基于隱式參數(shù)化耦合模型的車身集成優(yōu)化

梁紅喜 孫輝 吳澤勛 蔡劍 王德遠 彭弼安

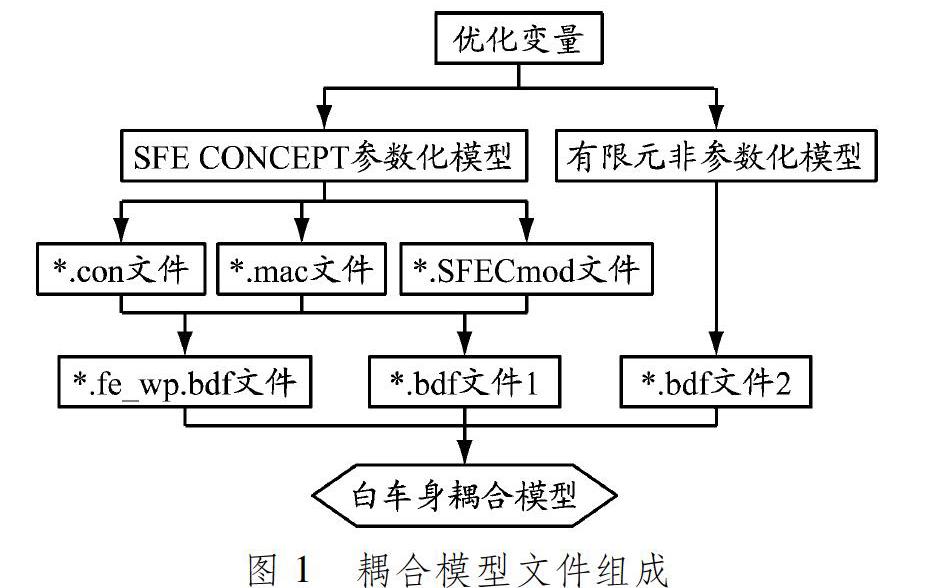

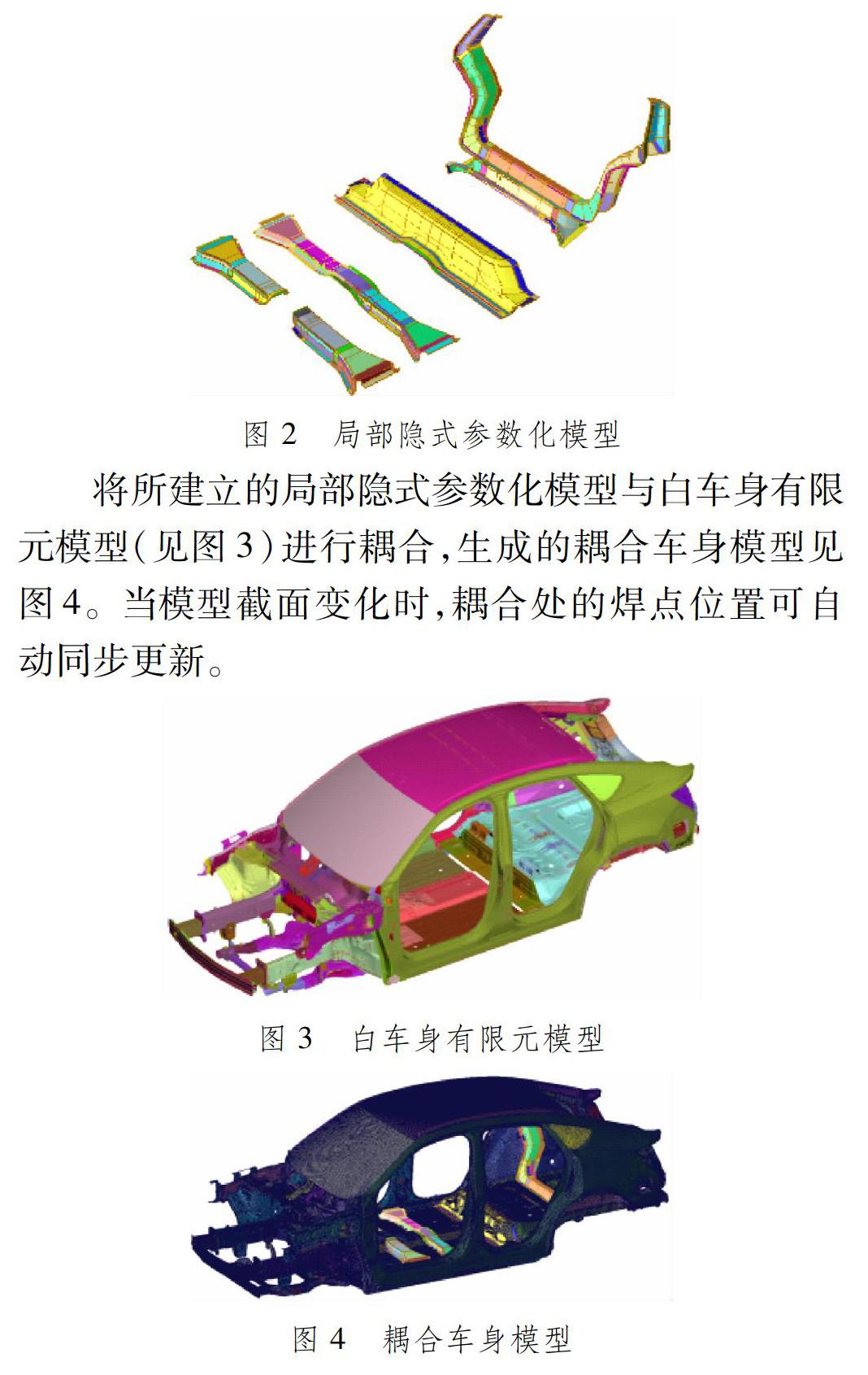

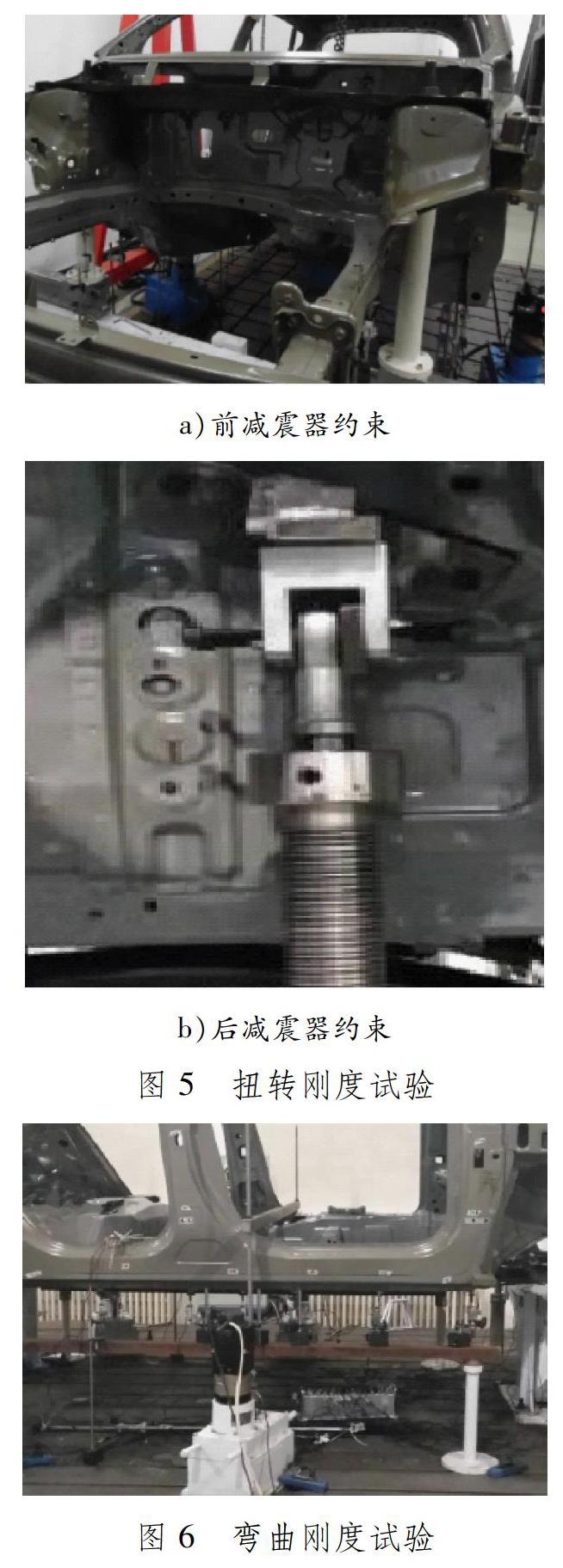

摘要: 為提高車身截面優(yōu)化效率,基于SFE CONCEPT構(gòu)建白車身關(guān)注部位的隱式參數(shù)化模型,并與白車身有限元非參數(shù)化模型進行耦合,使參數(shù)化模型與有限元模型耦合邊界處的連接關(guān)系隨截面變化自動更新,通過試驗驗證耦合模型的有效性。基于試驗設(shè)計(design of experiments, DOE)方法、近似模型、多目標(biāo)優(yōu)化等策略,對白車身耦合模型進行剛度和模態(tài)等多學(xué)科集成優(yōu)化,實現(xiàn)車身局部結(jié)構(gòu)快速輕量化設(shè)計。

關(guān)鍵詞: 車身; 隱式參數(shù)化; 模型耦合; 多學(xué)科優(yōu)化; 輕量化

中圖分類號: TP391.92; U462.3 ? 文獻標(biāo)志碼: B

Abstract: To improve the efficiency of vehicle body section optimization, the implicit parametric model of interesting locations of body in white is built based on SFE CONCEPT. The model is coupled with the non-parametric finite element model of body in white, and then the connection relationship between the coupling boundary of the parametric model and the finite element model is updated automatically with the change of the section. The validity of the coupling model is verified by tests. Based on the design of experiments(DOE) method, approximate model, multi-objective optimization and other strategies, the multi-disciplinary integrated optimization of stiffness and mode is carried out on coupling model of body in white. The fast lightweight design of local structure of vehicle body can be realized.

Key words: vehicle body; implicit parameterization; model coupling; multi-disciplinary optimization; lightweight

0 引 言

在新車型開發(fā)中,如何在縮短研發(fā)周期的同時兼顧輕量化設(shè)計,已成為汽車企業(yè)的核心競爭力之一。[1-2]在早期的車型項目開發(fā)中,對多種拓撲設(shè)計方案進行快速預(yù)研分析并確定優(yōu)化方案,可實現(xiàn)仿真驅(qū)動設(shè)計,提高新車型開發(fā)效率。在車身快速優(yōu)化方面,諸多學(xué)者基于隱式參數(shù)化建模,結(jié)合多學(xué)科集成優(yōu)化設(shè)計方法進行研究[3-5],并在整車參數(shù)化建模和優(yōu)化方面取得一定成果。在車身局部結(jié)構(gòu)截面優(yōu)化方面,基于隱式參數(shù)化模型自動耦合有限元非參數(shù)化模型進行多學(xué)科集成優(yōu)化,同時考慮耦合模型拓撲連接關(guān)系自動優(yōu)化的研究較少。

借鑒現(xiàn)有研究成果,本文在某新車型設(shè)計階段引入隱式參數(shù)化建模技術(shù),對車身所需優(yōu)化結(jié)構(gòu)進行隱式參數(shù)化建模,并與白車身有限元非參數(shù)化模型進行耦合。在保證耦合模型邊界處拓撲連接關(guān)系準(zhǔn)確性的基礎(chǔ)上,通過試驗驗證耦合模型的有效性。……