelligent particle swarm optimization algorithm[D]//Harbin:Harbin Institute of Technology,2008. [10] Sireteanu N A.Semantic Integration of Knowledge Management Systems[J].Communications of the IBIMA,2008(3):20-25. 基于物聯網-混合云企業的生產配置管理 李光榮1*, 劉彩霞2,魯 泳1,王云霞1,王志亮1,胡升平3 1.南京工程學院 機械工程學院, 南京 211167;2.新鄉職教中心,河南 新鄉 453001;3.南京比鄰軟件有限公司,南京 210008 研究了基于多叉樹理論的物聯網-混合云企業的生產資源配置方法,建立了基于多叉樹的生產資源配置模型,為充分合理地應用生產資源配置奠定了理論基礎。 多叉樹;物聯網;混合云企業;配置 TP391.72 2013-01-08 Sponsored by research fund project of Nanjing institute of technology (CKJB201201), the Support Peoject of Science and Technology of Jiangsu Province (BE2011712), the Planning Project of Humanities and Social Science Research Fund of the Ministry of Education(12YJAZH151),the College Fund Project of Jiangsu Province (10KJB460003),the Youth Project of Humanities and Social Science Research Fund of Theministry of Education (12YJCZH209)*LI Guangrong,Associate Professor.E-mail:grongli@njit.edu.cn 10.3969/j.issn.1001-3881.2013.06.005

4.Conclusions

- 機床與液壓的其它文章

- Research and Realization of the Control System for Cement Screw Packing Machine Based on MCGS and S7-200PLC

- Modeling and Simulation about Sinusoidal Non-circular Gear Pitch Curve of the High Order and Denatured Feature

- The Study of Stability Control Based on the Yawing Moment of Electric Vehicle

- Structure Optimization Design of Time-Grating with Variable Coupling Coefficient Based on ANSOFT Electromagnetic Analysis

- Prediction Chatter Stability and Bifurcation in Milling Machine

- Design of Structure Optimization for Engine Exhaust Manifold