增壓缸內(nèi)置氣控閥的動(dòng)態(tài)特性及仿真

王成剛,張博,晏芙蓉,何凡

武漢工程大學(xué)機(jī)電工程學(xué)院,湖北 武漢 430205

增壓缸內(nèi)置氣控閥的動(dòng)態(tài)特性及仿真

王成剛,張博,晏芙蓉,何凡

武漢工程大學(xué)機(jī)電工程學(xué)院,湖北 武漢 430205

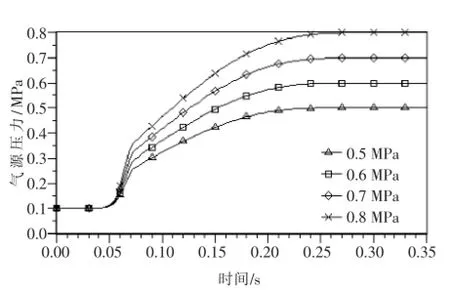

為了解決增壓缸增力適應(yīng)問(wèn)題,研究了增壓缸內(nèi)置二位三通閥動(dòng)態(tài)特性.利用AMEsim軟件中氣動(dòng)及液壓零件庫(kù)組件對(duì)該二位三通氣控閥進(jìn)行了建模與仿真,分析了該閥處于不同工作壓力下位移、速度、質(zhì)量流量和焓流量曲線(xiàn).結(jié)果表明:在工作壓力為0.5MPa時(shí),該閥的換向時(shí)間約為195ms;當(dāng)工作壓力為0.5~0.8 MPa范圍內(nèi),氣源壓力每增加0.1 MPa,該閥換向速度加快約為13ms;質(zhì)量流量與焓流量峰值隨著氣源壓力增大而增大,但其達(dá)到峰值時(shí)間與趨于0點(diǎn)時(shí)間基本沒(méi)有變化.該二位三通閥的啟動(dòng)壓力約為0.24 MPa,響應(yīng)時(shí)間約為35ms.數(shù)學(xué)計(jì)算與軟件仿真數(shù)據(jù)誤差在可接受范圍,結(jié)果可靠.

增壓缸;內(nèi)置氣控閥;AMEsim建模仿真;動(dòng)態(tài)特性

0 引言

新型氣-液增壓缸利用力的平衡原理,以低壓氣體推動(dòng)活塞桿使密封油腔內(nèi)液壓油增壓,高壓油推動(dòng)液壓活塞桿沖壓工件;新型氣-液增壓缸綜合了氣動(dòng)與液壓技術(shù)的優(yōu)勢(shì),高效節(jié)能,控制方便,適用于大規(guī)模大批量自動(dòng)化的現(xiàn)代工業(yè)生產(chǎn)領(lǐng)域,擁有很高的經(jīng)濟(jì)效益和市場(chǎng)前景,普遍適用于各類(lèi)沖壓加工行業(yè).

新型氣-液增壓缸研究的技術(shù)難點(diǎn)在于:(1)軟到位技術(shù).(2)增力自適應(yīng)技術(shù).(3)旁路能量釋放技術(shù).其工作行程包括:1)靜止準(zhǔn)備.2)軟到位快進(jìn)行程[1].3)增力行程.4)返回行程.

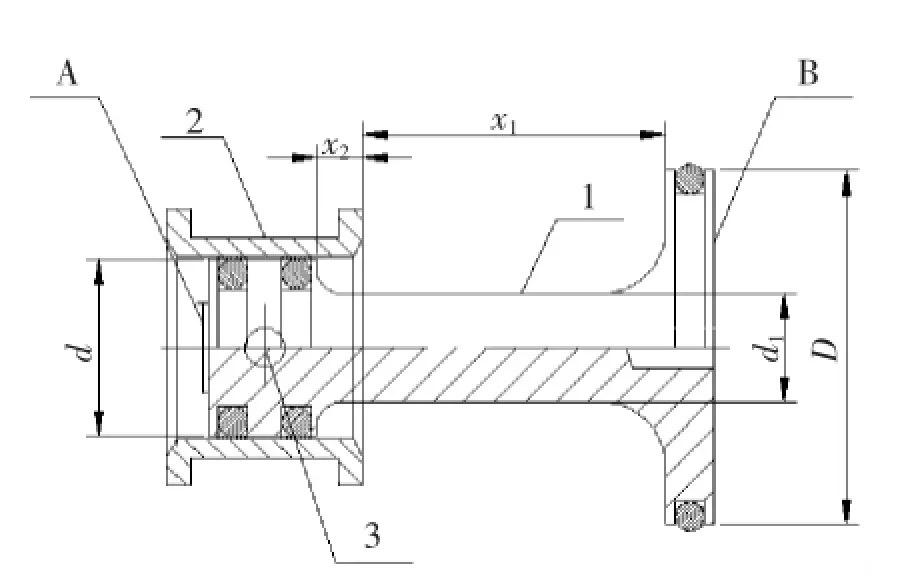

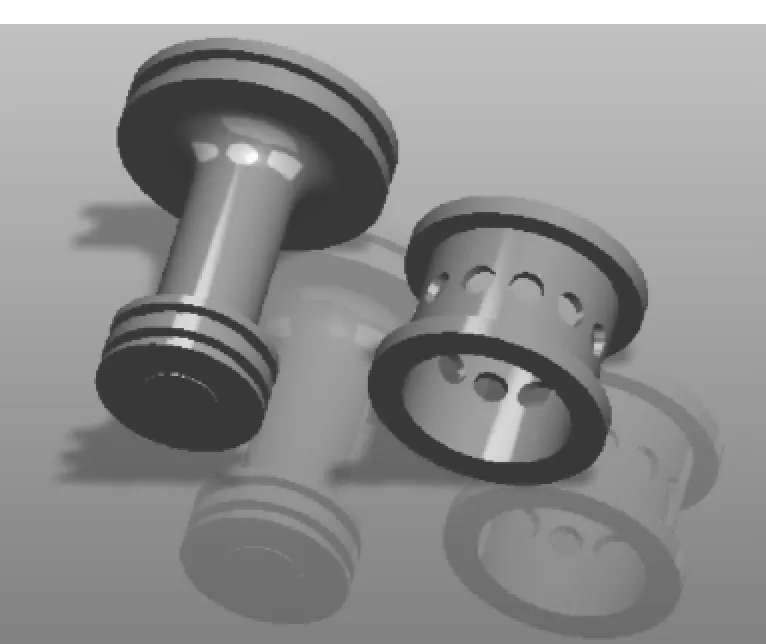

完成增力適應(yīng)的控制機(jī)構(gòu)為內(nèi)置二位三通換向閥.圖1為該氣閥實(shí)物圖.其原理是閥芯小活塞端直通氣源壓力,液壓活塞桿由氣壓推動(dòng)至與工件貼合后,工作腔內(nèi)容積不再增大,這時(shí)工作腔內(nèi)氣壓極速增至工作氣壓,氣體經(jīng)由管路通入閥芯大活塞端,此時(shí)閥芯打開(kāi),氣體經(jīng)由閥瓣孔進(jìn)入氣缸中從而推動(dòng)氣缸活塞桿下壓.

本文以增壓缸內(nèi)置二位三通閥為研究對(duì)象,利用AMEsim軟件對(duì)該二位三通氣控閥進(jìn)行了建模與仿真[2].

圖1 二位三通閥實(shí)物圖Fig.1 Physical diagram of 3/2-way valve

1 工作原理

如圖2所示,當(dāng)增壓缸處于工作準(zhǔn)備狀態(tài)時(shí),A端面連通氣源,且與氣源間加入單向閥裝置用以保壓,此時(shí)閥芯小端面位于閥瓣右側(cè)將閥瓣氣孔3封閉,B端與外界大氣連接.當(dāng)增壓缸處于快進(jìn)行程時(shí),閥芯位置與準(zhǔn)備狀態(tài)時(shí)相同,外置氣控閥連接快進(jìn)缸,與閥芯A端連接切斷,但A端設(shè)置有單向閥,使得其繼續(xù)保持氣源壓力,B端繼續(xù)與外界大氣連接.當(dāng)增壓缸處于增力階段時(shí),閥芯B端面與氣源連接,A端保持氣源壓力,由力平衡原理,此時(shí)閥芯向左移動(dòng),使得閥瓣孔3與氣源相連,氣控閥打開(kāi).當(dāng)增壓缸處于回程行程時(shí),B端連接外置大氣,閥芯迅速回到原位完成一次換向,重復(fù)以上過(guò)程[3~4].圖3為該二位三通閥三維圖.

圖2 二位三通閥結(jié)構(gòu)圖.1—閥芯;2—閥瓣;3—閥瓣氣孔Fig.2 Structure diagram of 3/2-way valve.1—valve core,2—valve disc,3—valve disc porosity

圖3 二位三通閥三維圖Fig.3 3Dmodel of 3/2-way valve

2 數(shù)學(xué)模型

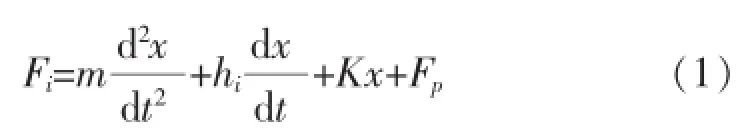

二位三通閥在增壓缸整體運(yùn)行過(guò)程中閥芯兩端受力情況直接影響其開(kāi)關(guān)精度大小.閥芯運(yùn)動(dòng)過(guò)程中會(huì)受到:摩擦力、粘滯力及氣體推動(dòng)力等影響,故由牛頓第二定律得出閥芯的力平衡方程:

式(1)中:Fi為閥芯驅(qū)動(dòng)力;hi為粘性摩擦系數(shù);K為彈性力剛度系數(shù);Fp為氣體推動(dòng)力;m為閥芯質(zhì)量.

因閥芯大活塞端直接與端蓋孔形成密封,只有閥芯小活塞端與閥瓣密封,因此節(jié)流口過(guò)流面積可用以下公式表示:

式(2)中:A為節(jié)流口過(guò)流面積;D為閥芯大活塞端直徑;d為閥芯小活塞端直徑;d1為閥芯桿直徑;x1,x2為閥芯大、小活塞端距閥瓣端部距離,數(shù)學(xué)模型圖如圖2所示.

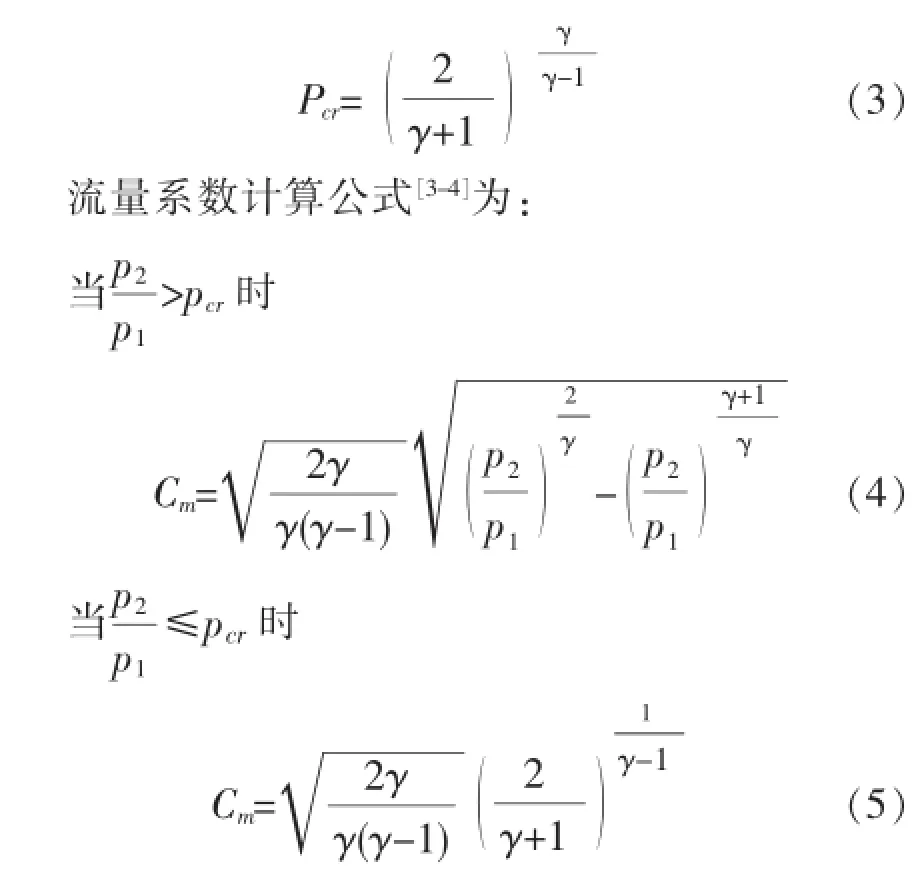

通過(guò)查閱文獻(xiàn)[5]可知,理想氣體流動(dòng)臨界壓力比為

式(3)~(5)中:γ為等熵面發(fā)熱系數(shù);p1為上游壓力;p2為下游壓力;pcr為臨界壓力比;Cm為流量系數(shù).

通過(guò)查閱文獻(xiàn)[6],可知在閥瓣孔面積不變的前提下,下游氣體壓力比與上游氣體壓力比小于臨界壓力比0.528前,閥瓣孔的流量系數(shù)基本保持0.72左右,故取Cm=0.72.

3 仿真與分析

3.1 仿真模型的建立

利用AMEsim提供的氣動(dòng)元件設(shè)計(jì)庫(kù)(PCD)以及液壓元件設(shè)計(jì)庫(kù)(HCD)對(duì)整體增壓缸進(jìn)行建模,因二位三通閥運(yùn)行條件模擬為真實(shí)增壓缸中條件,故給出整體增壓缸模型如圖4所示,整體增壓缸由(PCD)庫(kù)中7個(gè)子模型以及(HCD)庫(kù)中2個(gè)子模型組成.其中二位三通閥由(PCD)庫(kù)中2個(gè)子模型及質(zhì)量塊組成.模型中增壓缸由外置電磁閥控制,由一簡(jiǎn)單氣體壓力源提供動(dòng)能,由外部管路連接增壓缸各氣、液通路[7~8].

圖4 增壓缸整體AMEsim圖Fig.4 AMEsim diagram of pressure cylinder

建模過(guò)程中各個(gè)子模型主要仿真技術(shù)參數(shù)如下:

空氣絕熱指數(shù)k為1.4;氣體常數(shù)R為287.4;流量系數(shù)μ為0.72;氣源壓力P為0.5~0.8MPa;空氣密度ρ為1.895×10-3kg/m3;質(zhì)量塊M為0.05 kg;大活塞直徑D為32mm;小活塞直徑d為20mm;活塞桿直徑d1為12mm.

通過(guò)查閱文獻(xiàn)[9]可知該模型摩擦力計(jì)算公式,并由公式計(jì)算得出:滑動(dòng)摩擦力Ff為12 N;靜摩擦力FS為20 N.

3.2 仿真結(jié)果分析

由圖5閥芯位移-時(shí)間曲線(xiàn)中所示,閥芯于33 ms時(shí)啟動(dòng),當(dāng)達(dá)到約228 ms時(shí)閥芯移動(dòng)到0.015m的極限位置,此時(shí)完成增壓缸增力適應(yīng)行程,閥芯換向完畢.因此閥芯的驅(qū)動(dòng)時(shí)間是33ms,完成整個(gè)換向時(shí)間約為180ms.

圖5 位移-時(shí)間曲線(xiàn)Fig.5 Curves of displacementand time

圖6為閥瓣出氣孔處氣體壓力-時(shí)間曲線(xiàn),圖7為進(jìn)氣孔處氣體體力-時(shí)間曲線(xiàn).從圖7中可以看出主閥芯于54 ms時(shí)處于臨界打開(kāi)位置.54~78 ms時(shí)閥打開(kāi),氣體迅速由入口流向出口.約258ms時(shí)閥出入口氣壓同時(shí)到無(wú)限接近達(dá)氣源壓力的極限壓力.

圖8、圖9分別為氣源壓力0.5~0.8MPa時(shí)該閥的質(zhì)量流量和焓流量曲線(xiàn),從圖8~9中可以看出,該閥的質(zhì)量流量與焓流量均于33 ms開(kāi)始迅速增加,于66ms處達(dá)到峰值而后迅速減小.需要注意的是閥完成換向后,系統(tǒng)質(zhì)量流量和焓流量于78mm至309ms處緩慢下降最終無(wú)限趨近于0.

圖6 入口氣體壓力與時(shí)間曲線(xiàn)Fig.6 Curves of entrance gas pressure and time

圖7 出口氣體壓力與時(shí)間曲線(xiàn)Fig.7 Curves of export gas pressure and time

圖8 質(zhì)量流量曲線(xiàn)Fig.8 Curves ofmass flow and time

圖9 焓流量曲線(xiàn)Fig.9 Curves of enthalpy flow and time

由圖5可以看出閥芯于33ms開(kāi)始移動(dòng),由圖8、圖9可以看出系統(tǒng)焓流量于66ms時(shí)到達(dá)峰值,故該二位三通閥的響應(yīng)時(shí)間為約35ms.

假設(shè)工作壓力為0.5MPa,由于閥芯于33ms時(shí)開(kāi)始移動(dòng),從圖7中看出該時(shí)間點(diǎn)處閥口壓力為0.24MPa,當(dāng)靜摩擦力為20 N時(shí),通過(guò)公式計(jì)算得出該閥芯需0.19 MPa壓力方可啟動(dòng),而AMEsim仿真得出的該閥啟動(dòng)壓力為0.24MPa左右,相差不足30%,由此可以認(rèn)為該二位三通閥的啟動(dòng)壓力約為2.4MPa.

4 結(jié)語(yǔ)

通過(guò)對(duì)該閥的建模與仿真分析得到以下結(jié)論:

(1)0.5MPa氣源壓力條件下,該閥需195ms完成換向,由圖5得出相比較氣源壓力0.6~0.8 MPa時(shí)閥芯的換向速度而言,雖增大工作壓力可以提高換向速度,但由于閥芯A端氣源推動(dòng)力隨之增大,增加氣源壓力對(duì)閥工作時(shí)間影響相對(duì)不大,0.5~0.8 MPa壓力范圍內(nèi)氣源壓力每增加0.1MPa,該閥換向速度加快約13ms.

(2)分析了該二位三通閥于0.5~0.8MPa氣源壓力條件下的質(zhì)量流量、焓流量變化.由圖6、圖7可見(jiàn)質(zhì)量流量與焓流量峰值隨著氣源壓力增大而增大,但其達(dá)到峰值與趨于0點(diǎn)時(shí)間基本沒(méi)有變化.

(3)通過(guò)公式計(jì)算及仿真分析得出,該二位三通閥的啟動(dòng)壓力約為0.24MPa,響應(yīng)時(shí)間約為35ms.

(4)通過(guò)仿真得出該二位三通閥移動(dòng)時(shí)各項(xiàng)參數(shù)變化情況,得出其動(dòng)態(tài)特性,為解決增壓缸增力適應(yīng)行程提供理論指導(dǎo),為進(jìn)一步整體研究增壓缸氣液特性及設(shè)計(jì)制造提供科學(xué)指導(dǎo).

[1]于鴻飛,徐雙用,張遠(yuǎn)深,等.基于AMEsim的氣液增壓缸動(dòng)態(tài)性能分析[J].液壓與氣動(dòng),2015(4):64-67.

YU Hong-fei,XU Shuang-yong,ZHANG Yuan-shen,et al.The s imulation r esearch on d ynamic p erformance of p ressurized g as-liquid c ylinder b ased on AMEsim[J].Chinese Hydraulics and Pneumatics,2015(4):64-67.(in Chinese)

[2]謝建,羅治軍,田桂,等.基于AMEsim的多級(jí)液壓缸建模與仿真[J].機(jī)床與液壓,2010(4):126-129.

XIE Jian,LUO Zhi-jun,TIAN Gui,et al.Modeling and s imulation of t elescopic m ulti-stage c ylinder b ased on AMEsim[J].Machine Tool&Hydraulics,2010(4):126-129.(in Chinese)

[3]郭楠.氣液增壓系統(tǒng)的動(dòng)態(tài)特性分析與優(yōu)化研究[D].北京:北京印刷學(xué)院,2013.

GUO Nan.Syudy on d ynam ic p erformance a nalysis and o ptimization of g as-liquid p ressurization s ystem[D].Beijing:Beijing Institute of Graphic Communication,2013.(in Chinese)

[4]TOSHIHARU K,RYOTA N,MANABU S.Development of a web client server system for pneumatic circuit simulation based on bond graphs[C]//Proceedings of the IEEE International Conference on Systems,2012:5-7.

[5]王成剛,謝小恒,肖健,等.基于AMESim沖擊氣缸二位五通氣控閥的建模與仿真研究[J].液壓氣動(dòng)與密封,2013(1):10-13.

WANG Cheng-gang,XIE Xiao-heng,XIAO Jian,et al.Modeling and s imulation of i mpact c ylinder 5/2-way p neumatic c ontrol v alve b ased on AMESim[J].Hydraulics Pneumatics&Seals,2013(1):10-13.(in Chinese)

[6]趙飛.基于AMESim的氣動(dòng)系統(tǒng)建模與仿真技術(shù)研究[D].秦皇島:燕山大學(xué),2010.

ZHAO Fei.Research on t he m odeling and s imulation of t he p neumatic s ystem b ased on AMESim[D].Qinhuangdao:Yanshan University,2010(in Chinese)

[7]李萬(wàn)德.快速氣液增壓缸的設(shè)計(jì)與應(yīng)用[J].機(jī)床與液壓,2004(2):102-112.

LIWan-de.The d esign and a pplication of s peediness p neumatic-hydraulic Pressure-Cylinder[J].Machine Tool&Hydraulics,2004(2):102-112.(in Chinese)

[8]翟大勇,周志鴻,林嘉棟,等.基于AMESim的壓路機(jī)振動(dòng)液壓系統(tǒng)仿真研究[J].液壓氣動(dòng)與密封,2010(1):13-17.

ZHAI Da-yong,ZHOU Zhi-hong,LIN Jia-dong,et al.Study o n t he h ydraulic s ystem of r oller b ased on AMEsim[J].Hydraulics Pneumatics&Seals,2010(1):13-17.(in Chinese)

[9]趙洪敏.抽油泵柱塞與泵筒摩擦力計(jì)算的討論[J].石油機(jī)械,1993(2):34-37.

ZHAO Hong-m in.Discussion on t he c alculation of f riction b etween t he p ump p lunger and t he c ylinder b arrel[J].China Petroleum Machinery,1993(2):34-37.(in Chinese)

Dynam ic characteristics and simulation of built-in pneumatic control valve of pressure cylinder

WANG Cheng-gang,ZHANG Bo,YAN Fu-rong,HE Fan

School ofMechanical&Electrical Engineering,Wuhan Institute of Technology,Wuhan 430205,China

To solve the problem of pressure cylinder power adaptation,the dynamic characteristics of built-in two-position three-way pneumatic control valve in the pressure cylinder was studied.The built-in pneumatic control valve wasmodeled and simulated by using the pneumatic component design and the hydraulic component design components library of AMEsim software,and the displacement,velocity,mass flow and enthalpy flow of the valve under different working pressures were also analyzed.The results show that the reversing time of valve is about 195 ms when the working pressure is 5 bar,and the valve reversing speed increases 13 ms when the working pressure increases 1bar every time in ranges of 0.5-0.8 MPa;the peak values of mass flow and enthalpy flow of built-in pneumatic control valve increase with air pressure increasing,while the time to peak values and to 0 values have no significant differences.What’smore,the start-up pressure of built-in pneumatic control valve is 0.24MPa,and the response time is about 35 ms.Themathematical results and simulation data remain in an acceptable range,and the results are reliable.

pressure cylinder;AMEsim modeling and simulation;built-in pneumatic control valve,dynamic characteristics

TH138

A

10.3969/j.issn.1674-2869.2015.12.013

1674-2869(2015)12-0060-05

本文編輯:陳小平

2015-10-15

湖北省教育廳2015年科研項(xiàng)目(B2015374)

王成剛(1974-),男,湖南祁東人,副教授,博士.研究方向:應(yīng)力分析、計(jì)算機(jī)測(cè)控技術(shù)、PLC控制;新型化工設(shè)備的研究與開(kāi)發(fā).