可調(diào)導(dǎo)葉式軸流泵壓力脈動數(shù)值分析

王 凡 錢忠東 郭志偉 郜元勇

(1.武漢大學(xué)水資源與水電工程科學(xué)國家重點實驗室, 武漢 430072; 2.長江勘測規(guī)劃設(shè)計研究有限責(zé)任公司, 武漢 430010)

可調(diào)導(dǎo)葉式軸流泵壓力脈動數(shù)值分析

王 凡1錢忠東1郭志偉1郜元勇2

(1.武漢大學(xué)水資源與水電工程科學(xué)國家重點實驗室, 武漢 430072; 2.長江勘測規(guī)劃設(shè)計研究有限責(zé)任公司, 武漢 430010)

軸流泵葉輪內(nèi)部的壓力脈動是影響其運行穩(wěn)定性和葉片疲勞破壞的重要因素之一,為了研究壓力脈動的特征和根源,探索壓力脈動的水力優(yōu)化方法,應(yīng)用CFD方法模擬軸流泵內(nèi)部非定常流動,在模型試驗結(jié)果驗證的基礎(chǔ)上,計算了葉輪葉片和導(dǎo)葉表面的壓力脈動,采用快速傅里葉變換進行信號處理和分析比較。研究結(jié)果表明:葉輪葉片表面壓力脈動的主頻是導(dǎo)葉通過頻率,導(dǎo)葉表面壓力脈動的主頻是葉片通過頻率;在小流量工況下,通過調(diào)節(jié)導(dǎo)葉角度可以顯著降低葉輪葉片和導(dǎo)葉表面因動靜干涉引起的壓力脈動,從而降低疲勞破壞的風(fēng)險。

軸流泵; 可調(diào)導(dǎo)葉; 葉片; 壓力脈動; 數(shù)值模擬

引言

軸流泵通常應(yīng)用在大流量、低揚程的條件下。在農(nóng)業(yè)灌溉、防洪防澇、市政供水、船舶動力和航天工業(yè)中被廣泛使用。軸流泵機組的壓力脈動是影響大型機組穩(wěn)定運行的主要原因之一。大量國內(nèi)外學(xué)者研究了水力機械的壓力脈動特性[1-11]。施衛(wèi)東等[12]和王福軍等[13]重點研究了軸流泵在不同工況下的壓力脈動特性,對不同位置測點的壓力脈動進行了分析,發(fā)現(xiàn)在小流量工況下,泵內(nèi)各部分壓力脈動幅值會顯著增大,但測點均布置在管道邊壁,未涉及到葉輪葉片及導(dǎo)葉葉片上的壓力脈動規(guī)律。

此外,流體的壓力脈動還與固體結(jié)構(gòu)所承受的動態(tài)應(yīng)力密切相關(guān)[14],是造成水力機械關(guān)鍵過流部件疲勞破壞的原因之一,影響其使用壽命,并造成嚴重的經(jīng)濟損失。研究表明[15-16],在絕大多數(shù)運行工況下動靜干涉是引起動態(tài)應(yīng)力的典型現(xiàn)象之一。當(dāng)動靜干涉相關(guān)的激勵頻率與葉輪或者導(dǎo)葉的自然頻率相一致時,機械共振能夠放大動態(tài)應(yīng)力,潛在地導(dǎo)致較高的疲勞破壞速率和顯著的裂紋擴散[17]。

本文研究一種可調(diào)導(dǎo)葉式軸流泵。對5個典型運行工況的內(nèi)部流動進行數(shù)值模擬,重點分析葉輪葉片和導(dǎo)葉表面壓力脈動的頻率特性和幅值分布。對于壓力脈動幅值較大的小流量工況,對比導(dǎo)葉角度調(diào)節(jié)前后的壓力脈動,并對壓力脈動變化的原因進行分析。

1 軸流泵計算模型

1.1 幾何模型及網(wǎng)格劃分

本文使用的模型軸流泵,其設(shè)計工況的主要參數(shù)如下:流量Q=330 L/s,揚程H=3.3 m,額定轉(zhuǎn)速n=1 450 r/min。葉輪直徑D1=300 mm,葉頂間隙h=0.15 mm,輪轂直徑d=99.34 mm,葉輪葉片數(shù)量為3,導(dǎo)葉數(shù)量為5。導(dǎo)葉角度調(diào)節(jié)方向的定義如圖1所示。

圖1 導(dǎo)葉調(diào)節(jié)示意圖Fig.1 Adjustment of guide vanes

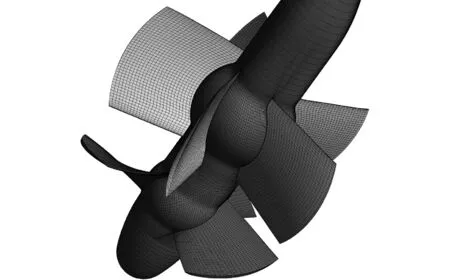

計算區(qū)域包括進口流道、葉輪、導(dǎo)葉和出口彎肘管道,同時考慮葉頂間隙。采用多塊結(jié)構(gòu)化六面體網(wǎng)格對計算域進行空間離散。如圖2所示,葉輪葉片采用J型網(wǎng)格結(jié)構(gòu),導(dǎo)葉葉片采用H型網(wǎng)格結(jié)構(gòu),用O型網(wǎng)格在葉片壁面建立邊界層。為了提高計算精度,壁面y+值被控制在4以內(nèi)。

圖2 葉輪和導(dǎo)葉網(wǎng)格Fig.2 Mesh of the impeller and the guide vanes

采用5套網(wǎng)格進行網(wǎng)格無關(guān)性分析,計算結(jié)果如圖3所示,考慮到計算結(jié)果的精確性和計算時間的經(jīng)濟性,最終確定網(wǎng)格單元總數(shù)約為2.0×106進行計算。

圖3 網(wǎng)格無關(guān)性測試Fig.3 Mesh independence

1.2 計算方法

數(shù)值模擬采用三維不可壓縮雷諾時均Navier-Stokes(RANS)方程和SSTk-ω湍流模型[18-19]。采用有限體積法對控制方程進行離散,采用SIMPLEC算法求解壓力-速度耦合。

采用總壓進口和質(zhì)量流量出口邊界組合[20],壁面為無滑移邊界條件。首先進行定常計算,其結(jié)果作為初始流場進行非定常計算。采用滑移網(wǎng)格模型來模擬動靜干涉。每個時間步葉輪轉(zhuǎn)動3°,整個計算時長為14個轉(zhuǎn)動周期。

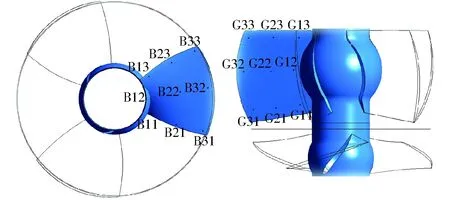

在葉輪葉片及導(dǎo)葉的壓力面和吸力面共設(shè)置了36個監(jiān)測點,以獲得關(guān)鍵過流部件壁面上較為詳細的壓力脈動信號,具體布置如圖4所示。

圖4 監(jiān)測點布置Fig.4 Survey points

1.3 數(shù)學(xué)模型驗證

圖5 數(shù)值模擬結(jié)果與試驗結(jié)果對比Fig.5 Comparison of numerical simulation with experiment

采用時均數(shù)據(jù)計算水泵的揚程,并與試驗數(shù)據(jù)進行比較,結(jié)果如圖5所示。可以看出,數(shù)值模擬的結(jié)果與模型試驗的數(shù)據(jù)趨勢一致,最高相對誤差在4%以內(nèi)。這說明,本文采用的幾何模型、數(shù)值方法、網(wǎng)格劃分以及邊界條件是合理的,計算結(jié)果是可靠的。

2 非定常流場計算結(jié)果

對5個典型工況(即流量分別為最優(yōu)工況流量的0.8、0.9、1.0、1.1、1.2倍)的壓力脈動進行分析和比較。分析方法采用快速傅里葉變換,以獲得壓力脈動的頻率特性和幅值。

2.1 葉輪葉片及導(dǎo)葉的壓力脈動

設(shè)計工況下,在葉片壓力面和導(dǎo)葉壓力面布置的監(jiān)測點頻譜特性如圖6、圖7(圖中相對頻率是指頻率與轉(zhuǎn)頻的比值)所示。可以看到葉輪葉片表面的壓力脈動頻率主要是導(dǎo)葉通過頻率(轉(zhuǎn)頻與導(dǎo)葉數(shù)乘積)和轉(zhuǎn)動頻率。總體來看導(dǎo)葉通過頻率下幅值較高的位置是壓力面B33點,而轉(zhuǎn)動頻率下幅值較高的位置則是壓力面B31點。葉輪葉片在一個轉(zhuǎn)動周期內(nèi)依次通過每一個導(dǎo)葉,因此葉輪葉片與導(dǎo)葉之間的動靜干涉所產(chǎn)生的壓力脈動在葉片表面表現(xiàn)出的主要頻率是導(dǎo)葉通過頻率。

圖6 設(shè)計工況下葉片壓力面頻譜特性Fig.6 Frequency spectra at pressure side of blade

圖7 設(shè)計工況下導(dǎo)葉壓力面頻譜特性Fig.7 Frequency spectra at suction side of blade

導(dǎo)葉表面的壓力脈動頻率主要是葉片通過頻率。幅值由進口邊至出口邊逐漸減小,由輪轂處至輪緣處逐漸增大,最大幅值出現(xiàn)在導(dǎo)葉壓力面G31點。在一個轉(zhuǎn)動周期內(nèi),各個葉片將會依次通過任一導(dǎo)葉,因此葉輪葉片與導(dǎo)葉之間的動靜干涉所產(chǎn)生的壓力脈動在導(dǎo)葉葉片表現(xiàn)出的主要頻率是導(dǎo)葉通過頻率。

由于軸流泵小流量工況下泵內(nèi)各部分壓力脈動幅值會顯著增大[7-8],下面著重分析導(dǎo)葉調(diào)節(jié)對軸流泵壓力脈動的影響。

2.2 導(dǎo)葉角度對小流量工況的影響

對不同導(dǎo)葉角度下軸流泵的內(nèi)部流動進行模擬,并對比壓力脈動的頻譜。可以看到,隨著導(dǎo)葉角度的調(diào)整,葉輪葉片測點(B33)的壓力脈動(圖8)主頻仍是導(dǎo)葉通過頻率,導(dǎo)葉角度調(diào)整后,其幅值有了明顯的下降。在測試的導(dǎo)葉角度范圍內(nèi),葉片壓力面測點主頻幅值由858.29 Pa降低至355.29 Pa,降低了約58.6%;葉片吸力面測點主頻幅值由465.09 Pa降低至189.55 Pa,降低了約59.2%。

隨著導(dǎo)葉角度的調(diào)整,導(dǎo)葉測點(G31)的壓力脈動(圖9)主頻仍是葉片通過頻率,導(dǎo)葉角度調(diào)整后,導(dǎo)葉壓力面測點主頻幅值由5 078.2 Pa降低至4 274.6 Pa,降低了約15.8%;導(dǎo)葉吸力面測點主頻幅值由3 937.5 Pa降低至3 058.3 Pa,降低了約22.3%。

圖8 不同導(dǎo)葉角度下葉片表面測點壓力脈動頻譜圖Fig.8 Frequency spectra of survey points on impeller blade with AGV

圖9 不同導(dǎo)葉角度下導(dǎo)葉表面測點壓力脈動頻譜圖Fig.9 Frequency spectra of survey points on guide vane with AGV

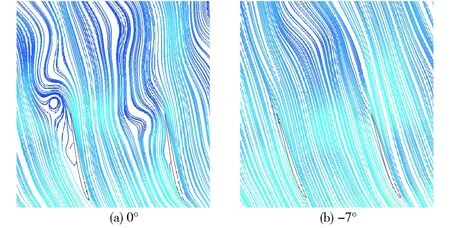

2.3 影響因素分析

在設(shè)計工況下,流體經(jīng)過葉輪做功,在葉輪出口邊按照設(shè)計的速度方向平順進入導(dǎo)葉區(qū)域,動靜干涉的強度也較小。在小流量工況下,由速度三角形理論可知,流體在葉輪出口邊的速度方向?qū)l(fā)生改變,并在導(dǎo)葉入口處產(chǎn)生沖角,加大了動靜干涉的強度,使得由動靜干涉引起的壓力脈動幅值變大。

導(dǎo)葉角度調(diào)整后,其安放角度比調(diào)整之前更加適應(yīng)流體的速度方向,使得沖角減小,減輕流體的沖擊作用(圖10)。同時導(dǎo)葉進口邊往下游方向移動,與葉輪出口邊之間的距離增大,也減弱了導(dǎo)葉受到的流體沖擊。因此,調(diào)整導(dǎo)葉角度能夠優(yōu)化小流量工況下軸流泵內(nèi)部的壓力脈動特性。

圖10 角度調(diào)整前后導(dǎo)葉流態(tài)Fig.10 Flow patterns around guide vanes after adjustment

3 結(jié)論

(1) 在測試工況范圍內(nèi),葉輪葉片表面壓力脈動的主頻是導(dǎo)葉通過頻率,導(dǎo)葉葉片表面壓力脈動的主頻是葉片通過頻率,造成壓力脈動的主要原因是葉輪與導(dǎo)葉之間動靜干涉。

(2) 壓力脈動幅值較高的位置為葉輪葉片出口邊外緣及導(dǎo)葉葉片進口邊外緣。

(3) 調(diào)節(jié)導(dǎo)葉角度可以顯著地降低小流量工況下動靜干涉造成的壓力脈動主頻幅值,其中葉輪葉片壓力面測點主頻幅值降低了58.6%,吸力面測點降低了59.2%;導(dǎo)葉葉片壓力面測點主頻幅值降低了15.8%,吸力面測點降低了22.3%。調(diào)節(jié)導(dǎo)葉角度能夠降低疲勞破壞的風(fēng)險。

1 ZHANG Desheng, SHI Weidong, CHEN Bin, et al. Unsteady flow analysis and experimental investigation of axial-flow pump[J]. Journal of Hydrodynamics, Ser. B, 2010, 22(1): 35-43.

2 WU Yulin, LIU Shuhong, DOU Huashu, et al. Numerical prediction and similarity study of pressure fluctuation in a prototype Kaplan turbine and the model turbine[J]. Computers & Fluids, 2012, 56(6):128-142.

3 ANUP K C, THAPA B, LEE Y H. Transient numerical analysis of rotor-stator interaction in a Francis turbine[J]. Renew Energ, 2014, 65(8):227-235.

4 GAO Z, ZHU W, LU L, et al. Numerical and experimental study of unsteady flow in a large centrifugal pump with stay vanes[J]. ASME Journal of Fluids Engineering, 2014, 136(7):69-74.

5 GUO L, LIU J T, WANG L Q, et al. Pressure fluctuation propagation of a pump turbine at pump mode under low head condition[J]. Science China Technological Sciences, 2014, 57(4):811-818.

6 LIU Q Z, YANG K, LI D Y, et al. Research of fluid-induced pressure fluctuation due to impeller-volute interaction in a centrifugal pump[C]∥IOP Conference Series: Materials Science and Engineering, 2013,52(2):022026.

7 SHEN J F, LI Y J, LIU Z Q, et al. Turbulent flow and pressure fluctuation prediction of the impeller in an axial-flow pump based on LES[C]∥IOP Conference Series: Materials Science and Engineering, 2013, 52(3): 032015.

8 程千, 馮衛(wèi)民, 周龍才,等. 前置導(dǎo)葉對軸流泵馬鞍區(qū)工況回流渦特性的影響[J/OL]. 農(nóng)業(yè)機械學(xué)報, 2016, 47(4):8-14. http:∥www.j-csam.org/jcsam/ch/reader/view_abstract.aspx?file_no=20160402&flag=1.DOI:10.6041/j.issn.1000-1298.2016.04.002. CHENG Qian, FENG Weimin, ZHOU Longcai, et al. Effects of inlet guide vane on characteristics of backflow vortex in hump region of axial flow pump[J/OL]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(4):8-14. (in Chinese)

9 馮衛(wèi)民, 程千, 郭志偉,等. 前置導(dǎo)葉可調(diào)式軸流泵低頻壓力脈動特性研究[J/OL]. 農(nóng)業(yè)機械學(xué)報, 2015,46(10):62-67. http:∥www.j-csam.org/jcsam/ch/reader/view_abstract.aspx?file_no=20151010&flag=1.DOI: 10. 6041 /j. issn. 1000- 1298.2015.10.010. FENG Weimin, CHENG Qian, GUO Zhiwei, et al. Characteristics of low frequency pressure fluctuation in axial flow pump with variable inlet guide vane[J/OL]. Transactions of the Chinese Society for Agricultural Machinery, 2015,46(10):62-67. (in Chinese)

10 QIAN Zhongdong, ZHENG Biao, HUAI Wenxin, et al. Analysis of pressure oscillations in a Francis hydraulic turbine with misaligned guide vanes[J]. Proc. IMechE, Part A: Journal of Power and Energy, 2010, 224(1):139-152.

11 QIAN Z D, LI W, HUAI W X, et al. The effect of runner cone design on pressure oscillation characteristics in a Francis hydraulic turbine[J]. Proc. IMech E, Part A: Journal of Power & Energy, 2012, 226(1):137-150.

12 施衛(wèi)東,冷洪飛,張德勝,等.軸流泵內(nèi)部流場壓力脈動性能預(yù)測與試驗[J].農(nóng)業(yè)機械學(xué)報, 2011, 42(5): 44-48. SHI Weidong, LENG Hongfei, ZHANG Desheng, et al. Performance prediction and experiment for pressure fluctuation of interior flow in axial-flow pump[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(5): 44-48.(in Chinese)

13 王福軍, 張玲, 張志民. 軸流泵不穩(wěn)定流場的壓力脈動特性研究[J]. 水利學(xué)報, 2007, 38(8):1003-1009. WANG Fujun, ZHANG Ling, ZHANG Zhimin. Analysis on pressure fluctuation of unsteady flow in axial-flow pump[J]. Journal of Hydraulic Engineering, 2007, 38(8):1003-1009.(in Chinese)

14 LIU Xin, LUO Yongyao, WANG Zhengwei. A review on fatigue damage mechanism in hydro turbines[J]. Renewable and Sustainable Energy Reviews, 2016, 54:1-14.

15 GUILLAUME R, DENIAU J L, SCOLARO D, et al. Influence of the rotor-stator interaction on the dynamic stresses of Francis runners[C]∥IOP Conference Series: Earth and Environmental Science, 2012, 15(5): 052011.

16 WANG Z, XIAO Y, YAN Z. Experimental and numerical analysis of blade channel vortices in a Francis turbine runner[J]. Engineering Computations, 2011, 28(2):154-171.

17 COUTU A, ROY M D, MONETTE C, et al. Experience with rotor-stator interactions in high head Francis runner[C]∥Proceedings of 24th IAHR Symposium on Hydraulic Machinery, 2008.

18 BENIGNI H, JABERG H. Stationary and transient numerical simulation of a bulb turbine[C]∥5th IASME/WSEAS International Conference on Fluid Machineries and Aerodynamics, 2007: 135-140.

19 MENTER F R. Two-equation eddy-viscosity turbulence models for engineering applications[J]. AIAA Journal, 1994, 32(8): 1598-1605.

20 FU Y, YUAN J, YUAN S, et al. Numerical and experimental analysis of flow phenomena in a centrifugal pump operating under low flow rates[J]. ASME Journal of Fluids Engineering, 2014, 137(1):205-207.

Pressure Oscillations Prediction of Axial Flow Pump with Adjustable Guide Vanes

WANG Fan1QIAN Zhongdong1GUO Zhiwei1GAO Yuanyong2

(1.StateKeyLaboratoryofWaterResourcesandHydropowerEngineeringScience,WuhanUniversity,Wuhan430072,China2.ChangjiangInstituteofSurvey,Planning,DesignandResuarchLtd.,Wuhan430010,China)

Pressure oscillations in the axial flow pump impeller are associated with operational stability of the pump unit and fatigue failure of the blade. In order to obtain the characteristics and sources of the pressure oscillations and investigate the effects of adjustable guide vanes (AGV) on pressure oscillations, the CFD method based on the RANS equations and SSTk-ωturbulence model was applied to simulate the unsteady flow inside the axial flow pump. The monitor points were located on the impeller blade and the guide vane. The static pressure of each survey point was recorded for 14 rotation periods. The calculated head was performed and supported by experimental data with the maximum relative error less than 4%. It indicates that the geometric model, numerical method, and simulation scheme are reasonable and reliable. Fast Fourier transformation method was used in the pressure signal processing. The main frequency of the pressure oscillations on the impeller blade is the guide vane passing frequency and the main frequency on the guide vane is the blade passing frequency, which indicates that the rotor-stator interaction between the impeller and the guide vanes is the source of the pressure oscillation in studied operating points. After adjustment of the guide vanes, the amplitudes of the pressure oscillations on both the impeller blade and the guide vane are reduced. The flow pattern with different guide vane angle was shown by the streamline, and the vortex flow was partly suppressed. It indicates that the rotor-tator interaction is improved in such operating conditions. The adjustable guide vane provides a valid solution to protect the impeller from potential fatigue failure.

axial flow pump; adjustable guide vane; blade; pressure oscillations; numerical simulation

10.6041/j.issn.1000-1298.2017.03.015

2016-06-12

2016-11-28

國家自然科學(xué)基金項目(51422906)

王凡(1988—),男,博士生,主要從事流體機械研究,E-mail: kraps@qq.com

錢忠東(1976—),男,教授,博士生導(dǎo)師,主要從事流體機械研究,E-mail: zdqian@whu.edu.cn

TH312

A

1000-1298(2017)03-0119-05