大疆總部,深圳,中國

建筑設計:福斯特及合伙人建筑事務所

圖1 外景渲染/Exterior rendering

部件的組合:大疆總部預制施工的益處

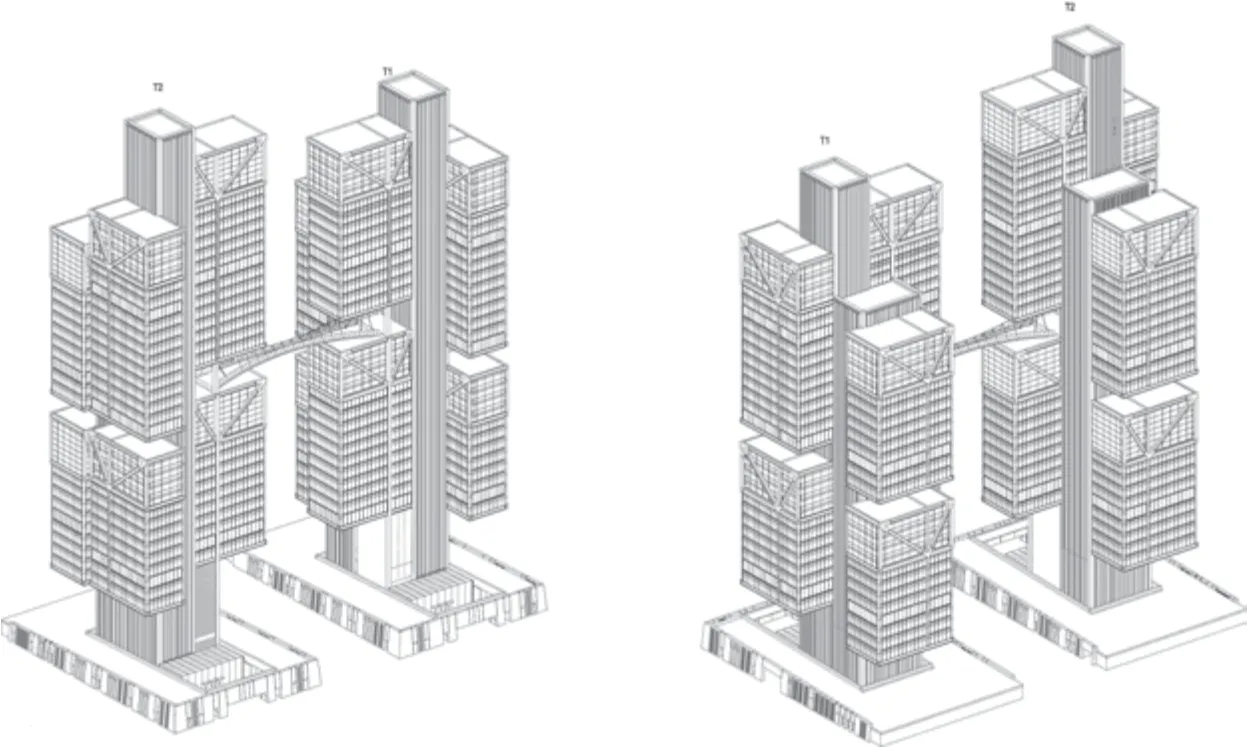

世界領先的機器人公司大疆的新總部位于深圳西南的南山區。這座新建筑的目標是成為公司“創新的核心”,挑戰辦公空間的傳統理念,并構成一個空中的創意社區。

總部功能包括辦公樓、研發中心、測試區和城市公共設施。建筑體量懸浮在地面之上,裙房屋頂設有一系列花園,將周圍的綠景引入基地內。從極簡主義的禪苑出發,它們被設計為靜思的區域,讓創意人才在此能夠恢復精力、重振一新。

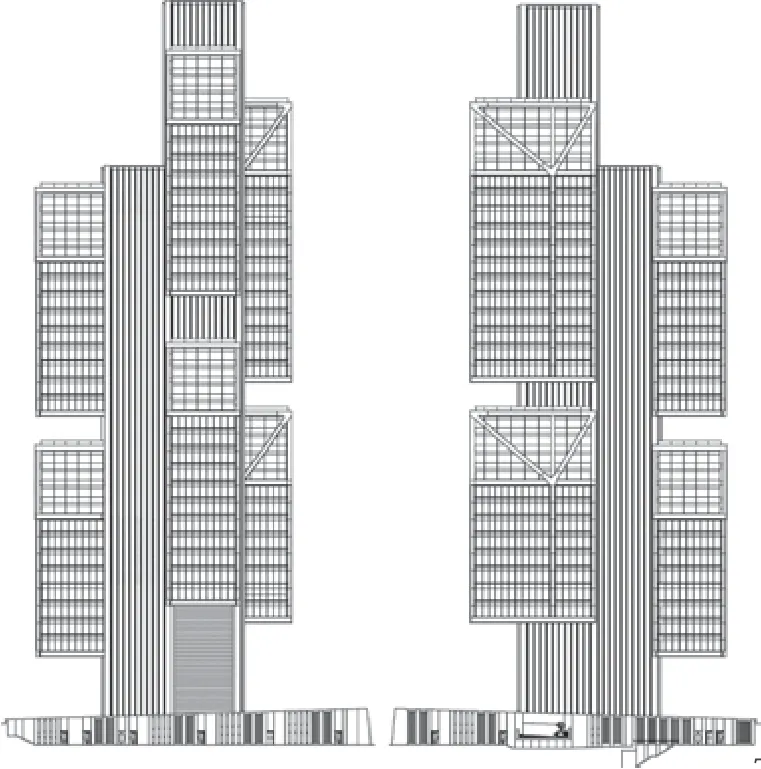

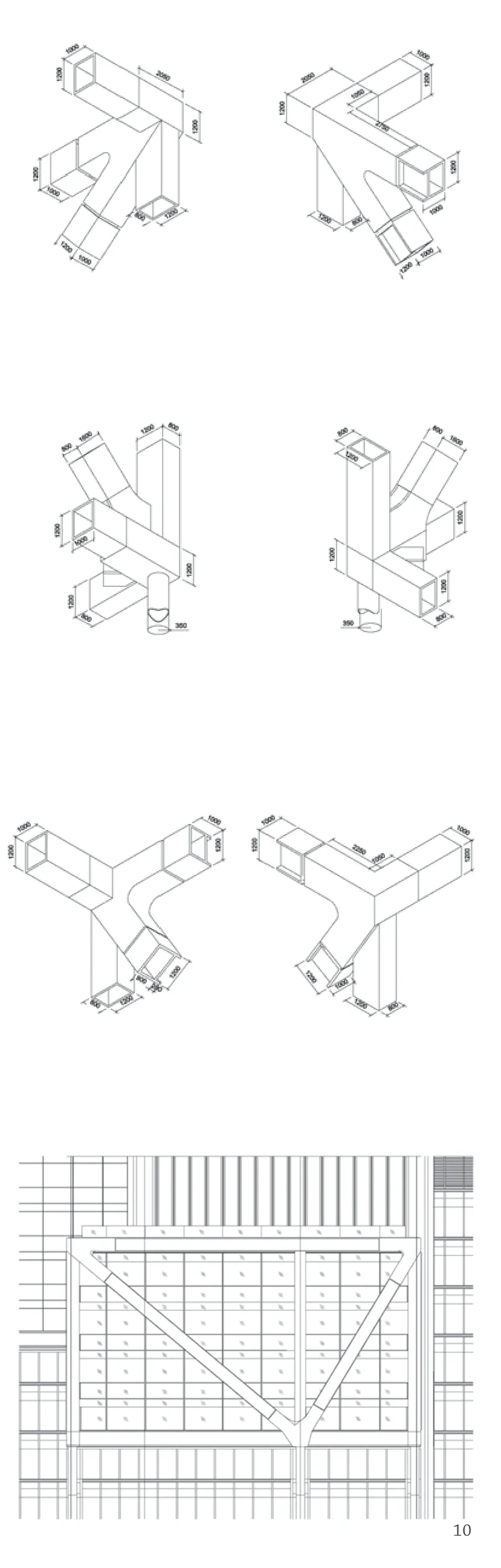

上方雙塔的辦公和研究空間被放在從中心核由巨型桁架和圓截面的鋼吊管挑出的懸空體塊中。這種創新性的懸掛結構減少了所需的柱子,從而形成了令人印象深刻的連續辦公和研究空間。它也能容納大疆獨有的4 層高的無人機試飛室,并賦予了塔樓在城市天際線襯托下的鮮明形象。所有鋼結構都暴露在外,增加了塔樓的獨特表達。

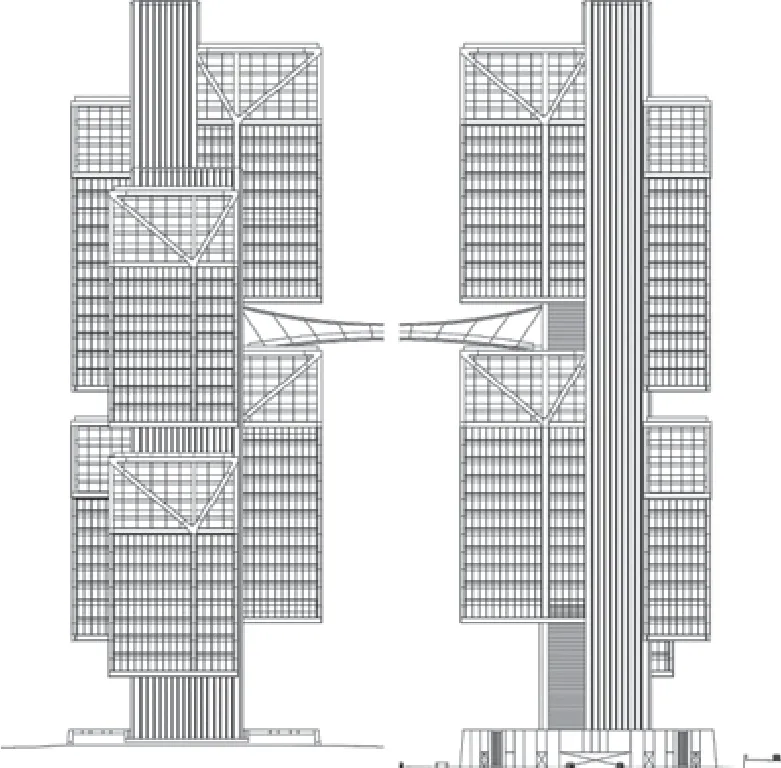

位于懸空體塊頂部的空中花園為大疆員工提供了可以享受的私密花園。這兩座塔樓由一座特別的“天橋”連接,而它與空中花園一同成為展示最新無人機技術的另一個平臺。

大疆的預制元素

建筑中有許多預制元素,包括幕墻系統、裙房立面上的花崗石板,以及橫跨雙塔的“天橋”。

預制的一體化幕墻系統由多個相同的單元組成。每個單元都在工廠中預制并預裝玻璃,然后在現場組裝。預制之所以更受歡迎是因為這些單元能在工廠里進行雙面密封,以獲得高標準的水密性和氣密性,并將保溫材料與玻璃安裝整合起來。

預制還能實現高精度。裙房立面的花崗石板都分配了唯一的二維碼,以跟蹤每塊石板的位置,并保證安裝正確。BIM 云服務用于為立面系統的安裝提供信息,并提供實時反饋。

橫跨在雙塔之間的90m“天橋”分3 個部位預制,然后在距地面110m 處現場吊裝。通過預制,設計團隊成功地用光滑的完成面表達出復雜的幾何形體。預制在質量控制中實現了高精度,并將誤差縮小到幾毫米。

預制為該項目帶來了許多益處。從施工管理看,它減少了現場工人的數量,實現了更好的工地管理。立面系統的裝配如今可以同鋼結構施工重疊,使工期縮短了約7 個月。

預制還有許多可持續性方面的益處。根據最近的研究,建造業消耗了全世界40%的能源。預制立面系統單元由建筑維護單元(BMU)吊起,再由建筑里的工人安裝。這就不再需要腳手架,并減少了用鋼量和能耗。整體外墻系統(EWS)和超過70%的內墻系統(IWS)都是無砌體、無灰泥的——二者都是建筑垃圾的主要成分,對環境有負面影響。此外,現場沒有使用密封劑,將化學污染物排放降到了最低程度。

圖2 外景渲染/Exterior rendering

上文列舉的所有益處都是在沒有顯著增加建筑材料數量或總成本的情況下實現的。這就讓預制成為大疆總部項目的首選。

福斯特及合伙人建筑事務所的合伙人邱維煬表示:“我們堅持不懈地探索在設計和施工階段實現更好品質和更高效率的創新之路。我們同大疆及多個顧問團隊緊密合作,努力在我們設計的每個元素上都實現這個目標——從建筑、室內設計到照明和景觀。這種密切合作也保證了高品質的成果以及創紀錄的施工速度。”□(尚晉 譯)

圖3 透視/3 D Perspective

A Kit of Parts: The Benefits of Prefabrication During the Construction of DJI Headquarters

The new headquarters for DJI, the world's leading robotics company is located in Nanshan District, to the southwest of Shenzhen. The new building is set to be the "heart of innovation" for the company, defying the traditional idea of office spaces to form a creative community in the sky.

The building functions including office, R&D labs, testing zones and city amenities. The building mass hovers above the ground level to allow a series of gardens on the podium roof that draw the surrounding greenery into the site. Based on minimalist zen gardens, these are designed as contemplative zones where the creative talent can refresh and reboot.

The office and research spaces in the two towers above are arranged in floating volumes cantilevered from central cores by large megatrusses and circular profiled steel hangers. The innovative suspension structure reduces the need for columns, thus creating impressive and uninterrupted office and research spaces. It also allows for quadruple-height drone flight testing labs that are unique to DJI,while giving the towers their distinctive identity,against the backdrop of the city's skyline. All the structural steelworks are exposed, adding to the tower's unique expression.

Located on the top of the floating volumes,the skygardens provide private gardens for the DJI staff to enjoy. The towers are linked by a feature"sky bridge", which, along with the skygardens will become another platform for showcasing the latest drone technology.

Prefabricated Elements at DJI

There are several prefabricated elements in the building, including the curtain wall system, the granite panels on the podium fa?ade and the "Sky Bridge" that spans across the two towers.

The Prefabricated unitised curtain-wall system consists of multiple identical units. Each unit is prefabricated and pre-glazed in factory and assembled on site. Prefabrication was preferred as the units could be double-sealed in factory to achieve a high-standard of water and air tightness,integrating insulation with the glazing.

圖4 內景渲染/Interior rendering

圖5 平面/Plan

圖6 內景渲染/Interior rendering

圖7 剖面/Section

圖8 立面/Elevation

Prefabricated for precision, the podium fa?ade granite panels have been allocated a unique QR code label to track each panel and ensure it is installed correctly. A BIM cloud service is being used to inform the installation of fa?ade system, providing real-time feedback.

The feature "Sky Bridge" which spans 90 metres between two towers has been prefabricated in three separate sections and hoisted and assembled on sit 110 metres above ground. Through prefabrication,the design team has managed to resolve its complex geometry with a smooth and sleek finish. It has allowed precision in quality control as the tolerance was brought down to a few millimetres.

Prefabrication has had several benefits for the project. In terms of construction management, it has reduced the number of construction workers on site allowing better ground management onsite.The installation of fa?ade system can now overlap with the construction of the steel structure, which shortens the construction stage by approximately seven months.

It has several sustainability benefits as well.According to recent research, the construction industry accounts for 40% of worldwide energy usage. The prefabricated fa?ade system units are hoisted by BMU and installed by workers inside the building, eliminating the need for scaffolding and reducing steel tonnage and energy usage.The entire external wall system (EWS) and more than 70% of internal wall system (IWS) are nonmasonry and plaster-free, both of which are big contributors to building waste and therefore have a negative environmental impact. In addition, onsite application of sealant is avoided, minimising the emission of chemical pollutants.

All the benefits listed above have been achieved without a significant increase in building material quantity or overall cost, making prefabrication the preferred choice for the DJI Headquarters project.

Young Wei-Yang Chiu, Partner, Foster +Partners, said "We are always looking for ways in which we can innovate and achieve better quality and efficiency in the design phase as well as during the construction phase. We have been working very intensely with DJI and the various consultant teams to achieve this for each of the components we designed, from architecture, interior design through to the lighting and the landscaping. This close collaboration has also made it possible to ensure the high quality of work whilst maintaining a record speed of construction. "□

圖9 建造過程實景/Construction process

項目信息/Credits and Data

客戶/Client: 大疆/DJI

主持建筑設計/Principal Architect: Foster + Partners

設計團隊/Design Team: Grant Brooker, Young Wei Chiu,Takuji Hasegawa, Jolanda Oud, Yunfu Yi, Edin Gicevic,Andres Harris, Aquilino Fernandez Lopez, Pavan Birdi,Saman Ziaie, Ben Mowat, Julio Alberto Garcia Pizarro,Theodora Maria Moudatsou, Nina Haylock, Lindsay Duncan,Matt Morris, Alejandro Gavira Fernandez, Wolfgang Muller,Tulin Kori, Carlo Pedata, Maude Pinet

合作設計/Collaborator: CAPOL

顧問/Consultant: ARUP

裝配式部件及材料/Prefabricated Parts & Materials: 外立面玻璃板,裙樓外立面花崗巖板,天橋/Fa?ade glazing panels, podium fa?ade granite panels, Sky Bridge

裝配率/Percentage of Prefabrication: 100%外墻系統+70%

內墻系統/100% of EWS + 70% of IWS

項目面積/Project Area: 160,000 m2

建筑面積/Floor Area: 2511 m2

設計周期/Design Period: 2016.05–2017.08

建造周期/Construction Start Time: 2017.01

預計建成時間/Anticipated Completion Time: 2021.12

繪圖/Drawings: Foster + Partners

照片來源/Construction Photos Courtesy: 大疆置業/DJI Land

圖10 鋼結構細部/Steel structure detail

圖11 -13 建造過程實景/Construction process