In fluence of Ni/Mn ratio on magnetostructural transformation and magnetocaloric effect in Ni48?x Co2Mn38+x Sn12(x=0,1.0,1.5,2.0, and 2.5)ferromagnetic shape memory alloys?

Ishfaq Ahmad Shah,Najamul Hassan,Abdur Rauf,Jun Liu(劉俊), Yuanyuan Gong(龔元元),Guizhou Xu(徐桂舟),and Feng Xu(徐鋒),?

1 Jiangsu Key Laboratory of Advanced Microamp;Nano Materials and Technology,School of Materials Science and Engineering, Nanjing University of Science and Technology,Nanjing 210094,China

2 Herbert Gleiter Institute of Nanoscience,Nanjing University of Science and Technology,Nanjing 210094,China

In fluence of Ni/Mn ratio on magnetostructural transformation and magnetocaloric effect in Ni48?xCo2Mn38+xSn12(x=0,1.0,1.5,2.0, and 2.5)ferromagnetic shape memory alloys?

Ishfaq Ahmad Shah1,Najamul Hassan1,Abdur Rauf2,Jun Liu(劉俊)1, Yuanyuan Gong(龔元元)1,Guizhou Xu(徐桂舟)1,and Feng Xu(徐鋒)1,?

1 Jiangsu Key Laboratory of Advanced Microamp;Nano Materials and Technology,School of Materials Science and Engineering, Nanjing University of Science and Technology,Nanjing 210094,China

2 Herbert Gleiter Institute of Nanoscience,Nanjing University of Science and Technology,Nanjing 210094,China

An investigation on the magnetostructural transformation and magnetocaloric properties of Ni48?xCo2Mn38+xSn12(x=0,1.0,1.5,2.0,and 2.5)ferromagnetic shape memory alloys is carried out.With the partial replacement of Ni by Mn in the Ni48Co2Mn38Sn12alloy,the electron concentration decreases.As a result,the martensitic transformation temperature is decreased into the temperature window between the Curie-temperatures of austenite and martensite.Thus,the samples with x=1.5 and 2.0 exhibit the magnetostructural transformation between the weak-magnetization martensite and ferromagnetic austenite at room temperature.The structural transformation can be induced not only by the temperature, but also by the magnetic field.Accompanied by the magnetic-field-induced magnetostructural transformation,a considerable magnetocaloric effect is observed.With the increase of x,the maximum entropy change decreases,but the effective magnetic cooling capacity increases.

Ni–Co–Mn–Sn alloy,magnetostructural transformation,magnetocaloric effect,magnetic entropy change

1.Introduction

Room-temperature magnetic refrigeration is an innovative cooling technology with the advantages of high efficiency,low cost,and environmental friendliness.In this technology,magnetic materials are used as the refrigerants.To maximize the cooling capacity of magnetic refrigeration at room temperature(RT),the magnetic refrigerants should exhibit a large magnetic entropy or temperature change under a magnetic field.[1–4]During the last decade,the large magnetocaloric effect(MCE)has been successively observed in magnetic alloys that experience a magnetic-field-induced firstorder phase transition,including Gd–Si–Ge-based alloys,[5]MnAs1?xSbx,[6]Mn–Fe–P–As,[7]La(Fe1?xSix)13,[8]and especially,Ni–Mn-based magnetic shape memory alloys.[9,10]

Rare-earth-free Ni–Mn-based magnetic shape memory alloys(Ni–Mn–X,X=Al,Ga,Sn,In and Sb)display a structural transformation between magnetic martensite and austenite.Various investigations on the structural,magnetic, and electrical properties of these alloys have been carried out.[11–17]It is found that the first-order magnetostructural transformation(MST)from the high-temperature austenite to the low-temperature martensite is accompanied by an obvious magnetization difference(ΔM)in some alloys with specific compositions.Due to the existence of ΔM,the MST can be driven by a magnetic field,and thus a large MCE can be achieved.[18–22]

Among Ni–Mn–X alloys,Ni–Mn–Sn attracts considerable attention due to its tunable MST,large MCE,and relatively low cost.From the application point of view,the designed material as a magnetic refrigerant should display the MCE and large effective refrigeration capacity(RCeff)at RT. In this work,we select Ni48Co2Mn38Sn12as the starting composition,which experiences a structural transformation above RT.By changing the Ni/Mn ratio,the structural transformation temperature(Tt)is decreased to RT.Meanwhile,the structural transformation is tuned into the Curie temperature window, which leads to a large ΔM and be in favor of the magneticfield-induced structural transformation(MFIST).Based on this improvement,large MCE,reduced hysteresis loss(HL), and improved RCeffare obtained.

2.Experimental details

The polycrystalline Ni48?xCo2Mn38+xSn12(x=0,1.0, 1.5,2.0,and 2.5)alloys were prepared by arc-melting appropriate amounts of high purity elements Ni(99.995 wt.% purity),Co(99.95 wt.%purity),Mn(99.998 wt.%purity), and Sn(99.99 wt.%purity)in argon atmosphere.The samples were re-melted three times for homogeneity.The obtained ingots were annealed at 900°C in vacuum for 24 h, and then quenched into cold water.The martensitic and reverse transformation behaviors were identified by differential scanning calorimetry(DSC)with the heating/cooling rate of 10 K/min.The crystal structures were investigated by powder x-ray diffraction(XRD)using Cu-Kαradiation at RT. The compositions of the elaborated alloys were confirmed by x-ray energy dispersive spectrometry(EDS).Magnetic measurements were performed on a physical property measurement system(PPMS).Isothermal magnetization(M–B)curves were measured using a so-called loop process to avoid the irreversibility caused by the magnetic-field-induced first-order MST.[23]Before each M–B measurement,the samples were cooled down to full martensitic state,and then gradually heated to the measurement temperature with a ramp rate of 3 K/min.To ensure the temperature stability of the measurement,a waiting time of 3 min was hold at the target temperatures.

3.Results and discussion

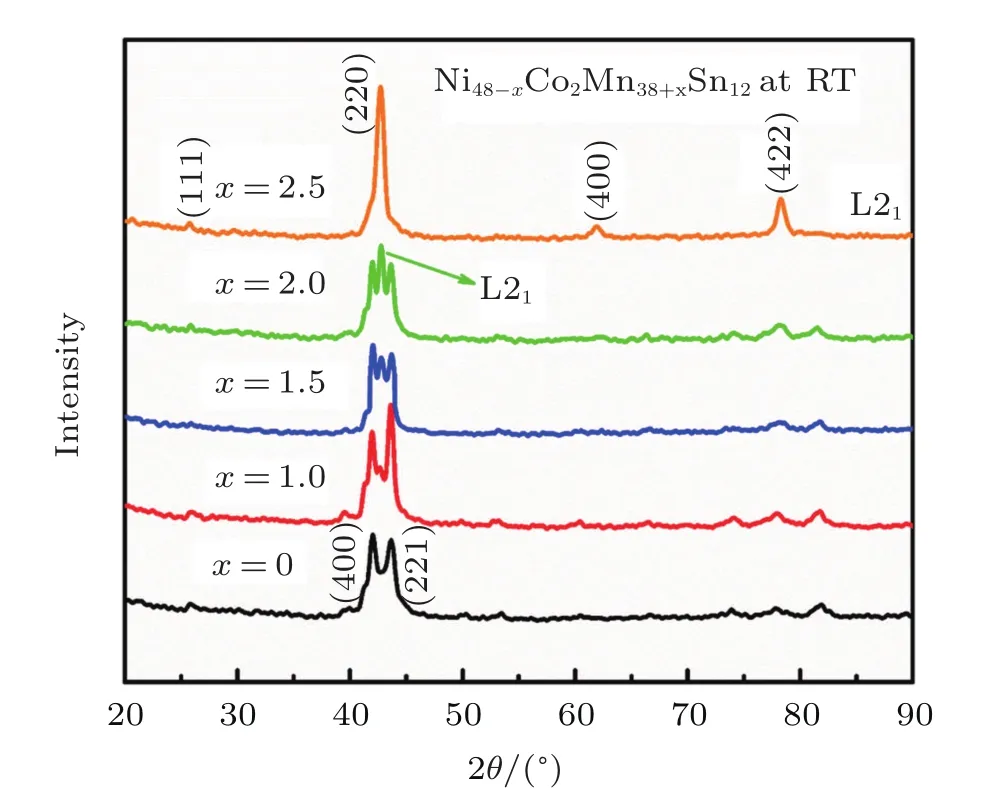

The XRD patterns of all the samples are shown in Fig.1. For x=0,the XRD pattern demonstrates a 4O modulated martensitic structure at RT.It suggests that the structural transformation in Ni48Co2Mn38Sn12occurs above RT.While for x=2.5,the presence of(111),(220),(400),and(422)peaks indicates a L21austenitic structure with the lattice constant of a=5.978?A.The coexistence of austenitic and martenitic phases is observed in the samples with 0<x<2.5 at RT.The XRD data indicates that Ttdecreases with x increasing.[24]

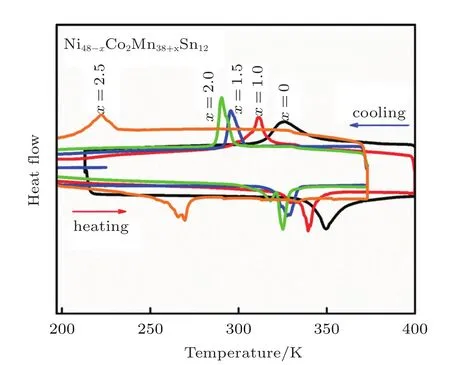

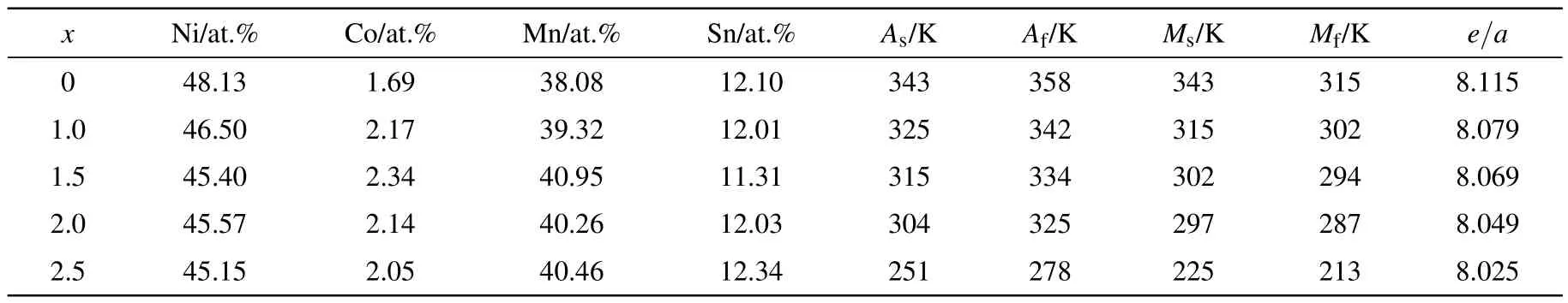

The thermal-induced structural transformation was investigated by DSC measurements.As shown in Fig.2,the large endothermic and exothermic peaks in the heating/cooling processes and the large thermal hysteresis indicate the occurrence of first-order structural transformation between martensite and austenite in these Heusler-type Ni48?xCo2Mn38+xSn12(x=0, 1.0,1.5,2.0,and 2.5)alloys.As x increases from 0 to 2.5,the Ttshifts to the lower temperatures by around 85 K and 110 K in the heating and cooling processes,respectively.It is known that the Ttof Ni–Mn-based shape memory alloys is sensitive to the electron concentration(e/a),and it decreases with the e/a decreasing.[25–28]The e/a calculated from the EDS results for our samples are listed in Table 1.It can be found that with the increase of x,the e/a decreases from 8.115 to 8.025,resulting in the observed decrease of Tt.

Fig.1.(color online)Powder XRD patterns of Ni48?x Co2Mn38+x Sn12 (x=0,1.0,1.5,2.0,and 2.5)alloys at RT.

Fig.2.(color online)DSC curves for Ni48?x Co2Mn38+x Sn12(x=0,1.0, 1.5,2.0,and 2.5)alloys in heating and cooling processes.

Table 1.The measured compositions and the characteristic phase-transition temperatures of Ni48?x Co2 Mn38+x Sn12(x=0,1.0,1.5, 2.0,and 2.5)alloys.

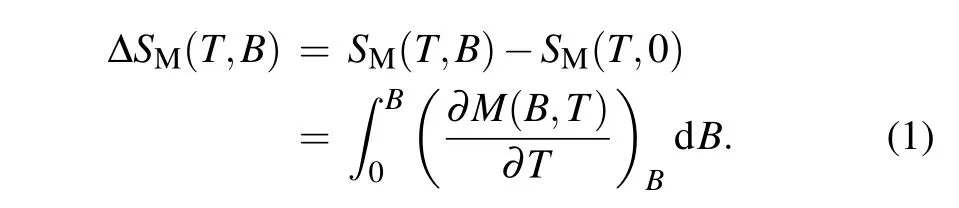

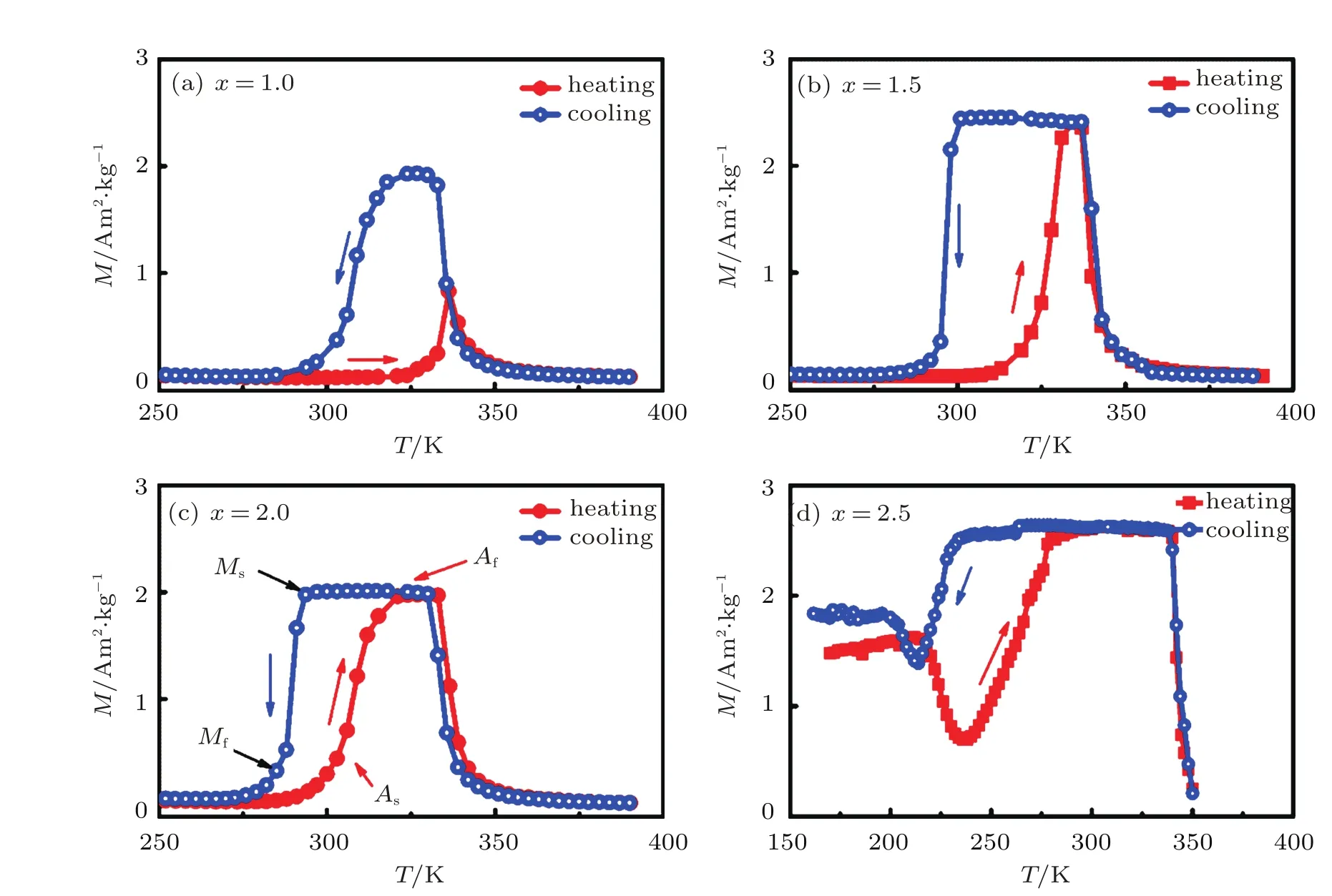

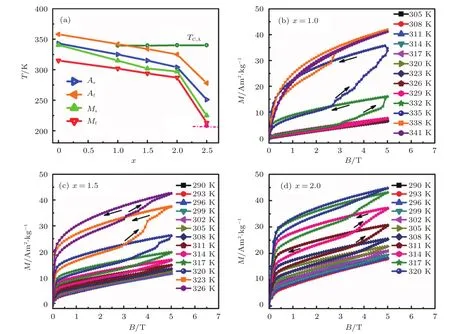

Figure 3 shows the temperature dependence of magnetization(M–T)of Ni48?xCo2Mn38+xSn12(x=1.0,1.5,2.0,and 2.5)alloys under an applied field of 0.01 T during the heating and cooling processes.For x=1.0,due to the fact of that the Ttin the heating process is close to the Curie-temperature of austenite(TC,A≈340 K),the ferromagnetic austenite is not obviously observed in the heating process,but can be found in the cooling process.The existence of thermal hysteresis proves the first-order nature of the structural transformation between martensite and austenite.With x increasing from 1.5 to 2.5,the Ttshifts to the lower temperatures.As a result,the ferromagnetic austenite appears both in the heating and cooling processes.It is found that TC,Ais nearly stable with the alteration of composition.The Curie temperature of martensite(TC,M)is not observed in the samples with x=1.0,1.5, and 2.0 in the temperature range of 250–400 K,but is found in the x=2.5 sample.In the heating process,the sample with x=2.5 experiences the magnetic ordering-disordering transition of martensite,and then the first-order MST from the low-magnetization martensite to ferromagnetic austenite.The TC,Mof x=2.5 is around 208 K.A phase diagram including austenitic start temperature As,austenitic finish temperature Af,martensitic start temperature Ms,martensitic finish temperature Mf,TC,M,and TC,Afor Ni48?xCo2Mn38+xSn12(x=0, 1.0,1.5,2.0,and 2.5)alloys is shown in Fig.4(a).According to Fig.4(a),it can be found that with the increase of x, the Ttis decreased into the temperature window between TC,Aand TC,M.Thus,the samples with x=1.5 and 2.0 exhibit the room-temperature MST between the weak-magnetization martensite and ferromagnetic austenite.This transition is accompanied by a large ΔM,which is favor of MFIST.Due to the existence of ΔM between martensite and austenite,the MST can be induced by a magnetic field.The M–B curves for Ni48?xCo2Mn38+xSn12(x=1.0,1.5,and 2.0)alloys with a temperature interval of 3 K in the heating process are shown in Figs.4(b)–4(d).With the increase of the magnetic field,an obvious slope change is observed when the temperature is close to As.This behavior suggests the existence of MFIST from the martensite to austenite.[29–31]

According to the M–B curves,the MCE of Ni48?xCo2Mn38+xSn12(x=1.0,1.5 and 2.0)alloys is estimated by the Maxwell equation[32]

Fig.3.(color online)M–T curves for Ni48?x Co2Mn38+x Sn12(x=1.0,1.5,2.0,and 2.5)alloys under an applied magnetic field of 0.01 T during the heating and cooling processes.

Fig.4.(color online)(a)Phase diagram for Ni48?x Co2Mn38+x Sn12(x=0,1.0,1.5,2.0,and 2.5)alloys as a function of x.(b)-(d)M?B curves for Ni48?x Co2Mn38+x Sn12(x=1.0,1.5,and 2.0)alloys with a maximum magnetic field of 5 T.

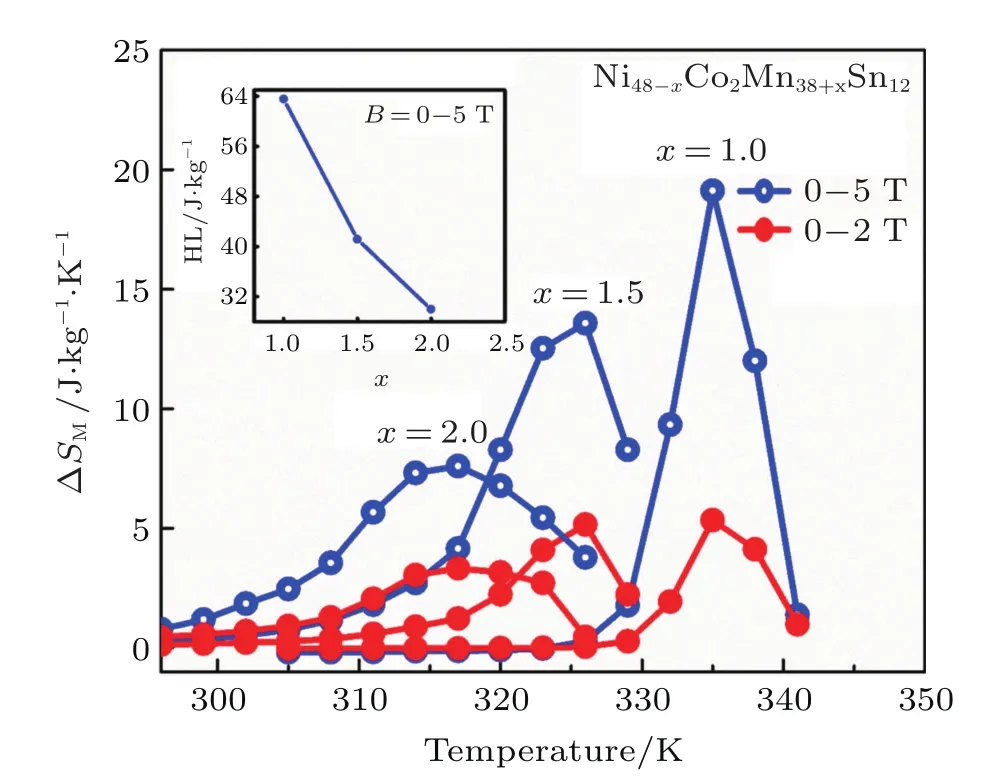

Fig.5.(color online)Temperature dependence of magnetic entropy change for Ni48?x Co2Mn38+x Sn12(x=1.0,1.5,and 2.0)alloys under the magnetic field variations of 0–2 and 0–5 T.The inset shows the x dependence of average HL for Ni48?x Co2Mn38+x Sn12(x=1.0,1.5 and 2.0) alloys under a magnetic field variation of 0–5 T.

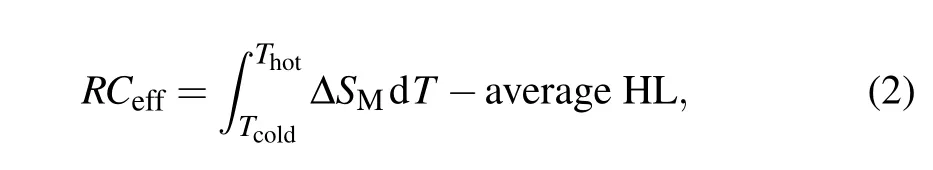

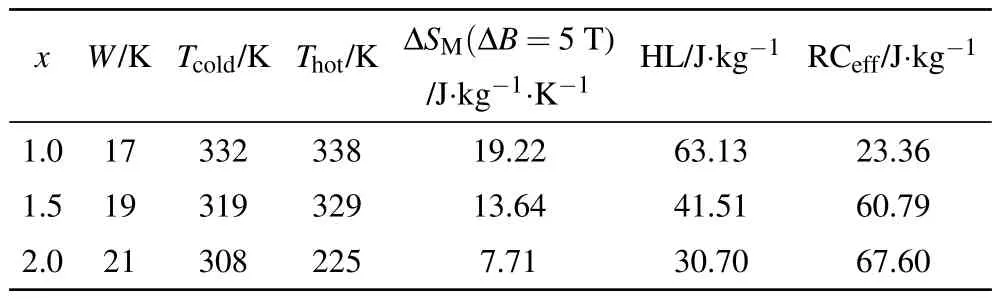

As shown in Fig.5,the maximum values of magnetic entropy change(ΔSM)with the magnetic field variation of 0–5 T are 19.22 J·kg?1·K?1,13.64 J·kg?1·K?1,and 7.71 J·kg?1·K?1for x=1.0,1.5 and 2.0,respectively,and with the magneticfield variation of 0–2 T,the corresponding values decrease to 5.75 J·kg?1·K?1,5.54 J·kg?1·K?1,and 3.57 J·kg?1·K?1, respectively.[33–38]The maximum ΔSMdecreases with the increase of x.It is found that the ΔSMis inversely proportional to the transformation width(W),which gradually increases with x increasing(shown in Table 2).As mentioned by Cugini et al.,[39]the transformation width is highly related to the structural discontinuity between the martensite and austenite phases,impurities,vacancies,and interstitial defects in Heusler-type alloys.Wu et al.[40]also reported that the magnetostructural transformation in the Mn–Ni–Ge alloy becomes broadened when the grain size decreases.Therefore,there are various factors that can influence the transformation width.In this work,it is found that accompanied by the increase of x,the transformation width increases.So,the observed broadened transformation width may be related to the increased chemical disorder.Besides ΔSM,the effective refrigeration capacity (RCeff)isalso an important parameter to evaluate the magnetic cooling capacity of MCE materials.Here,RCeffis calculated by

where Tcoldand Thotare the temperatures corresponding to the full width at half maximum(FWHM)of the ΔSMpeak, and average HL is calculated from the area surrounded by the hysteresis loops(M–B curves in Fig.4),as shown in the inset of Fig.5.[41,42]The calculated values for the transformation width,Tcold,Thot,ΔSM,average HL,and RCeffof Ni48?xCo2Mn38+xSn12alloys are summarized in Table 2.Although the maximum ΔSMdecreases with x increasing,the average HL is remarkably reduced.Therefore, an enhanced RCeffis obtained in the samples with x=1.5 and 2.The calculated values of RCeffare 23.36 J·kg?1, 60.79 J·kg?1,and 67.60 J·kg?1for x=1.0,1.5,and 2.0 with the magnetic field variation of 0–5 T,respectively, which are comparable to those of some other Ni–Mn-based Heusler alloys,such as Ni42Co8Mn30Fe2Ga18(70 J·kg?1, ΔB=5 T),Ni42.8Mn40.3Co5.7Sn11.2(72.10 J·kg?1,ΔB=3 T), Ni2Mn0.75Cu0.25Ga(72 J·kg?1,ΔB=5 T),Ni50Mn37Sn13(54 J·kg?1,ΔB=5 T),Ni45Co5Mn38Sb9Ge3(54 J·kg?1,ΔB= 5 T),and Ni52Mn26Ga22(58.7 J·kg?1,ΔB=5 T).[43–48]

Table 2.The transformation width W(=A f?A s),Tcold,Thot,magnetic entropy change ΔS M,hysteresis loss(HL),and effective refrigeration capacity(RCeff)of Ni48?x Co2Mn38+x Sn12(x=1.0,1.5,and 2.0)alloys.

4.Conclusion

In summary,we investigate the structural transformation and MCE in Ni48?xCo2Mn38+xSn12alloys with x=0,1.0,1.5, 2.0,and 2.5.The partial substitution of Ni by Mn stabilizes the austenite phase and leads to the decrease of Tt.For the samples with x=1.5 and 2,the MST between the weak-magnetization martensite and ferromagnetic austenite is achieved at RT.This transition is accompanied by a large ΔM,which is favor of MFIST.Accompanied by the MFIST,a considerable MCE is obtained.Maximum values of ΔSMare 19.22 J·kg?1·K?1, 13.64 J·kg?1·K?1,and 7.71 J·kg?1·K?1for x=1.0,1.5,and 2.0 under the magnetic field variation of 0–5 T,respectively. Although the maximum ΔSMis reduced with x increasing,the RCeffis remarkably improved.

[1]Gutfleisch O,Willard M A,Bruck E,Chen C H,Sankar S G and Liu J P 2011 Adv.Mater.23 821

[2]Guillou F,Porcari G,Yibole H,Van Dijk N and Bruck E 2014 Adv. Mater.26 2671

[3]Lyubina J 2017 J.Phys.D:Appl.Phys.50 053002

[4]Shah I A,Hassan N,Liu J,Gong Y Y,Zhou X G and Feng X 2017 Chin.Phys.B 26 017501

[5]Liu J,Gottschall T,Skokov K P,Moore J D and Gutfleisch O 2012 Nat. Mater.11 620

[6]Wada H,and Tanabe Y 2001 Appl.Phys.Lett.79 3302

[7]Hu F,Shen B,Sun J,Wang G and Cheng Z 2002 Appl.Phys.Lett.80 826

[8]Tagus O,Bruck E,Buschow K and Boer F D 2002 Nature 415 150

[9]Han Z D,Wang D H,Qian B,Feng J F,Jiang X F and Du Y W 2010 J. Appl.Phys.49 010211

[10]Zhang Y,Liu J,Zheng Q,Zhang J,Xia W,Du J and Ya A 2014 Scr. Mater 75 26

[11]Quetz A,Koshkidko Y S,Titov I,Rodionov I,Pandey S,Aryal A, Ibarra-Gaytan P J,Prudnikov V,Granovsky A,Dubenko I,Samanta T,Cwik J,Llamazares J L S,Stadler S,Lahderanta E and Ali N 2016 J.Alloys Compd.683 139

[12]Xuan H C,Han P D,Wang D H and Du Y W 2014 J.Alloys Compd. 582 369

[13]Varzaneh A G,Kameli P,Karimzadeh F,Aslibeiki B,Varvaro G and Salamati H 2014 J.Alloys Compd.598 6

[14]Li Z,Xu K,Zhang Y L and Jing C 2015 J.Appl.Phys.117 023902

[15]Ma S C,Shih C W,Liu J,Yuan J H,Lee S Y,Lee Y I,Chang H W and Chang W C 2015 Acta Mater.90 292

[16]Xuan H C,Zheng Y X,Ma S C,Cao Q Q,Wang D H and Du Y W 2010 J.Appl.Phys.108 103920

[17]Chen F H,Huang Q X,Jiang Z Y,Xuan H C,Zhang M G,Xu X H and Zhao J W 2016 Smart Mater.Struct.25 6

[18]Zheng H,Wang W,Xue S,Zhai Q,Frenzel J and Luo Z 2013 Acta Mater 61 4648

[19]Huang L,Cong D Y,Suo H L and Wang Y D 2014 Appl.Phys.Lett. 104 132407

[20]Ma S C,Wang D H,Zhong Z C,Luo J M,Xu J L and Du Y W 2013 Appl.Phys.Lett.102 032407

[21]Moya X,Narayan S K and Mathur N D 2014 Nat.Mater.13 439

[22]Chen F,Tong Y X,Tian B,Li L,Zheng Y F and Liu Y 2013 J.Magn. Magn.Mater.347 72

[23]Caron L,Ou Z Q,Nguyen T T,Cam-Thanh D T,Tegus O and Bruck E 2009 J.Magn.Magn.Mater.321 3559

[24]Maziarz W,Czaja P,Szczerba M J,Dobrzynska L L,Czeppe T and Dutkiewicz J 2014 J.Alloys Compd.615 S173

[25]Cong D Y,Roth S and Schultz L 2012 Acta Mater.60 5335

[26]Srivastava V,Chen X and James R D 2010 Appl.Phys.Lett.97 014101

[27]Bhatti K P,Khatib S E,Srivastava V,James R D and Leighton C 2012 Phys.Rev.B 85 134450

[28]Chen F H,Gong C W,Guo Y P,Zhang M G and Chai Y S 2013 Phys. Status Solidi A 210 2762

[29]Emre B,Bruno N M,Emre S Y and Karaman I 2014 Appl.Phys.Lett. 105 231910

[30]Luo H,Meng F,Jiang Q,Liu H,Liu E,Wu G and Wang Y 2010 Scr. Mater.63 569

[31]Ye M,Kimura A,Miura Y,Shirai M,Cui Y T,Shimada K,Namatame H,Taniguchi M,Ueda S,Kobayashi K,Kainuma R,Shishido T,Fukushima K and Kanomata T 2010 Phys.Rev.Lett.104 176401

[32]Zhong Z C,Ma S C,Wang D H and Du Y W 2012 J.Mater.Sci.Technol.28 193

[33]Pecharsky V K and Gschneidner Jr K A 1997 Phys.Rev.Lett.78 4494

[34]Benford S M and Brown G V 1981 J.Appl.Phys.52 2110

[35]Krenke T,Duman E,Acet M,Moya X,Manosa L and Planes A 2007 J.Appl.Phys.102 033903

[36]Sharma V K,Chattopadhyay M K and Roy S B 2010 J.Phys.D:Appl. Phys.43 225001

[37]Xuan H C,Chen F H,Han P D,Wang D H and Du Y W 2014 Intermetallics 47 31

[38]Niemann R,Heczko O,Schultz L and Fahler S 2010 Appl.Phys.Lett. 97 222507

[39]Cugini1 F,Porcari G,Fabbrici S,Albertini F and Solzi M 2016 Phil. Trans.R.Soc.A 374 20150306

[40]Wu R,Shen F,Hu F,Wang J,Bao L,Zhang L,Liu Y,Zhao Y,Liang F, Zuo W,Sun J and Shen B 2016 Sci.Rep.6 20993

[41]Brock J and Khan M 2017 J.Magn.Magn.Mater.425 1

[42]Sharma V K,Chattopadhyay M K and Roy S B 2007 J.Phys.D:Appl. Phys.40 1869

[43]Pathak A K,Dubenko I,Karaca H E,Stadler S and Ali N 2010 Appl. Phys.Lett.97 062505

[44]Chen F H,Gong C W,Guo Y P,Zhang M G and Chai Y S 2014 Chin. Phys.B 23 067501

[45]Stadler S,Khan M,Mitchell J,Ali N,Gomes A M,Dubenko I, Takeuchi A Y and Guimaraes A P 2006 Appl.Phys.Lett.88 192511

[46]Phan T L,Zhang P,Dan N H,Yen N H,Thanh P T,Thanh T D,Phan M H and Yu S C 2012 Appl.Phys.Lett.101 212403

[47]Sahoo R,Nayak A K,Suresh K G and Nigam A K,2012 J.Magn. Magn.Mater.324 1267

[48]Li Z B,Zhang Y D,Sanchez-Valdes C F,Sanchez-Llamazares J F,Esling C,Zhao X and Zuo L 2014 Appl.Phys.Lett.104 044101

27 April 2017;revised manuscript

23 May 2017;published online 9 August 2017)

10.1088/1674-1056/26/9/097501

?Project supported by the National Natural Science Foundation of China(Grant Nos.51601092,51571121,and 11604148),the Fundamental Research Funds for the Central Universities,China(Grant Nos.30916011344 and 30916011345),Jiangsu Natural Science Foundation for Distinguished Young Scholars, China(Grant No.BK20140035),China Postdoctoral Science Foundation(Grant No.2016M591851),the Natural Science Foundation of Jiangsu Province, China(Grant Nos.BK20160833 and BK20160829),Qing Lan Project of Jiangsu Province,China,Priority Academic Program Development of Jiangsu Higher Education Institutions,China,and NMG–NJUST Joint Scholarship Program for Ishfaq Ahmad Shah(Student ID:914116020118).

?Corresponding author.E-mail:xufeng@njust.edu.cn

?2017 Chinese Physical Society and IOP Publishing Ltd http://iopscience.iop.org/cpb http://cpb.iphy.ac.cn

- Chinese Physics B的其它文章

- Relationship measurement between ac-Stark shift of 40Ca+clock transition and laser polarization direction?

- Air breakdown induced by the microwave with two mutually orthogonal and heterophase electric field components?

- Collective motion of active particles in environmental noise?

- Temperature dependence of heat conduction coefficient in nanotube/nanowire networks?

- Analysis of dynamic features in intersecting pedestrian flows?

- Heat transfer enhancement in MOSFET mounted on different FR4 substrates by thermal transient measurement?