混合制冷劑中重烴對天然氣液化流程的影響

賈榮,林文勝

(上海交通大學制冷與低溫工程研究所,上海200240)

Introduction

The fossil fuels such as coal and oil are playing an important role in the industrial development.But with the serious oil crisis and detrimental environmental problem,as the cleanest fossil fuel,the demand of natural gas (NG)is increasing[1].Liquefied natural gas (LNG),which is produced by liquefying NG from atmospheric temperature to-160℃,is one of the most significant forms of transport in the international NG trade[2].Cascade liquefaction process,mixed refrigerant(MR)cycle and expender liquefaction process are the three basic NG liquefaction processes in the world.MR cycle is mostly concerned since its efficiency and simplicity.

In the MR cycle,mixed refrigerant is consisted of nitrogen and hydrocarbons (C1—C5)[3].With different MR components,the performance of the process is different. Many researchers[2-7]have studied the optimization of mixed refrigerant composition.Hatcheretal[8]have compared the optimal parameters(com-pressor outlet pressure,MR composition,etc.)based on different objective function for single mixed refrigerant (SMR)liquefaction process.Alabdulkaremetal[9]have optimized the composition of mixed refrigerants in propane pre-cooled process and compared with the results in other literatures.Xuetal[10]have studied the affections of nitrogen,methane,ethylene,propane andi-pentane concentration for the PRICO natural gas liquefaction process.

Although some publications focus on the MR composition[11-15],there are few papers report the effect of heavy hydrocarbons in MR.For some skid-mounted LNG plants,the customers may use oil injected screw compressors instead of centrifugal compressors or reciprocating compressors.So heavy hydrocarbons,such as butane and pentane are not welcome.This paper meanly reports the influences of the heavy hydrocarbons in MR,and proposes some feasible suggestions to reduce heavy hydrocarbons in MR.

1 Influence of heavy hydrocarbons

1.1 HYSYS model

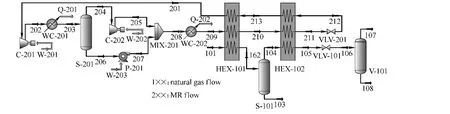

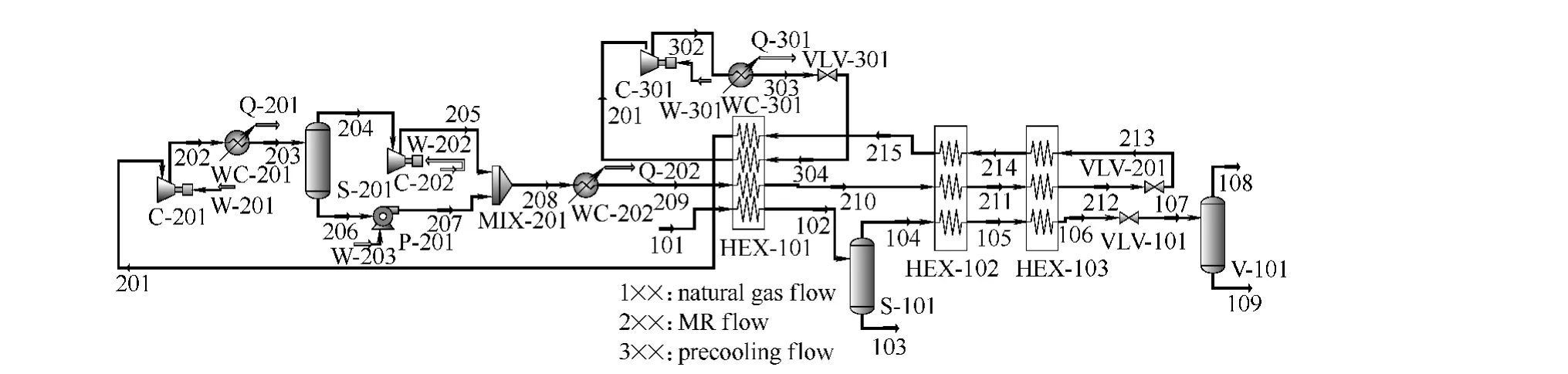

In the small-middle scale LNG plants,SMR liquefaction process is adopted widely.The PRICO process,proposed by Black&Veatch Company in the 1950s,is one of the typical SMR liquefaction processes.Fig.1is the flow sheet of PRICO process modeled by Aspen HYSYS 2006.In this work,the simulations are based on this process.

For the MR flow,MR having returned from the cold box (stream 201)is compressed by the first stage compressor (C-201),through the first condenser (WC-201),MR is partly condensed and then separated in the gas-liquid separator(s-201).The vapor phase (stream 204)is compressed again by the second stage compressor (C-202)and the liquid phase (stream 206)is pumped to the same pressure,and then the two flows is mixed.After condensed by the second condenser (WC-202),MR enters into the cold box(HEX-101, HEX-102)to be precooled.After passing the throttle (VLV-201),MR returns to the cold box to supply cold energy.

Fig.1 Flow sheet of PRICO process

1.2 Simulation conditions

The more MR evaporation curve matches NG liquefaction curve,the smaller minimum temperature approach will be.According to the second law of thermodynamics,with small minimum temperature approach,entropy generation and exergy loss can be reduced.In NG liquefaction process,the temperature of NG varies from atmospheric temperature to-160℃,so the boiling point temperatures of MR components should contain the temperature range.In this work,several kinds of materials among nitrogen and C1—C5are selected to satisfy the requirement.To determine the influence of heavy hydrocarbons,four kinds of MR components have been considered.Each condition is shown in Table 1.In the simulation,the composition of NG is shown in Table 2.

Table 1 Four kinds of MR components

Table 2 Composition of natural gas

Some parameters in the simulation remain constant.For example,the inlet pressure and temperature of NG respectively are 50bar (1bar=105Pa)and 20℃.The outlet pressure and temperature of production are 1.5bar and -162.7℃.The inlet and outlet pressure of MR is 2.5bar and 35bar.Other parameters,such as compressor isentropic efficiency and pressure drop in cold box,are derived from experience and remain constant.

To find the optimal parameters,an objective function is needed.There are many objective functions can be used.For example,to find the optimal operating conditions,minimum specific power consumption,minimum heat duty or minimum MR flow rate can be taken as objective function.in other aspects,minimum UA of cold box can be used as objective function to find the optimal design conditions.In this work,minimum specific power consumption is selected to determine the optimal operating conditions.

Some restricted conditions are carried to achieve optimization of the objective function.

(1)Guarantee MR to be vapored totally before entering into the compressor.

(2)Minimum temperature approach of the first cold box is between 2.8—3.0℃.

(3)Minimum temperature approach of the second cold box is between 2.4—2.5℃.

(4)Keep the liquefaction ratio constant.

1.3 Results and discussions

In each condition,change MR molar flow and the percentage of each component,and the optimal parameters can be reached under the objective function minimum specific power consum-ption.Some operating parameters are demonstrated in Table 3.

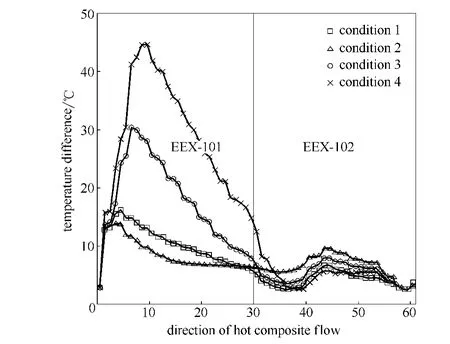

At the same liquefaction ratio,different MR composition makes MR flow and specific power consumption different.Even though minimum temperature approach tends to be the same,the temperature difference over all cold box is distinguishing.Fig.2shows the temperature difference varying with the flow of hot composite.There are two peak values over all the variation.At the beginning of heat exchange between hot and cold composite in HEX-101,temperature difference increases and reaches the highest point.In this process,MR temperature variety curve doesn't match that of NG well.

Table 3 Operating parameters of four conditions

Fig.2 Temperature difference varying with flow of hot composite

Compared with the four curves,the highest point in condition 4is much higher than that in condition 1and 2,and condition 4has the worst temperature matching.This is one reason why condition 4has the highest specific power consumption.

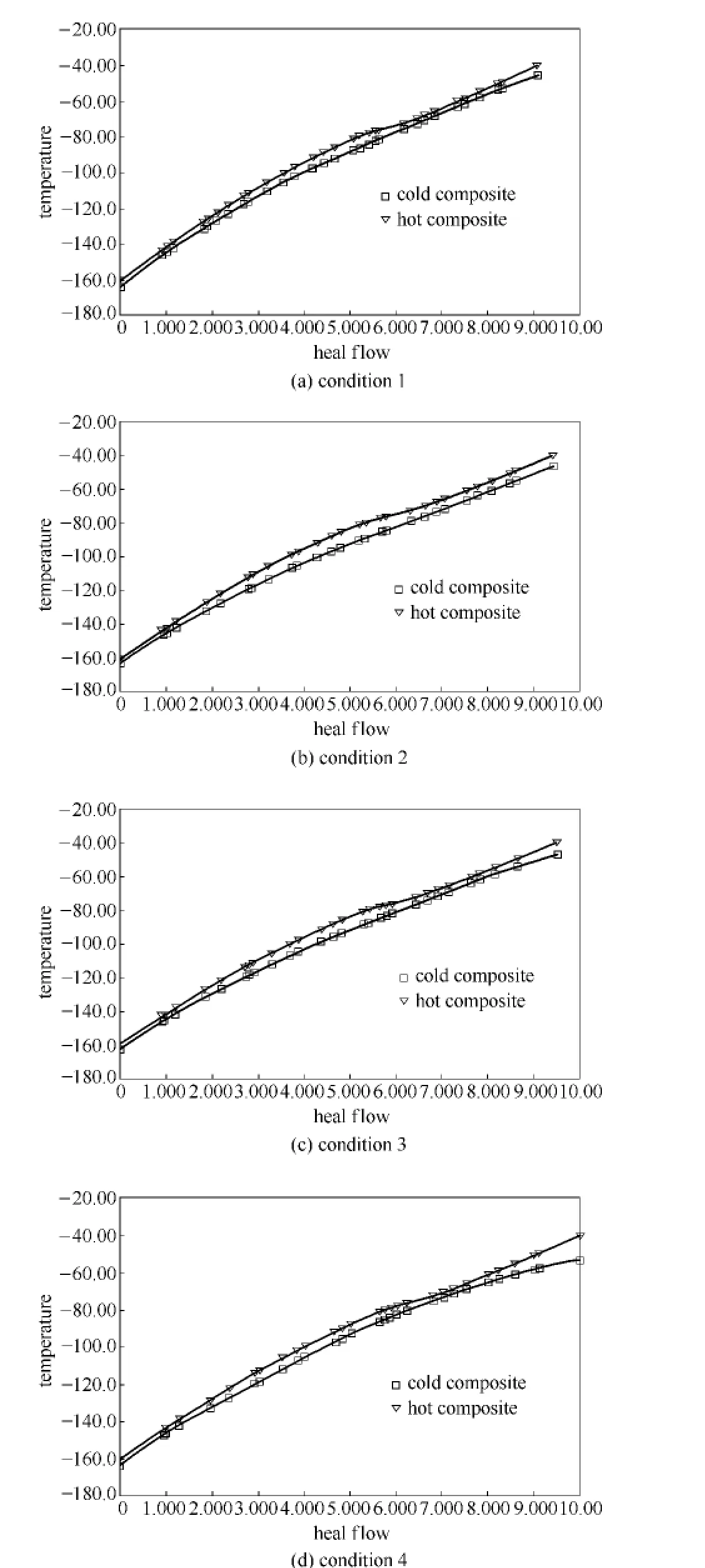

Temperature variety curve of HEX-101is shown in Fig.3 (a)— (d).It is obvious that hot composite has an average temperature drop while cold composite's temperature doesn't vary smoothly.In HEX-102,the variation of temperature difference is gentle.The peak value in HEX-102is much smaller than that in HEX-101.Fig.4 (a)—(d)shows cold and hot composite's temperature variety in the four conditions.All of the temperature curves match well.HEX-101can be taken as precooling section while HEX-102as liquefied section.It's concluded that entropy generation and exergy loss in precooling section are larger than those in liquefied section.

MR molar flow is also one of the factors that affect the specific power consumption.Fig.5 shows the four condition's comparison on MR molar flow.Condition 1needs the least MR flow while condition 4is 18.9%higher than condition 1.MR molar flow of condition 2is less than that of condition 3,which demonstrates thati-butane andi-pentane separately make different contribution on performance of the process.

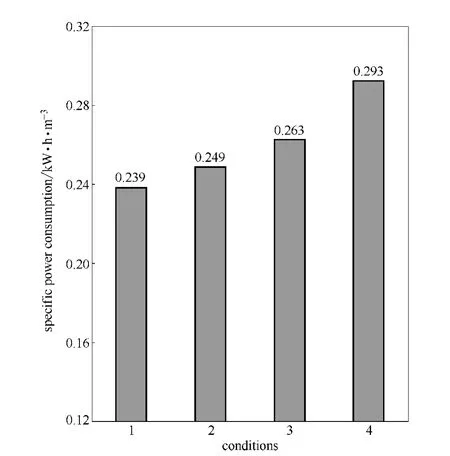

Fig.6clearly gives the specific power consumption of four conditions.Condition 4,in which there is noi-butane ori-pentane,needs to expend the most power among the four conditions while condition 1with bothi-butane andi-pentane perform the best.It is demonstrated that heavy hydrocarbons such as butane and pentane can improve the operating performance of the process and decline the specific power consumption.Compared with condition 4,specific power consumption of condition 1,2and 3respectively decrease by 18.4%,15.0%and 10.2%.Condition 2,only withi-pentane,has lower specific power con-sumption than condition 3,only withi-butane,which is shown that pentane makes more significant contribution on improving the operating performance of the liquefied process.

Fig.3 Temperature variety curve of HEX-101

Fig.4 Temperature variety curve of HEX-102

Fig.5 Comparison on MR molar flow

Fig.6 Comparison on specific power consumption

Considering the thermodynamic properties,the boiling point ofi-butane is-11.85℃,while that ofi-pentane is 27.85℃.Natural gas is cooled with initial temperature 20℃.So there is a better temperature match at the beginning of liquefaction process when mixed refrigerant containsi-pentane and the MR flow can be reduced as a result.In addition,when compressing the mixed refrigerant compositions respectively at the same condition,ipentane consumes the least power,i-butane,propane,ethylene,methane and nitrogen spend more and more power as a sequence.This is another reason that adding heavy hydrocarbons can reduce the specific power consumption.But if the heavy hydrocarbons is added too much,there will contain liquid at the inlet of compressor,and the minimum temperature approach can't reach the requirement.

For some skid-mounted LNG plants,oil injected screw compressors may be used in the process.Heavy hydrocarbonsi-butane andi-pentane are more likely to dissolve in the lubricant.To overcome the problem,MR containing no heavy hydrocarbons can be adopted.

2 Control of heavy hydrocarbons

The results above show that specific power consumption will increase significantly if neither butane nor pentane is included in the mixed refrigerant.To reduce the power consumption,precooling cycle is considered.Fig.7shows the flow sheet of PRICO process with precooling cycle.Three kinds of refrigerants have been used in the precooling cycle,(1)R290,(2)R507,and (3)R407C.The main optimal parameters are shown in Table 4.

The results demonstrate that adding aprecooling cycle can reduce the power consumption in some degree.Compared with condition 4,there is a 12%decline for the process with R290precooling,while the decrease can reach to 13%if the precooling refrigerant is R507or R407C.

Boiling temperatures of R290,known as propane,and R507,an azeotropic mixed refrigerant,are -42.01℃ and -46.7℃ respectively.For R407C,the boiling temperature slips from-43.6℃to 36.1℃since it is a non-azeotropic mixed refrigerant.R290is usually used as the precooling refrigerant in the natural gas liquefaction process,and R507and R407Care considered to replace some other refrigerants such as R22,which is more harmful for the ozone layer.

From the Table 4,it is obvious that the process with R507as precooling refrigerant has the lowest power composition,but the difference of the three materials is very small.

Fig.7 Flow sheet of process with precooling

Table 4 Operating parameters of conditions with precooling

3 Conclusions

In this work,influence of heavy hydrocarbons to the performance of natural gas liquefaction process has been analyzed.The conclusions are as follows.

(1)Heavy hydrocarbons such as butane and pentane can make MR temperature variety curve match that of natural gas well.They have much contribution to the decline of power consumption.For the typical SMR liquefaction process-PRICO process,the specific power consumption can be dropped from 0.293 (MR without C4or C5)to 0.239 (MR with C4and C5),with 18.4%reduction.

(2)C5has greater effect on reducing the power consumption than C4.Compared with condition 4 (MR without C5or C4)respectively,power consumption reduction of condition 2(MR with C5)is 5%larger than that of condition 3 (MR with C4).

(3)Liquefaction process operation with precooling is more economical.With propane precoo-ling,power consumption reduction can reach to 12%.

(4)Since adding aprecooling system to the liquefaction process can reduce the power consumption,the construction cost is also raised.In the engineering project,the factors,for example,the scale of the project,investment cost and operating duration,should be considered fully.Then select the best strategy to maximize the benefits.References

[1] Lin W S,Zhang N,Gu A Z.LNG (liquefied natural gas):a necessary part in China's future energy infrastructure [J].Energy,2010,35 (11):4383-4391.

[2] Cao W S,Lu X S,Lin W S,Gu A Z.Parameter comparison of two small-scalenatural gas liquefaction processes in skid-mounted packages [J].AppliedThermalEngineering,2006,26:898-904.

[3] He T B,Ju Y L.Design and optimization of a novel mixed refrigerant cycle integrated with NGL recovery process for small-scale LNG plant [J].Industrial&Engineering ChemistryResearch,2014,53:5545-5553.

[4] Aspelund A,Gundersen T,Myklebust J.An optimizationsimulation model for a simple LNG process [J].Computers&ChemicalEngineering,2010,34 (10):1606-1617.

[5] Mortazavi A,Somers C,Hwang Y.Performance enhancement of propane pre-cooled mixed refrigerant LNG plant[J].AppliedEnergy,2011,93:125-131.

[6] Khan M S,Lee S,Rangaiah G P,Lee M.Knowledge based decision making method for the selection of mixed refrigerant systems for energy efficient LNG processes [J].AppliedEnergy,2013,111:1018-1031.

[7] Mokarizadeh M,Mowla D.Energy optimization for liquefaction process of natural gas in peak shaving plant[J].Energy,2010,35:2878-2885.

[8] Hatcher P,Khalilpour R,Abbas A.Optimisation of LNG mixed-refrigerant processes considering operation and design objectives [J].Computers&ChemicalEngineering,2012,41:123-133.

[9] Alabdulkarem A,Mortazavi A,Hwang Y.Optimization of propane pre-cooled mixed refrigerant LNG plant [J].AppliedThermalEngineering,2011,31:1091-1098.

[10] Xu X W,Liu J P,Cao L.Optimization and analysis of mixed refrigerant composition for the PRICO natural gas liquefaction process[J].Cryogenics,2014,59:60-69.

[11] Xu X W,Liu J,Cao L,Pang W Q.Automatically varying the composition of a mixed refrigerant solution for single mixed refrigerant LNG (liquefied natural gas)process at changing working conditions [J].Energy,2014,64:931-941.

[12] Nogal F D,Kim J K,Perry S,Smith R.Optimal design of mixed refrigerant cycles [J].Industrial&Engineering ChemistryResearch,2008,47 (22):8724-8740.

[13] Lee G C,Smith R,Zhu X X.Optimal synthesis of mixedrefrigerant systems for low-temperature processes [J].Industrial&EngineeringChemistryResearch,2002,41(20):5016-5028.

[14] Xu X W,Liu J P,Jiang C,Cao L.The correlation between mixed refrigerant composition and ambient conditions in the PRICO LNG process [J].AppliedEnergy,2013,102:1127-1136.

[15] Zhao Min (趙敏),Li Yangzhong (厲彥忠).Analysis for selecting mixed refrigerant composition based on raw natural gas in propane pre-cooled mixed refrigerant liquefaction process[J].JournalofXi’anJiaoTongUniversity(西安交通大學學報),2010,44 (2):108-112.