U形管換熱器法蘭接頭密封性能分析

鄧超 柴慶友 莊嚴(yán) 徐明 呂明

摘 要: 將換熱器法蘭接頭作為一個(gè)系統(tǒng)進(jìn)行研究,建立了U形管換熱器法蘭接頭三維有限元模型。根據(jù)ASME中的經(jīng)驗(yàn)公式采用等厚無(wú)孔圓平板代替開孔管板,得出了管、殼程壓差作用下管板的應(yīng)力分布情況。考慮了墊片材料的非線性和時(shí)滯效應(yīng),著重分析了操作工況下不同管、殼程壓差對(duì)墊片應(yīng)力分布及法蘭接頭緊密性的影響。

關(guān) 鍵 詞:法蘭接頭;等效管板;壓差;墊片應(yīng)力;時(shí)滯效應(yīng)

中圖分類號(hào):TQ 051 文獻(xiàn)標(biāo)識(shí)碼: A 文章編號(hào): 1671-0460(2015)09-2196-03

Abstract: In this paper, the flange joint was studied as a system; the three-dimensional finite element model of U-shaped heat exchanger flange joint was established. According to ASME empirical formula, an equivalent round plate without opening was used to replace the tube plate with opening; stress distribution of the tube sheet under differential pressure was obtained. Considering the nonlinear characteristics and time lag effect of the gasket material, effect of the pressure difference on stress distribution of the gasket and sealing performance of the flange joint under operating conditions was analyzed.

Key words: Flange joint;Equivalent tube sheet; Pressure difference; Gasket stress; Hysteresis effect

U形管換熱器因其拆卸方便、結(jié)構(gòu)簡(jiǎn)單、承壓能力強(qiáng)等優(yōu)點(diǎn),被廣泛應(yīng)用于煉油、化工、輕工業(yè)等領(lǐng)域[1]。所采用的密封裝置形式多樣,其中螺栓法蘭連接應(yīng)用最為普遍。但法蘭接頭在研究中存在以下困難:(1)足夠的法蘭剛度僅能保證法蘭環(huán)不會(huì)產(chǎn)生過(guò)大的翹曲變形,而不能作為墊片是否滿足密封要求的判據(jù)。(2)必須將法蘭接頭作為一個(gè)系統(tǒng)進(jìn)行分析,考慮各元件間的相互作用。(3)法蘭接頭中的結(jié)構(gòu)和材料非線性特性[2]。采用APDL語(yǔ)句建立了參數(shù)化法蘭接頭的三維有限元模型,考慮了墊片材料壓縮時(shí)應(yīng)力應(yīng)變曲線的非線性特性及回彈時(shí)的時(shí)滯效應(yīng),分析了不同管、殼程壓差對(duì)管板及管、殼程墊片應(yīng)力分布的影響。更為深入的理解了法蘭接頭構(gòu)件間的相互作用,為設(shè)計(jì)工作提供了參考和依據(jù)。

1 三維有限元模型的建立

1.1 三維有限元模型

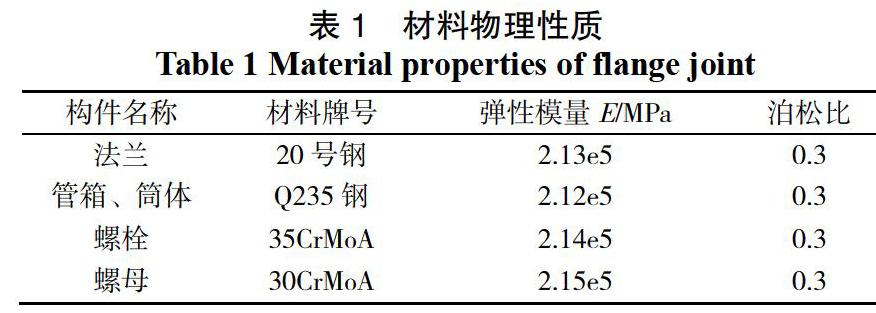

上、下法蘭均為PN40凹面長(zhǎng)頸對(duì)焊鋼制法蘭,管、殼程墊片為規(guī)格相同的以0Cr18Ni9為金屬骨架的柔性石墨金屬波齒復(fù)合墊片。……