石墨烯/聚丙烯腈皮芯結構纖維成型構筑及功能性

摘" 要:為開發新型復合纖維材料,提出以石墨烯為導電基材一步法構筑導電纖維的研究策略,采用微流控濕法紡絲工藝制備石墨烯/聚丙烯腈皮芯結構復合纖維,探究皮層和芯層紡絲液流量對石墨烯取向排列、纖維導電和電熱性能影響規律。通過微觀形貌觀察發現,復合纖維皮層石墨烯取向隨著紡絲液流量的變化呈現先增加后減小的趨勢,皮層流量為0.10 mL/min時石墨烯取向最佳。高度取向的石墨烯賦予復合纖維優異的力學性能和導電性能,使復合纖維的強度和電導率分別達到241.38 MPa和3.94 S/cm。在4 V電壓下,復合纖維表面的溫度達到約48.3 ℃,熱響應速率為2.0 ℃/s。研究表明通過調控不同的皮芯流量,調整復合纖維的結構和性能,可以成功制備出以石墨烯為基材的復合導電纖維。研究結果可為石墨烯復合加熱纖維的開發提供參考。

關鍵詞:石墨烯;微流控;濕法紡絲;導電纖維;電加熱性能

中圖分類號:TS176

文獻標志碼:A

文章編號:1009-265X(2024)12-0001-09

DOI: 10.19398j.att.202403028

收稿日期:20240321

網絡出版日期:20240524

基金項目:山東省重大科技創新工程項目(2023CXGC010612、2023CXGC010504);山東省科技型中小企業創新能力提升工程項目(2021TSGC1189);2023年山東省重點研發計劃項目(2023CXPT022);生物多糖纖維成形與生態紡織省部共建國家重點實驗室項目(ZDKT202008、ZDKT202103);山東省自然科學基金項目(ZR2022QA017);山東省大學青年創新技術計劃創新團隊(2023KJ360);國家自然科學基金項目(12202223)

作者簡介:崔瑞祺(1997—),女,河南商丘人,碩士生,主要從事功能導電纖維方面的研究。

通信作者:房寬峻,E-mail:13808980221@163.com

功能性紡織材料具有柔軟、質輕和智能等特點,引起了研究者的廣泛關注,可為人們的生活帶來極大的便利。導電纖維是功能性紡織材料重要的組成部分之一,具有簡單、安全、高效和可控性能[1-2]。石墨烯是碳原子以sp2雜化軌道組成蜂窩狀晶格的二維碳材料,獨特結構使其在光、電、力學等方面具有優異的性能[3-5],因此石墨烯復合導電纖維成為研究人員關注的焦點。石墨烯纖維的制備方法有濕法紡絲[6]、干法紡絲[7]、干噴濕紡[8]、限域水熱組裝[9]、薄膜卷繞[10]和模板輔助CVD法[11]等。與其他方法相比,濕法紡絲法具有操作簡單、高效和可規模化等特點,是制備石墨烯纖維常用的方法[12]。通過選取合適的石墨烯紡絲方法來設計微觀結構和功能,改善石墨烯的片層易卷曲、相互作用弱的問題,有效地將石墨烯在微觀尺度的優異性能傳遞至宏觀尺度[13-14],最大限度地表達出石墨烯的高導電性、高機械強度和高比表面積等[15-17]。

隨著石墨烯纖維應用領域的不斷擴大,石墨烯纖維的結構和功能與理論預測值仍有較大差異,在實際應用中有很大的改進空間。微流控技術的興起為研究人員制備新型纖維提供新的思路[18],微流控濕法紡絲技術是將微流控技術和濕法紡絲相結合,精確控制纖維形狀和結構組成。與傳統紡絲方法相比,該技術在微平臺上靈活組合多功能組件,賦予纖維的多功能與變化性,且紡絲過程具有連續可控、安全和環保等優點。隨著濕法紡絲系統的優化和制備工藝的完善,石墨烯復合纖維將實現集成、批量、連續生產和制備[19],并將應用于更廣泛的領域。

本文采用石墨烯納米片和聚丙烯腈為混合紡絲液,通過微流控濕法紡絲技術,對纖維的結構進行微觀調控,擬制備一種耐彎折、可電加熱的皮芯導電纖維,并對該纖維的結構形狀、力學性能、導電性能、電加熱性能進行研究。本文研究結果可為利用微流控濕法紡絲開發優質導電纖維及其電加熱織物提供新的思路與見解。

1" 實驗

1.1" 實驗材料

聚丙烯腈(Polyacrylonitrile,PAN,分子摩爾質量15000 g/mol),阿拉丁試劑有限公司,在80 ℃、6 h真空干燥后使用。二甲基亞砜(Dimethyl sulfoxide, DMSO),上海阿拉丁生化科技有限公司。石墨烯納米片(Graphene nanosheets, GNPs,純度大于99.88%;片徑:3~15 μm;厚度:2~5 nm;質量分數為3.86%;EC:450 S/cm),青島巖海碳材料有限公司。微流控濕法紡絲Y形芯片(內徑700 μm),南京捷達公司。

1.2" 配制石墨烯/聚丙烯腈紡絲液

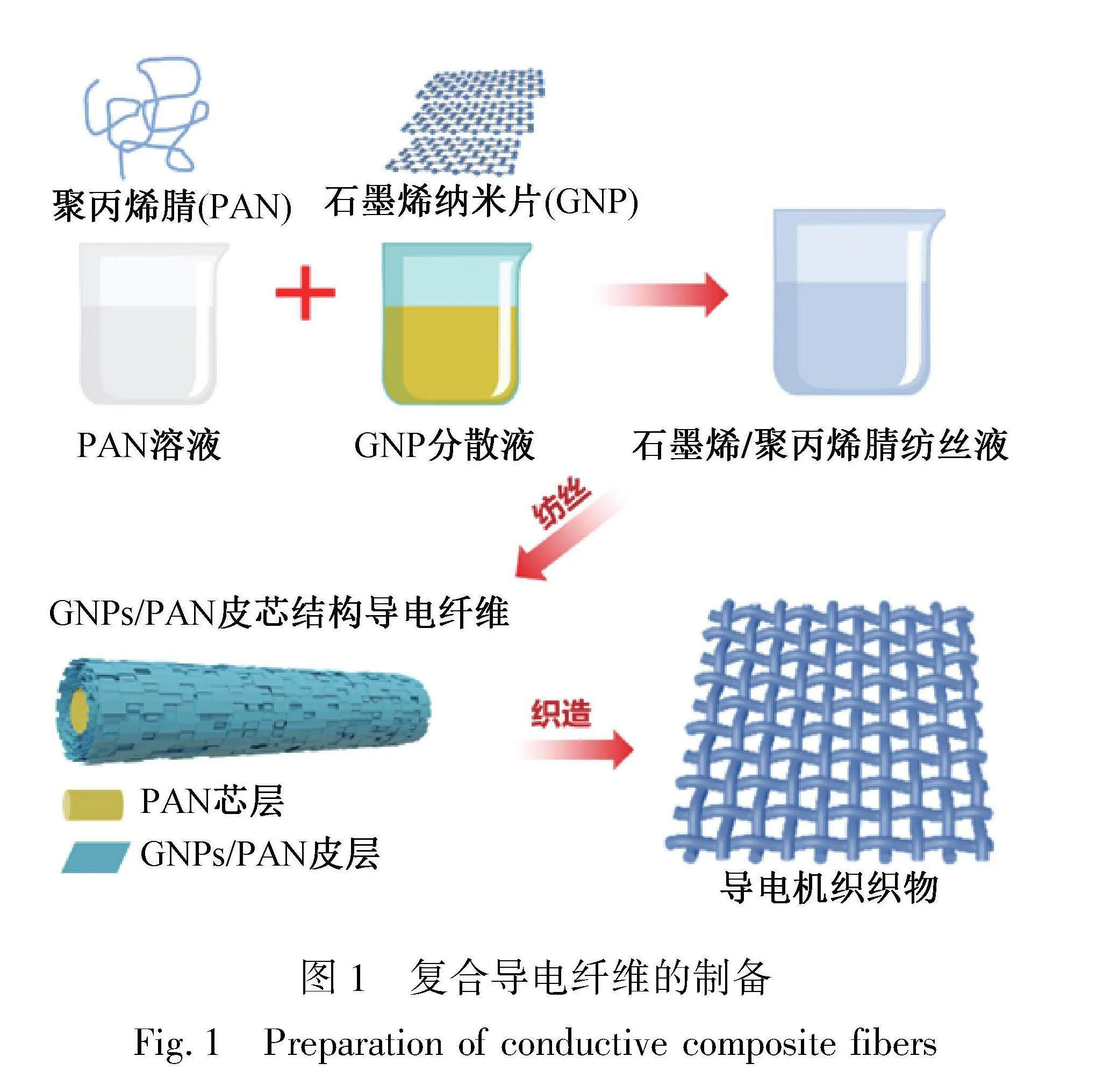

采用溶液共混法制備石墨烯/聚丙烯腈(GNP/PAN)紡絲液,具體過程如圖1所示。PAN溶液制備:將PAN放入DMSO溶液中,室溫下機械攪拌8 h,得到分散均勻的PAN溶液(質量分數為20%),靜置消泡待用。GNPs分散液制備:將GNPs放入DMSO溶液中磁力攪拌2 h,使用細胞粉碎機270 W超聲0.5 h,工作2 s停5 s,防止超聲導致溶液的溫度升高,制備均勻石墨烯分散液。GNP/PAN混合紡絲液的制備:將混合均勻的PAN溶液和石墨烯溶液進行混合攪拌10 min、用細胞粉碎儀270 W超聲2 h,得到混合均勻的復合紡絲溶液,皮層混合紡絲液中GNPs的質量分數為6.5%。

1.3" 微流控濕法紡絲

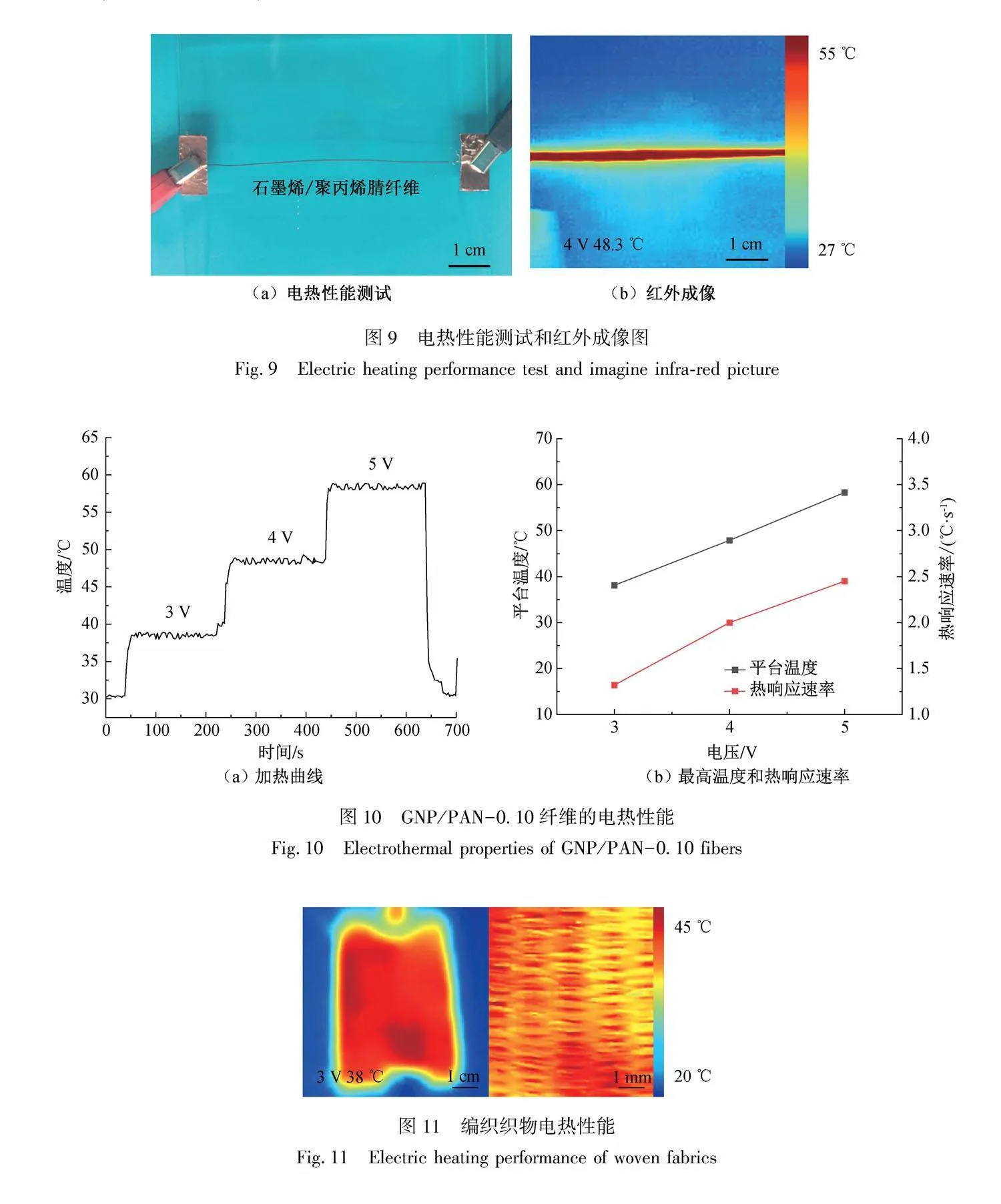

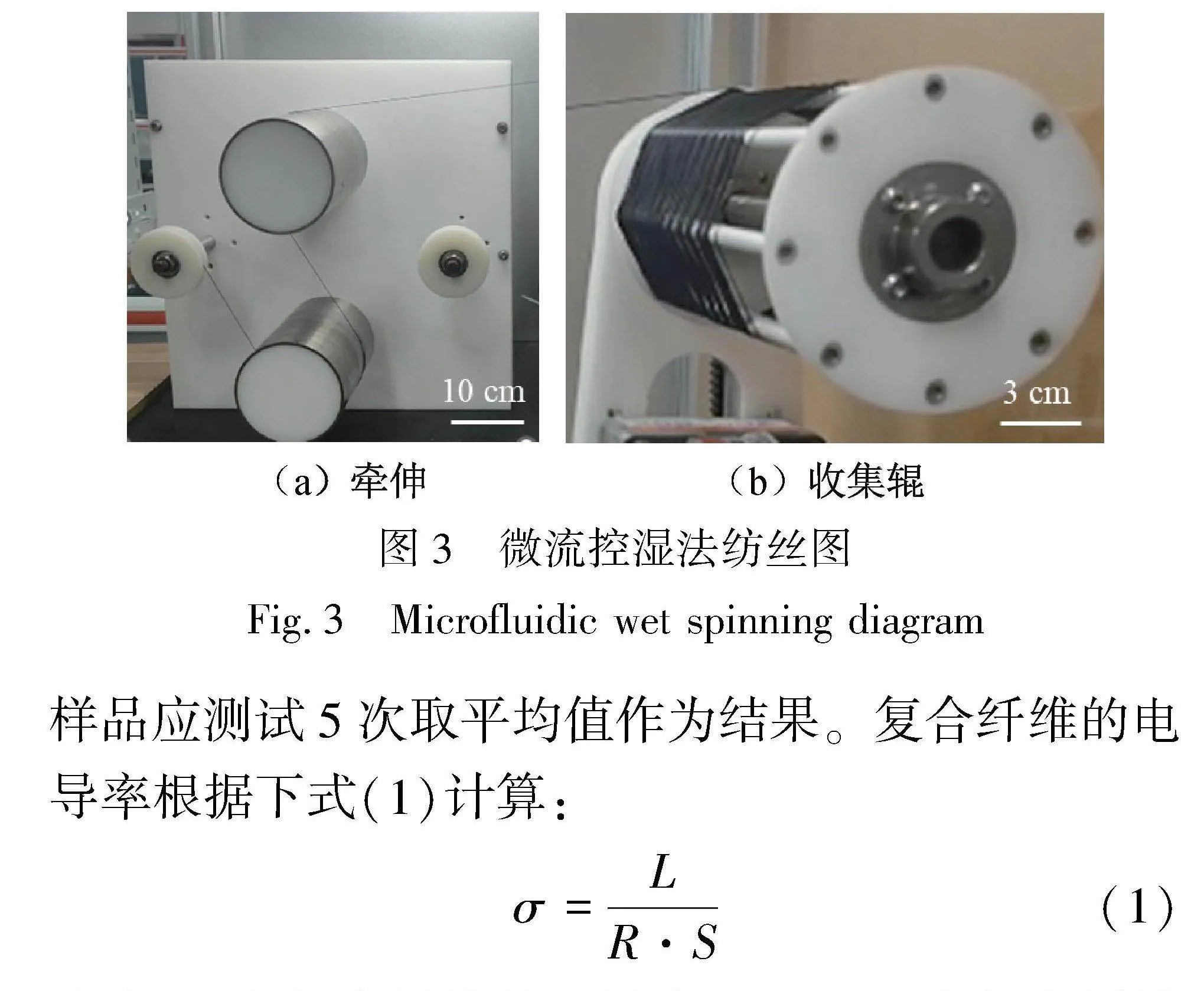

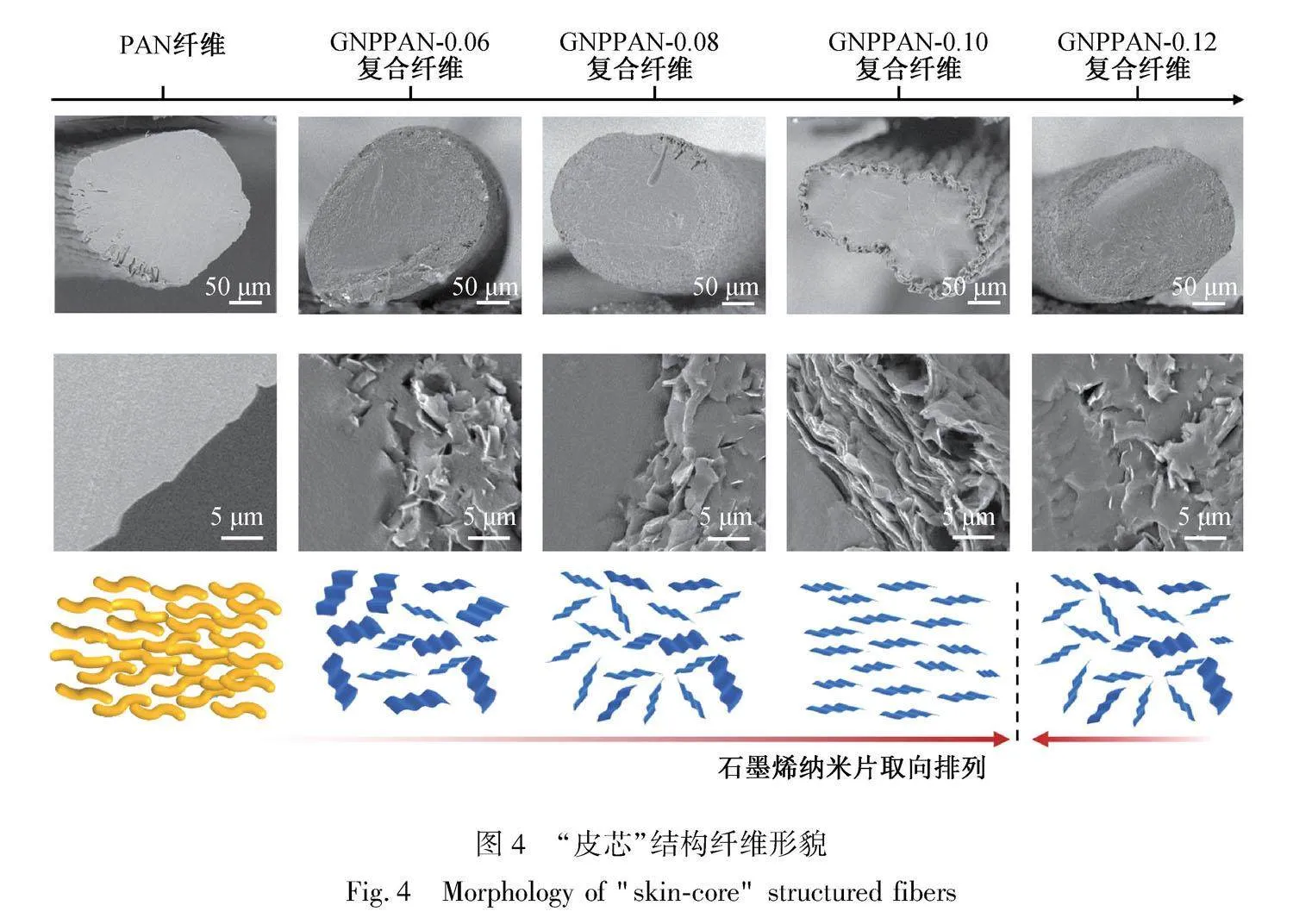

圖2為微流控濕法紡絲系統原理圖,微流控濕法紡絲系統由推進泵、Y型微流控芯片、凝固浴和纖維熱牽伸部分組成。使用推進泵將芯層的PAN溶液(質量分數為20%)和皮層的GNP/PAN紡絲溶液輸送至微流控芯片的出口,以皮層溶液的流量為變量,其流量分別為0.06、0.08、0.10、0.12 mL/min,芯層PAN溶液的流量固定為0.08 mL/min,實現纖維的微觀結構調控。擠出的初生纖維進入凝固浴(DMSO/水,質量分數為60%,溫度30~35 ℃),隨后依次經過第一道機械牽伸(2.0 r/min)、第二道凝固浴(DMSO,質量分數為5%,室溫)、第二道機械牽伸(3 r/min,見圖3(a))、水洗凝固浴和收集器(5 r/min,見圖3(b)),經過兩道牽伸可以增強纖維中的取向。最后,在溫度為130 ℃的烘箱中干燥180 s,隨后冷卻至室溫,從圖4觀察到,得到復合導電纖維GNP/PAN-0.06、GNP/PAN-0.08、GNP/PAN-0.10、GNP/PAN-0.12對應紡絲液流量為0.06、0.08、0.10、0.12 mL/min。

1.4" 測試表征

1.4.1" 掃描電鏡截面形貌表征

將復合纖維放入液氮中冷凍5 min,脆斷得到纖維的截面,采用掃描電子顯微鏡(復納科學儀器 (上海) 有限公司)觀察纖維的表面和截面結構形貌,測量纖維的直徑和皮層占比圖。

1.4.2" 拉曼光譜測試

采用DXR2型拉曼光譜儀(美國賽默飛公司)對復合纖維樣品結構相互作用分析,通過拉曼譜線中的D帶、G帶和2D帶對復合纖維材料進行表征。

1.4.3" 力學性能測試

萬能材料試驗機(美國INSTRON英斯特朗公司)測試得到纖維應力-應變曲線。拉伸速度設置為10 mm/min,輸入樣品直徑、線密度等參數,測試計算纖維的拉伸強度,每個樣品進行10次試驗,取平均值作為結果。

1.4.4" 電學性能測試

取長為10 cm的纖維樣品,使用4200A-SCS型半導體參數分析儀(泰克科技(中國)有限公司),在電壓(0~5 V)下測試復合皮芯纖維的電阻,每個

樣品應測試5次取平均值作為結果。復合纖維的電導率根據下式(1)計算:

σ=LR·S(1)

式中:σ為復合纖維的電導率,S/cm;R為復合纖維的電阻,Ω;L為復合纖維的長度,cm;S為復合纖維的橫截面積,cm2。

1.4.5" 纖維焦耳熱性能測試

采用恒壓恒流電源(美國Tektronix公司)測試導電纖維的焦耳熱性能,測試導電纖維在3、4、5 V的連續電壓梯度下溫度隨時間變化曲線和溫度響應,每個電壓施加200 s。使用熱成像儀(HM-TPK-AQF/W, 杭州海康威視數字技術股份有限公司)拍攝獲得導電纖維的熱紅外成像圖片。

2" 結果和討論

2.1" 纖維結構調控

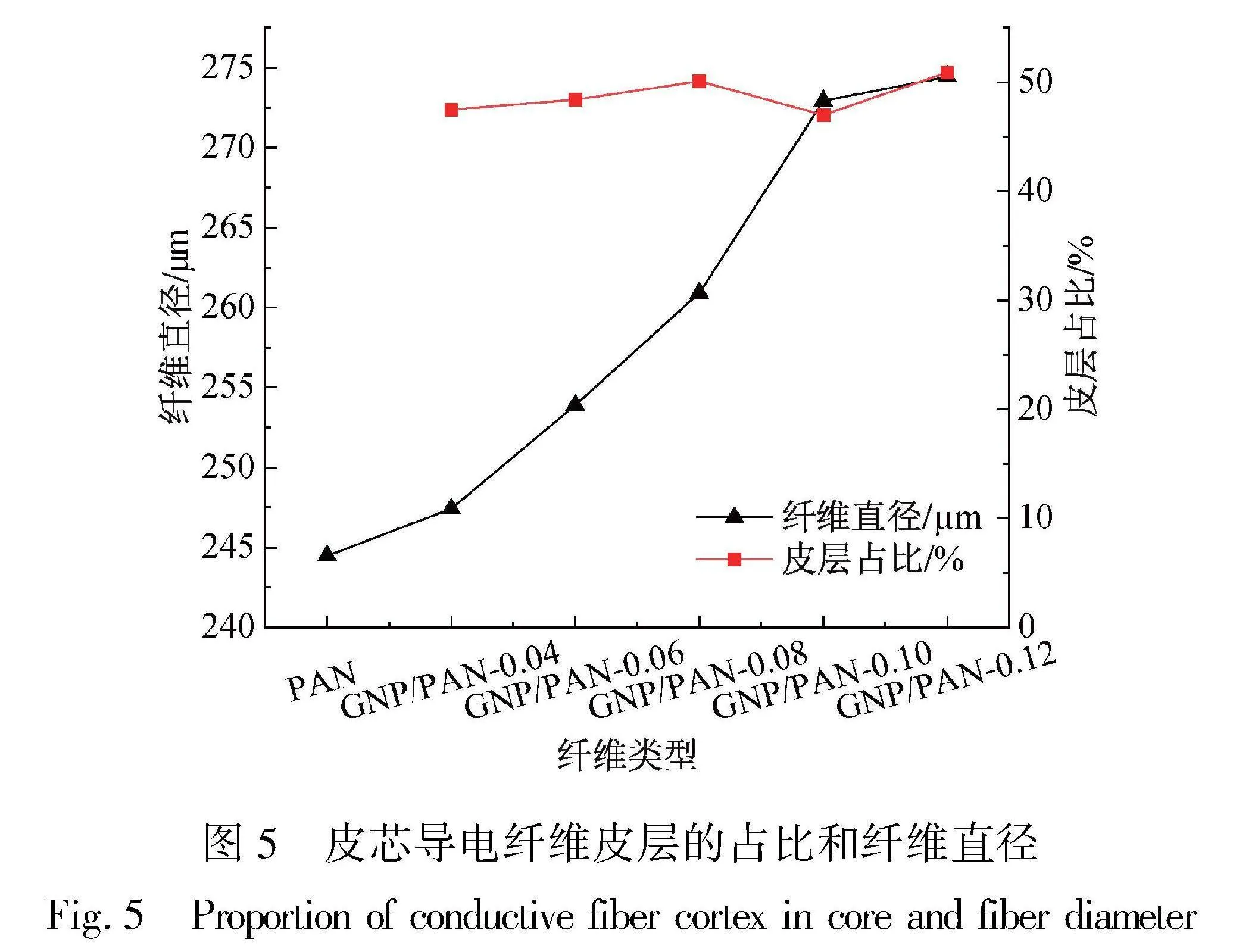

本文利用搭建的微流控濕法紡絲系統,實現制備不同皮芯結構的雙組份纖維,并探討不同流量對纖維結構形貌的影響。在復合纖維制備過程中,其中數字標號依次代表GNP/PAN紡絲液流量,對應0、0.04、0.06、0.08、0.10、0.12 mL/min,芯層PAN紡絲液的流量固定為0.08 mL/min,其他參數不變。不同皮層流量制備的復合纖維SEM圖如圖4所示,4種復合纖維均形成“皮芯”結構形貌,芯層為純的PAN聚合物,皮層為GNP/PAN復合材料。隨著皮層GNP/PAN紡絲液流量的不斷增加,纖維皮層厚度呈現先增加后減小的趨勢,分別為47.5%、48.4%、50.1%、47.0%、50.5%,與其他復合纖維相比,GNP/PAN-0.10纖維表層呈現石墨烯納米片取向排列形成明顯的沿纖維方向取向的形貌。從圖5可以觀察到,皮層流量為0.10 mL/min時,皮層占比最低為47.0%。與PAN纖維相比,隨著表層流量增加纖維直徑呈增加趨勢,復合纖維直徑增加范圍為30~50 μm。在紡絲過程中,復合纖維皮層的石墨烯納米片由混雜到取向,當皮層的流量為0.10 mL/min時,石墨烯的排列取向最佳[20]。皮層和芯層紡絲液進入到微流控紡絲通道時,流量較高的芯層溶液會對皮層溶液產生流體力學聚焦作用,使石墨烯納米受到沿流動方向的牽引取向[21]。當皮層流量大于芯層流量時,GNP發生堆積和堵塞,造成復合纖維皮層的石墨烯取向和排列降低。

2.2" 纖維性能表征

2.2.1" GNP/PAN復合纖維的作用關系

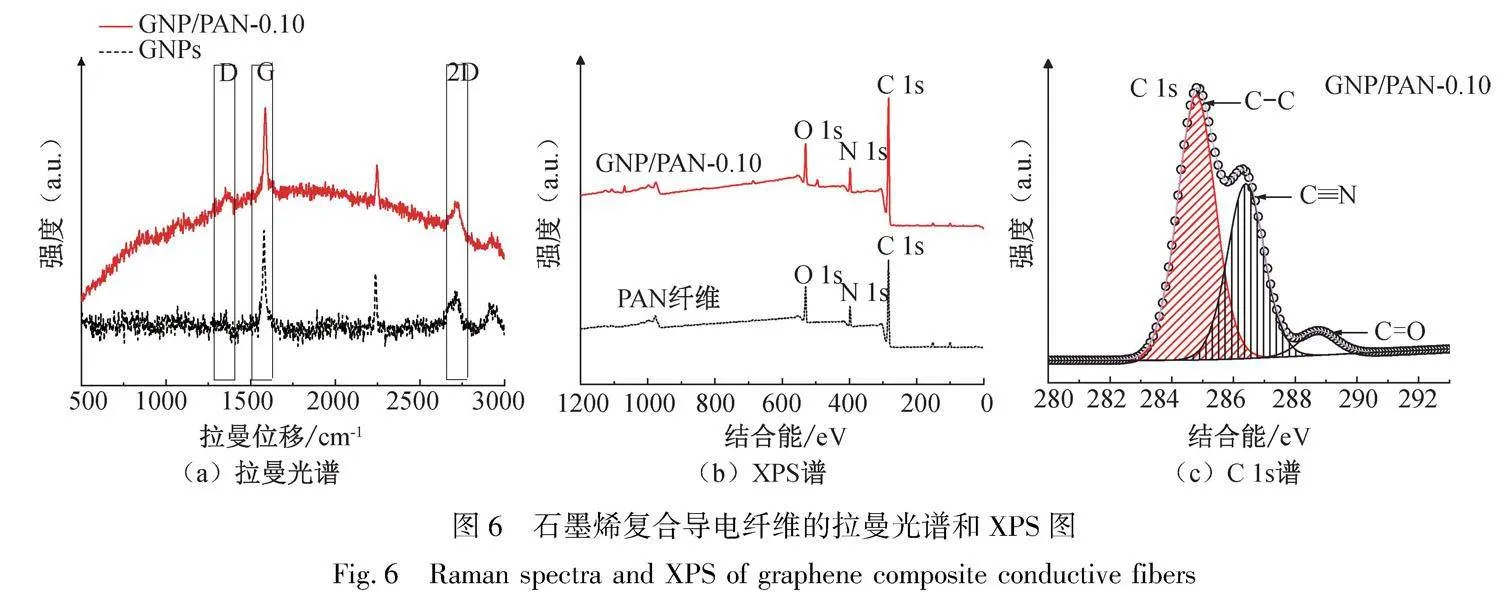

圖6(a)展示GNP/PAN-0.10復合纖維的拉曼

表征,在復合纖維中加入GNPs后,出現與石墨烯相似的D峰、G峰、2D峰[22],位置分別為1350、1580、2700 cm-1。GNP/PAN-0.10復合纖維與GNPs相比,復合纖維拉曼曲線的3個峰分別向右偏移,此現象是GNPs所處化學環境變化所致,其上少量含氧官能團與PAN磺酸基基團相互作用引起[23]。圖6(b)顯示GNP/PAN-0.10復合纖維XPS表征,復合纖維中碳和氧元素高于PAN纖維,表明石墨烯中存在少量含氧官能團。對GNP/PAN-0.10復合纖維進行分峰,如圖6(c)所示,284.8、286.3、288.5 eV處分別對應對C—C鍵、—CN鍵、—COOH鍵振動峰。

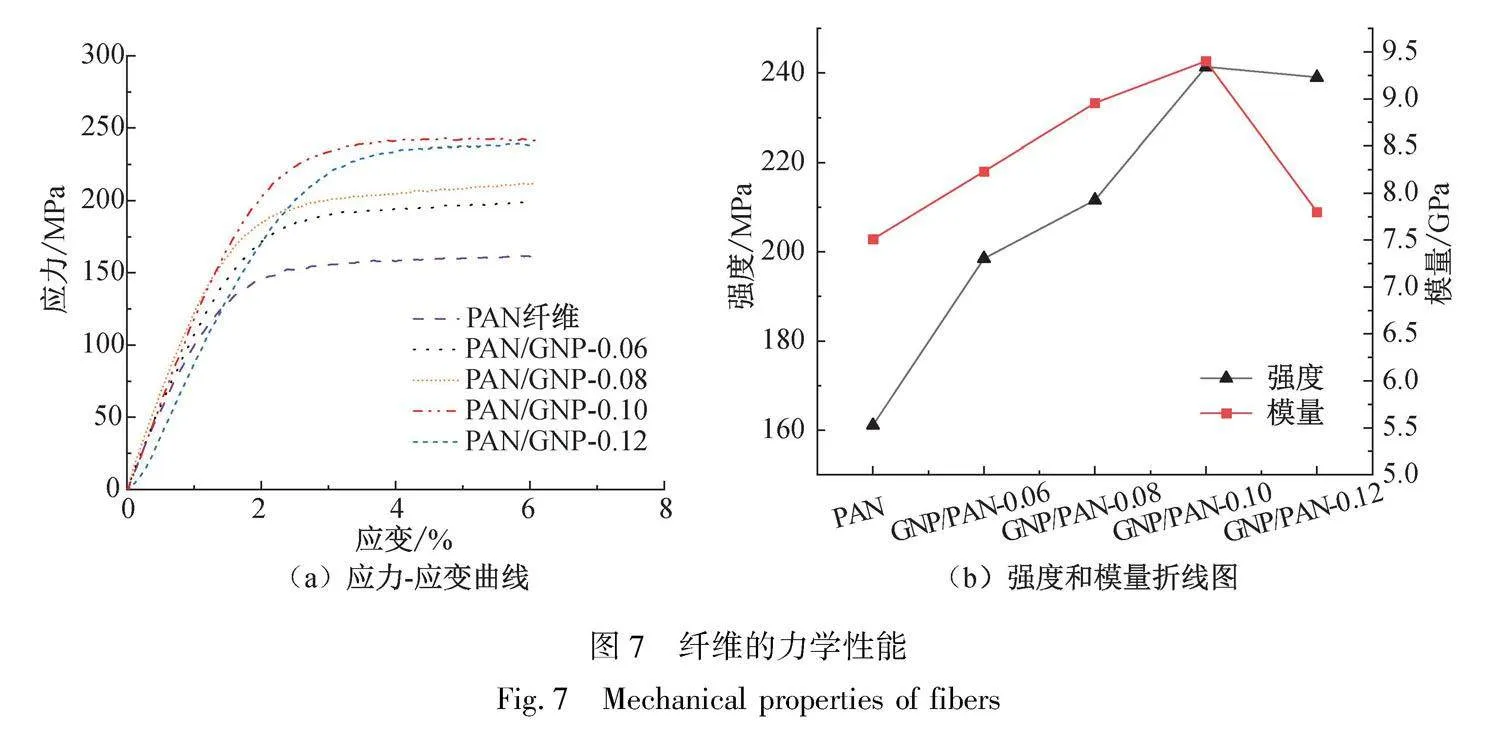

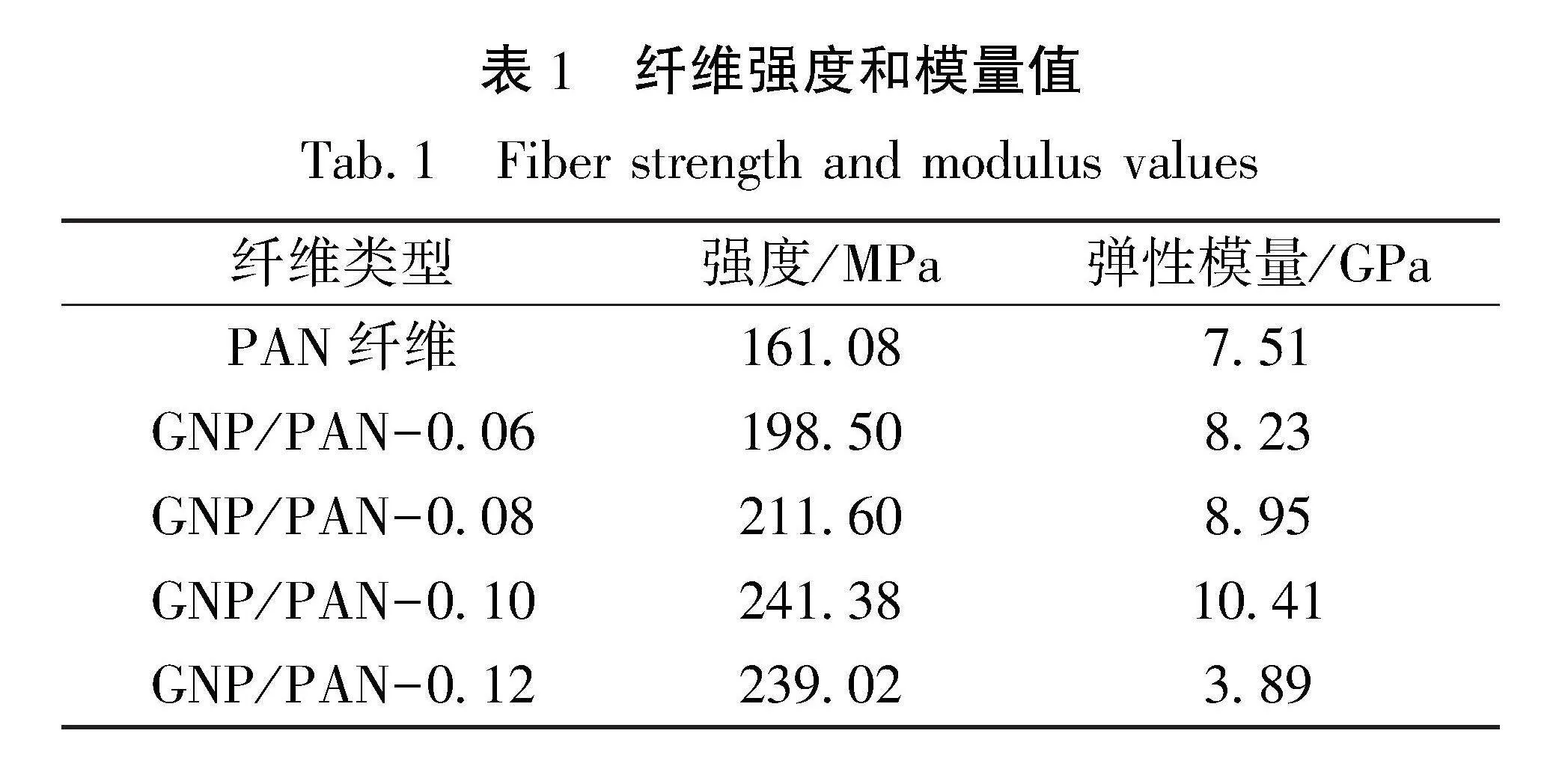

2.2.2" 力學性能

圖7(a)是PAN纖維和4種復合纖維的應力-應變曲線,圖7(b)和表1為纖維斷裂強度和模量值。結果顯示與PAN纖維(161.08 MPa)相比,石墨烯復合導電纖維強度和模量得到顯著提高。復合纖維的強度和模量隨著皮層流量的變化呈現先增加后減小的趨勢,GNP/PAN-0.10復合纖維呈現最高的力學強度(241.38 MPa)和模量(10.41 GPa),分別比PAN纖維的增加49.85%和38.61%。值得注意的是,4種復合纖維的力學強度和模量與其表層石墨烯取向變化趨勢一致,取向度高的GNP/PAN-0.10復合纖維展現優異力學性能。由于石墨烯由混雜到取向的排列,芯層的PAN大分子鏈段在微流控芯片通道中牽伸取向,皮層的石墨烯納米片由各向同性變成沿纖維軸向的橫觀各向同性,增強了復合纖維沿纖維軸向的力學性能。

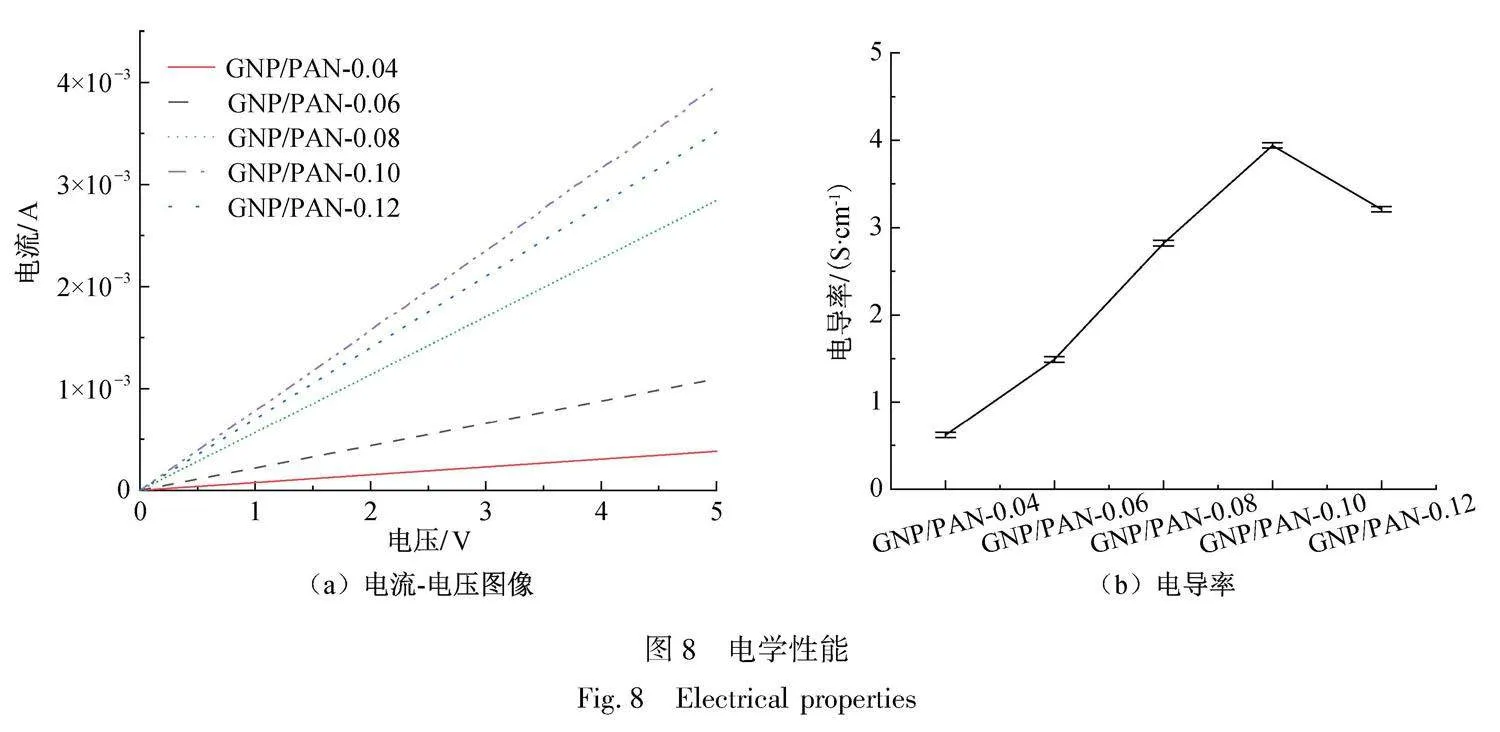

2.2.3" 導電性能

導電填料和有效的導電通路是提高纖維導電性能的先決條件。PAN和GNP/PAN復合纖維的電學性能如圖8所示,在石墨烯作為導電填料添加之后的復合纖維均具有導電性,電導率分別為0.62、1.49、2.82、3.94、3.21 S/cm。復合纖維隨著皮層流量的增加,纖維導電性能呈現先增加后減小的趨勢,GNP/PAN-0.10纖維的電導率最大為3.94 S/cm,較GNP/PAN-0.04纖維的電導率增加了535.48%。這與皮層石墨烯取向構建的導電通路密切相關,從圖4可以觀察到,GNP/PAN-0.10復合纖維皮層的GNPs沿纖維方向取向排列,GNPs之間相互堆疊搭接,為電子的快速傳遞提供有效路徑,從而增強復合纖維的導電性能[24-25]。

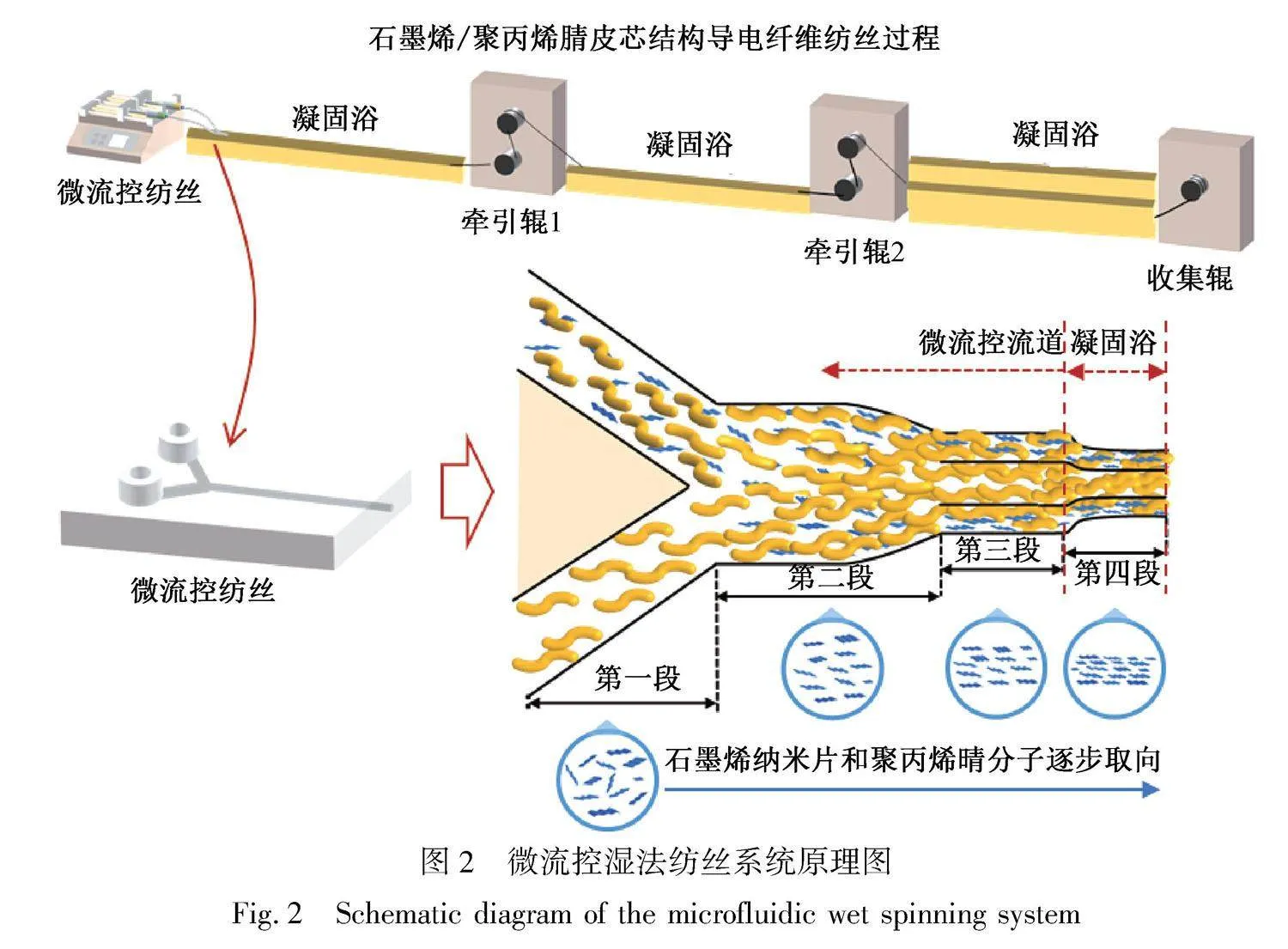

2.2.4" 電熱性能

圖9所示為復合纖維兩端加上電壓的圖片和紅外加熱圖像,皮芯導電纖維平放在玻璃板上面,使用銅膠帶固定復合纖維兩端進行加壓。在復合纖維的兩端施加不同電壓研究電熱性能,其表面溫度隨時間的變化曲線如圖10所示。從圖10(a)可以觀察到,在復合纖維的兩端施加3、4、5 V梯度電壓下的溫度曲線,在施加3 V的低電壓下,表面溫度迅速上升到38 ℃(接近人體溫度)。在纖維的兩端加上4 V電壓時,纖維的表面溫度48.3 ℃,去掉纖維的兩端的電壓之后,纖維表面的溫度迅速降低到室溫。圖10(b)顯示了在不同電壓下纖維的熱響應速率,在施加4 V電壓下的熱響應速率為2.0 ℃/s,皮芯復合纖維在梯度電壓下經過焦耳熱還原后,具有良好的加熱能力和熱穩定性。從圖11可以觀察到,皮芯復合纖維進行經緯紗交替編織成導電織物的熱紅外成像,在織物施加3 V電壓下,織物表面的溫度可以達到38 ℃。

3" 結論

本文利用溶液共混法制備了石墨烯納米片/聚丙烯腈紡絲液,通過微流控濕法紡絲技術制備皮芯結構復合導電纖維,主要結論如下:

a)微流控濕法紡絲技術制備皮芯復合導電纖維,纖維表層石墨烯的取向受到皮層紡絲液流量影響,芯層流速固定為0.08 mL/min、皮層的流速為0.10 mL/min,GNP/PAN-0.1復合纖維表層石墨烯取向最佳。

b)GNP/PAN-0.10纖維展現最大力學強度為241.38 MPa和模量為10.41 GPa,與PAN纖維(強度為161.08 MPa和模量為7.51 GPa)相比GNP/PAN-0.10復合纖維強度和模量增加49.85%、38.61%。

c)取向度最佳的GNP/PAN-0.10纖維電導率達到最大值為3.94 S/cm,在4 V電壓下皮芯復合纖維的溫度為48.3 ℃,熱響應速率達到2.0 ℃/s,將GNP/PAN-0.10纖維編織成織物,在3 V電壓下,織物表面的溫度達到38 ℃。

本文制備的皮芯導電纖維具有良好的電熱效應,具有安全性、可靠性、熱穩定性和溫度可控等優異的焦耳熱性能,為制備與石墨烯相關的導電復合纖維提供一定的參考。

參考文獻:

[1]謝金林,張京,郭宇星,等.導電纖維在新型紡織品中的應用進展[J]. 現代紡織技術, 2023, 31(6): 241-254.

XIE Jinlin, ZHANG Jing, GUO Yuxing, et al. Application progress of conductive fibers in the applicationofnew textiles[J]. Advanced Textile Technology, 2023, 31(6): 241-254.

[2]LEE Y H, KIM J S, NOH J, et al. Wearable textile battery rechargeable by solar energy[J]. Nano Letters, 2013, 13(11): 5753-5761.

[3]強濤濤,邱波強,朱潤桐.氧化石墨烯/多孔SiO2微球復合材料的吸附性能研究[J].皮革科學與工程,2023,33(2):28-33.

QIANG Taotao, QIU Boqiang, ZHU Runtong. Study on the adsorption properties of graphene oxide/porous SiO2 micro-sphere composites[J]. Leather Science and Engineering,2023,33(2):28-33.

[4]王光鑫, 李華, 趙桂艷, 等. 碳系導電納米材料填充高分子導電復合材料及其研究進展[J]. 石油化工高等學校學報, 2020, 33(5): 1-7.

WANG Guangxin, LI Hua, ZHAO Guiyan, et al. Progress of carbonaceous conductive nanomaterials filled conductive polymer composites[J]. Journal of Petrochemical Univer-sities, 2020, 33(5): 1-7.

[5]楊春, 賴艷瓊, 張艷麗, 等. 一種蜂窩狀三維石墨烯的制備及表征[J]. 云南民族大學學報(自然科學版), 2020, 29(1): 24-27.

YANG Chun, LAI Yanqiong, ZHANG Yanli, et al. Preparation and characterization of honeycomb-like three-dimensional graphene[J]. Journal of Yunnan Minzu University(Natural Sciences Edition), 2020, 29(1): 24-27.

[6]CHOI W, KWON Y, YU W R, et al. Graphite fiber electrode by continuous wet-spinning[J]. ACS Applied Energy Materials, 2022, 5(7): 8963-8972.

[7]NING M, WANG S, LI H, et al. Direct fabrication of graphene oxide fiber by injection spinning for flexible and wearable electronics[J]. Journal of Materials Science, 2020, 55: 12065-12081.

[8]LEN-BIGUES L, FLORES A, GMEZ-FATOU M A, et al. PET/graphene nanocomposite fibers obtained by dry-jet wet-spinning for conductive textiles[J]. Polymers, 2023, 15(5): 1245.

[9]LI Y, JIN Y, CHENG J, et al. Achieving superior electromagnetic wave absorbers with 2D/3D heterogeneous structures through the confinement effect of reduced gra-phene oxides[J]. Carbon, 2023, 213: 118245.

[10]WANG Y, LIU Z. Spontaneous rolling-up and assembly of graphene designed by using defects[J]. Nanoscale, 2018, 10(14): 6487-6495.

[11]CHOI Y S, YEO C S, KIM S J, et al. Multifunctional reduced graphene oxide-CVD graphene core-shell fibers[J]. Nanoscale, 2019, 11(26): 12637-12642.

[12]湯萍萍. 高性能石墨烯纖維的制備與性能研究[D]. 北京: 北京化工大學, 2021.

TANG Pingping. Preparation and Properties of High Per-formance Graphene Fiber[D]. Beijing: Beijing University of Chemical Technology, 2021.

[13]蹇木強, 張瑩瑩, 劉忠范. 石墨烯纖維: 制備、性能與應用[J]. 物理化學學報, 2022, 38(2): 22-39.

JIAN Muqiang, ZHANG Yingying, LIU Zhongfan. Gra-phene fibers: Preparation, properties, and applications[J]. Acta Physico-Chimica Sinica, 2022, 38(2): 22-39.

[14]王慧, 艾姣, 成思蓉, 等. 聚丙烯腈/石墨烯雜化濕法紡絲復合纖維性能研究[J]. 紡織科學與工程學報, 2023, 40(3): 45-49.

WANG Hui, AI Jiao, CHENG Sirong, et al. Property study on polyacrylonitrile/graphene hybrid wet-spinning composite fiber[J]. Journal of Textile Science and Engin-eering, 2023, 40(3): 45-49.

[15]SUN Z, FANG S, HU Y H. 3D graphene materials: From understanding to design and synthesis control[J]. Chemical Reviews, 2020, 120(18): 10336-10453.

[16]肖琪,孫紅玉,賈濟如,等.復合導電織物的制備及其性能研究[J].絲綢,2023,60(11):64-70.

XIAO Qi, SUN Hongyu, JIA Jiru, et al. Preparation and properties of composite conductive fabrics[J]. Journal of Silk, 2023, 60(11): 64-70.

[17]聞俊峰, 蔣亞東, 楊亞杰, 等. 化學氣相沉積導電聚合物復合納米薄膜及性能[J]. 功能材料, 2014, 45(16): 16101-16106.

WEN Junfeng, JIANG Yadong, YANG Yajie, et al. Preparation and performance of conducting polymer nano-composites prepared by chemical vapor-phase polymeri-zation method[J]. Journal of Functional Materials, 2014, 45(16): 16101-16106.

[18]張波, 胡希麗, 曲麗君. 微流控紡絲技術及多元結構微流控纖維柔性可穿戴應用[J]. 復合材料學報, 2023, 40(5): 2536-2549.

ZHANG Bo, HU Xili, QU Lijun. Microfluidic spinning technology and flexible wearable application of multi-structure microfluidic fiber[J]. Acta Materiae Compositae Sinica, 2023, 40(5): 2536-2549.

[19]BO L, HU L, WANG N, et al. Methylene blue modified graphene film as high-performance electrode towards all-in-one flexible supercapacitors with \"all-graphene\" struc-ture[J]. Journal of Power Sources, 2024, 591: 233839.

[20]HU X, TIAN M, PAN N, et al. Structure-tunable graphene oxide fibers via microfluidic spinning route for multifunctional textiles[J]. Carbon, 2019, 152: 106-113.

[21]HU X, TIAN M, XU T, et al. Multiscale disordered porous fibers for self-sensing and self-cooling integrated smart sportswear[J]. ACS Nano, 2020, 14(1): 559-567.

[22]LIU X, DONG H, LI Y, et al. Thermal conductivity and raman spectra of carbon fibers[J]. International Journal of Thermophysics, 2017, 38(10): 150.

[23]YU Rufang, HONG Xinghua, ZHU Chengyan, et al. Electrical heating properties of fabrics coated by reduced graphene oxide[J]. Journal of Textile Research, 2021, 42(10): 126-131.

[24]HONG X, SUN W, ZHANG S, et al. Washable and multifunctional electronic textiles via in situ lamination for personal health Care[J]. Advanced Fiber Materials, 2024, 6(2): 458-472.

[25]潘陳浩,石磊,傅雅琴.高應變石墨烯紗線的制備及其電化學性能[J].現代紡織技術,2023,31(5):157-164.

PAN Chenhao, SHI Lei, FU Yaqin. Preparation and electrochemical performance of high strain graphene yarns with electrochemical properties[J]. Advanced Textile Technology, 2023, 31(5): 157-164.

Fabrication and functional study of graphene/polyacrylonitrile skin core structural fibers

CUI" Ruiqi1," SHANG" Yuanyuan1,2,3," LI" Juanjuan1," ZHANG" Hao1," SHI" Baohui1,2,3," FANG" Kuanjun1

(1a.College of Textiles amp; Clothing; 1b.Ecological Textile Provincial Co-construction Collaborative

Innovation Center; 1c.State Key Laboratory of Biopolysaccharide Fiber Forming and Ecological Textile;

1d.Shandong Key Laboratory of Medical and Health Textile Materials; 1e.Shandong Ecological Textile

Collaborative Innovation Center; 1f.Laboratory of Low Carbon Textile and Functional Manufacturing

of Shandong Universities, Qingdao University, Qingdao 266071, China; 2a.Engineering Research

Center of Industrial Textiles, Ministry of Education; 2b.Key Laboratory of High Performance Fibers

and Products, Ministry of Education, Donghua University, Shanghai 201620, China;

3.Shandong Jinguan Mesh Co., Ltd., Binzhou 251712, China)

Abstract:

Graphene, as a new type of two-dimensional carbon nanomaterial, has emerged as a prominent research focus in recent years due to its unique composition and excellent conductivity, thermal conductivity, and mechanical properties. The graphene fiber, a novel carbon-based fiber crafted from graphene layers, inherits the advantages of graphene, such as lightweight and flexibility. In many practical applications, balancing the multiple properties of graphene fibers can be challenging, and it is necessary to choose a suitable spinning method to regulate the chemical composition and structure of graphene fibers and polymers, so as to broaden the application field of graphene-based fibers. Polyacrylonitrile is a synthetic fiber with good elasticity and weather resistance. It can be used in industrial production through wet spinning and can be combined with graphene incorporation to obtain high-performance composite fibers. Microfluidic spinning technology is a new type of spinning technology developed on the basis of microfluidic chip technology, which is combined with wet spinning technology to build a microfluidic wet spinning system. Microfluidic chip technology enables precise control over the microstructure of spinning solutions and is characterized by a high degree of miniaturization, integration, and cost-effectiveness. This article utilizes microfluidic wet spinning technology to prepare a novel type of conductive fiber with a core-sheath structure. By precisely adjusting the spinning fluid inside the microfluidic chip spinning channel, the spinning fluid exhibits laminar flow characteristics in the microchannel. Through a simple process, the directional control of graphene in the fiber outer layer is achieved, fully utilizing the high conductivity and high specific surface area of the outer layer material, as well as the mechanical properties of the core layer polyacrylonitrile fiber. As the flow rate of the composite fiber layer increases, the arrangement of graphene in the fiber layer gradually becomes standardized under shear stress and compression in the microfluidic chip channel, forming a continuous conductive path.The article studied the morphology, mechanical properties, and electrical properties of skin core fibers. In SEM images and stress-strain curves, compared with pure polyacrylonitrile fibers, the diameter and strength of composite fibers showed a trend of first increasing and then decreasing with the increase of skin solution. The resistance of core-sheath composite fibers decreased and the conductivity increased. When the skin flow rate reached a certain value, due to the aggregation of graphene in microchannels, the conductivity of the composite fibers decreased, and their mechanical properties also declined. It could be found that by applying different voltages at both ends of the composite fiber to test the electrical heating performance of the composite fiber, the highest temperature reached by the fiber and the heating rate per second vary under different voltages. The higher the voltage applied at both ends of the fiber, the greater the maximum temperature reached and the heating rate also increases. The test shows that the core-sheath fibers had good thermal stability and electrical cycling, and the voltage at both ends of the composite fiber could be quickly heated to the expected temperature.Functional heating conductive fibers are poised for long-term development in the textile industry, driven by intelligent production processes and technologies. The study of microfluidic wet spinning of graphene and polyacrylonitrile in this article can provide some reference for the development and application of conductive fibers.

Keywords:

graphene; microfluidics; wet spinning; conductive fibers; electric heating performance