Research on algorithm design of CNC machine fault diagnosis based on fault tree*

Jiang-tao HUANG,Jia-hai WANG,Jian-fei WEN,Shu-yu ZHAO

1The Sino-German School for Postgraduate Studies,Tongji University,Shanghai 201804,China;2School of Mechanical Engineering,Tongji University,Shanghai 201804,China;3Schaeffler (China) Co.,Ltd,Taicang 215400,China

ResearchonalgorithmdesignofCNCmachinefaultdiagnosisbasedonfaulttree*

Jiang-tao HUANG?1,Jia-hai WANG1,2,Jian-fei WEN3,Shu-yu ZHAO1,2

1TheSino-GermanSchoolforPostgraduateStudies,TongjiUniversity,Shanghai201804,China;2SchoolofMechanicalEngineering,TongjiUniversity,Shanghai201804,China;3Schaeffler(China)Co.,Ltd,Taicang215400,China

Based on the fault tree analysis method and CNC machine emergency stop case,this paper illustrates the algorithm analysis,recursive algorithm design,algorithm for solving MCS over BDD figure,modular decomposition algorithm,and quantitative analysis for fault tree.It provides CNC machine fault diagnosis based on fault tree with a good theoretical foundation.

Fault tree,Algorithm,Quantitative analysis,CNC machine,Fault diagnosis

CNC machine is a high-end mechatronic product which has many reasons resulting in errors.It usually costs a lot to complete failure diagnosis which sometimes is even not good enough to solve problems.In this case,failure diagnosis of equipment has become a hot topic.

Proposed by Walson in Bell Laboratory,Fault Tree Analysis (FTA)[1] was only used for predicting the random possible failure of missile launch.Nowadays,it is internationally recognized as a simple and effective method for the reliability and failure diagnosis.

1.Fault tree analysis

FTA[2-3] is made up of several different elements: fault symptom—fault reason—the cause of the reason—…— the ultimate reason,the result—the reason—the cause of the reason—…— the ultimate cause.By reverse analysis,it can get a fault tree analysis diagram by levels.

FTA has five steps[4-6]: basic definitions,establish fault tree,the basic symbol and graphic of fault tree,algorithm design,and quantitative analysis.

2.FTA of CNC machine emergency stop

In the real production process,CNC machine of S factory often occur a failure alarm that is a serious emergency stop alarm.And at the same time,it’s usually accompanied by several or more fault alarms.CNC machine emergency stop fault tree is shown in Figure 1,and the meaning of symbols is shown in Table 1.

Figure 1.CNC machine emergency stop fault tree

Table 1.Meaning of symbols

3.Fault diagnosis algorithm design

3.1.Recursivealgorithmdesign

Change fault tree into a Binary Decision Diagram (BDD) by ite structure[7].Define m intearray,class structure and class object of ite,in order to store ite structure and BDD structure.

Since the fault tree structure is calculated to determine the order from the bottom to the top,all the sub-events are known.And the sequence and number of sub-events determine the calculation steps.For example:H=H1+H2+H3.WhileHis sought,others are sub-events.Then the calculation sequence can be determined asA=H1+H2,H=A+H3.According to this calculation order anditestructure,the equation generates a correspondingiteclass object when a function is called everytime,and will record data in m_itearray.H1is expressed asite(x1,I1,I2),andH2is expressed asite(x2,J1,J2).The flowchart is shown in Figure 2.

3.2.AlgorithmforsolvingMCSbasedonBDDfigure

1) Basic principle

In BDD diagram,node represents the bottom event of the fault tree,and the path from root node to leaf node represents that bottom events are disjoint or lose efficacy.

2) Algorithm

MCS of monotonous associated fault tree will be got by following several steps:

① Search the data on the path from root node to leaf node in BDD,which is “1”.In the search,only concern that the failure node of bottom event which is “1”,and a collection of these nodes is CS of the fault tree;

② Get MCS of fault tree by the minimal cut sets.

3) Instance analysis

Since the structure function of the CNC machine fault tree is very simple,the MCS is the bottom event.So according to this principle,analyzing the BDD diagram,the cut sets are as follows:

{x1,x2},{x1,x3},{x2,x3},{x1,x2,x3},{x3,x4,x5}

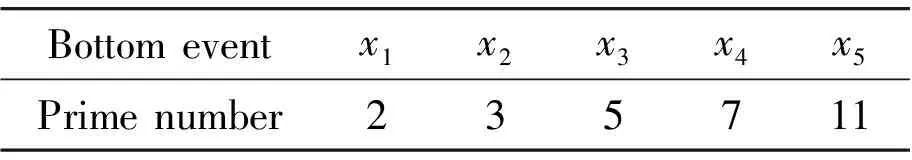

The relationship between bottom eventxiand prime number is shown in Table 2.

Table 2.Bottom event xi and prime number

Then get prime number product of five cut sets in the following Table 3.

Table 3.Prime number product of five cut sets

By dividing each two prime number product,the last unavailable dividend numbers are 6,10,15,385.Hence,the MCS are as follows:

{x1,x2},{x1,x3},{x2,x3},{x3,x4,x5}

4) Algorithm process realization

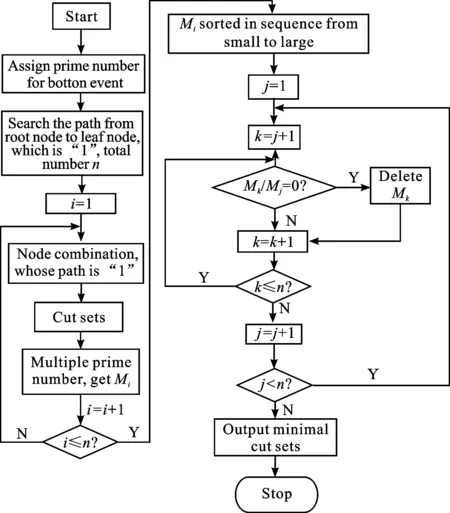

The flowchart of the specific algorithm process,which is achieved by computer,is shown in Figure 3.

Figure 3.Prime number algorithm process

3.3.Modulardecompositionalgorithmdesign

After the establishment of the fault tree,usually the constructed fault tree would be pretreated to make relevant quantitative and qualitative analysis.

Variable definitions:

① Variable I,storing visiting times in the counter.

② Array data list[7],marking visited nodes.

③ Three variables for each node

Visit1: the first traversal time;Visit2: the second traversal time;Visit end: the last traversal time.

④ Two limit variables for each gate node

Min: the minimum traversal time to all the child nodes of this gate node;Max: the maximum traversal time to all the child nodes of this gate node.

As shown in Figure 4,it is the flowchart of the modular decomposition algorithm.

Figure 4.Modular decomposition algorithm flowchart

4.Quantitative analysis of fault tree

4.1.Calculatetheprobabilityoffaulttree

Given the minimal cut set (MCS),Kj(X),structure function of the MCS is formula (1)

(1)

In this formula,kis the number of MCS,andKj(X) is defined as formula (2)

(2)

Find the probability of the top event which is the probability to leadΦ(X)=1.The left one is the probability of top event.For example:

(3)

Suppose thatEiis belong to all bottom events ofKj,then

(4)

IfFjis on behalf of the probability of events,then

(5)

According to formula (3),

{Er}-

(6)

According to the description,the probability of the top event can be calculated based on the MCS of fault tree.Top event:

T=C1+C2+…+Cn

(7)

In this formula,C1,C2,Cnare MCS.

The probability of the top event:

(8)

In this formula,Ci,Cj,Ckmeans thei,j,kMCS respectively.

So there is an approximation aboutPT,then:

(9)

4.2.Calculatetheimportanceofeventsonfaulttree

Importance of bottom events plays an important role in determining the fault part.This paper introduces a variety of different importance,several important and common used definition of importance[8-9].

(10)

In this formula,Pi(C) includes all the probabilities of MCS about part I andPTmeans the probability of top event.

(11)

In this formula,Pi(C) means the probability of minimal cut setsCi,andPTrepresents the probability of top event.

3) Event structure importance of fault tree

Given that a fault tree hasnbasic events,each basic event has two states: happened (Xi=1) and not happened (Xi=0).It is assumed that the state ofXiturns from 0 to 1,and other states remain unchanged.For the state of top events,there are three situations:

①Φ(0i,X)=0→Φ(1i,X)=0

②Φ(0i,X)=0→Φ(1i,X)=1

③Φ(0i,X)=1→Φ(1i,X)=1

For a fault tree withnbasic events,its structural functionΦ(X),which hasnBoolean function.Their domains have 2nstate number,which turns fromΦ(0i,X)=0 toΦ(0i,X)=1,multiplied by a weighting system 1/2n-1,then structural function ofXiis expressed withIθ(i).

(12)

Structural importance of basic events is ordered by descending sequence.When it is very big,the basic event should be first inspected,maintained and improved.

4) Unit probability importance analysis

Top event probability changes are caused by changes of bottom event probability,the probability importanceIg(i),

(13)

In this formula,qiis bottom event probability.

qi=Pr{Xi=1}=E{Xi}i=1,2,…,n

gis top event probability:

g=g(q)q=(q1,q2,…,qn)

When there is only AND gate,the top event probability:

(14)

Obviously,when there are “AND” and “OR” gate,The formula is still satisfied:

g(q)=qi[1i,q]+(1-qi)[0i,q]

then:

Ex[θ(1i,X)-θ(0i,X)]≥0

(15)

Because 0 (16) Depending on the theoretical basis of fault tree analysis,MCS,Binary Decision Diagram conversion,ite structure,modularity of complex fault tree,etc.,based on the theoretical basis,the relevant mathematical model was built.According to specific example,algorithm flow was analyzed,and quantitative analysis of the fault tree was made.These are very helpful to CNC machine fault diagnosis based on fault tree. [1]Chen S K,Ho T K,Mao B H.Reliability evaluations of rail way power supplies by fault-tree analysis[J].Electric Power Applications,IET,2007. [2]Xiang J,Futatsugi K.Fault tree and formal methods in system safety analysis[C].In: Proc.of the fourth International Conference on Computer and Information Technology,2004:1115-1128. [3]Zampino E J.Application of fault-tree analysis to troubleshooting the NASAGRC icing research tunnel[J].Symposium on Reliability and Maintainability,2001:16-22. [4]Xiang J,Ogata K,Futatsugi K.Formal fault tree analysis of state transition systems[C].In: Proc.of Fifth International Conference on Quality Software,2005:124-131. [5]Krasich M.Use of fault tree analysis for evaluation of system-reliability improvements in design phase[J].Symposium on Reliability and Maintainability,2000:1-7. [6]Tarjan R E.Depth First Search and Linear Graph Algorithm[J].Computer,1972,1(4):104-160. [7]Luo Huang.Research on Several key Problems Based on Fault Tree Analysis[D].Chengdu: University of Electronic Science and Technology of China,2011.[8]Haifan Zhang.Introduction to Software Engineering[M].The fifth edition.Beijing: Tsinghua university press,2008.[9]Jianfei Wen.Fault Tree Based Research of Intelligent CNC Expert System[D].Shanghai: Tongji University,2012. 基于故障樹的數控機床故障診斷算法設計的研究* 黃江濤?1,王家海1,2,文劍飛3,趙淑玉1,2 1同濟大學 中德學院,上海 201804;2同濟大學 機械與能源工程學院,上海 201804;3舍弗勒(中國)有限公司,江蘇 太倉 215400 根據故障樹分析法的具體理論基礎,以數控機床急停實例分析了算法流程;設計了遞歸算法、基于BDD圖求解MCS算法及模塊化分解算法;并進行了故障樹相關的定量分析,為基于故障樹的數控機床故障診斷奠定了基礎。 故障樹;算法;定量分析;數控機床;故障診斷 TP306+.3 2013-12-30 *Project supported by the Major Program from the Ministry of Science and Technology of China: High speed compound CNC machine tool and key technological innovation platform (Grant No.2011ZX04016-21) ? Jiang-tao HUANG,E-mail: jiangtao_huang_tj@hotmail.com 10.3969/j.issn.1001-3881.2014.06.0075.Epilogue

- 機床與液壓的其它文章

- Investigation of helical ball micro milling with variable radial immersion*

- Numerical simulation of the double suction balance type screw compressor working process*

- Parameter optimization of electro-hydraulic proportionalsystem of PID based on the improved ant colony algorithm

- Flying cutter machining and cutter design based on the machining principle of cycloid rotational indexing

- Simulation of multi-modal control in electro-hydraulicposition servo-system*

- Optimal design and security verification of flying cutterbased on finite element analysis