大型風力機復合材料葉片研究

周里群, 鄭明遠, 彭 杰, 李玉平, 邢帥恒

(湘潭大學 機械工程學院,湖南 湘潭411105)

As the renewable,the wind power develops more and more strongly,and its widely use to improve the energy structure has far-reaching significance[1,2].The blade is the key components of a large wind turbine;a single blade weight can reach tonnage.Inertia force,gravity,wind-load and others make blades force and dynamic performance more complex,which cause the blades structure rigidity to change in the operation process,and then influence the blade modal frequency change.Therefore,analysis of blades structure modal frequency cannot really reflect the actual operation of the dynamic characteristics of large wind turbine blade,the premier problem-solving for composite blade dynamics design of large wind turbine is how to avoid resonance frequency zone more accurately.[3]introduced the basic theory of wind turbines.[4~6]analyze finite element model and modal frequency of the blade with ANSYS.[7]used finite element method for static strength analysis of the blade with the shell element discretization over the skin and three-dimensional“sandwich”element to simulate the spar web.[8]compiled the modal calculation procedure of the blade,optimizing resonance frequency of the blade by setting up a variable for rigidity of cap beam.[9,10]provide the dynamic characteristics of wind turbine blade and tower structure flexibility for numerical computation.Based on the above research foundation,this paper analyzed finite element model for the 1.5MW wind turbine composite blade,comparing the modal frequency of the blade in actual operation and combining with the research results of relationship between blade fibers plies angle and modal frequency,in order to improve the operation reliability of the wind turbine.

1 1.5MW wind turbine blade

1.1 The blade structure

The blade of large wind turbine is hollow structure;it consists of leading edge,trailing edge,beam cap and blade web.At present,most of large blades are made of composite materials of fiber reinforced plastic(FRP),FRP has the merit of high specific strength,good fatigue properties and well damping properties.

This paper studies the blade with 1.5MW horizontal axis of direct drive wind turbine,the rated speed for 12~19r/min,the length of blade is 34m.The shape of blade and aerodynamic section are relatively complex,using the CAD software to model directly will be more complex.However,using the large finite element analysis software APDL (Ansys Parametric Design Language)in ANSYS to parameterize language design can simplify the modeling process greatly.According to the parameters of the 1.5MW wind turbine blade,the paper researches 3Dshell structure generating programs of the large wind turbine blade of 1.5MW.The finite element model is shown in Fig.1.

1.2 Composite ply material

As wind turbine blade layer material for FRP is anisotropic,in order to simulate its material characteristics and layer,we adopted composite material of SHELL99to blade structure,anisotropy characteristic of composite material and layer distribution can be considered in the unit.In this thesis,there are six freedoms in each node,and the skins of blade were 26layers.Using the symmetric layers,the fiber angles are 0°,±45°.The mechanical properties of glass fiber reinforced plastic materials as shown in Tab.1.

Tab.1 Material Character of FRP

2 Modal frequency analysis of the blade

2.1 Additional stiffness

The inertial centrifugal force caused by the blade rotary motion,wind load and other loads of the coupling action increases when the wind turbine rotating,it’s increasing the blade stiffness as well appearing stiffening effect.When rotating blade offsets in its rotation plane or vertical surface displacement,applying a restoring force to each blade under inertial centrifugal force and impacting the stiffness of one blade,the additional stiffness caused by loads makes the blade in the rotation condition compared with modal state of the modal frequency increases.If the blade rotation frequency and blade natural frequency is equal in the design of the blades,which will cause blade of resonance,and then damage the blade.

2.2 Analyzing the modal frequency of the blade

This paper adopts and analysis the finite element algorithm by Block Lanczos,this algorithm can directly create a set of Lanczos vector.To reduce the equation of motion can make the result accurate.We can get the characteristic values of equation solution by solving the motion equation of the reduc-tion,to avoid the iterative process and improve the computational efficiency.Generally,the first few order natural frequency for the engineering has practical significance;therefore,we merely calculate and analyze the first six order modal frequency of the blade.

According to the theory of vibration,power mainly focus on first or second order modal frequency place in the vibration process of blade.According to the Fig.2,which show the first three order modals for the blade at rated speed,the first order is mainly the pendulum vibration,the second order is given priority to brandish vibration,the third order is mainly the flap and lag,and simulation results are that as the main mode of vibration,the first three orders vibration pattern of the blade mainly flap or lag,and the torsional vibration does not appear.Modal displacement in tip of blade is the largest,and relative modal displacement close to 1/3of the tip of blade is larger,which is related with the blade quality and inertial moments that along the span direction decreasing,therefore,in the design process of the blade,density,inertial moments of the cross section and the stability of dynamic performance are positively correlated.

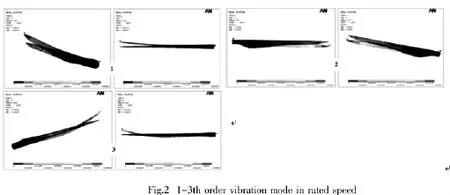

Fig.3shows that the stiffening effects of the rotating blade are discussed.The influence of the dynamic stiffening effect on the blade vibration mode is then analyzed.Wind turbine is to rely on blade rotation to get the wind power,considering inertia force caused by the blade rotation,the modal analysis of the leaves in the working status is more close to the actual status of the blade,by analyzing the first six order stiffening effect mode of the blade at speed(0~19r/min)on wind machine work,we can see that each order modal frequency of the blade will increase with the increasing of the blade speed.By comparison,simulation results are that the modal frequency of the blade will increase,and make stiffness of the blade larger when the rotate velocity increased.

At close to zero speed,the first five order natural frequency of the blade at the rated speed 19r/min increases by 4.77%,1.06%,1.17%,0.2%and 0.4%,the first order increases largely,which need us pay more attention;other orders impacts turn out to be small and can be ignored in a engineering practice.

2.3 Campbell diagram of the blade

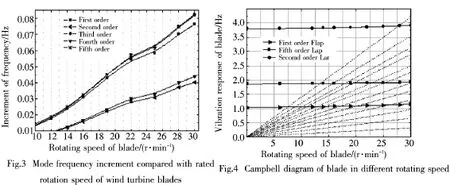

The blade of wind turbine is rotational structure,if rotation frequency of the rotor and natural frequency of the blade are in integral multiple or coincide,the blade and vibration force resonate,as well as damage the blade greatly,which should be avoided during the blade design.

Under the resonance conditions,natural frequency of the blade is equal to the force load rotation frequency or harmonic frequency.Fig.4is Campbell diagram for 1.5MW blade of wind turbine,drawn based on the result of finite element calculation of the natural frequency of the blade.In Campbell chart,natural frequency relative to the rotating frequency curve was drawn.With checking resonance for the blade of wind turbine,the first order flap and first order lag are major considerations.Applying the value formula f=2πn,the rotation frequency of the blade at rated speed is 0.31Hz.As Fig.4show that the lines from origin stand for integer times of rotation frequency when the blade is on work,and during the operation range of the wind turbine,at the point of intersection of lines,the blade could resonate possibly.

Due to being three blades,the work frequency of wind turbine at the rotating speed is 3f.According to the Fig.4,we can know rotary work frequency of the blade is 0.93Hz,lower than first order flap frequency in different rotating speed,therefore,the main orders modal frequency of the blade won’t intersect in work interval and vibration frequency,blade is safe in the rotating speed range,won’t resonate with the vibration force.And when the rotating speed rises to 25r/min,3times of the blade of rotation frequency is 1.26.Resonation will occur to between blade and external excitation force.

3 Ply angles and frequency of the blade

3.1 Stiffness of the blade

Stiffness of the blade generally includes static stiffness and dynamic stiffness.Static stiffness means ability for deformation resistance under static loads,while ability for deformation resistance under dynamic loads is called dynamic stiffness that namely dynamic forces caused by unit amplitude.The static stiffness is general measured under the action of the static load of the deformation,as vibration frequency of the structure to measure dynamic stiffness.If action force changes slowly,which stands frequency of action force far less than the natural frequency of structure,it can be considered dynamic stiffness and static stiffness are the same basely.Otherwise,frequency of action force is far higher than the natural frequency of the structure,the structure deformation is small while the dynamic stiffness is big.

The shape and size of the blade sections are not all the same,there is considerable difference in geometry,which leads to be inequable about distribution of blade stiffness.

It is known that the axial strain of the composite blade is related to axial and shear fiber angles.At the same time,the different thickness of layers from the tail to the tip and the change for sections of blade web also cause blade stiffness and quality distributed unevenly,therefore,changing for layers in cross section characteristic and the structure performance will affect modal vibration mode of blade and the changes for all order natural frequency.

In the progress of design airfoil and blade structure,besides the general strength and aerodynamic performance,natural frequency of blade and vibration mode changes caused by geometric and stiffness distribution need to take into account.Aerodynamic load covered the wind turbine blade is called dynamic load,and its frequency is integral multiples of rotor speed,for the wind turbine unit of three blades,to avoid blade resonance or having greater dynamic stress,the frequency of first order of the blade requires three times speed higher than 15%of rotating frequency.

3.2 Ply angles and frequency

The blade skin of wind turbine is made up of dozens and even hundreds of layers of glass fiber reinforced plastic materials.In the progress of design the blade,the skin layers direction for glass reinforced plastic material are determined by the strength of the blade.For general design of the blade,the fiber layer direction of 0°and a small amount layer direction of 45°are mainly used,distribution for fiber material layer cause the changes for blade quality distribution,to decide the change for stiffness,therefore,the direction of the blades fiber layer of the dynamic characteristics has great influence to the inherent frequency and vibration mode.

At the range from 0°~90°,we select and research 0°,15°,25°,45°,65°and 85°of the single layer angle,to scheme respectively each single layer of the blade skin structure,fiber layer is designed according to the symmetry of positive and negative,as well symmetrical manner of upper and lower skin angle,and then calculates two kinds mode frequency of conditions at zero speed and rated speed.The simulation results show that the blade first order frequency decrease gradually with changes at 0°and 45°layer,reflecting the rigidity gradually reducing along the blade span direction;to improve first order modal frequency,the blade skin of 0°layer proportion needs to be increased.

4 Conclusions

We analyzed the wind turbine blade of composite material model based on finite element method in this paper,and compared changes of blade modal frequency in the condition of different operation,as well as checking resonance frequency of the blade with Campbell diagram.Meanwhile,the relationship between the blade fiber layer angle and the modal frequency was analyzed.The results showed that the blade in operation won't resonate to damage,stress stiffening of large wind turbine blade in operation effects on the modal frequency significantly,which cannot be oversight in practical application;and the layer angles of the blade of wind turbine can change the stiffness of blade,and affect the modal frequency,which means modal frequency of the blade can be devised.

[1]JUI S C,CHIEN K C,HUANG I K,et al.Failure analysis of wind turbine blade under critical wind loads[J].Engineering Failure A-nalysis,2013,27:99-118.

[2]ZHOU L Q,ZHOU K,YIN S M.Wind leaf design and modeling method research based on UG[J].Natural Science Journal of Xiangtan University,2011,33(2),,90-93.

[3]TONY B,DAVID S,NICK J,et al.Wind Energy Handbook[M].John Wiley&Sons Ltd,2001.

[4]ZHAO N.Model analysis and stability analysis of wind turbine blades based on ansys modeling[C].FRP/CM,2010.

[5]FU C.Dynamic response analysis of wind turbine blade[J].Acta Energiae Solaris Sinica.2010,37(7):917-921.

[6]ZHAO M G.Modeling and model analysis for large wind turbine blade[J].Journal of Taiyuan University of Science and Technology,2012,33(3):190-193.

[7]KONG C,BANG J.Structural investigation of composite wind turbine blade considering various load cases and fatigue life[J].Energy,2005,30(11):2 101-2 114.

[8]WANG J L.Analysis and optimization design for wind turbine blade natural frequency[C]//Fluid Machinery.FRP/CM.2010,6:14-18.

[9]LIU X.Structure dynamic response analysis of horizontal axis wind turbines[J].Acta Energiae Solaris Sinica,2009,6(30):804-809.

[10]BYONG Y K,JEONG Y H,CHEOL H,et al.Dynamic analysis of hybrid wind power composite blades according to stacking properties method[J].International Journal of Precision Engineering and Manufacturing,2012,13(7):1 161-1 166.