Mn—Fe—Ce/Al2O3/堇青石催化劑低溫NH3—SCR脫硝性能研究

王寬嶺 王學海 劉忠生

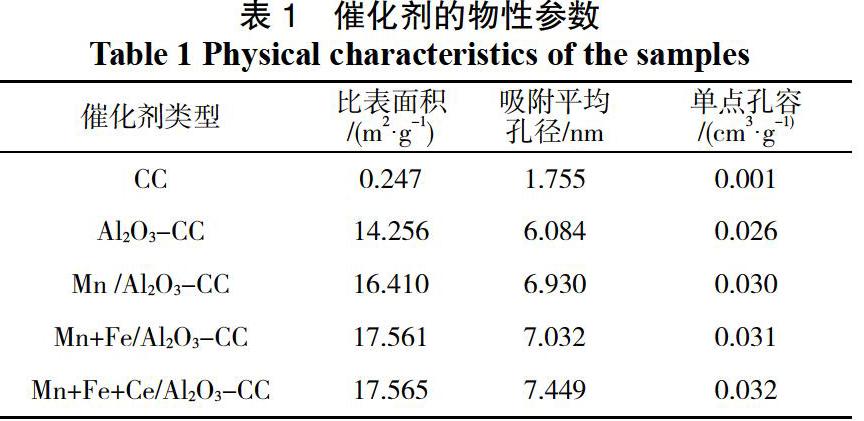

摘 要:先采用溶膠凝膠法在堇青石蜂窩陶瓷載體上涂覆鋁溶膠漿液,再通過浸漬法負載活性組分Mn和助劑,制備了NH3選擇性催化還原NOx低溫脫硝催化劑Mn-Fe-Ce/Al2O3/堇青石,實驗結果顯示:Ce和Fe的添加可以明顯提高催化劑的低溫脫硝活性,在體積空速4 000 h-1時和120 ℃條件下,NO轉化率由86.3%提高到93.5%,并且在120~300 ℃范圍內,NO的轉化率均保持在93%以上。XRD、BET、NH3-TPD和H2-TPR結果表明:Fe和Ce改性后增加了催化劑的比表面積和孔體積、酸性位點、NH3的吸附能力和氧化能力,提高了催化劑的SCR活性。

關 鍵 詞:氮氧化物;選擇性催化還原;催化劑;堇青石

中圖分類號:TQ 426 文獻標識碼: A 文章編號: 1671-0460(2015)09-2057-04

Abstract:Mn-Fe-Ce/Al2O3/cordierite monolithic catalyst was prepared via coating Al sol on honeycomb-like cordierite carrier by sol-gel method, loading Mn and additives by impregnation method. The Mn-Fe-Ce/Al2O3/cordierite monolithic catalyst was used for low-temperature selective catalytic reduction (SCR) of NOx with ammonia. The results show that the activity of the catalyst can be significantly improved after doping Fe and Ce. The conversion of NO can be improved by doping Ce and Fe from 86.3% to 93.5% at 120 ℃ with a gas hourly space velocity(GHSV) of 4 000 h-1. The conversion of NO can be more than 93% at 120~ 300 ℃. The XRD,BET, NH3 adsorption and H2-TPR show that the catalyst after adding proper Ce has larger specific surface area and pore volume, contains more acidic site, which can promote NH3 adsorption and NO oxidation activity. These factors may lead to the increasing of the SCR activity of Mn-Fe-Ce/Al2O3/CC catalyst.

Key words: NOx; Selective catalytic reduction(SCR); Catalysts; Cordierite

來自電廠、工業窯爐及煉廠等固定源排放的氮氧化物(NOx)是主要的大氣污染物之一,會導致酸雨和光化學煙霧的形成,對環境及人體健康產生嚴重的危害[1]。因此,世界各國都制定了嚴格的NOx排放標準。在眾多的NOx去除技術中,氨的選擇性催化還原(NH3-SCR)是應用范圍和去除效果最好的技術之一[2]。NH3-SCR技術的核心是脫硝催化劑。目前,大規模工業化應用的SCR催化劑組成為V2O5-WO3(MoO3)/TiO2(銳鈦礦),其反應活性高且抗二氧化硫性能強,但反應溫度必須控制在320~400 ℃之間[3],難以在煙氣除塵脫硫之后應用,灰塵對催化劑磨損大且安裝運行費用較高。我國現有電廠鍋爐和一些煉廠的余熱鍋爐省煤器和空氣預熱器(催化劑活性溫度區間)間沒有預留空間,改造難度和費用大。除此之外,大量工業鍋爐和窯爐等也是重要NOx排放源,但他們排煙溫度大都在300 ℃以下,限制了主流中溫SCR脫硝技術的推廣。……