冷凍消融預(yù)冷系統(tǒng)熱力學(xué)分析

, , ,

(1.上海理工大學(xué) 能源與動力工程學(xué)院,上海 200093; 2.上海理工大學(xué) 醫(yī)療器械與食品學(xué)院,上海 200093)

冷凍消融預(yù)冷系統(tǒng)熱力學(xué)分析

夏元通1,徐彬凱2,葉萍2,劉寶林2

(1.上海理工大學(xué) 能源與動力工程學(xué)院,上海200093;2.上海理工大學(xué) 醫(yī)療器械與食品學(xué)院,上海200093)

冷凍治療因其具有無痛、微創(chuàng)、易恢復(fù)并可與其他治療方式結(jié)合等優(yōu)點(diǎn)[1-2],已成為外科手術(shù)的主要方法之一.其原理主要有兩種:相變制冷和J-T (焦耳-湯姆遜)效應(yīng).由于相變制冷冷刀直徑大、溫度不易控制等缺點(diǎn),在當(dāng)前較為先進(jìn)的冷凍手術(shù)中,已逐漸被氣體節(jié)流冷刀所代替[3].但是,節(jié)流冷刀氣體的工作壓力大,氬氦刀氬氣工作壓力在20 MPa以上,風(fēng)險高且不易推廣.趙慶孝等[4]在氮?dú)夤?jié)流冷刀系統(tǒng)中加入預(yù)冷環(huán)節(jié),不僅可以降低冷刀氣體的工作壓力,提高氣體的有效利用率,同時可增大氣體焓差,提高制冷量[4],現(xiàn)已成為J-T冷刀發(fā)展的新方向.預(yù)冷方式也因此成為研究內(nèi)容之一,葉萍[5]研究了以熱電制冷作為預(yù)冷方式實(shí)現(xiàn)從20 ℃至-40 ℃的預(yù)冷溫度,分別對氮?dú)夂蜌鍤饫涞兜慕禍靥匦赃M(jìn)行研究;于子淼等[6]設(shè)計了三級半導(dǎo)體制冷器對氮?dú)饫涞哆M(jìn)行預(yù)冷,并對該預(yù)冷方式作了深入研究;上海導(dǎo)向醫(yī)療系統(tǒng)有限公司為其靶向刀產(chǎn)品設(shè)計研發(fā)了多級自復(fù)疊預(yù)冷,率先實(shí)現(xiàn)了冷刀氣體超低溫預(yù)冷.

1 熱力學(xué)分析

1.1循環(huán)描述

圖1為設(shè)備采用的帶回?zé)崞鞯恼魵鈮嚎s式制冷系統(tǒng)圖以及循環(huán)的壓焓圖和溫熵圖.其中,1—2s表示壓縮機(jī)等熵壓縮過程,1—2表示實(shí)際壓縮過程,3—4和e—1分別表示回?zé)崞鲀?nèi)液體過冷和氣體過熱.p為壓力,T為熱力學(xué)溫度,s為比熵,h為比焓.表1列出了循環(huán)的各項指標(biāo).

圖1 帶回?zé)岬膯渭壵魵鈮嚎s式制冷循環(huán)系統(tǒng)圖、壓焓圖及溫熵圖

表1 循環(huán)各項指標(biāo)Tab.1 Parameters of a refrigeration cycle

注:R134a制冷劑-30 ℃及以下部分僅用于理論計算,實(shí)際應(yīng)用中無法達(dá)到.

由于制冷系統(tǒng)實(shí)際運(yùn)行時的工況十分復(fù)雜,為簡化分析,作如下假設(shè)[7-8]:

a. 系統(tǒng)各部件處于穩(wěn)態(tài)條件下;

b. 除蒸發(fā)器與冷凝器外,制冷劑在連接管路內(nèi)的壓降及其與外界的熱交換均為零;

c. 制冷劑在蒸發(fā)器和冷凝器內(nèi)的壓力不變;

d. 忽略制冷劑在系統(tǒng)內(nèi)的動能和勢能變化.

1.2理論模型

(1)

式中:qe為單位質(zhì)量制冷量;wi為壓縮機(jī)比功.

(2)

或者為[13]

(3)

壓縮機(jī)

(4)

(5)

冷凝器

(6)

(7)

回?zé)崞?/p>

(8)

(9)

毛細(xì)管

(10)

(11)

蒸發(fā)器

(12)

(13)

(14)

(15)

(16)

2 分析討論

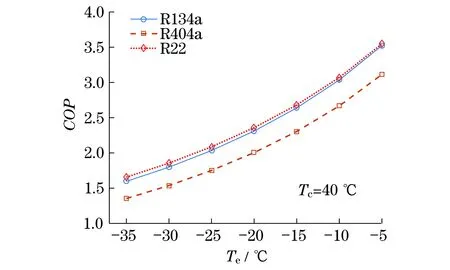

圖2 性能系數(shù)隨蒸發(fā)溫度的變化曲線(Tcon=40 ℃)Fig.2 Variation of COP with the change of evaporator temperature (Tcon=40 ℃)

圖3 性能系數(shù)隨冷凝溫度的變化曲線(Tevap=-30 ℃)Fig.3 Variation of COP with the change of condenser temperature (Tevap=-30 ℃)

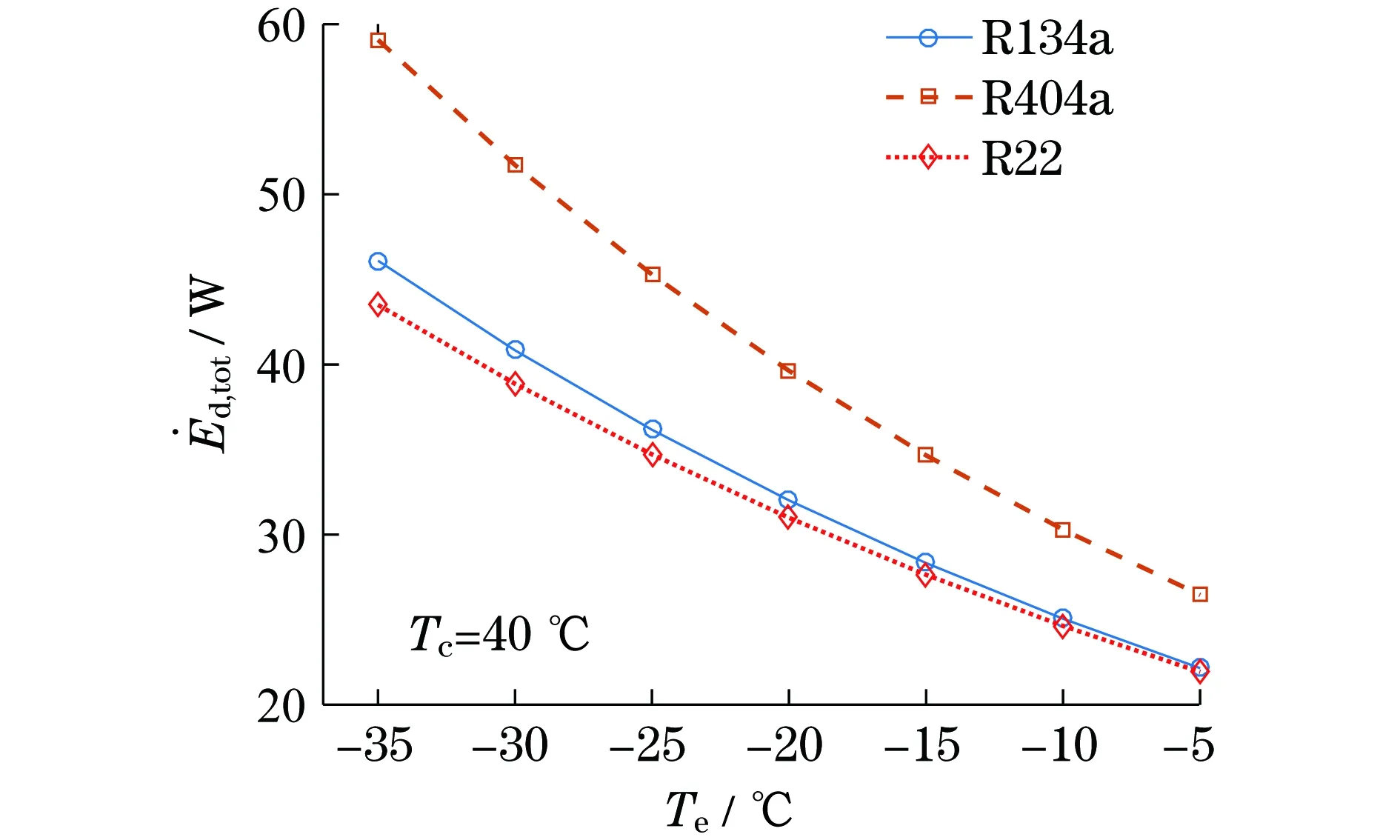

圖4 總損失隨蒸發(fā)溫度的變化曲線(Tcon=40 ℃)Fig.4 Variation of total exergy destruction with the change of evaporator temperature (Tcon=40 ℃)

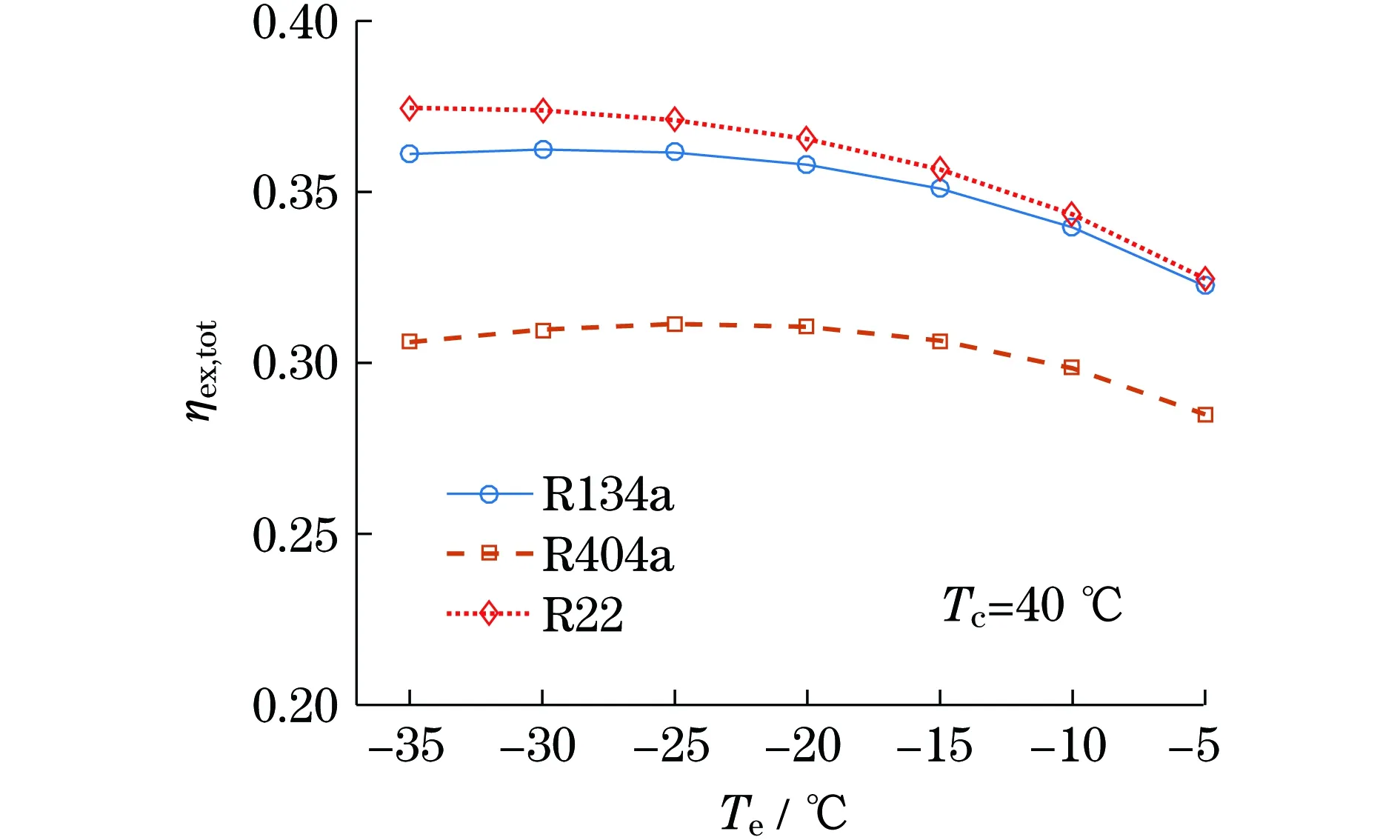

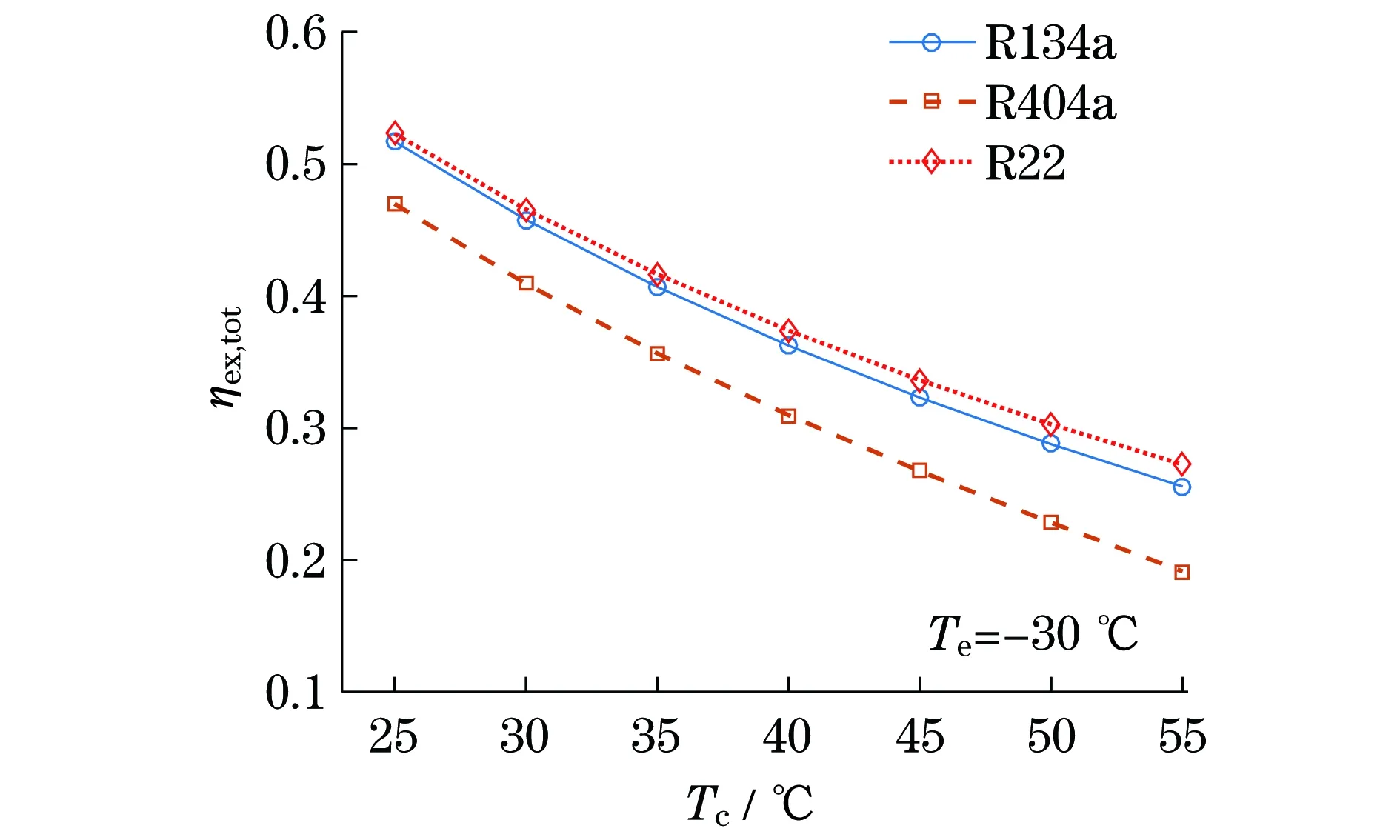

如圖2和圖3所示,3種制冷劑在所選工況下COP均隨蒸發(fā)溫度的升高而升高,隨冷凝溫度的升高而降低.這是因為蒸發(fā)溫度上升,單位制冷量增加且壓縮機(jī)耗功減少,導(dǎo)致COP增加.而冷凝溫度升高,提高了壓縮機(jī)的排氣壓力,使壓縮機(jī)壓比增大,導(dǎo)致壓縮機(jī)效率降低,同時在蒸發(fā)器入口處,制冷劑的比焓提高,這意味著在給定工況下總的制冷量減小,導(dǎo)致系統(tǒng)COP減小.系統(tǒng)COP最大的為R22,R134a次之,R404a最小.在蒸發(fā)溫度Te=-30 ℃,冷凝溫度Tc=40 ℃時,R22與R134a制冷劑的COP比R404a制冷劑的分別大20.7%,17.0%,而此時R22的僅比R134a的大3.17%.蒸發(fā)溫度由-5 ℃降低到-35 ℃時,R134a,R404a,R22這3種制冷劑的性能系數(shù)分別降低了54.7%,56.5%,53.4%,而冷凝溫度由25 ℃升高到55 ℃時,COP分別降低了50.5%,59.2%,47.9%.R22降幅最小,說明隨著蒸發(fā)溫度與冷凝溫度溫差的增大,R22的性能要比R134a,R404a的優(yōu)越.在相同制冷條件下,系統(tǒng)COP越大,產(chǎn)生的冷凝熱相對越小,這對減小設(shè)備內(nèi)溫度非常重要.

圖5 總損失隨冷凝溫度的變化曲線(Tevap=-30 ℃)Fig.5 Variation of total exergy destruction with the change of condenser temperature (Tevap=-30 ℃)

圖6 總效率隨蒸發(fā)溫度的變化曲線(Tcon=40 ℃)Fig.6 Variation of total exergy efficiency with the change of evaporator temperature (Tcon=40 ℃)

圖7 總效率隨冷凝溫度的變化曲線(Tevap=-30 ℃)Fig.7 Variation of total exergy efficiency with the change of condenser temperature (Tevap=-30 ℃)

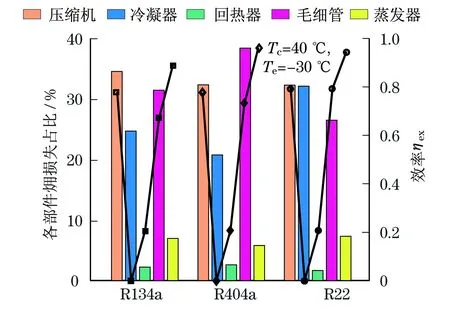

圖8 系統(tǒng)各部件損失占比(條形圖)及其效率(折線圖)Fig.8 Percentage (bar) of exergy destruction and exergy efficiency (line) in different components of system

3 結(jié) 論

單級蒸氣壓縮式制冷系統(tǒng)可實(shí)現(xiàn)氮?dú)狻鍤狻⒍趸肌⒁谎趸葰怏w的預(yù)冷,是冷凍治療系統(tǒng)的重要組成部分,其設(shè)計是否科學(xué)合理決定整個設(shè)備的品質(zhì).本文從能量利用的角度對其進(jìn)行理論分析,為今后試驗臺搭建提供了方向性指導(dǎo),也可作為其他相關(guān)制冷設(shè)備的理論參考.分析主要得出以下結(jié)論:

a. 在3種制冷劑中,R22各項性能最為優(yōu)越,其次是R134a,最后是R404a.所以,R22是作為冷凍治療設(shè)備預(yù)冷系統(tǒng)制冷劑的最佳選擇.

b. 雖然R22環(huán)境友好程度不如R134a,但作為一種非常優(yōu)秀的制冷劑,在未來相當(dāng)長時間里仍可用于醫(yī)療行業(yè).在所研究的各項指標(biāo)中,R134a雖略遜R22,但差距不大,因此,在制冷劑限制比較嚴(yán)格的發(fā)達(dá)國家地區(qū),可選用R134a作為替代.

[1] MIRKHALILI S M,RAMAZANI S A A,NAZEMIDASHTARJANDI S.Mathematical study of probe arrangement and nano-particle injection effects on heat transfer during cryosurgery[J].Computers in Biology and Medicine,2015,66:113-119.

[2] YU T H,LIU J,ZHOU Y X.Selective freezing of target biological tissues after injection of solutions with specific thermal properties[J].Cryobiology,2005,50(2):174-182.

[3] SHURRAB M,WANG H D,KUBO N,et al.The cooling performance of a cryoprobe:establishing guidelines for the safety margins in cryosurgery[J].International Journal of Refrigeration,2016,67:308-318.

[4] 趙慶孝,楊鵬飛,常兆華.新型超低溫冷凍醫(yī)療系統(tǒng)的設(shè)計與實(shí)驗研究[J].制冷學(xué)報,2009,30(6):57-60.

[5] 葉萍.乳腺腫瘤冷凍消融靶向治療技術(shù)研究[D].上海:上海理工大學(xué),2012.

[6] 于子淼,武衛(wèi)東,姜博仁,等.基于半導(dǎo)體制冷預(yù)冷的氮?dú)饫鋬龅断到y(tǒng)實(shí)驗研究[J].低溫工程,2014(1):50-54.

[7] AHAMED J U,SAIDUR R,MASJUKI H H.A review on exergy analysis of vapor compression refrigeration system[J].Renewable and Sustainable Energy Reviews,2011,15(3):1593-1600.

[8] RASTI M,AGHAMIRI S,HATAMIPOUR M S.Energy efficiency enhancement of a domestic refrigerator using R436A and R600a as alternative refrigerants to R134a[J].International Journal of Thermal Sciences,2013,74(6):86-94.

[9] ARORA A,KAUSHIK S C.Theoretical analysis of a vapour compression refrigeration system with R502,R404A and R507A[J].International Journal of Refrigeration,2008,31(6):998-1005.

[10] HUA Z Z,ZHANG H,LIU B L,et al.Refrigeration technology[M].Beijing:Science Press,2009.

[11] CHO H,PARK C.Experimental investigation of performance and exergy analysis of automotive air conditioning systems using refrigerant R1234yf at various compressor speeds[J].Applied Thermal Engineering,2016,101:30-37.

[12] YATAGANBABA A,KILICARSLAN A,KURTBA.Exergy analysis of R1234yf and R1234ze as R134a replacements in a two evaporator vapour compression refrigeration system[J].International Journal of Refrigeration,2015,60:26-37.

[13] YAN G,CUI C F,YU J L.Energy and exergy analysis of zeotropic mixture R290/R600a vapor-compression refrigeration cycle with separation condensation[J].International Journal of Refrigeration,2015,53:155-162.

[15] JOYBARI M M,HATAMIPOUR M S,RAHIMI A,et al.Exergy analysis and optimization of R600a as a replacement of R134a in a domestic refrigerator system[J].International Journal of Refrigeration,2013,36(4):1233-1242.

[16] DAYMA A S,AGRAWAL N,NANDA P.Energetic and exergetic analyses of a transcritical N2O heat pump system[J].International Journal of Low-Carbon Technologies,2014,9(4):277-283.

[17] DOOHAN R S,KUSH P K,MAHESHWARI G.Exergy based optimization and experimental evaluation of plate fin heat exchanger[J].Applied Thermal Engineering,2016,102:80-90.

[19] 鄭賢德.制冷原理與裝置[M].2版.北京:機(jī)械工業(yè)出版社,2008:68-70.

[20] YUMRUTAR,KUNDUZ M,KANOLU M.Exergy analysis of vapor compression refrigeration systems[J].Exergy,An International Journal,2002,2(4):266-272.

[21] 宋義樂.絕熱節(jié)流過程的熵變特性分析[D].北京:華北電力大學(xué),2013.

ThermodynamicAnalysisofSubcoolerinaCryoablationSystem

XIAYuantong1,XUBinkai2,YEPing2,LIUBaolin2

(1.SchoolofEnergyandPowerEngineering,UniversityofShanghaiforScienceandTechnology,Shanghai200093,China;2.SchoolofMedicalInstrumentandFoodEngineering,UniversityofShanghaiforScienceandTechnology,Shanghai200093,China)

The VCRS (vapor compression refrigeration system) was applied as a subcooler to obtain the needed temperature of a cryoablation system by J-T effect,and a mathematic model based on the first and second laws of thermodynamics was established for the energy and exergy analysis using R134a,R22 and R404a in the subcooling system of the cryoablation system.The effects of the evaporator and condenser temperatures on theCOP,total exergy destruction and total exergy efficiency of the system were investigated.The exergy destruction and exergy efficiency in different system components were also displayed.The R134a and R404a systems have lowerCOPand exergy efficiency but higher exergy destruction compared to the R22 system.However,the performance of R134a system is closer to the R22 system.So,the best refrigerant is R22 and R134a is a good alternative to R22.The major exergy destruction occurs in the compressor,condenser and capillary tube among all system components.The reasons and improvement suggestions were presented.

cryoablation;exergyanalysis;thermodynamics;subcoolingsystem

1007-6735(2017)05-0438-06

10.13255/j.cnki.jusst.2017.05.006

2017-03-02

浦東新區(qū)科技發(fā)展基金資助項目(PKJ2014-S16)

夏元通(1992-),男,碩士研究生.研究方向:低溫生物醫(yī)學(xué)技術(shù).E-mail:wellxia@163.com

劉寶林(1968-),男,教授.研究方向:低溫生物.E-mail:blliuk@163.com

TB61

A

(編輯:丁紅藝)