漢諾威大樓,布拉德福德,英國

建筑設計:克勞斯-舍恩貝里建筑事務所

Architect: Kraus Sch?nberg Architects

漢諾威大樓,布拉德福德,英國

建筑設計:克勞斯-舍恩貝里建筑事務所

Architect: Kraus Sch?nberg Architects

Hanover House Bradford, United Kingdom, 2008

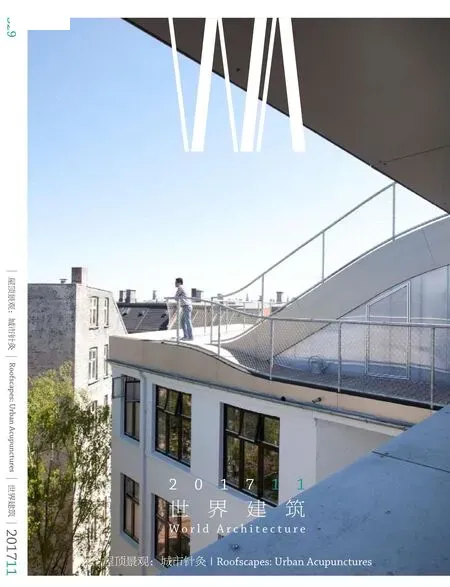

1 外景/Exterior view

項目信息/Credits and Data

客戶/Client: 加布集團/Garbe Group

結構工程/Structural Engineer: EDA

項目管理/Project Management: Maber

總建筑面積/Gross Floor Area: 1300m2

造價/Cost: £1,600,000

攝影/Photos: 克勞斯-舍恩貝里建筑事務所/Kraus Sch?nberg Architects

英國二級保護建筑漢諾威大樓的改造是對一座維多利亞時期庫房的翻新及屋頂的擴建。

漢諾威大樓位于布拉德福德的小德國區(qū),那是一個歷史價值很高、美輪美奐的保護區(qū)。這個地區(qū)獨到的特色源自風格統(tǒng)一的19世紀建筑。

所用的砂巖和立面的裝飾將街區(qū)統(tǒng)一起來——盡管與許多其他同時代的半工業(yè)區(qū)一樣,小德國區(qū)的建筑大小和形式各不相同。因此,屋頂的景觀也是豐富多樣的。

這就為新屋頂的設計帶來了靈感,并對周圍的建筑形式、大小和朝向作出新的闡釋。

屋頂輪廓的雕刻特征并非只是一場建筑幻想,而是與周邊建筑的屋頂景觀相映成趣,并構成了生活的空間。

為了建造一個高效的結構,這個屋頂被設計成一個自承重體系,避免給現(xiàn)有的樓板增加荷載。我們用人造木板作為可持續(xù)的高性能材料,以外墻為支撐創(chuàng)造出一個反復折疊的屋面。

屋頂折射出主體的結構、日照方向和各種景象。

進深15m的樓層平面需要精心設計的方案,以避免出現(xiàn)梁架過大的低效屋頂結構。所以屋面是順著折板反復折疊的,這樣就形成了一個以外墻為支撐的自承重結構。在高處,屋頂的承重點深入建筑內部,將結構的跨度從15m縮短到10m。傾斜的陽臺側墻將這些點上的反作用力傳到外墻上。任何形成的側向力都被傳導在起拉結作用的樓板上。

屋面由交錯層壓人造木板制成。140mm厚的木板傳熱系數很好,構成了保溫良好的屋頂。

所選的屋頂掛板用現(xiàn)代材料對街區(qū)傳統(tǒng)的石板瓦屋頂進行了新的闡釋。新屋頂采用無煙煤預銹化立縫鋅掛板,外觀與原屋頂相似。這個復雜的屋頂造型包括各種屋脊和天溝、斜墻、折面、曲面和輻射狀轉角。這就需要一種能夠滿足這些條件的施工技術。立縫鋅屋頂是克服這一難題的最佳方案。

其空間概念已融入施工和結構,并構成了一個整體。□(尚晉 譯)

The development of the grade II listed Hanover House involves the refurbishment and roof extension of a Victorian warehouse building.

Hanover House is located in Bradford's Little Germany, a conservation area of great historical interest and beauty. The unique character of the area is created by the uniformity of buildings dating from the 19th century.

The used sandstone material and the ornamental treatment of the facades unify the blocks - although, as with many other semiindustrial areas from the period, the buildings in Little Germany vary in size and form. Accordingly,the roofscape is one of great diversity.

This informs the design of the new roof, which reinterprets the surrounding forms, sizes and orientations.

The sculptural aspect of the roof silhouette is no mere architectural fancy, but ref l ects the roofscape of the surrounding buildings and has been used to form the living spaces.

Aiming to create a highly efficient structure, the roof has been designed as a self-supporting system to avoid additional loading onto the existing floors.We used engineered timber as a sustainable highperformance material, creating a roof surface which folds up and down and bears on the external walls.

The roof form reflects the construction of the primary structure, daylight direction and views.

The deep floor plan of 15m required an engineered solution to avoid an inefficient roof structure with oversized beams. Therefore the roof surface folds up and down to a folded plate creating a self supporting structure, which bears on the external walls. At high level the load bearing points of the roof are taken further into the building in order to shorten the span of the structure from 15m to 10m. The inclined balcony side walls transfer the reaction forces at these points into the external wall.Any resulting lateral forces are transferred into the floor plate which acts as a tie.

The roof surface is made of cross laminated engineered timber boards. The 140mm thick board has a good value and adds up to a highly insulated roof.

The chosen roof cladding re-interprets the traditional slate tiled roofs of the neighbourhood with a modern material. Similar in appearance the new roof is clad in anthracite pre-patinated standing seam zinc. The complex roof geometry with various ridges and valleys, inclined walls, folds, bends and radiused corners required a construction technique to accommodate these conditions. The standing seam zinc roof was an optimal solution for this challenge.

The spatial concept has merged with the construction and structure and has formed one entity. □

3 外景/Exterior view

4 模型/Model

5 剖面/Section

6 四層平面/Floor 3 plan

7 立面/Elevation

8 剖面/Section

9 外景/Exterior view

10 草圖/Sketches

11 立面/Elevation

12-18 施工中/Under construction

19.20 草圖/Sketches

21-23 施工中/Under construction

24 外景/Exterior view

25-27 內景/Interior views