Development of remotemonitoring system for hydraulic power station

Jia-haiWANG,Chao-yue HUANG,Qing-ze YU,Jing-dong WEI1 School of Mechanical Engineering,Tongji University,Shanghai01804,China

2 CDHK,Tongji University,Shanghai201804,China

Development of remotemonitoring system for hydraulic power station

Jia-haiWANG1,2,Chao-yue HUANG?2,Qing-ze YU2,Jing-dong WEI21School of Mechanical Engineering,Tongji University,Shanghai201804,China

2CDHK,Tongji University,Shanghai201804,China

W ith the developmentof the industrial technology the hydraulic power station are w idely used in different industries.The hydraulic power unites usually work in remote areas,and the ambient is very poor,so that the maintenance and management issues become increasingly prom inent.To solve this problem,the sensors and Indramotion MLC65 can be used to collect and process the information,the w ireless Technology-GPRS-DTU to transfer remote data,SQL 2005 database and Web technology based on B/S structure to design the remotemonitoring system of the hydraulic power station.It realized not only real-time status monitoring,data storage and query function,butalso a visual data manipulation,timely alarm and warning functions.It is a good solution to the maintenance,regulation and other problem s of the hyd raulic power station.

Hydraulic power station,GPRS DTU technology,Remotemonitoring,Web technology

Jia-haiWANG,PhD.? Chao-yue HUANG,

E-mail:Huangchaoyue88@163.com

1.Introduction

Hydraulic power station is a hydraulic power source system,which ismainly made up ofmotors,pumps,hydraulic valves,accessories such as filters,coolers,batteries and other components.With the development of industry,hydraulic power station provides so smooth,strong and easy to control power etc.So that it has got increasingly prominent,and widely used in heavymachinery,agriculturalmachinery,forestrymachinery,automobile,shipbuilding industry,aerospace industry,mining machinery,and road machinery[1].In this industry,there are some problems still not solved,e.g.the time ofmaintain is very long,theworking status of hydraulic power unit cannot be got in time,the cost of maintenance and management of themachine is very high.So the demand of the company for remote real-time monitoring of the hydraulic power station is growing.

Remote monitoring technology has experienced three development stages,from the original analog to digital surveillance monitoring,and then to the currently popular network video surveillance monitoring[2].At the same time the development of remote monitoring technology has achieved a lot at home and abroad.Great changes aboard have been made in many areas[3]from January 1997,the first session of the “Internet-based remote monitoring diagnostic work conference”to“intelligent early warning and remotemonitoring technology in the field of the production process study”by French ALARM.In China,Tongji University,Tsinghua University,Xi’an Jiaotong University,Huazhong University of Science and Technology,Harbin Institute of Technology,Nanjing University and other colleges and universities havemade some advanced research,e.g.a remote service system for manufacturing companies is designed by Tongji University[4].Based on the large power station equipment a remote online monitoring and diagnostic systems is designed by Tsinghua Uni-versity[5].Through those study and research experience a theoretical and practical basis is provided for the development of remote monitoring system for hydraulic power station.

2.System design and implementation

2.1.System design

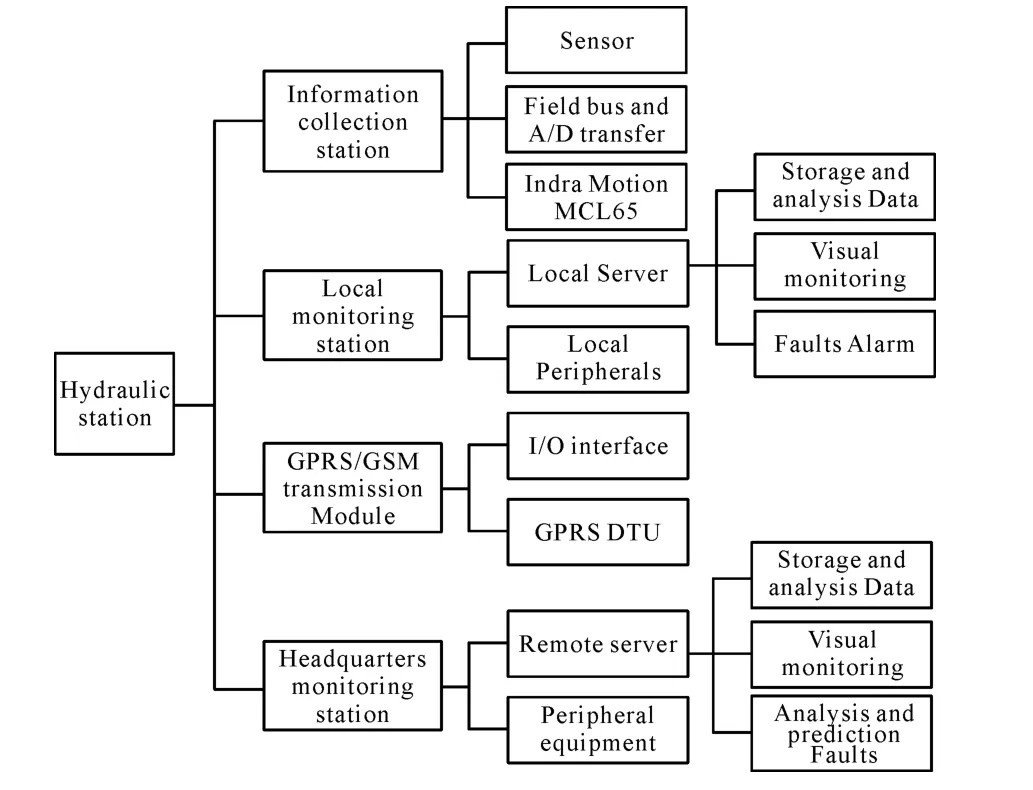

The main design process of remote monitoring system of hydraulic power stations is as follow:firstly,collecting the signal from flow valves,proportional valves,pressure valves and other components of existing hydraulic power station,including temperature,pressure,displacement and other signal,which should be processed by A/D conversion after transmitted by the Fieldbus,and then this signal will be initially disposed via the field PC.Secondly,using the GPRS wireless communication technology to transmit this data remotely and taking advantage of Web Server technology to visualize transmitted data,and the fault can be analyzed and diagnosed in a remote server ormobile server.So the status ofworking and components of hydraulic power station will be received in real-time,and faultalarm can be also timely disposed,which improve maintenance efficiency and reducemaintenance costs.The overall scheme is shown in Figure 1.

Figure 1.The overall scheme

2.2.System implementation

According to the technical configuration of hydraulic power stations and the demands of remotemonitoring systems,remotemonitoring system of hydraulic power station can be divided into four parts:data acquisition module,the local monitoring module,GPRS communication module and the remotemonitoring station,the structure of system functions is followed in Figure 2.

Figure 2.Function structure

2.3.Information collection station

Data acquisition station includes sensors,fieldbus,A/D module,aswell as PLC/MCU.Themain transducer signal of Hydraulic power stations contain 4~20 mA,± (0~5)V,± (0~10)V,(0~1)V analog signals etc.;0 ~10 kHz frequency signals or all kinds of counter signals.Current signals,voltage and temperature signals,displacement signal,work pressure and other signal transmitted by sensors.Use Profil-BUS R-ILPB BK DP/V1 in Bosch Rexroth to transfer these signals,to reduce on-site electromagnetic interference and improve the stability of steady signal through A/D analog to digital transition,and then collect these signals using DAQ(data acquisition)card.Figure 3 is the principle of collected information.

Figure 3.Principle of collected information

2.4.Localmonitoring station

Localmonitoring station mainly composes of the field computer,the local database and local peripherals.By using Bosch Rexroth Indrawork Engineering software and ST language,which are unified programming standards language according with IEC61131-3,program directly on Indra Motion MCL65 controller to control components and the engineering system,through IndraMotion MCL65 controller,some functions can be achieved,e.g.an alarm signal can be provided,and the real-time data signals can also be stored in the controller.Using the module in Indrawork Engineering further visualization interface can be also provided,such as charts,statistical analysis of datamap etc.Local database also stores and backups the datawhich is collected in the field.Local peripheralsmainly provide printing services data.

2.5.GPRS transm itm odule

2.5.1.GPRS technology

General packet radio service(GPRS)is a new bearer service,which is developed on the base of existing GSM digital mobile communication system.It has increased three main components in the subsystem network,which are the serving GPRS support node(SGSN),the Gateway GPRS Support Node(GGSN)and the Packet Control Unit(PCU).At the same time the software is upgraded rapidly,therefore,GSM network has steadily upgraded to 2G era and will stable transit to 4G era.For the first time GPRS fully realized mobile INTERNET function by allowing intercommunication of the existing INTERNET and new GPRSnetwork.That is,when the user connect the internet via a gateway GGSN of GPRS system,GGSN will provide corresponding dynamic address,routing,DNS,security,accounting and others internet functions.The mobile client can get GPRS services,as long as it can pass through three stages,attached to the GPRSnetwork,activate Packet Data Protocol(PDP)context establish TCP/UDP link.Theoretical data transfer speed of GPRS has been reached 171.2 Kb/s and GPRSmobile networks is worldwide,without any geographical restrictions.That’swhy GPRS is used in this system.

2.5.2.GPRS DTU

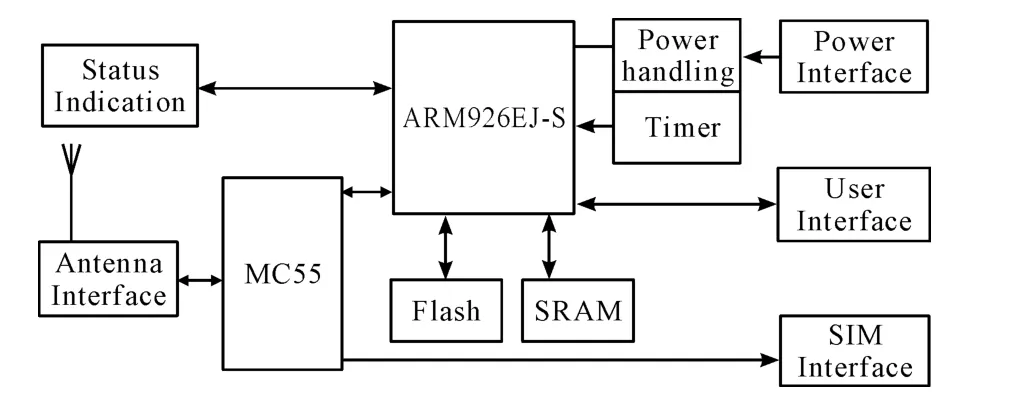

GPRS DTU is responsible for receiving and sending data and it is the key module of GPRSwireless communications.Hydraulic power station adopts IndralMotion MLC65 controller of Bosch Rexroth.In order to bettermatch the PLC controller,GPRSDTU needs to be designed.GPRSDTU contains hardware and software,GPRSDTU hardware is designed by ST ARM926EJ-S and Siemens MC55,which is tri-band wireless module.The ARM926EJ-S processor features a Jazelle?technology enhanced 32-bit RISC CPU,flexible size instruction and data caches,tightly coupled memory(TCM)interfaces and memory management unit(MMU).It also provides separate instruction and data AMBA?AHBTMinterfaceswhich are suitable for Multi-layer AHB based systems.The ARM926EJ-S processor implements the ARMv5TEJ instruction set which includes an enhanced 16 x 32 bitmultiplier capable of single cycle MAC operations and 16-bit fixed point DSP instructions to enhance performance ofmany signal processing applications as well as supporting Thumb?technology.GPRS DTU internal structure is shown in Figure 4.GPRS DTU software includes:TCP/IP(Transmission Control Protocol/Internet interconnection agreements),OS(Operating System),program flow,PPP(Point to Point Protocol).Currently,popular embedded AS have Linux,ü C/OS-II and WINCE[6].Remote monitoring hydraulic power station is prevail real-time task,Linux and WINCE is non-realtime OS,butüC/OS-IIis a priority-based preemptive multi-tasking real-time martial OS.It gives a different priority to each task,when task is switched,it can be achieved quickly,and it approximately every moment makes the highest priority task running,which is very suitable for real-time acquisition of hydraulic power station running state data.Therefore,software of GPRSDTU uses üC/OS-IIas kernel.

Figure 4.GPRSDTU internal structure

2.6.Remotemonitoring station

Remotemonitoring station is the core of the remotemonitoring system,it ismainlymade up of routers,firewalls,Web servers,database servers,application servers,printers and other equipment.On the one hand it responds to the client’s request,extracts real-time status data devices from the database and then publishes this data to the browser,so the user can be available to view and browse this real-time status data.On the other hand database accepts customer orders,which are sent from the browser,and also store the information in a database for the querying in the future.

2.6.1.Web server

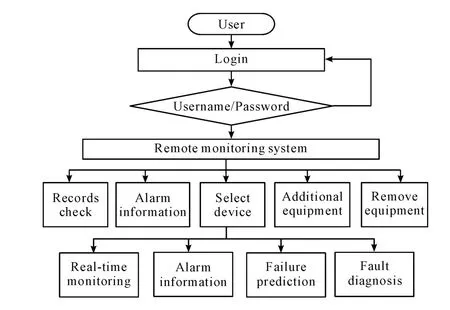

Web server includes server hardware and software in two parts,a common Web server hardware platforms include routers,PC servers,and other ordinary PC,server software includes:Apache,Microsoft IIS and Netscape Enterprise server,common database service contains Sybase,Oracle,and SQL Server.The function of WEB server is to provide services for the client,publish system information,control the login of the web pages and embed controls to control web pages,on which the remote control Web pages for the remote device can be placed.User operation flowchart is shown in Figure 5.At present,the production of dynamic web has two main methods,ASP(Active Server Page)and JSP(Java Server Page),where we use Window2007 Server and Java Server Page JSP technology to design dynamic interactive Web.

Figure 5.User operation flowchart

2.6.2.Application server

Application servers aremainly IBMWebSphere,BEAWeb Logic,Planet Application etc.where Tomcat is open source and free,it is not only compliant to Servlet/JSP container,but also provides graphical data processingmodule.Therefore,based on Tomcat application server to handle a variety of logic algorithm is more advantageous.There are a variety of softwares of monitoring interface,which is used to monitor remote equipment,and telecommunications servicemodule.Application server connectswith onsite monitoring host through remote communication servicemodule.It can not only send a connected application to the PC in the field,but also accept the connected application,which is from the field PC.According to the ways of the connections in the field and the communication link between remote communication module and the field,the user can observe the status of field devices via devicemonitoring interface.The user can also send control commands to field devices via the user interface.

2.6.3.Database server

The database servermain stores a variety of system information,including user permissions,device identification.It will generate operation log of the system.Log record mainly the information which is related to the remote operation,including the operating rights to the remote user,IP address,the name of the connected remote device,the remote user name,connection time,the remote users IP address,the remote device IP address,disconnect time and etc.These data directly store into the database,so that it can reference in the future.At the same time,database also stores the information of remote devices and some historical data,remote users can understand the performance of the remote device,usage situation,manufacturers information and some other information through information in the database.

Application server of monitoring interface software also offers accessing interface database through ODBC calling.Application server writes list of controlled equipment,controlled device information,as well as historical data of the controlled equipment to the database;equally by calling ODBC data source data can be exchanged between the Web server and the database,the registered information of the user can bewritten to the database,in the same user login information,equipment lists,equipment information can also be called from database.

3.Conclusion

This paper took advantage of ST language and JAVA language respectively to program PLC controller and application server,and used the GPRSwireless communication technology to transmit the data and Web server to achieve wireless accessing,the system hydraulic power station has the following features:

1)Remote transmit the hydraulic station status data.

2)Real-time monitor the hydraulic station on the local workstation and remote devices.

3)Analyzing the collected information and provide visual interface.

4)Predict the faults of the hydraulic station,diagnose the faults and provide.

5)Using B/SWeb Server,itworksmore effectively.

[1] Liu Bo.Design of remote data transmission system based on GPRS[D].Dalian:Dalian Maritime University,2008.

[2] Yang Shuzi,SHI Tielin,Li Dongxiao.Develop and design of distributed monitoring and diagnosis system[J].Vibration testing and diagnosis,1997,17(1):1 -6.

[3] Wang Jianxin,Yang Shifeng,Shi Yongjiang.Status and trends of development of remote monitoring technology[J].Foreign Electronic Measurement Technology,2005(4):10-11.

[4] Ren Wei,Wang Jian,Zhang Hao,et al.Manufacturing industrial site remotemonitoring system design and development[J].Modular Machine Tool & Automatic Manufacturing Technology,2000(5):33-35.

[5] Liu Ronghui,Liu Guangchang.Design Network Integrated Monitoring System[J].Computer Systems & Applications,2004(1):36 -42.

[6] Wangyao Ting,GuoWencheng.Design ofembedded software based on GPRS DTU[J].Instrumentation user,2013(17):87-89.

液壓動力站的遠程監控系統的研究

王家海1,2,黃朝岳2?,俞慶澤2,魏靖東2

1.同濟大學機械與能源工程學院,上海 201804;

2.同濟大學中德學院,上海 201804

隨著工業技術的發展,液壓動力站的運用越來越廣泛。由于其工作地方偏遠、工作環境惡劣,液壓動力站的維護、管理問題越來越突出,針對這些問題,利用傳感器和Indramotion MLC65采集數據,采用GPRSDTU無線傳輸技術對數據進行遠程無線傳輸,利用SQL 2005數據庫技術和B/S結構的Web技術,設計了液壓動力站的遠程監控系統。該系統不但實現了通過服務端的實時狀態監控和數據存儲、查詢功能,而且實現了數據的可視化操作、即時報警和預警功能,很好地解決了液壓動力站的維護、管理等問題。

液壓動力站;GPRSDTU技術;遠程監控;Web技術

T1

10.3969/j.issn.1001-3881.2014.24.003

2014-07-22