劣質(zhì)柴油脫色、脫渣、脫臭工藝研究

姚遠(yuǎn)

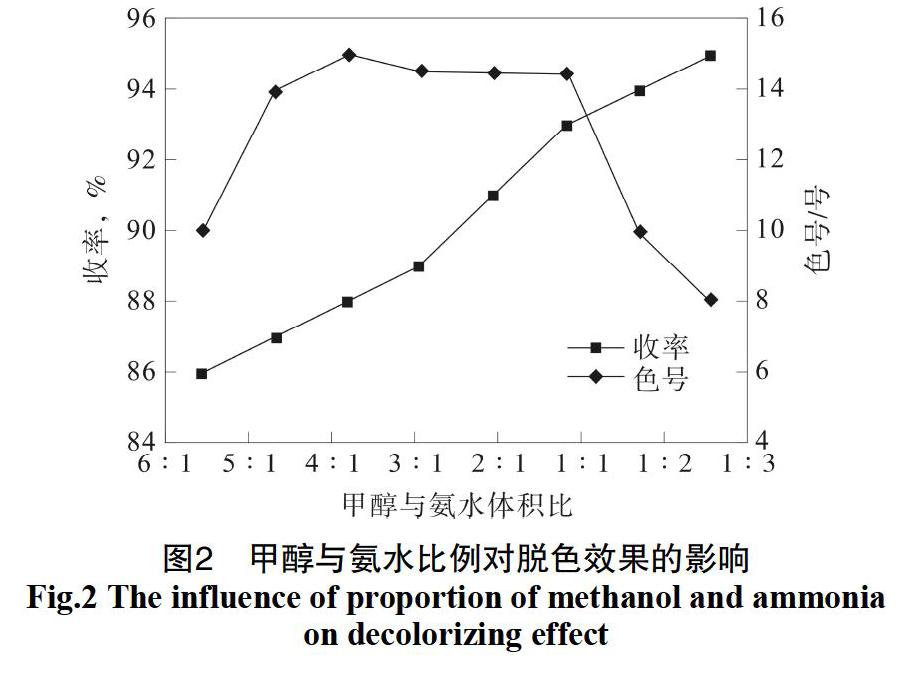

摘 要: 柴油是我國主要能源之一,但柴油長期儲(chǔ)存顏色變深、渣質(zhì)增多、氣味變臭,嚴(yán)重影響了柴油的質(zhì)量和使用性能。本文主要對(duì)劣質(zhì)柴油進(jìn)行研究,分析影響其安定性的因素。選擇酸洗結(jié)合甲醇-氨水復(fù)合溶劑萃取法對(duì)其進(jìn)行精制。達(dá)到了較好的脫色、脫渣、脫臭效果。選擇的酸為硫酸,酸油比0.2:50(v:v),酸洗后再用甲醇氨水復(fù)合溶液進(jìn)行溶劑萃取。氨水濃度為15%,甲醇與氨水體積比為5:1,萃取溫度30攝氏度,萃取后柴油色號(hào)能降到6~7號(hào)。

關(guān) 鍵 詞:劣質(zhì)柴油;顏色;渣質(zhì);氣味

中圖分類號(hào):TE 624 文獻(xiàn)標(biāo)識(shí)碼: A 文章編號(hào): 1671-0460(2015)09-2116-04

Abstract: Diesel oil is one of the major energy in our country, but long-term storage of diesel oil can make the color darker, the slag increase, which will affect the quality of the diesel. In this paper, the inferior diesel was studied, and factors to affect its stability were analyzed. The method of pickling and alcohol ammonia composite solution extraction was used to refine the inferior diesel. Good decoloring, deslagging and deodorization effect was achieved. The pickling process used H2SO4,the acid-oil ratio was 0.2:50(v:v). After the pickling, methanol-ammonia complex solution was used to carry out solvent extraction, the ammonia concentration was 15%, the volume ratio of methanol to ammonia was 5:1(v:v), and the extraction temperature was 30 ℃. After the extracting, the diesel color number was reduced to 6~7.

Key words:Diesel; Color; Slag quality; Smell

近年來,柴油的總需求量越來越大,世界各國都在加大柴油生產(chǎn)力度。影響柴油化學(xué)安定性的因素有很多,主要可以分為外界因素和內(nèi)在因素,其中外界因素對(duì)柴油的安定性產(chǎn)生一定的影響,但內(nèi)在因素對(duì)柴油的安定性具有決定性作用。柴油中的不安定性組分有很多,主要為不飽和烴類,酸性含氧、含硫化合物,吲哚、吡咯等堿性氮化物,苯胺、萘胺等非堿性氮化物[1,2]。

1 實(shí)驗(yàn)藥品

硫酸、氫氧化鉀、氫氧化鈉、氨水、甲醇、乙醇、糠醛、二甲基亞砜、N,N-二甲基甲酰胺、乙酸、蒸餾水、劣質(zhì)柴油等。

2 實(shí)驗(yàn)步驟

(1)準(zhǔn)確量取一定體積的柴油,倒入1號(hào)燒杯中,將轉(zhuǎn)子放入燒杯中,將燒杯置于磁力攪拌器上攪拌。

(2)用移液管量取定量的酸滴加到1號(hào)燒杯中,繼續(xù)攪拌。

(3)停止攪拌,取出燒杯,于常溫下靜置。

(4)上層清油倒入2號(hào)燒杯。

(5)將2號(hào)燒杯中的油與一定體積的萃取劑混合。攪拌一定時(shí)間,倒入分液漏斗靜置分離。……