Progress in Technology of Main Liquid Rocket Engines of Launch Vehicles in China

TAN Yonghua ,ZHAO Jian ,CHEN Jianhua ,XU Zhiyu

1 Academy of Aerospace Propulsion Technology,Xi'an 710100

2 Xi'an Aerospace Propulsion Institute,Xi'an 710100

Abstract:Liquid propellant rocket engines for a launch vehicle are an essential aerospace technology,representing the advanced level of hi-tech in a country.In recent years,China's aerospace industry has made remarkable achievements,and liquid rocket engine technology has also been effectively developed.In this article,the development processes of China's liquid rocket engines are discussed.Then,the performance features of China's new generation liquid rocket engines as well as the flight tests of the new-generation launch vehicles are introduced.Finally,the development direction and the most recent progress of the next generation large-thrust liquid rocket engine is presented.

Key words:China's aerospace industry,liquid rocket engine,technology progress

1 INTRODUCTION

The development history of China's liquid rocket engines has evolved through three phases:imitation at the very beginning; independent research; and now comprehensive and innovative upgrading.China's liquid rocket engine family consists of storable propellant engines,cryogenic propellant engines liquid oxygen/liquid hydrogen (LOX/LH2),and high-pressure staged combustion (HPSC) LOX/kerosene rocket engines.

China began to develop the LM-2,LM-3,LM-4 vehicles in the 1970s,using the 750 kN nitrogen tetroxide/unsymmetrical dimethylhydrazine (N2O4/UDMH) rocket engines as the main power units.By virtue of these launch vehicles,satellite launching,manned space flight and lunar exploration programs have been successfully realized.Although the LM-2,LM-3 and LM-4 launch vehicles are still in service and carry out most of the launch missions,the limited launch capabilities confine their application more and more[1].It should be noted,the propellants are not nontoxic or environmentally friendly.China decided to change in the early 1990s,and to develop 1200 kN HPSC LOX/kerosene rocket engine and 500 kN LOX/LH2 rocket engines[2-4].Consequently,the launch capability of the new-generation launch vehicles LM-5,LM-6 and LM-7,using these two types of rocket engines as main power units,has been significantly improved,and will fully undertake the launch missions for China's space station construction program,lunar exploration program and so on[5,6].

Since entering the 21st century,to meet the requirements for human lunar landing,other space programs,and extensive space accesses,China has been demonstrating and making advanced research on lunar landing modules,heavy launch vehicles and their propulsion systems,and has confirmed the development of the 4800 kN LOX/kerosene rocket engines and 2000 kN LOX/LH2 rocket engines[7-16],which will be the key missions of China's large thrust liquid rocket engine development.In this article,the development history and status of China's liquid main power units and technologies are introduced in Section 2.The features of the new generation launch vehicle main power units are particularly analyzed in Section 3.Finally,the development direction and technology of the new generation large thrust liquid rocket engines of the heavy launch vehicles are presented in Section 4.

2 STATUS OF CHINA'S IN-SERVICE LIQUID MAIN POWER UNITS

2.1 Main Power Units of LM-2,LM-3 and LM-4

The LM-2,LM-3 and LM-4 launch vehicles consist of 18 versions in total,of which 13 of them are still in service.The first development phase featured the LM-2,which was modified from strategic missile propulsion technology.Then LM-3,LM-3A and LM-4 were derived following the evolution rules of launch vehicle technologies and requirements,which denote the second development phase.In the third phase,LM-2E was developed to provide commercial launch services.In the fourth phase LM-2F was developed for the manned spaceflight program.The main power units of LM-2,LM-3 and LM-4 include the YF-20(710 kN),YF-40 (49 kN) storable propellant rocket engines,and the YF-73 (44 kN),YF-75 (83 kN) cryogenic propellant (LTP)LOX/LH2 rocket engines (Figure 1),which were developed from the 1960s to the 1980s.These four types of engine,which have successfully performed more than 300 launches,stand as the corner stone of the great successes in the past.

Figure 1 Spectrum of LM-2,LM-3 and LM-4 and their main power units

YF-20,the main engine of the conventional launch vehicles LM-2,LM-3 and LM-4,is a gas generator (GG) cycle N2H4/UDMH engine.It is not only used as a booster in single-engine configuration,but also used in the first stage where quad-engines are parallel connected,and in the second stage as a single-engine with verniers.The LM-3 launch vehicle adds YF-73,a high-energy LTP LOX/LH2 GG cycle rocket engine,in the third stage,whose vacuum thrust is 44 kN,and specific impulse is 420 s.The LM-3A adopts a higher-performance YF-75 LOX/LH2 rocket engine in the third stage,where the YF-75 is composed of two independent engines that are an improved version of the YF-73 by expanding the nozzle area ratio.The engine continues to use GG cycle,and raises the vacuum thrust of the single engine to 83 kN,with a vacuum specific impulse is 440 s.The LM-4 launch vehicles adopt the storable propellant engine YF-40 and is modified in the third stage.The YF-40 uses GG cycle,generating a vacuum thrust of 49 kN,with a vacuum specific impulse of 303 s.

During the development and application of conventional launch vehicles,the basic development processes,namely‘Research & Design -Development & Integration -Test & Verification -Improvement & Redesign',plus a package of research methodologies and development approaches,that are adapted to China's industrial foundation and management,have been explored.These will be the most important assets of China's space industry in the future.

2.2 Main Power Units of the New-Generation Launch Vehicles LM-5,LM-6,and LM-7

2.2.1 Introduction to LM-5,LM-6,and LM-7

China's new-generation launch vehicles such as LM-5,LM-6,and LM-7 completely adopted the new-generation,high-performance,nontoxic and environmentally friendly rocket engines,including YF-100 (1200 kN),YF-115 (180 kN),YF-77 (500 kN),and YF-75D (90 kN),which were developed from middle 1990s[2-7].The four new types of engines have improved China's launch vehicle technology base significantly,enriched China's launch vehicle system,and will contribute to launch vehicle re-generation and become the corner stone of China's space industry in the future.

The 1200 kN YF-100 is China's first oxidizer-rich HPSC rocket engine,and the 180 kN YF-115 is the first HPSC high altitude engine.The 500 kN YF-77 is China's first large-thrust LOX/LH2 rocket engine,and the 90 kN YF-75D is the first expander cycle LOX/LH2 rocket engine,which demonstrates that China has comprehensively mastered GG and the expander cycle technologies of LOX/LH2 rocket engines.The first test flights of the LM-5,LM-6,and LM-7 were all successful.The launch capacity of LM-5 to low Earth orbit (LEO) has been increased to 25 tons.

Figure 2 The main engines of LM-2,LM-3 and LM-4

Table 1 Performance of the main engines of the in-service storable propellant launch vehicles

Figure 3 Spectrum of the new-generation launch vehicles and their main power units

LM-6,a two-stage launch vehicle,was designed to launch small satellites,with a payload capacity of 500 kg into 700 km solar synchronous orbit (SSO).The first stage uses one YF-100 engine,and the second stage adopts one YF-115 engine.The launch vehicle features nontoxic,and short launch preparation time.The first flight was carried out successfully on September 20,2015.

LM-7 is a two-and-a-half-stage launch vehicle,which is nontoxic and of high reliability and is to be used to launch cargo spacecraft for China's Manned Space Program.The LM-7 propulsion system consists of one dual YF-100 in the core stage,one quad YF-115 in the second stage,and four single YF-100 for boosters,which can launch 13.5 tons payloads into LEO,or 5.5 tons payloads into geostationary transfer orbit (GTO).Its maiden flight test was carried out successfully on June 25,2016.

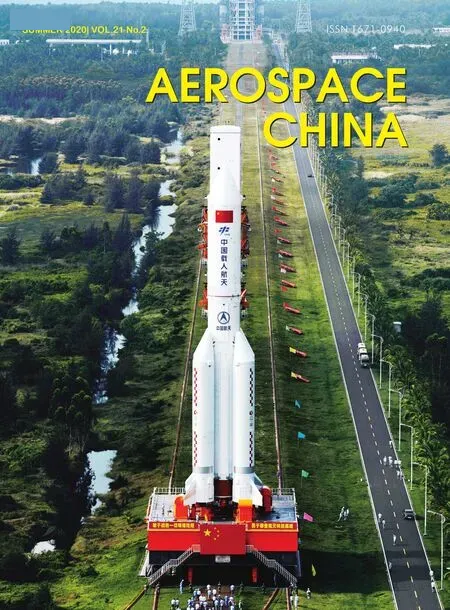

Table 2 China's new-generation launch vehicles

LM-5 is a two-and-a-half-stage launch vehicle,whose power units include two YF-77 engines in the core stage,two YF-75D engines in the second stage,and 8 YF-100 engines in four boosters.It is able to launch 25 tons payloads into LEO,or 14 tons payloads into GTO.LM-5 conducted its maiden flight successfully on November 3,2016.However,the second flight failed on July 2,2017.During the following two years,a series of investigations and tests were conducted to resolve the issues regarding the structural robustness of the oxygen turbo-pump.On December 27,2019,LM-5 conducted its third flight successfully,which validated the investigations and optimizations.Furthermore,LM-5B which was modified from LM-5,with a one-and-a-half-stage configuration,was launched successfully on May 5,2020.

2.2.2 Features of the new generation main powers

YF-100 is a large-thrust,high-performance,nontoxic,and highly-reliable LOX/kerosene rocket engine[3].It adopts an advanced oxidizer-rich combustion cycle stage and self start scheme,and has the capacity for regulating a wide-range of thrust and mixing ratio.Many key technologies were developed,such as the system design of the high pressure oxidizer-rich combustion cycle LOX/kerosene rocket engine,start and reliability control of the staged combustion engine,wide-range thrust regulating,high-power and a high-efficiency turbopump,large-flow high-efficiency and steady combustion,reliable cooling technology of the thrust chamber,new material applications and technics.During the research and manufacture process,more than 50 new materials were developed,and about 110 new techniques were applied in the engineering.The YF-100 engines were tested for over 57,000 seconds,with more than 2000 seconds of accumulative test time with one single engine before the LM-5's first flight.

YF-115 was designed as a nontoxic,high-performance,and highly-reliable upper stage LOX/kerosene engine.It adopts a staged combustion cycle and exterior energy start scheme,thus enabling it to start up twice quickly and works with low inlet pressure.

YF-77[4],a pump-fed GG cycle LOX/LH2 rocket engine,is used as the main power unit of the LM-5 with a dual engine module.During the research process,43 key technologies,such as steady combustion,cooling of the high-pressure largescale chamber,high-performance and high-specific-power multi-stage hydrogen turbopump technology,high-performance steady combustion injector,cooling of the large heat flux thrust chamber,were developed and improved.Before LM-5's first flight,YF-77 had been tested for 38,000 seconds,with a single test engine conducting 15 starts.

The YF-75D LOX/LH2 rocket engine is used in the second stage of the LM-5 in a dual-engine module.The engine adopts a closed expander cycle,and the specific impulse is the highest in China.It significantly simplifies the system by removing the gas generator and its co-system,as a result,the reliability of YF-75D is improved.During YF-75D's development,re-start technology at high attitude,system design of a closed expander cycle,heat transfer from the thrust chamber,amongst other technological improvements,were successfully implemented.

Figure 5 YF-77 and YF-75D LOX/LH2 rocket engine

During engine R&D,a lot of new research methods,manufacture techniques,test and measurement approaches were introduced or developed.The traditional R&D mode was innovated by applying three-dimensional structural design,simulation and a digital design platform system.Additive manufacturing,automatic welding,and laser holography detection were widely applied to increase efficiency,precision and quality.Besides,a large number of fundamental issues,such as spray combustion,fluid-structure interaction,mechanical and thermal strength were studied in depth.Moreover,the valve semi-physical simulation tests,turbo cold flow tests,bearing and sealing rotating tests and research were strengthened and refined.A new R&D mode for the liquid rocket engine,featured digital design,advanced manufacturing,sub-system verification,gradually matured,contributing to innovation and development for the future.

3 RECENT PROGRESS OF CHINA'S LIQUID MAIN POWER UNIT

3.1 YF-100 Modifier Engine

YF-100 has been continuously modified and improved in recent years,by developing and applying swing-after-pump thrust vector regulation,vibration damping technology for the high-pressure large-flow turbopump,electromechanical servo flow-regulator and control technology,etc.Especially,the swingbehind-pump thrust vector regulation can decrease the swing moment by 50%,as a result,the ratio of thrust to mass increased by 15%.In addition,the swing space can be decreased in the multi-engine parallel connection configuration,with the result that a 5 m-diameter launch vehicle can hold 7 engines in a parallel connection configuration.The modifier thrust at sea level increases to 1250 kN,and the specific impulse increased to 302 s.The modification project started in 2016.The first engine tested successfully for 50 seconds in May 2017.To date,it has successfully passed 11 tests,and cumulated 3,600 seconds operation in total

Figure 6 YF-100 modifier and hot test

3.2 4800 kN LOX/kerosene Rocket Engine

With the implementation of the manned spaceflight program,lunar exploration and other space programs,and for large-scale deep space exploration,human lunar landing,and the space station program,as main tasks to be undertaken by China's space industry,a heavy launch vehicle was imperative.It was conceived that the heavy launch vehicle's boosters and core first stage will adopt a 4800 kN LOX/kerosene rocket engine,the second stage will adopt 2200 kN staged combustion LOX/LH2 engines,and the upper stage will adopt 250 kN LOX/LH2 engines[8-16].

China started to demonstrate the large thrust LOX/kerosene engine in 2010.In August 2016,the precombustion chamber and turbopump joint hot test was successfully conducted for 6 seconds at 70% of planned working conditions.It has now finished 3 precombustion chamber and turbopump joint tests.In June 2019,the first prototype of the whole engine was produced.

Figure 7 4800 kN LOX/kerosene engine combined turbopump-precombustion chamber test

There were a large number of key technologies to be researched[12],such as step start-up technology,the swing-behindpump thrust vector regulation for a large thrust LOX/kerosene engine,high-pressure,high-performance and large-flow combustion assembly,a large-power high-performance turbopump,high-pressure large-flow regulator and low-temperature valves,hot test,health management,operation and maintenance,adaptability to the mechanical and thermal environment.

3.3 2000 kN LOX/LH2 Rocket Engine

The 2000 kN LOX/LH2 staged combustion cycle engine[10,11],designed with a 453 s specific impulse,will be used for the heavy launch vehicle's second stage.It can be seen from the development history of China's LOX/LH2 engines that the technology path is from the GG cycle to expander cycle,then to the more advanced staged combustion cycle,and the trend is for higher thrust,higher specific impulse,and more an advanced cycle type.

For the 2000 kN LOX/LH2 staged combustion cycle engine[13-16],the key technologies include control technology during start-up and shut-down processes,regulating a wide-range of thrust,high-pressure hydrogen and oxygen turbopump,long-life thrust chamber body heat transfer,super-scale high-performance nozzle extension,new materials and manufacturing,static and dynamic sealing,plus hot test.

Following the demonstration,a reduced-scale pre-burner had been tested 10 times,and a reduced-scale combustion chamber and reduced-scale thrust chamber had been tested 6 times in 2018.In June 2019,four hot tests for the full-scale pre-burner were performed,which marked a breakthrough for large-flow pre-burner technology.At the same time,the hydrogen and oxygen turbopump,and pre-pressurization turbopump were tested in a liquid nitrogen atmosphere[15,16].

Figure 8 2000 kN LOX/LH2 engine and key technology verification test

3.4 LOX/methane Rocket Engines

From the 1980s,China started to research the technology of liquid oxygen and hydrocarbon (e.g.kerosene,methane)rocket engines,and achieved the combustion and heat transfer performance for kerosene and methane[17-18].The key technologies of LOX/methane rocket engines have been investigated since 2005.During the following ten years,the LOX/methane gas generator and thrust chamber were verified several times.At the same time,a LOX/methane rocket engine was developed based on LOX/LH2 technologies,and a 600 kN LOX/LH2 engine was tested successfully.

In recent years,the LOX/methane engines draw more and more attention,with U.S.commercial space companies developing the Raptor and BE-4 LOX/methane engines.China is developing 2000 kN LOX/methane rocket engines,which will be used as main power units for the space transportation system,capable of reuse for more than 50 times.In parallel,Chinese commercial space companies have focused on LOX/methane engines as well,with 800 kN and 150 kN LOX/methane engines passing hot tests.

4 CONCLUSIONS

According to the short-term,medium-term,and long-term development plans,China is entering an intensive launch period.The development of China's liquid main power unit technology keeps to the rule which is “one generation in service,one generation standing by,and one generation in research”.Facing the new challenges,the development of liquid main propulsion and power in China features the following.

In the near future,storable propellant launch vehicles will continue to undertake major launch missions,so it is important to enhance quality control systems to ensure the quality and stability of the engines.

The new-generation launch vehicles will play a more important role.Engine reliability and adaptability improvement should be focused on continuously,as well as engine performance optimization.

The 4800 kN LOX/kerosene and 2000 kN LOX/LH2 engines are under development,which will be the main power units for the future heavy launch vehicles.The 4800 kN LOX/kerosene engine has already been successful with several combined turbopump-precombustion chamber tests.

LOX/methane engines are becoming a research hotspot for their potential benefit of being reusable and for in-situ propellant preparation,which may support missions like Mars exploration and future space flights.

- Aerospace China的其它文章

- The LM-2D Launch Vehicle is Being Hoisted

- Maiden Flight of the LM-5B Carrier Rocket

- LM-11 Launched Two New Technology Experimental Satellites

- LM-2D Carried Two Satellites into Space

- LM-2C Launched HY-1D Satellite Successfully

- LM-2D Successfully Launched Three Satellites into Orbit on One Launch