Battery Full Life Cycle Management and Health Prognosis Based on Cloud Service and Broad Learning

Yujie Wang,, Kaiquan Li, and Zonghai Chen, Senior

Dear editor,

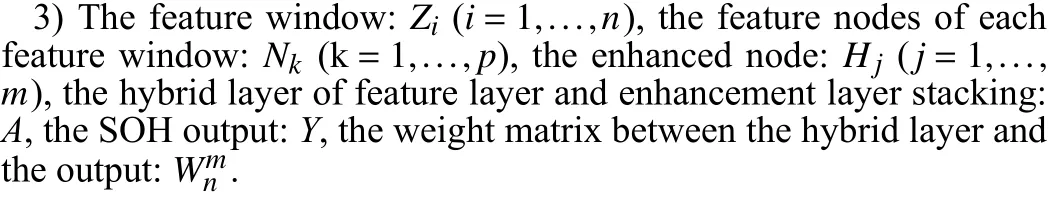

This letter presents battery full life cycle management and health prognosis based on cloud service and broad learning. Specifically, a cloud-based framework for battery full life cycle management is presented. Then, the broad learning method is proposed for battery state-of-health (SOH) prediction. The features of charging data including the constant current time, constant voltage time, and the total charging time are selected as the input characteristics of the network to estimate SOH. Moreover, the empirical mode decomposition is carried out on the initial data to restore the most essential attenuation trajectory of battery capacity. Experimental results show that the proposed method can provide more accurate battery SOH prediction than several state-of-the-art methods.

Lithium-ion batteries are now widely used in the applications of electrified transportation [1], smart grid [2], and smart buildings. The degradation of lithium-ion batteries has restrictions of the energy and power capability, as well as the performance of the cost and lifetime.Therefore, battery degradation has been a critical issue in energy storage applications. The whole life cycle management and health prognosis of battery systems have become hot and difficult issues in battery management. The future battery management system should be deeply integrated with intelligent algorithms and networked services to provide more reliable prediction and diagnosis results [3].

In the practical application, batteries will inevitably experience gradual performance fading during its lifetime and their performance degradation is influenced by the factors including battery manufacturing, operation, and environmental conditions. Specifically, the manufacturing process will first determine the initial performance of the battery. High performance batteries will then be used in a wide range of electronic applications until their capacity reach 80% of their nominal capacity and are taken out of service. During the battery full life cycle, a wide range of overcharging and over discharging, internal or external short circuits, may damage the battery and even lead to thermal runaway, combustion, and explosion[4]. Therefore, effective battery management becomes essential.

The traditional battery management system without aging information storage function is difficult to effectively estimate the battery life. In addition, the artificial intelligence-based battery life prediction algorithms also require large computational capability.Therefore, it is necessary to expand the functions of the traditional battery management system by using cloud computing and big data storage. Fig. 1 presents a cloud-based framework for future battery management system.

Related work: Significant studies have been devoted to solving the problem of life prediction of battery performance which can be classified into three categories: mechanism-based, feature-based, and data-driven approaches.

Fig. 1. Cloud-based framework for battery management.

The mechanism-based prediction approaches require the study of the effect of each aging factor on battery degradation. This approach begins with a physics-based model. Then, the law of aging process influence on state variables can be studied. The mechanism-based life prediction method is applicable to batteries in almost all state conditions and operation modes. A detailed explanation of the battery aging process is given, which can be used by battery manufacturers and designers for battery design improvement. Wanget al. [5]proposed a single-particle based degradation model for lithium-ion batteries which can predict the battery cycling capacity with less than 2% error. Compared with other methods, the analysis of battery control strategy based on this approach can be more detailed and accurate. The disadvantages of this approach are that the model requires fine parameters and has high complexity. Moreover, the tests for aging factors are complicated, and there are difficulties in establishing a perfect aging mechanism model.

The feature-based life prediction approaches use the evolution patterns of the feature parameters exhibited during the battery aging process to establish the correspondence between the values of the feature quantities and the battery health state for life prediction. The feature-based battery life prediction mainly focuses on the characteristics of charging data and electrochemical impedance spectroscopy(EIS). Renet al. [6] presented a battery life prediction method by using impedance spectra analysis. Experimental results showed that the prediction errors are within ±5%. The EIS can give a more detailed description of the battery impedance, which can be used to estimate the battery life characteristics. However, it requires special measurement instruments. The pulse impedance measurement is another approach which is simple and can be measured quickly online. The test results can describe the impedance of the battery to a certain extent, reflecting the growth of battery impedance with the decay of life, and can also be used as battery life characteristics.

The data-driven approaches describe the battery recession performance from the perspective of the test data, and the commonly used algorithms include support vector machine (SVM), Gaussian process regression (GPR) [7], neural networks (NN) [8], etc. Liet al.[9] proposed a machine-learning-enabled data-driven model for battery SOH prediction by using GPR. The proposed technique is promising for battery SOH prediction under various cycling cases.Wanget al. [10] proposed an on-line synthesis method to estimate the battery SOH and remaining useful life. Specifically, the fusion of partial incremental capacity and artificial neural network (ANN) are helped for the health prognosis. The data-driven prediction approach does not require mechanistic knowledge of the object system and is a more practical prediction method based on the collected data. This approach can be predicted by mining the implicit information through various data analysis and learning methods, thus avoiding the complexity of model acquisition.

Problem statement: Conventional neural network algorithms rely on the quantity and quality of the aging data. Complicated topologies are usually required to ensure enough accuracy, which leads to complex parameter optimization. Moreover, pe-life data batches are too small to achieve accurate estimates and as the time scale lengthens, the model parameters are updated dynamically with the increase of data volume only through the time-consuming retraining process.

Basic concepts:

1) The definition of SOH: The ratio of the current available capacity to the nominal capacity.

2) Multi-metric features during battery charging process: Constant current time with its corresponding proportion, constant voltage time with its corresponding proportion, and the total charging time.

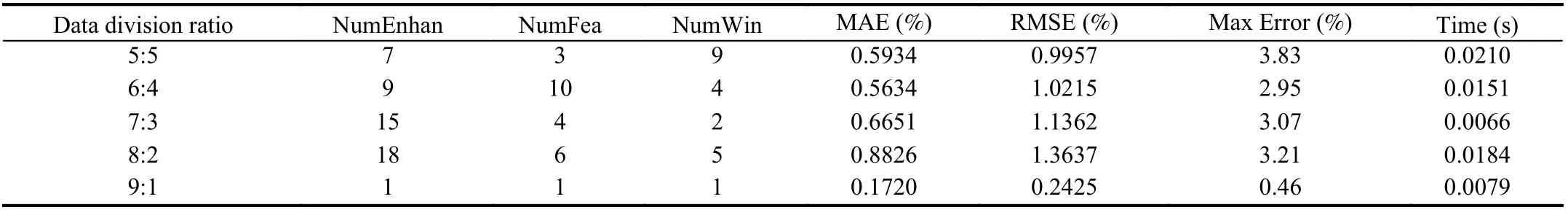

4) Data division ratio: training datasets/ testing datasets, NumEnhan: number of enhancement nodes, NumFea: number of feature window, NumWin: number of feature node in a feature window.

Proposed prediction model: The broad learning approach is proposed for SOH prediction of lithium-ion batteries, as shown in Fig. 2. The broad learning system (BLS) is developed on the basis of the random vector function linked neural network as an alternative to deep learning (DL) network. Traditional DL networks have complex topological structures and a large number of parameters to be optimized, which will not only lead to time-consuming training process, but also require exponential efforts to achieve better accuracy.In order to alleviate the above problems, BLS uses horizontal expansion to efficiently rebuild the model in an incremental learning way, and its fast-learning characteristics can effectively shorten the long training process without causing catastrophic forgetting.

Fig. 2. BLS-based health prognosis for lithium-ion batteries.

wheredandbare composed of pseudo inverse ofAand new data.

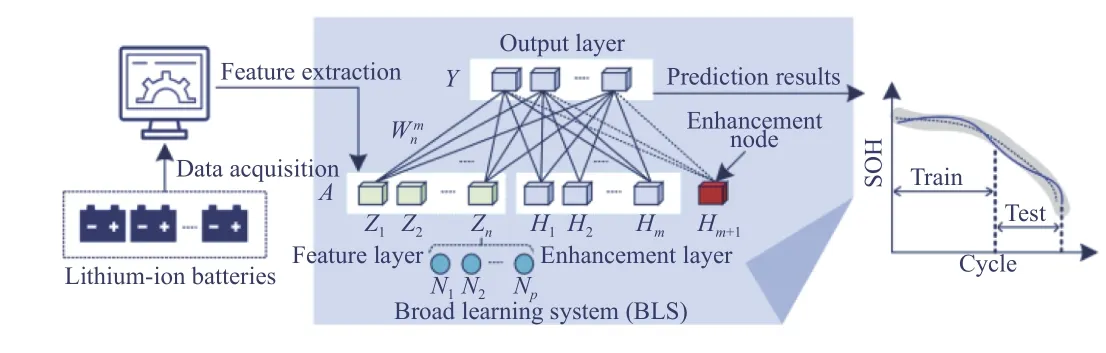

Experiments: In this work, the capacity degradation paths of different datasets are used for the comparison experiments. The corresponding testing conditions including the various C-rate at ambient temperature (25°C). The cells with 2.5 Ah rated capacity were chosen to conduct constant current (CC) discharging and constant current constant voltage (CCCV) charging with cut-off voltages of 3.0 V and 4.2 V, respectively. The different operating profiles are introduced in detail, listed in Table 1, and the experimental setup is shown in Fig. 3.

In the practical application process, continuous and variable discharge current with fluctuation will lead to incomplete and unstable discharge process. However, it is easy to obtain regular offset charging curve through fixed charging mode, and extracthealth factors highly related to aging attenuation. To obtain effective capacity attenuation information more comprehensively, constant current time with its corresponding proportion, the constant voltage time with its corresponding proportion, and the total charging time are selected as the input characteristics of the network. In order to eliminate the influence caused by capacity regeneration in the process of battery aging, empirical mode decomposition is carried out on the initial data to restore the most essential attenuation trajectory of battery capacity. By using a fixed width sliding window to carry out rolling decomposition of capacity attenuation data, the data of the test data set can be dynamically input into the estimation model trained offline to realize the real-time online estimation of battery SOH in actual application scenarios.

Table 1.Battery Cycle Aging Experiment Profiles

Fig. 3. The experimental setup.

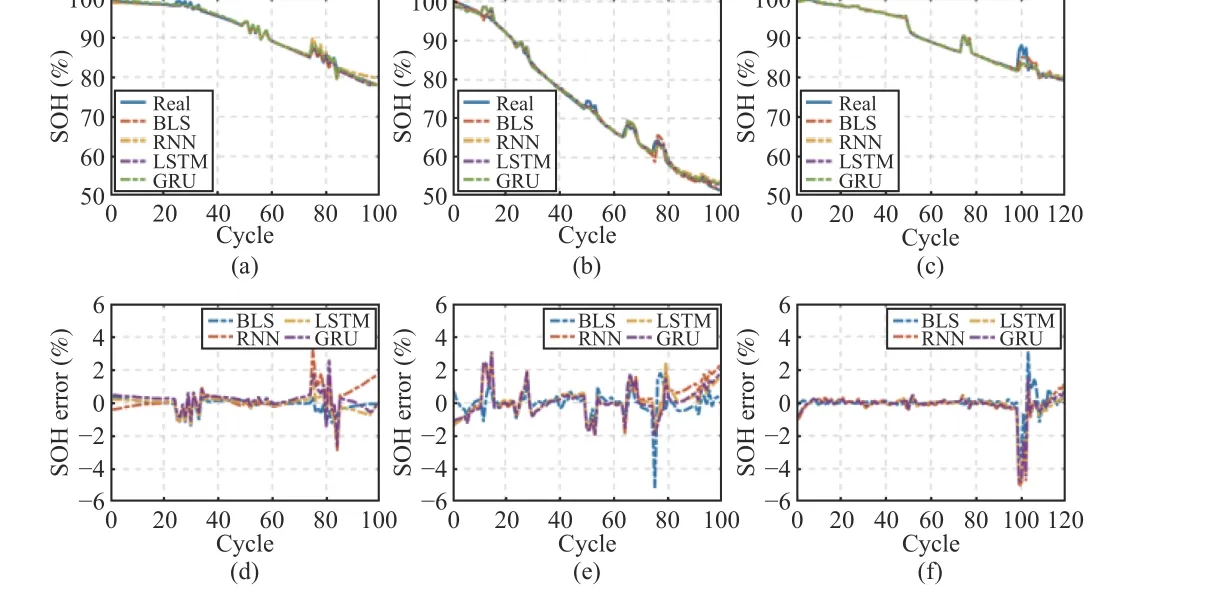

To verify the accuracy of the BLS-based estimation architecture,the aging datasets of different battery are divided into 70% training sets and 30% test sets firstly. Furthermore, three classical algorithms are widely used in the prediction of time series data, including long short-term memory (LSTM) neural network, recurrent neural network (RNN), and gate recurrent unit (GRU). The gate structure endows them with memory function, which are selected for comparison of estimation performance and to emphasize the difference between BLS and the three classical neural networks. The SOH estimation result and error curves of different neural networks for different batteries are shown in Fig. 4.

Fig. 4. The SOH estimation process and error curves of different neural networks for three datasets: (a) and (d) are B01; (b) and (e) are B02; (c) and(f) are B03.

From Figs. 4(a)–4(c), the catalytic effect of charging ratio on battery aging is stronger than that of discharging current by crossreferencing. The capacity regeneration in the aging process changes the capacity decay trajectory to a certain extent. All the selected classical neural networks can follow the sudden change trend with certain estimation accuracy from Figs. 4(d)–4(f).

It is obvious that for the classical neural network algorithms, the prediction errors of both GRU and LSTM are lower than the RNN under the same working conditions, which has proved that the performance enhancing effect of the unique gate structure in GRU and LSTM. Moreover, for datasets under different working conditions, the estimation performance of BLS is not weaker than that of LSTM and GRU, and even better in B03, which corroborate the high accuracy of the proposed estimation model.

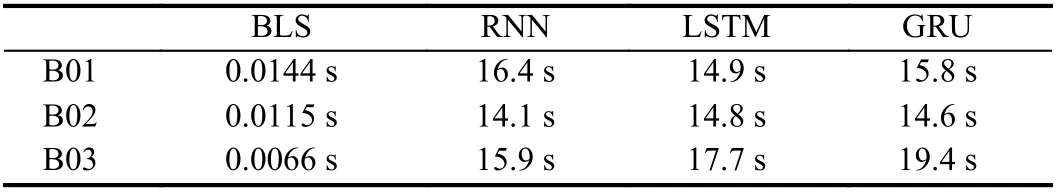

In order to further highlight the superiority of the proposed estimation method, the four neural networks are compared from the perspective of time cost. To make sure the fairness of comparison,the corresponding time of different networks for the same amount of data are shown in Table 2.

Table 2.Time Consumed by Different Networks

As can be seen from Table 2, the classical neural network algorithms have the most complex structure resulting in the longest training time. In contrast, the training time of BLS is much smaller than other neural networks under the three operating conditions,which explains that the weight matrix of BLS is updated much faster than the weight updating algorithms used in conventional neural network, such as back propagation.

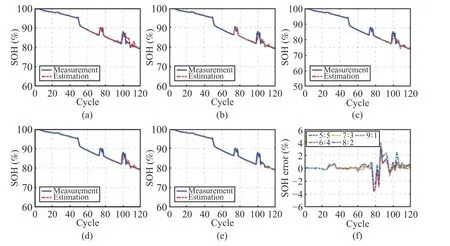

According to the above comparison results, the proposed estimation model based on BLS has good performance in the accuracy and time complexity. To further analyze the impact of data division and the number of network nodes on the performance of BLS, different division ratios are used for the same dataset and grid search is applied to find the optimal number of nodes. The prediction results of BLS and estimation error curves with different data division ratio of B03 are shown in Fig. 5. The optimal combination of the number of nodes with different division results of B03 is given in the following Table 3. The root mean-square error (RMSE), mean absolute error(MAE), maximum error, and time are chosen to portray the performance of BLS from different descriptive perspectives.

Fig. 5. The prediction results of BLS with different data division ratio of B03:(a) 5:5; (b) 6:4; (c) 7:3; (d) 8:2; (e) 9:1; (f) error curves.

Table 3.The Optimal Combination of the Number of Nodes With Different Division Results of B03

The MAE and RMSE of the test set are low under different data division ratios. When the training set accounted for 90%, battery SOH estimation effect of the test set was the best, mainly due to the sufficient information contained in a large amount of training data.When the proportion of training set decreases to 50%, the proposed estimation model can still extract effective attenuation information from limited data. The estimation error MAE and RMSE are 0.5934% and 0.9957%, respectively. The maximum errors in the test data set all occurred in the capacity regeneration stage, but the error size was still maintained below 4%. The total time consumed,including training time and test time, is within 0.1s under different proportions of training sets.

Conclusions: This letter presents a novel approach for the battery health prognosis based on BLS. Experimental results show that the proposed method can provide more accurate battery SOH prediction and faster speed than the conventional neural network algorithms for real-time online estimation. Even in the capacity regeneration stage,the proposed estimation model based on BLS has better performance.As the aging of Lithium-ion batteries deepens, when the model accuracy is insufficient due to the change of aging pattern as the capacity decay data gradually increases, the network structure of BLS can be dynamically extended based on incremental learning in short time so as to maintain high accuracy without the need for timeconsuming retraining process.

Acknowledgments: This work was supported by the National Key Research and Development Program of China (2020YFB1712400).

IEEE/CAA Journal of Automatica Sinica

2022年8期

IEEE/CAA Journal of Automatica Sinica

2022年8期

- IEEE/CAA Journal of Automatica Sinica的其它文章

- Complex-Valued Neural Networks:A Comprehensive Survey

- Visuals to Text: A Comprehensive Review on Automatic Image Captioning

- Cyberbullying and Cyberviolence Detection: A Triangular User-Activity-Content View

- Networked Knowledge and Complex Networks: An Engineering View

- Estimation Based Adaptive Constraint Control for a Class of Coupled String Systems

- Multi-Attention Fusion and Fine-Grained Alignment for Bidirectional Image-Sentence Retrieval in Remote Sensing