離子液體預處理對馬鈴薯莖葉厭氧消化的影響

葛一洪 邱 凌 羅時海 李姍珊 于秀男 郭曉慧

(1.西北農林科技大學農學院, 陜西楊凌 712100;2.西北農林科技大學農業部農村可再生能源開發利用西部科學觀測實驗站, 陜西楊凌 712100;3.西北農林科技大學機械與電子工程學院, 陜西楊凌 712100)

離子液體預處理對馬鈴薯莖葉厭氧消化的影響

葛一洪1,2邱 凌2,3羅時海2,3李姍珊2,3于秀男2,3郭曉慧2,3

(1.西北農林科技大學農學院, 陜西楊凌 712100;2.西北農林科技大學農業部農村可再生能源開發利用西部科學觀測實驗站, 陜西楊凌 712100;3.西北農林科技大學機械與電子工程學院, 陜西楊凌 712100)

馬鈴薯莖葉是一種豐富的木質纖維素生物質資源,但其高結晶度、穩定的剛性結構使其不易水解酸化,微生物在短時間內難以直接高效利用。研究了離子液體和助溶劑對馬鈴薯莖葉進行預處理后其木質纖維素結構組分變化及厭氧消化產沼氣的變化。結果表明,預處理后的馬鈴薯莖葉木質素質量分數降低31.8%~43.9%,離子液體脫除馬鈴薯莖葉木質素能力由高到低依次為[C2mim]Ac、[C2mim]Ac/DMSO、[C4mim]Cl/DMSO、DMSO、[C4mim]Cl。離子液體中陰離子可與纖維素羥基上的氫質子形成氫鍵作用,降低其結晶度,長鏈分子斷裂成短鏈分子,使厭氧消化的啟動滯后期較未處理馬鈴薯莖葉提前9 d,累積產沼氣量提高3.2%~76.3%,最高產甲烷體積分數提高14.3%~25.1%。各處理組累積產沼氣量和最高產甲烷體積分數分別為:T5(7.21 L,69.2%)、T4(5.12 L,64.5%)、T2(5.07 L,65.7%)、T3(4.35 L,64.3%)、T1(4.22 L,63.2%)。經無機鹽-離子液體雙水相體系回收DMSO、[C2mim]Ac和[C4mim]Cl,回收率分別為95.1%、91.8%和89.6%。

馬鈴薯莖葉; 離子液體; 木質纖維素; 厭氧消化

引言

馬鈴薯莖葉屬于一種木質纖維素生物質資源,主要由10%~30%的木質素、20%~45%的纖維素和20%~40%的半纖維素組成,而纖維素和半纖維素都是大分子多糖聚合物,發生水解反應時,氧橋斷裂可轉化成葡萄糖[1-2]。但馬鈴薯莖葉的細胞壁在進化的過程中形成了以纖維素為骨架物質,半纖維素附著在纖維素微纖絲表面,彼此通過氫鍵相連,木質素與半纖維素共價連接,填滿細胞壁中纖維素和半纖維素之間的空隙形成結晶度高的疏水穩定結構[3-5]。該結構使得微生物不能在短時間內將馬鈴薯莖葉的細胞壁進行降解,這意味著木質纖維素無法被微生物直接高效利用[6-9]。因此需要先將馬鈴薯莖葉進行預處理,打散其緊密結構,增加表面多孔性,使微生物能迅速接觸其中的大分子多糖聚合物,生產甲烷[10-12]。馬鈴薯莖葉的資源量、分布情況和資源化利用途徑見文獻[13]。

木質纖維素類生物質資源的預處理方法有很多,酸處理、堿處理、氧化處理、離子液體處理等均屬于化學預處理方法。CHANDRA等[14]在37℃下,用4% NaOH對小麥秸稈進行預處理120 h,使沼氣產量提高了87.5%,甲烷產量提高了111.6%。MONLAU等[15]用4% HCl(pH值2.3)在170℃條件下對向日葵稈進行預處理1 h,使產甲烷潛力提高了21%~29%。各種方法均能增加原料的可觸面積,溶解半纖維素和木質素,但只有離子液體預處理方法能降低纖維素的結晶度[16],且其他方法都存在處理周期長、回收難或處理效果差等問題。

離子液體(Ionic liquids, ILs)是一種在室溫范圍(20~25℃)內均呈液態的熔融鹽,由有機陽離子和無機(有機)陰離子構成,具有對無機和有機化合物良好的溶解性、導電性好、強極性、不易揮發、易合成、易回收、可循環使用、對水和空氣穩定、無毒環保等優點[17-20]。SWATLOSKI等[21]發現離子液體1-丁基-3-甲基咪唑氯鹽能直接溶解纖維素,LI等[22]發現離子液體預處理柳枝稷可降低其中纖維素的結晶度并促進其水解過程。離子液體預處理馬鈴薯莖葉進行厭氧消化的研究未見報道,為此本文選用離子液體對馬鈴薯莖葉進行預處理,研究其對馬鈴薯莖葉厭氧消化產沼氣的促進效果及產氣特性,以期為離子液體在馬鈴薯莖葉這一生物質資源中的開發和利用研究提供理論依據與實驗數據參考,從而更好地為工業應用提供科學依據。

1 材料與方法

1.1 試驗材料

(1)馬鈴薯莖葉取自陜西省楊凌國家農業高新技術產業區現代農業示范園,取回后自然曬干、粉碎至2~3 mm備用。

(2)1-乙基-3-甲基咪唑乙酸鹽([C2mim]Ac,W131887),1-丁基-3-甲基咪唑氯鹽([C4mim]Cl,B110177),助溶劑二甲基亞砜(Dimethyl sulfoxide, DMSO,D103277)均購于上海某試劑公司。試驗中其他化學試劑均購于廣州市某化學試劑有限公司,均為分析純。

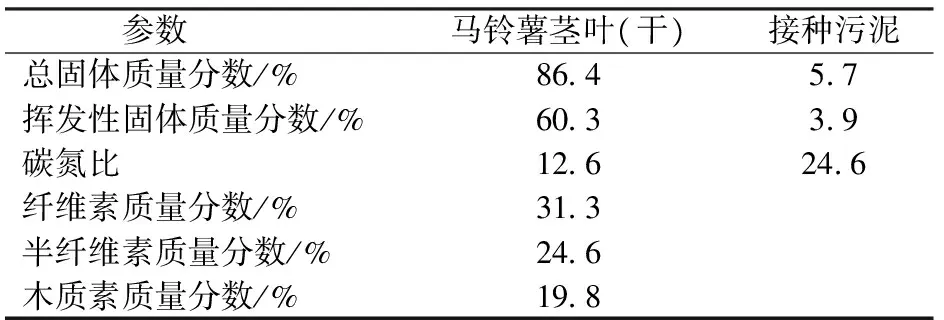

(3)接種污泥源于西北農林科技大學農業部農村可再生能源開發利用西部科學觀測實驗站長期馴化的厭氧污泥。試驗原料的成分含量如表1所示。

表1 試驗材料成分含量Tab.1 Components and contents of experimental materials

1.2 試驗方法

1.2.1預處理方法

于500 mL高筒燒杯中按質量分數5%加入馬鈴薯莖葉樣品5 g和100 g ILs,添加助溶劑的處理組分別加入20 g DMSO。在130℃硅油浴加熱下磁力攪拌進行溶解,處理時間為120 min。樣品加熱溶解后于高筒燒杯中加入100 mL抗溶劑(去離子水與丙酮體積比1∶1),隨即形成沉淀物,即預處理樣品再生成富纖維材料。再將樣品置于離心管,10 000 r/min離心5 min后過濾上清,并用去離子水反復沖洗沉淀物3次,置于90℃干燥箱中加熱干燥24 h后備發酵使用。

1.2.2回收ILs方法

離子液體回收采用無機鹽-離子液體雙水相體系,加入20 g K3PO4于含有ILs的溶液中,振蕩混勻后在室溫下靜置12 h,靜置分層后上層為富離子液體相,下層為富無機鹽相[23]。

1.2.3厭氧消化方法

厭氧消化器采用500 mL發酵瓶,發酵體積為400 mL,處理組裝100 mL接種物、15 g未處理馬鈴薯莖葉、5 g經ILs預處理的再生馬鈴薯莖葉;對照組裝100 mL接種物和20 g未處理馬鈴薯莖葉,填料密封后向厭氧消化器中吹入氮氣2 min以排凈厭氧消化器內的氧氣,每個厭氧消化器連接一個集氣瓶和收集瓶,相互之間用乳膠管連接密封,厭氧消化器置于往復式恒溫震蕩水浴搖床進行序批式中溫厭氧消化(35℃)至產氣結束。試驗共計6個處理,每個處理設置3個重復,試驗裝置如圖1所示。

圖1 試驗裝置示意圖Fig.1 Test unit schematic diagram1.取液樣閥門 2.取樣管 3.厭氧消化瓶 4.導氣管 5.可控恒溫水浴搖床 6.取氣樣三通閥門 7.集氣瓶 8.排水管 9.集水量筒

每天08:00和20:00打開搖床,100 r/min振蕩20 min,使反應器內的料液混合均勻。每天09:00測定一次氣體產量和氣體成分。

1.2.4指標檢測方法

每日氣體產量采用排水集氣法測定;氣體成分采用GC2014C型氣相色譜儀(日本島津公司)測定,TCD檢測器,檢測器和進樣口溫度為100℃,柱溫箱溫度為90℃,載氣為氬氣,流速為30 mL/min;總固體采用105℃干燥箱加熱干燥24 h至質量恒定,差重法測定;揮發性固體采用550℃馬弗爐灼燒6 h,差重法測定;馬鈴薯莖葉纖維素、半纖維素、木質素采用范氏法換算[24],中性洗滌纖維和酸性洗滌纖維采用A220型半自動纖維素測定儀(美國ANKOM公司)測定。

2 結果與分析

2.1 ILs對馬鈴薯莖葉木質纖維素結構組成的影響

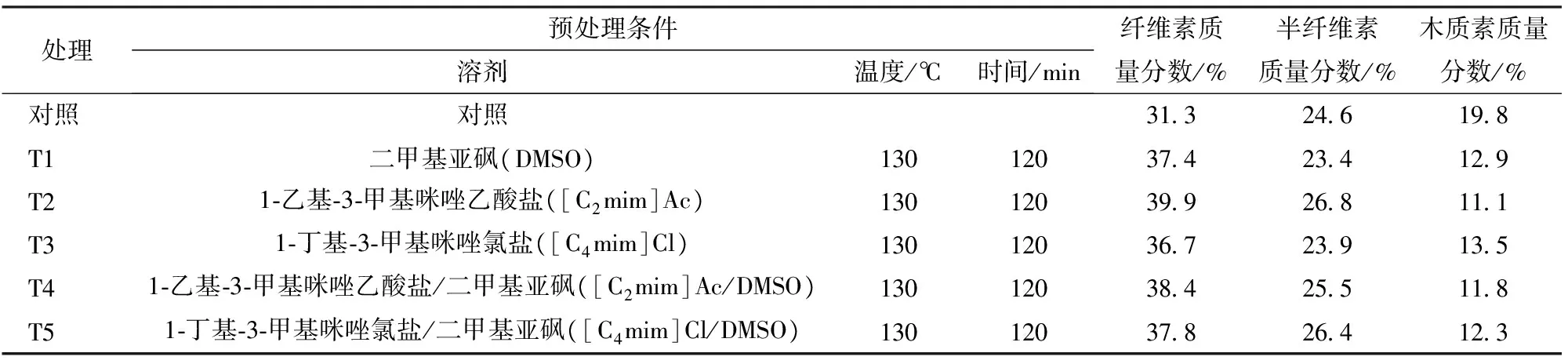

試驗結果表明,通過DMSO、[C2mim]Ac、[C2mim]Ac/DMSO、[C4mim]Cl、[C4mim]Cl/DMSO處理后,馬鈴薯莖葉再生纖維素質量分數分別提高19.5%、27.5%、22.7%、17.3%、20.8%,在試驗過程中可觀察到馬鈴薯莖葉的外形結構逐漸發生膨脹,隨后伴有大量的團狀微粒出現。BRANDT等[25]研究松木片中木質纖維素降解時也出現膨脹及團聚現象,XU等[26]研究認為膨脹和團狀微粒的出現是由纖維素的羥基質子與ILs中陰離子形成大量氫鍵導致。這也就表明ILs破壞了馬鈴薯莖葉的木質纖維素結構,增加了其表面的多孔性使其結晶度降低而結構變得松散。

通過試驗觀察可知,助溶劑DMSO的加入可明顯降低離子液體的粘稠度,并增加預處理系統的流動性。結果表明,在[C2mim]Ac、[C4mim]Cl中加入DMSO后,馬鈴薯莖葉木質素質量分數分別為11.8%、12.3%,T5處理組(表2)較T3處理組脫除木質素效果提高了8.9%,但DMSO對[C2mim]Ac的影響效果不顯著。由表2可知,馬鈴薯莖葉經離子液體在130℃下預處理120 min后,其再生纖維素質量分數可提高17.3%~27.5%,木質素質量分數可降低31.8%~43.9%,各處理中所用離子液體溶解和脫除木質纖維素能力由高到低依次為[C2mim]Ac、[C2mim]Ac/DMSO、[C4mim]Cl/DMSO、DMSO、[C4mim]Cl。

2.2 ILs對馬鈴薯莖葉厭氧消化產氣特性的影響

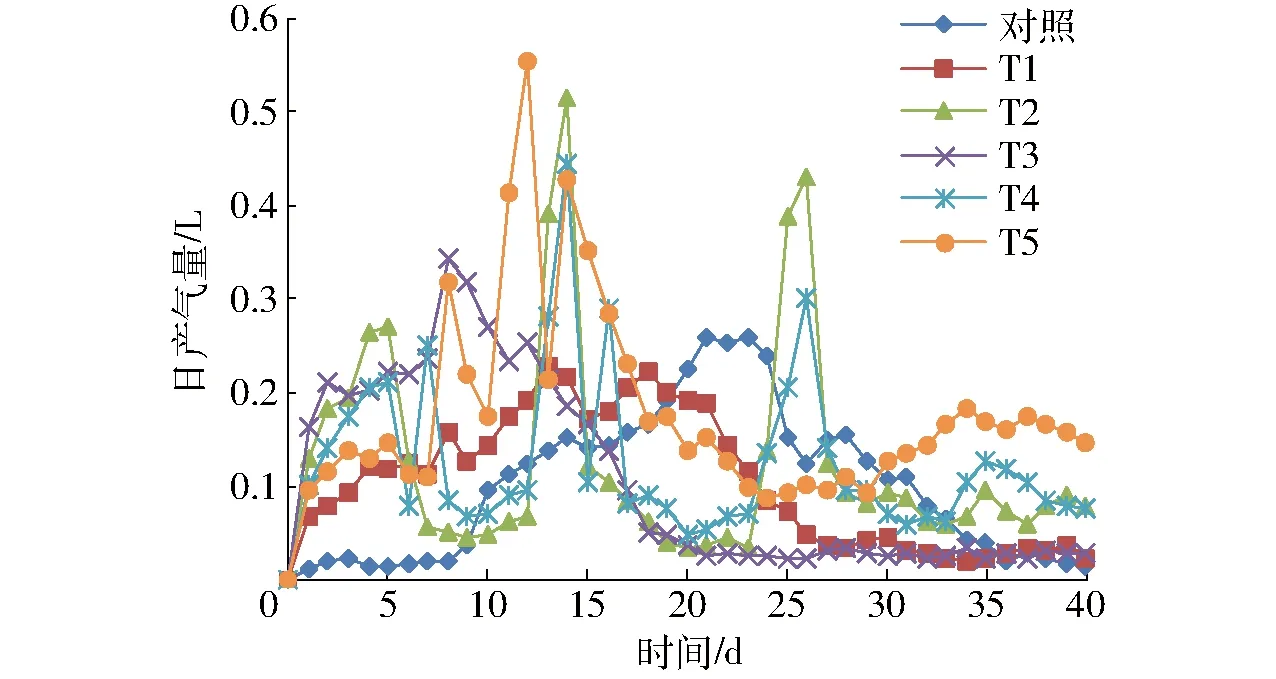

離子液體對馬鈴薯莖葉厭氧消化的日產氣變化影響如圖2所示,未經處理的馬鈴薯莖葉直到厭氧消化第10天才開始正式產氣,單日產氣量0.09 L。而經過離子液體處理的馬鈴薯莖葉則在厭氧消化第1天就開始正常產氣,單日產氣量分別為T1處理組0.07 L、T2處理組0.13 L、T3處理組0.16 L、T4處理組0.10 L、T5處理組0.09 L。結果表明ILs中Ac-、Cl-離子和馬鈴薯莖葉纖維素長鏈分子中—OH上的氫質子形成氫鍵作用,導致纖維素的結晶度降低,長鏈上的氧橋更易斷裂變成短鏈分子[27],使馬鈴薯莖葉在厭氧消化水解酸化階段的啟動遲滯期縮短了9 d。

表2 不同離子液體預處理馬鈴薯莖葉木質纖維素結構組成變化Tab.2 Lignocellulosic composition of untreated and pretreated potato stem leaves by ILs

圖2 不同ILs預處理馬鈴薯莖葉厭氧消化日產氣量變化Fig.2 Changes of daily biogas production from potato stem leaves untreated and pretreated by ILs

厭氧消化前15 d,各ILs處理組均出現1或2次產氣高峰。在所有處理中第1個產氣高峰出現在第5天的T2處理組,單日產氣量為0.27 L。T5處理組第12天的單日產氣量最高,達到整個厭氧消化周期的峰值0.55 L,而對照組的產氣最高峰出現在第21天,單日產氣量為0.26 L,比T5處理組單日產氣量低52.7%。T2和T4處理組在發酵過程中同時在第14和26天出現2次產氣高峰,T2處理組單日產氣量分別為0.52 L和0.43 L,T4處理組單日產氣量分別為0.45 L和0.30 L,較對照組平均高出108.4%。T3處理組在發酵前10 d的日產氣量均高于T5處理組,平均每日產氣量高出0.08 L,但發酵第13天,T3處理組日產氣量開始驟降,到第21天產氣已基本停止,而T5處理組日產氣量仍有0.15 L。在厭氧消化第40天,其它處理組均已基本停止產氣時(小于0.09 L),T5處理組仍能保持日產氣量0.14 L。

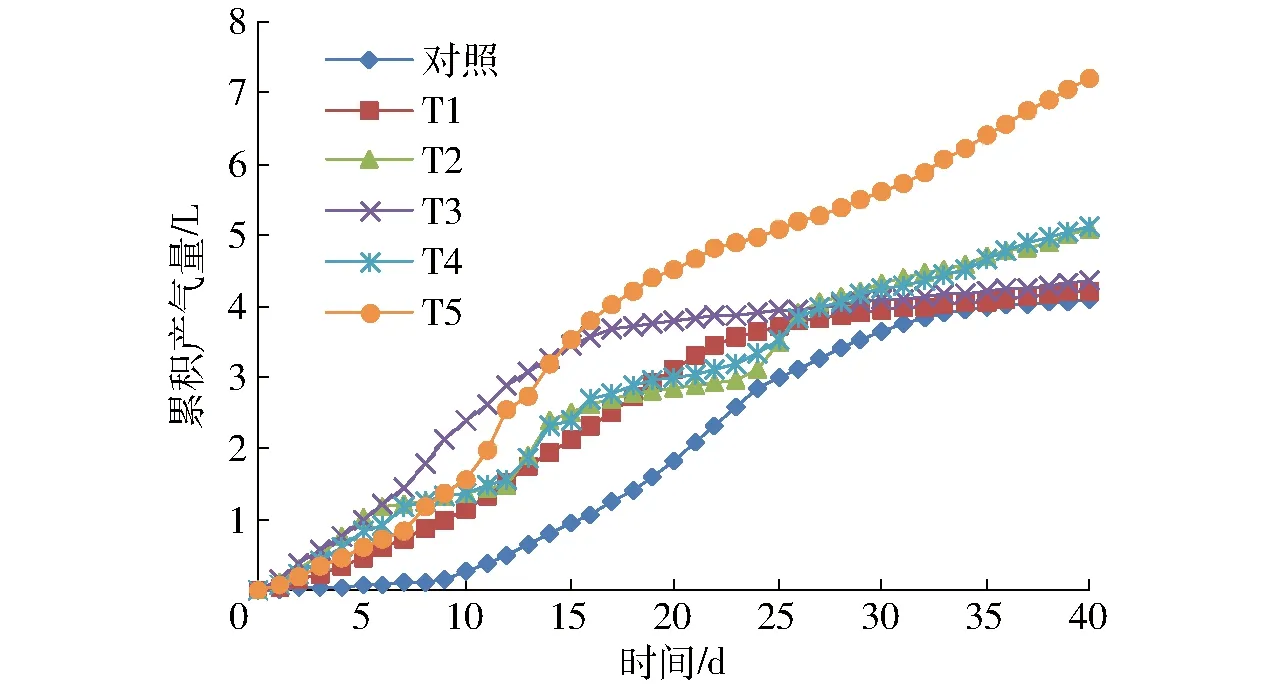

各處理組累積產氣量如圖3所示。由圖可知,厭氧消化前14 d,T3處理組累積產氣量最高(3.27 L),但從第15天被T5處理組超越,并且最終所有處理中T5的累積產氣量最高(7.21 L),較T3處理組高出65.7%。厭氧消化周期內T4和T2處理組的累積產氣量最終并沒有明顯差距,分別為5.12 L和5.07 L。這說明助溶劑DMSO對[C4mim]Cl影響較大,對[C2mim]Ac幾乎沒有影響。ILs預處理馬鈴薯莖葉厭氧消化累積產氣量由高到低依次為T5(7.21 L)、T4(5.12 L)、T2(5.07 L)、T3(4.35 L)、T1(4.22 L),比對照組(4.09 L)高出3.2%~76.3%。

圖3 不同ILs預處理馬鈴薯莖葉厭氧消化的累積產氣量變化Fig.3 Cumulative biogas production changes from potato stem leaves untreated and pretreated by ILs

圖4 不同ILs預處理馬鈴薯莖葉厭氧消化產甲烷體積分數變化Fig.4 Methane concentration changes of biogas from potato stem leaves untreated and pretreated by ILs

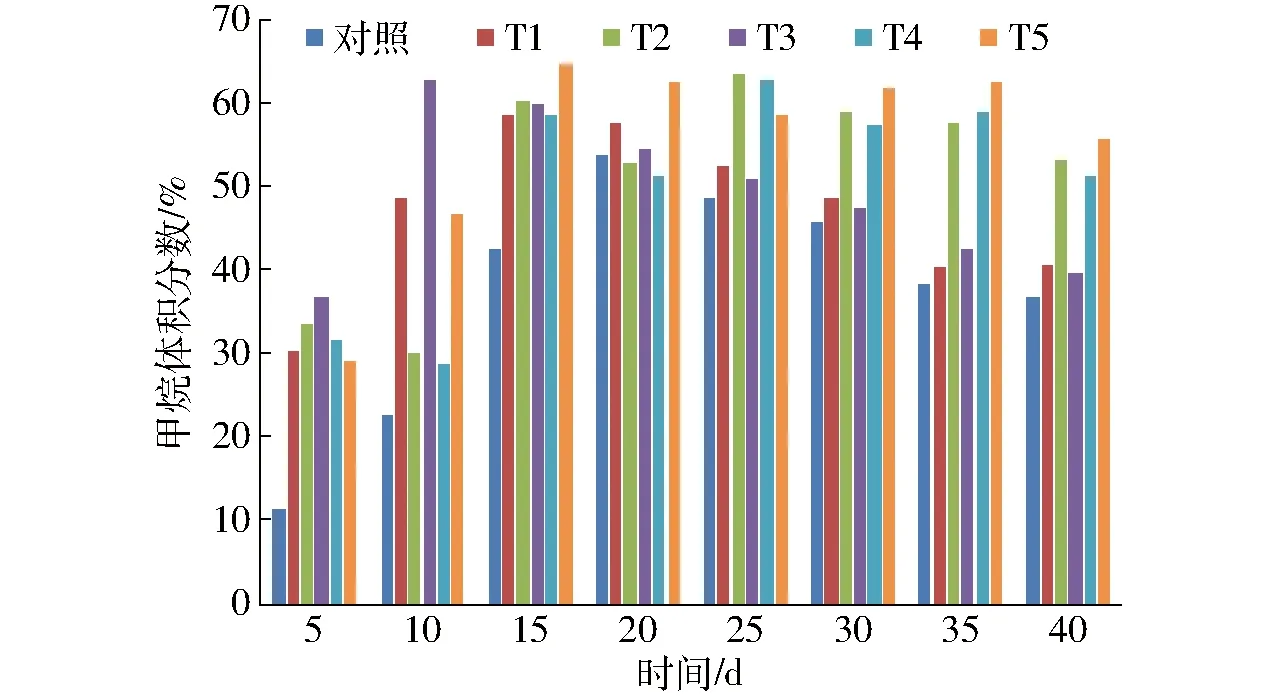

不同離子液體預處理馬鈴薯莖葉厭氧消化產甲烷體積分數變化如圖4所示。試驗表明,馬鈴薯莖葉經[C4mim]Cl、[C4mim]Cl/DMSO、[C2mim]Ac、[C2mim]Ac/DMSO預處理后,明顯提高了沼氣中甲烷體積分數。厭氧消化第5天,各ILs處理組甲烷體積分數較對照組高出155.8%~223.9%(甲烷產量高出18.8~58.67 mL);第13天,各ILs處理組甲烷體積分數均已超過50%;第15天,T5處理組甲烷體積分數達到64.6%(甲烷產量為226.75 mL),而對照組甲烷體積分數僅為42.5%(甲烷產量為60.35 mL)。馬鈴薯莖葉經ILs預處理后,得到大量纖維素分解后的短鏈分子,加速了產甲烷階段的進程,使產甲烷菌在厭氧消化初期就可以進行富集,成為優勢菌種。整個厭氧消化周期內,對照組產甲烷體積分數最高為55.3%(甲烷產量為142.67 mL),各ILs處理組最高產甲烷體積分數由高到低依次為T5(69.2%)、T2(65.7%)、T4(64.5%)、T3(64.3%)、T1(63.2%),較對照組高出14.3%~25.1%。

2.3 ILs的回收

通過觀察加入磷酸鉀鹽的無機鹽-離子液體雙水相體系分離ILs過程,按分離速率由快到慢依次為DMSO、[C4mim]Cl/DMSO、[C2mim]Ac/DMSO、[C2mim]Ac、[C4mim]Cl。DMSO、[C2mim]Ac和[C4mim]Cl的回收率分別為95.1%、91.8%和89.6%。結果表明,離子液體分離速率的快慢與其回收率的大小呈正相關,也就說明分離速率能夠間接反映出雙水相體系對離子液體的分離回收能力。

3 結論

(1)離子液體[C4mim]Cl、[C2mim]Ac和助溶劑DMSO對馬鈴薯莖葉進行預處理,木質素質量分數較對照組降低31.8%~43.9%,各處理組溶解和脫除木質纖維素能力由高到低依次為T2、T4、T5、T1、T3。

(2)預處理后的馬鈴薯莖葉可使厭氧消化啟動滯后期提前9 d,各處理組厭氧消化的累積產沼氣量較對照組提高3.2%~76.3%,各處理組累積產沼氣量由高到低依次為T5(7.21 L)、T4(5.12 L)、T2(5.07 L)、T3(4.35 L)、T1(4.22 L)、對照組(4.09 L)。各處理組最高產甲烷體積分數分別為T5(69.2%)、T2(65.7%)、T4(64.5%)、T3(64.3%)、T1(63.2%),較對照組(55.3%)高出14.3%~25.1%。

(3)經無機鹽-離子液體雙水相體系回收DMSO、[C2mim]Ac和[C4mim]Cl,回收率分別為95.1%、91.8%和89.6%。另外離子液體預處理樣品后的化學殘留極少,對樣品的后續處理影響較低。

1 HA M A, APPERLEY D C, EVANS B W, et al.Fine structure in cellulose microfibrils: NMR evidence from onion and quince [J].Plant, 1998, 16(2):183-190.

2 ATALLA R H, VANDERHART D L.Native cellulose.A composite of two distinct crystalline forms [J].Science, 1984, 223:283-285.

3 翟蔚, 陳洪章, 馬潤宇.離子液體中纖維素的溶解及再生特性[J].北京化工大學學報:自然科學版, 2007, 34(2): 140-143.

ZHAI Wei, CHEN Hongzhang, MA Runyu.Structural characteristics of cellulose after dissolution and regeneration from the ionic liquid [Bmim]Cl [J].Journal of Beijing University of Chemical Technology: Natural Science Edition, 2007, 34(2): 140-143.(in Chinese)

4 ADEMARK P, VARGA A, MEDVE J, et al.Softwood hemicellulose-degrading enzymes fromAspergillusniger: purification and properties of a beta-mannanase [J].Journal of Biotechnology, 1998, 63(3):199-210.

5 MOROHOSHI N.Chemical characterization of wood and its components [M]∥HON D N N, SHIRAISHI N.Wood and cellulosic chemistry.New York: Marcel Dekker, Inc., 1991: 331-392.

6 張元晶, 魏剛, 張小冬, 等.木質纖維素生物質預處理技術研究現狀[J].中國農學通報, 2012, 28(11): 272-277.

ZHANG Yuanjing, WEI Gang, ZHANG Xiaodong, et al.Status in pretreatment technologies of lignocellulosic biomass [J].Chinese Agricultural Science Bulletin, 2012, 28(11): 272-277.(in Chinese)

7 HSU T A.Pretreatment of biomass [M]∥WYMAN C E.Handbook on bioethanol: production and utilization.Washington, DC: Taylor & Francis, 1996: 179-212.

8 KIM S, HOLTZAPPLE M T.Lime pretreatment and enzymatic hydrolysis of corn stover [J].Bioresource Technology, 2005, 96(18):1994-2006.

9 ZHENG Y.Lignocellulosic biomass pretreatment for bioethanol production [M]∥ERBAUM J B.Bioethanol: production, benefits and economics.New York: Nova Science Publishers, 2009:1-48.

10 FERNANDES T V, KLAASSE BOS G J, ZEEMAN G, et al.Effects of thermo-chemical pretreatment on anaerobic biodegradability and hydrolysis of lignocellulosic biomass [J].Bioresource Technology, 2009, 100(9): 2575-2579.

11 LIEW L N, SHI J, LI Y.Methane production from solid-state anaerobic digestion of lignocellulosic biomass [J].Biomass and Bioenergy, 2012, 46: 125-132.

12 XIAO W P, CLARKSON W W.Acid solubilization of lignin and bioconversion of treated newsprint to methane [J].Biodegradation, 1997, 8(1): 61-66.

13 葛一洪, 邱凌, HASSANEIN A A M, 等.馬鈴薯莖葉與玉米秸稈混合厭氧消化工藝參數優化[J/OL].農業機械學報, 2016, 47(4): 173-179.http:∥www.j-csam.org/jcsam/ch/reader/view_abstract.aspx?flag=1&file_no=20160423&journal_id=jcsam.DOI: 10.6041/j.issn.1000-1298.2016.04.023.

GE Yihong, QIU Ling, HASSANEIN A A M, et al.Optimization of anaerobic digestion parameters with mixed material of potato stem leaf and corn straw [J/OL].Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(4): 173-179.(in Chinese)

14 CHANDRA R, TAKEUCHI H, HASEGAWA T, et al.Improving biodegradability and biogas production of wheat straw substrates using sodium hydroxide and hydrothermal pretreatments [J].Energy, 2012, 43: 273-282.

15 MONLAU F, BARAKAT A, STEYER J P, et al.Comparison of seven types of thermo-chemical pretreatments on the structural features and anaerobic digestion of sunflower stalks [J].Bioresource Technology, 2012, 120: 241-247.

16 ZHENG Yi, ZHAO Jia, XU Fuqing, et al.Pretreatment of lignocellulosic biomass for enhanced biogas production [J].Progress in Energy and Combustion Science.2014, 42:35-53.

17 HAYKIR N I, BAHCEGUL E, BICAK N, et al.Pretreatment of cotton stalk with ionic liquids including 2-hydroxy ethyl ammonium formate to enhance biomass digestibility [J].Industrial Crops and Products, 2013, 41: 430-436.

18 QIU Z, AITA G M, WALKER M S.Effect of ionic liquid pretreatment on the chemical composition, structure and enzymatic hydrolysis of energy cane bagasse [J].Bioresource Technology, 2012, 117: 251-256.

19 GAO J, CHEN L, YAN Z, et al.Effect of ionic liquid pretreatment on the composition, structure and biogas production of water hyacinth (Eichhorniacrassipes) [J].Bioresource Technology, 2013, 132: 361-364.

20 WEERACHANCHAI P, LEE J M.Effect of organic solvent in ionic liquid on biomass pretreatment [J].ACS Sustainable Chemistry and Engineering, 2013, 1(8): 894-902.

21 SWATLOSKI R P, SPEAR S K, HOLBREY J D, et al.Dissolution of cellulose with ionic liquids [J].Journal of the American Chemical Society, 2002, 124(18): 4974-4975.

22 LI C, KNIERIM B, MANISSERI C, et al.Comparison of dilute acid and ionic liquid pretreatment of switchgrass: biomass recalcitrance, delignification and enzymatic saccharification [J].Bioresource Technology, 2010, 101(13): 4900-4906.

23 LI S H, HE C Y, LIU H W, et al.Ionic liquid-based aqueous two-phase system, a sample pretreatment procedure prior to high-performance liquid chromatography of opium alkaloids [J].Journal of Chromatography B, 2005, 826(1-2): 58-62.

24 VAN SOEST P J, ROBERTSON J B, LEWIS B A.Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition [J].Journal of Dairy Science, 1991, 74(10): 3583-3597.

25 BRANDT A, HALLETT J P, LEAK D J, et al.The effect of the ionic liquid anion in the pretreatment of pine wood chips [J].Green Chemistry, 2010, 12(4): 672-679.

26 XU A, WANG J, WANG H.Effects of anionic structure and lithium salts addition on the dissolution of cellulose in 1-butyl-3-methylimidazolium-based ionic liquid solvent systems [J].Green Chemistry, 2010, 12(2): 268-275.

27 ZHANG Y T, DU H B, QIAN X H, et al.Ionic liquid-water mixtures: enhancedKwfor efficient cellulosic biomass conversion [J].Energy Fuels, 2010, 24(4): 2410-2417.

EffectofIonicLiquidsPretreatmentonAnaerobicDigestionofPotatoStemLeaves

GE Yihong1,2QIU Ling2,3LUO Shihai2,3LI Shanshan2,3YU Xiunan2,3GUO Xiaohui2,3

(1.CollegeofAgronomy,NorthwestA&FUniversity,Yangling,Shaanxi712100,China2.WesternScientificObservingandExperimentalStationforDevelopmentandUtilizationofRuralRenewableEnergy,MinistryofAgriculture,NorthwestA&FUniversity,Yangling,Shaanxi712100,China3.CollegeofMechanicalandElectronicEngineering,NorthwestA&FUniversity,Yangling,Shaanxi712100,China)

With the fulfillment of China’s potato staple food strategy, potato stem leaves gradually become plentiful lignocellulosic biomass resources.However, its cell wall has high-crystalline structure and available surface area which were difficult to hydrolyze and produce biogas by microorganism.Therefore, the effect of lignocellulosic composition, structural and anaerobic digestion from the pretreated potato stem leaf by ionic liquids and dimethyl sulfoxide was evaluated.The potato stem leaf was pretreated with ionic liquids 1-N-butyl-3-methyimidazolium chloride ([C4mim]Cl), 1-ethyl-3-methlyimidazolium acetate ([C2mim]Ac) and dimethyl sulfoxide (DMSO) under the condition of 130℃ for 120 min.Compared with untreated group (19.8% lignin content), the composition and structure of lignocellulosic from the regenerated potato stem leaf was changed and the lignin content was reduced by 31.8%~43.9%.The dissolving capability of the solvents followed the order: [C2mim]Ac, [C2mim]Ac/DMSO, [C4mim]Cl/DMSO, DMSO, [C4mim]Cl.The anaerobic digestion data demonstrated the lag phase of anaerobic digestion start-up period was shortened by 9 d.Because the solubility of cellulose was risen with the increase of the H-bonds accepting ability of the anions which would form more efficient H-bonds between the hydroxyl protons of cellulose and the anion, meanwhile, the crystalline structure of cellulose became lower and the surface became more porous.In other words, the hydrolytic acidification stage was almost accomplished after pretreatment.Plenty of the small molecular substances, which were easy to be used by methanogens, were dissolved out.The cumulative biogas production and the highest methane content were increased by 3.2%~76.3% and 14.3%~25.1%, respectively, compared with untreated potato stem leaf.The cumulative biogas production and the highest methane content of each pretreated groups were 7.21 L and 69.2% ([C4mim]Cl/DMSO), 5.12 L and 64.5% ([C2mim]Ac/DMSO), 5.07 L and 65.7% ([C2mim]Ac), 4.35 L and 64.3% ([C4mim]Cl), 4.22 L and 63.2% (DMSO), respectively.The ionic liquids were almost completely recovered by aqueous biphasic systems (ABSs) with tripotassium phosphate (K3PO4), the recovery rates of DMSO, [C2mim]Ac and [C4mim]Cl were 95.1%, 91.8% and 89.6%, respectively.There were still many issues in putting ionic liquids into practical applications, including the high cost of ILs, regeneration systems and requirements and mechanism of inhibitor generation.Further research was urgently required to dispose such challenges.

potato stem leaves; ionic liquid; lignocellulose; anaerobic digestion

10.6041/j.issn.1000-1298.2017.10.033

X71; S216.4

A

1000-1298(2017)10-0266-06

2017-01-10

2017-05-12

國家自然科學基金面上項目(51576167)

葛一洪(1984—),男,博士生,主要從事生物質能源方面的研究,E-mail:cn.gyhong@qq.com

邱凌(1957—),男,教授,博士生導師,主要從事生物能源與環境工程方面的研究,E-mail:ql2871@126.com