鋁合金激光焊接的質量問題研究

賀東偉

摘 要:相較于傳統的焊接技術,鋁合金激光焊接有許多優點,但在焊接中,依然存在著一系列質量問題。本文結合近些年來激光焊接技術的研究現狀,簡要分析了鋁合金激光焊接的特性和焊接過程中出現的質量問題,并對激光焊接工藝的優化提出了相應的措施。

關鍵詞:鋁合金;激光焊接;質量

中圖分類號:V261.34 文獻標識碼:A 文章編號:1003-5168(2018)23-0054-02

Study on Quality of Laser Welding of Aluminum Alloy

HE Dongwei

(Heilongjiang Polytechnic,Harbin Heilongjiang 150080)

Abstract: Compared with the traditional welding technology, aluminum alloy laser welding has many advantages, but there are still a series of quality problems in welding. Based on the current research status of laser welding technology in recent years, the characteristics of laser welding of aluminum alloy and the quality problems in the process of welding were briefly analyzed, and the corresponding measures for the optimization of laser welding process were put forward.

Keywords: aluminum alloy;laser welding;quality

近年來,激光焊接技術取得了飛速發展,被越來越廣泛地應用到制造業中。與以往的焊接技術相比,激光焊接技術有明顯的優勢,正逐步取代傳統的焊接工藝。鋁合金激光焊接工藝推動了工業的發展,為經濟發展作出了極大的貢獻。

1 激光焊接技術

激光焊接技術是用高能量的激光作為熱源,將金屬熔化后進行焊接[1]。激光焊接技術分為熱傳導焊接和深熔焊接,熱傳導焊接是將高強度的激光束輻射到金屬的表面,利用激光強大的能量將金屬熔化,形成焊縫。深熔焊接是在高功率的激光束照射下,金屬材料發生蒸發現象形成小孔,小孔能有效吸收激光束的能量,將金屬熔化。相較于其他焊接技術,激光焊接技術有許多的優勢。如發射的激光束有很高的密度,蘊含的能量巨大,因而在焊接時有很高的效率。被焊接的工件受熱區域小,不易發生變形,深寬比較大。激光焊接還能進行微型焊接,通過將激光束聚焦能形成較小的光斑,作出精密的定位,從而進行微小型元件的焊接[2]。

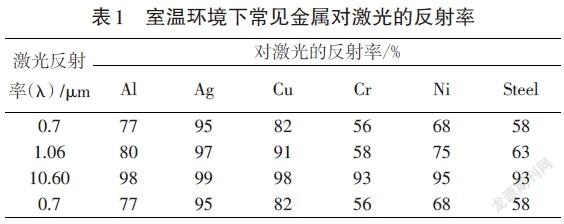

2 鋁合金激光焊接中存在的質量問題