水旱兩用秸稈還田組合刀輥作業性能試驗

張秀梅,夏俊芳,張居敏,賀小偉,梁世芳,張 順,吳 昊,萬 松

(華中農業大學工學院,武漢430070)

水旱兩用秸稈還田組合刀輥作業性能試驗

張秀梅,夏俊芳※,張居敏,賀小偉,梁世芳,張 順,吳 昊,萬 松

(華中農業大學工學院,武漢430070)

為了檢測水旱兩用秸稈還田組合刀輥的田間作業質量和功率,采用無線遙測技術,利用動力輸出軸一體化扭矩傳感器,對安裝組合刀輥的耕整機進行了田間作業質量和作業功耗優化參數性能測試試驗,并與傳統旋耕刀輥、螺旋刀輥進行田間作業質量及功耗對比試驗。田間試驗結果表明:組合刀輥性能檢測試驗中,水田和旱地植被埋覆率分別為94.3% 和96.5%,耕深分別為20.8和20.3 cm,耕深穩定性分別為92.3%和90.6%,耕后地表平整度分別為0.9和1.2 cm,功率消耗分別為27.6 和31.2 kW,均達到了設計目標;與其他刀輥對比試驗中,組合刀輥作業質量優于螺旋刀輥和傳統旋耕刀,作業功耗稍高。該研究可為實現水田和旱地高茬秸稈埋覆還田和土壤耕整提供參考。

農業機械;優化;試驗;組合刀輥;秸稈還田;水田旱地;作業性能;功耗

0 引言

機械化秸稈直接埋覆還田有利于提高農田肥力,減少由秸稈焚燒所引起的環境污染,提高土壤有機質含量,降低化肥施用量,實現農業的可持續性發展[1-5]。中國長江中下游地區多為麥-稻、油-稻等水旱輪作種植模式,缺乏與該模式相配套的通用型秸稈埋覆還田機具,“雙搶”期間,農民在作物收獲后不得不直接焚燒秸稈,既污染了環境,又加劇了土壤生態環境的惡化[6-10]。

針對目前中國尚無合適的水旱通用型秸稈還田耕作機具,華中農業大學基于前期研究成果[11-15],研制出了主要由螺旋橫刀和傳統旋耕刀(IIT245旋耕刀)組合而成的水旱兩用秸稈還田組合刀輥[16-17],但其田間作業質量及功耗相較于螺旋刀輥和傳統旋耕刀輥如何有待研究。

作業質量和功率消耗是評價農機具性能最為重要的指標[18-19]。目前國內外對旋耕機作業質量的研究已經很普遍,而且比較成熟;國外農機具田間作業功率的測試主要采用先進的數字遙測測試分析技術,通過數學耦合式傳感器實時采集轉速和扭矩數據。國內對旋耕機作業功耗的研究還比較落后,而且由于田間作業條件的復雜性,進行實際田間作業功耗測試的報道較少,現有研究也主要采用有線傳輸技術測試[19-22],這種方法測試人員需攜帶測試儀器跟隨作業機具一起移動,設備安裝和人員測試條件受到很大限制,在復雜的田間作業條件下存在穩定性和安全性問題,適應性稍差,使用不夠方便。為了更加準確、方便而安全地測試機具田間作業功耗,課題組基于前期研究基礎[23-24]定制了專用的功率無線遙測裝置,該裝置集測量和無線收發技術一體,測試人員不用隨作業機具一起移動,只需在一定范圍內的田邊道路上進行測試,即可實時采集設備的扭矩、轉速及功率數據。

本文對水旱兩用秸稈還田組合刀輥依照國標測試方法進行了一序列田間作業質量和功率測試試驗,并將其同傳統旋耕刀輥和螺旋刀輥進行田間作業質量—功率測試的對比試驗,以期為機具的進一步優化設計和推廣應用提供參考。

1 材料與方法

1.1 試驗刀輥

試驗主要刀輥為水旱兩用秸稈還田組合刀輥,簡稱組合刀輥。該刀輥主要包括刀盤1、傳統旋耕刀2、彎刀3、刀軸4和螺旋橫刀5,結構如圖1所示。組合刀輥排布設計為螺旋橫刀旋轉半徑小于彎刀和傳統旋耕刀的旋轉半徑,保證彎刀和傳統旋耕刀比螺旋橫刀先入土,可降低后續橫刀切土阻力[16]。此刀輥結合了傳統旋耕刀碎土能力強以及課題組研制的螺旋橫刀秸稈埋覆性能好的優點,適用于水田、旱地的高茬秸稈直接埋覆還田耕整作業[17]。

圖1 組合刀輥結構示意圖Fig.1 Structure diagram of combination blade roller

田間作業時,依靠拖拉機三點懸掛機構來控制刀輥懸掛高度,進而控制實際旋耕深度,刀輥軸隨拖拉機直線前進的同時正向旋轉,實現“銑削”土壤和秸稈的切削模式。首先刀盤彎刀和傳統旋耕刀在旋轉中將土壤及植被沿機組前進方向切斷破茬,接著螺旋橫刀在已耕區域內沿橫向整幅切削土壤,同時刀輥在旋轉中將切下的土壤及秸稈向后拋擲,撞擊擋板后落下被壓埋,最后平地裝置將地表拖平[17]。

1.2 功率測試系統

功率測試系統為課題組基于前期對功率測試系統的研究與實際應用情況,聯合黑龍江省農業機械工程科學研究院研制了專用的功率測試裝置-田間機械動力學參數遙測儀之旋轉功率測量模塊,由扭矩輸出軸轉速一體傳感器(轉速測量范圍0~4 000 r/min,精度為±1%F.S.;扭矩測量范圍0~1 000 N·m,精度為±1%F.S.;參數信號最大接收發送距離:100 m)、無線動態數據采集器和采集軟件主機組成。該系統采用Zigbee無線傳輸技術,配套動力輸出軸一體化扭矩傳感器,實現在田間現場接收配套機具的扭矩、轉速、功率等各種動力學信號,并直接處理和分析,實時獲得測試數據。

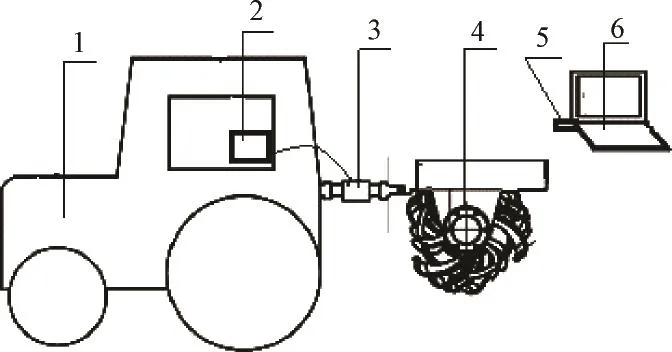

試驗中,首先將傳感器與拖拉機動力輸出軸及被測旋耕刀輥通過萬向節連接在一起;然后用相應的通信線纜,連接傳感器與數據采集器的對應通道接口(扭矩/速度),同時將天線連接到采集器;最后將無線設備通過USB接口連接到主機,主機上測試數據界面顯示傳感器測試的實時數據,如圖2所示。

圖2 功率測試系統安裝示意圖Fig.2 Installation schematic map of power testing system

1.3 試驗參數測定方法與評價指標

試驗條件參照國家標準《農業機械試驗條件、測定方法的一般規定》[25],田間作業質量指標按照國標GB/T5668-2008[26]執行,作業質量評價標準在參照GB/T5668-2008、NYT 499-2002[27]和DB44 T 367-2006[28]的基礎上按照旋耕埋草機的作業質量檢測標準(DB42/T440.1-2007)進行檢測。

1.4 試驗設計與方法

影響旋耕機作業質量和功耗的主要因素有刀輥轉速、機組前進速度、耕深、土質、秸稈茬密度、秸稈茬物理特性和耕整刀結構參數及排列方式等。由于土質、秸稈茬密度、秸稈茬物理特性這些參數受自然條件環境影響較大,屬不可控因素,故在土質、秸稈、刀輥參數相同的情況下,影響組合刀輥作業質量的主要因素有刀輥轉速、機組前進速度和耕深。為明確上述3個因素對作業質量的影響,作業質量用秸稈埋覆率來衡量(90%為合格標準),采用L9(34)正交試驗表對組合刀輥進行正交試驗研究[29],然后根據優化參數進行田間作業性能檢測,最后在相同作業條件下與關鍵作業部件分別為螺旋刀輥及傳統旋耕刀的機具,進行田間作業質量和作業功耗的對比試驗。

2 田間試驗

2.1 正交試驗

2.1.1 正交試驗條件與方法

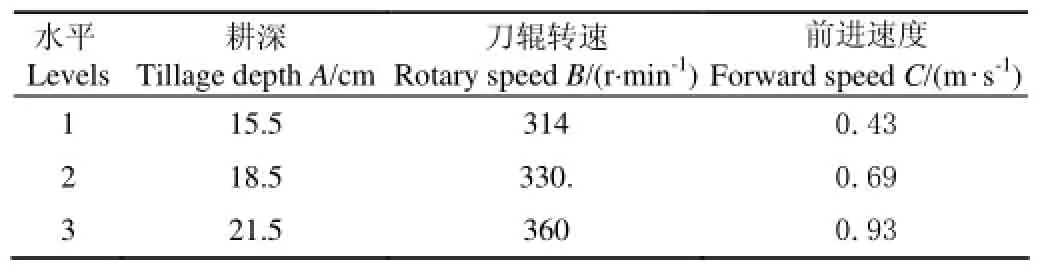

在華中農業大學現代農業科技試驗基地選取晚稻收獲后經過晾曬的高茬水稻田,測得耕作前土壤含水率為36.5%,土壤堅實度為544.5 kPa,秸稈高度35.7 cm,秸稈量660 g/m2。組合刀輥由拖拉機LX954驅動。結合該刀輥前期大量田間試驗實際情況,各因素水平表如表1所示。

表1 正交試驗因素水平表Table 1 Factors level of orthogonal test

2.1.2 較優方案的確定

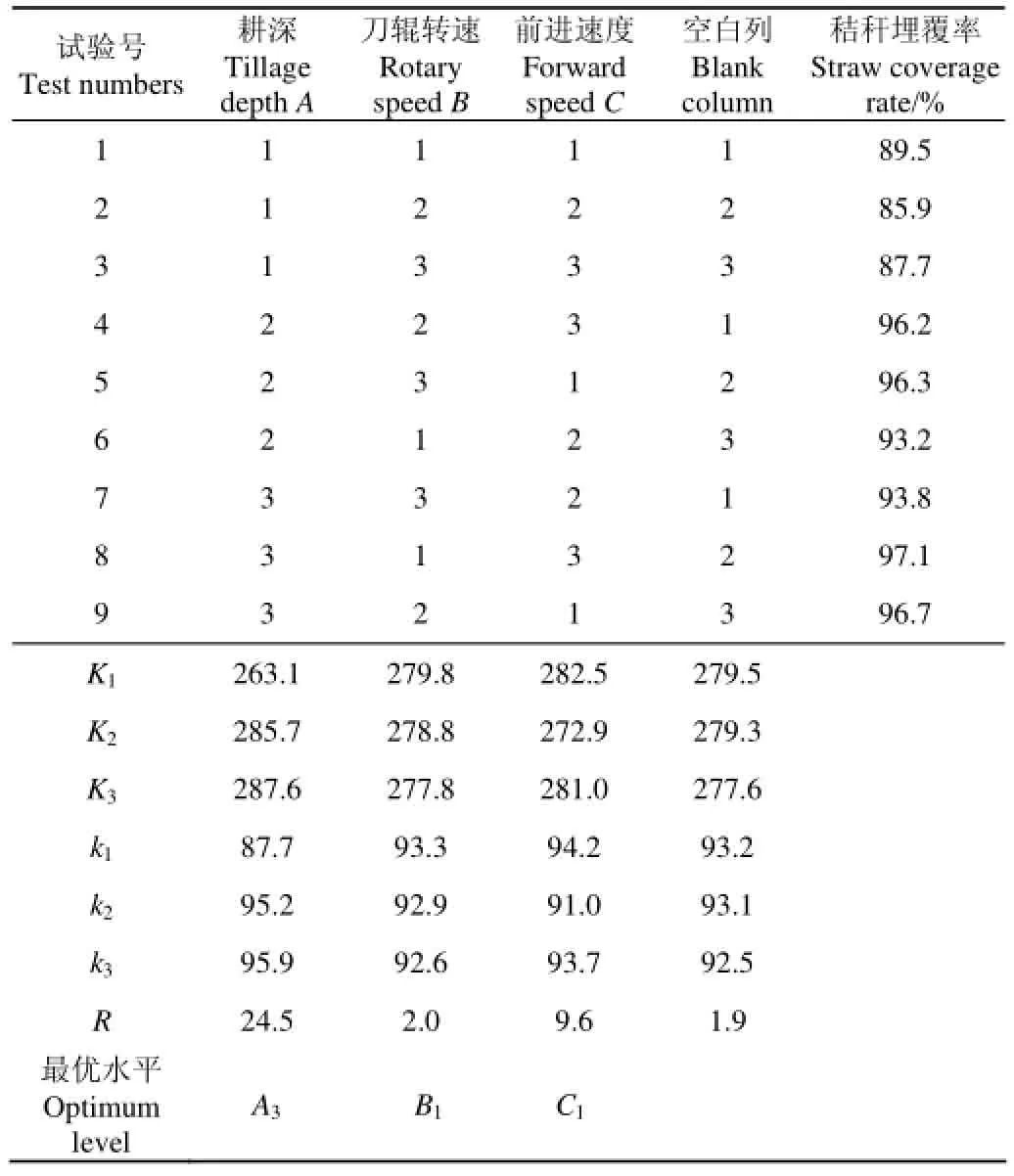

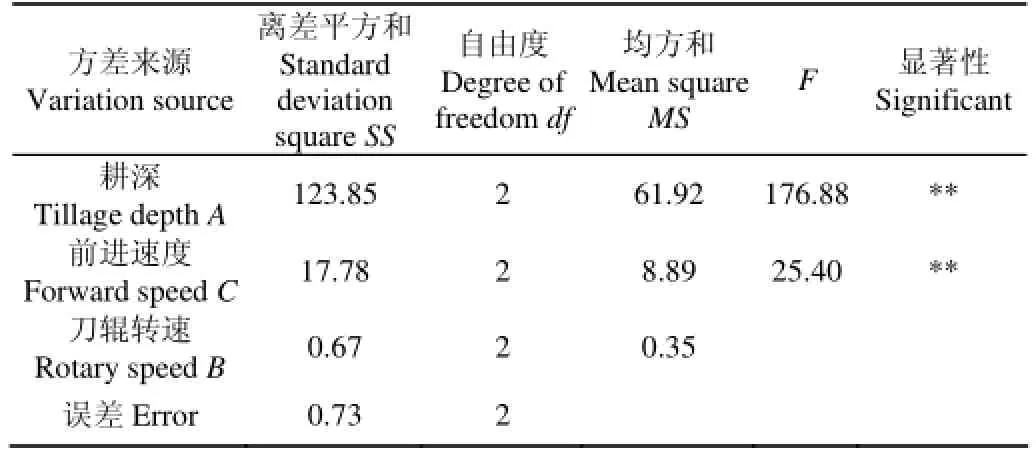

根據上述選定的3因素3水平正交試驗方案及評價指標進行9組試驗,每組試驗重復3次,結果取平均值,方案及結果與極差分析如表2所示。為進一步分析各因素對評價指標的影響顯著性,進行了方差分析,如表3所示。

1)極差與方差分析

試驗指標為秸稈埋覆率越大越好,從表2中可知,影響秸稈埋覆率的各因素從主到次依次為耕深、前進速度、刀輥旋轉速度,最優方案應取各因素最大K值所對應的水平,極差分析得到的最優方案為A3B1C1,即耕深21.5 cm,前進速度為0.43 m/s,刀輥旋轉速度314 r/min。

表2 試驗結果分析表Table 2 Range analysis of experimental results

表3 方差分析結果Table 3 Results of variance analysis for rapeseed seeding quality

表2極差分析得出了耕深、前進速度、刀輥旋轉速度這3個因素對水旱兩用秸稈還田組合刀輥作業質量影響的主次順序及較優水平組合。為進一步分析各因素對各評價指標影響的顯著性,進行了方差分析,由表3得出:耕深和前進速度對秸稈埋覆率影響極顯著,刀輥旋轉速度對秸稈埋覆率影響不顯著。

2)較優試驗方案擬定

作業質量以秸稈埋覆率最高為重點考察目標,確定影響作業質量的主次因素依次為耕深A、前進速度C、刀輥旋轉速度B。極差分析得到的較優組合為A3B1C1,方差分析得到耕深A對秸稈埋覆率影響極顯著,前進速度的影響極顯著,刀輥旋轉速度的影響不顯著。由于因素A最重要,則較優組合中A3因素水平保持不變;因素B影響不重要,加上刀輥轉速提高,有利于土壤的細化、秸稈的攪碎及土壤與秸稈的揉合,故將優方案中因素B1調整為B2,則優方案變為A3B2C1,即正交表中的第9號試驗,秸稈埋覆率達到96.7%;考慮耕整機的作業效率,擬將前進速度分別提高到C2、C3因素水平,優方案變為A3B2C2或者A3B2C3,均不包含在正交表已做的9個試驗中,需要進一步試驗驗證。

3)驗證試驗

在華中農業大學現代農業科技試驗基地選取晚稻收獲后的高茬水稻田,測得耕作前土壤含水率為32.9%,土壤堅實度為893.6 kPa,秸稈高度33.6 cm,田間秸稈平均分布為24墩/m2,18株/墩。組合刀輥由拖拉機LX954驅動,先按照方案A3B2C2,即拖拉機前進速度0.69 m/s,刀輥旋轉速度330 r/min,耕深調至21.5 cm進行田間試驗,重復3個來回行程,然后保持刀輥旋轉速度和耕深不變,將拖拉機前進速度提升至0.93 m/s,重復3個來回行程。試驗結果測得方案A3B2C2秸稈埋覆率為92.2%,方案A3B2C3秸稈埋覆率為90.9%,均達到設計目標要求,但是埋覆效果均差于方案A3B2C1。

4)較優作業參數

綜合上述試驗及前期大量田間試驗結果,該機田間作業的最佳參數范圍為:拖拉機前進速度0.43~0.93 m/s,刀輥旋轉速度330 r/min左右,耕深實測;實際田間作業時,需要根據田間狀態,包括土壤、秸稈或者植被狀態,在上述最佳作業參數范圍內適當調整,一般在旱地作業時前進速度要慢于水田作業。

2.2 性能檢測試驗

2.2.1 試驗條件

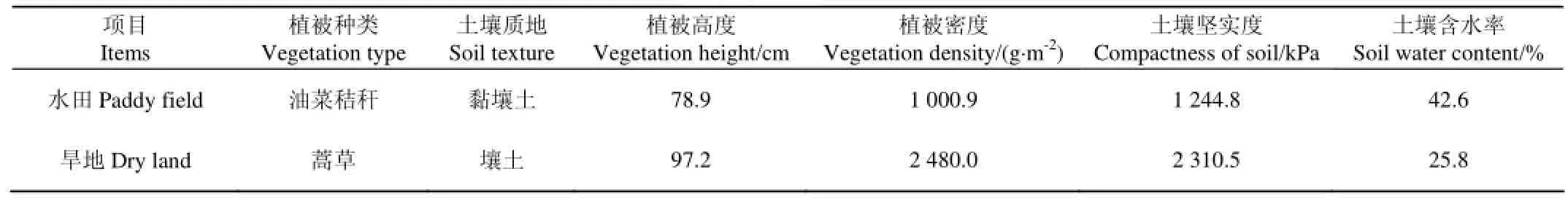

2015年5月23日和24日分別在華中農業大學油菜核心實驗區和玉米試驗地進行水田試驗和旱地試驗,水田試驗田前茬作物為中國廣泛種植的油菜,于2015年5月中下旬收割,耕整前田塊泡水8 h后將水放掉至田面不見明顯的水。旱地試驗地前茬作物為玉米,于2014年10月中下旬收獲后一直處于閑置狀態,屬于中國廣泛存在的冬閑地,耕整前地間長滿雜草類植被,主要為蒿草。測得試驗條件如表4所示。考慮到田塊土壤堅實度較大,加上旋耕機的功率消耗隨著前進速度和刀輥轉速的增加而增大[30],按照上述優化方案初步設定組合刀輥轉速330 r/min,機組前進速度不低于0.43 m/s,以實測為準,進行水田和旱地作業性能測試試驗。

表4 組合刀輥田間試驗條件Table 4 Field conditions during performance test of combination blade roller

2.2.2結果與分析

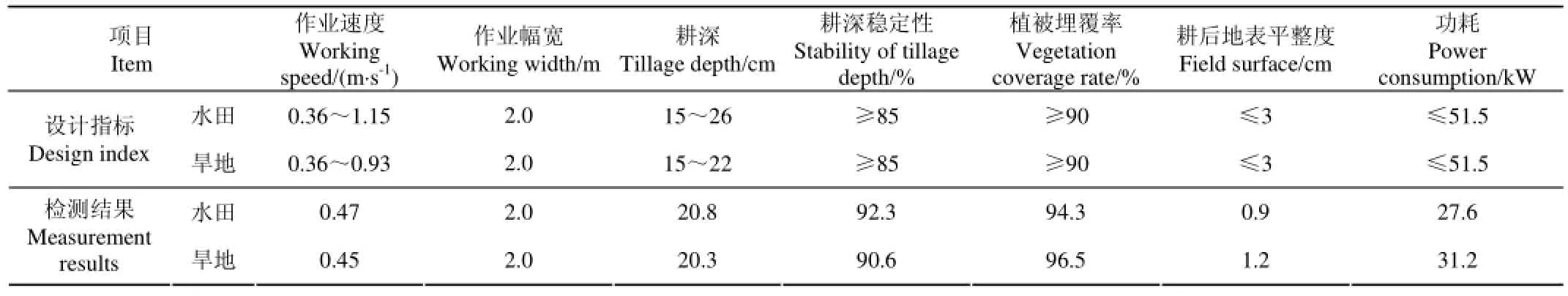

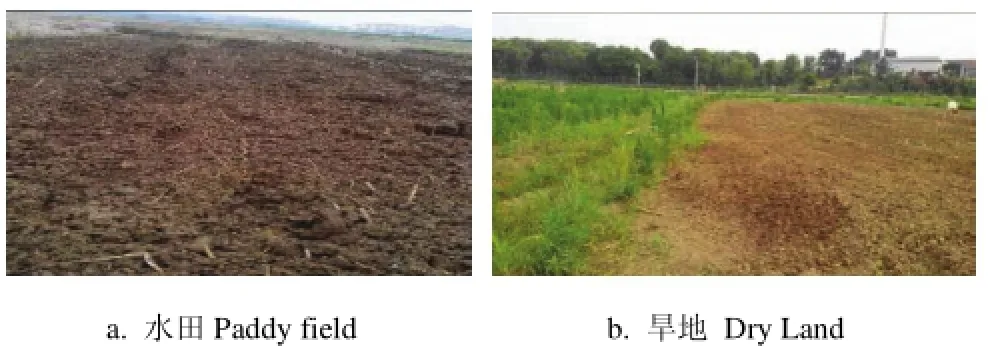

田間作業性能指標與原設計指標對比結果如表5所示,其中測量結果為平均值,耕作效果如圖3所示。

由表4、表5可知:1)水旱兩用秸稈還田組合刀輥對高達78 cm的油菜秸稈和97 cm的蒿草進行水田和旱地埋覆還田試驗,一次作業后耕深分別為20.8、20.3 cm,耕深穩定性分別為92.3%、90.6%,植被埋覆率分別為94.3%、96.5%,耕后地表平整度分別為0.9、1.2 cm,功耗為27.6、31.2 kW,田間作業質量和功耗指標均符合原設計指標,達到了預期設計目標;2)實際水田和旱地作業速度分別為0.47和0.45 m/s,均高于0.43 m/s。但從作業效率來說均偏低,接近下限,主要原因為:水田泡田時間較短,耕作前田間已不見明顯的水,為水田旱耕作業,土壤堅實度較大,加上土壤為黏壤土;旱地土壤堅實度大,而且雜草高而密集,因而作業速度較慢;3)本試驗旱地作業與正交表中第9號試驗的作業速度和刀輥轉速較為一致,但二者田間的土壤及植被差異較大,試驗結果對比:植被埋覆率前者為96.5%,后者96.7%;耕深前者為20.3 cm,后者21.5 cm,較為接近。由此可見,該組合刀輥田間作業適應性較強,可用于不同物理性質的土壤、秸稈及雜草綠肥的田間埋覆還田。

表5 組合刀輥田間作業性能檢測結果Table 5 Measurement results of the working performance of combination blade roller

圖3 組合刀輥耕后效果圖Fig.3 Diagram after tillage of combination blade roller

2.3 對比試驗

2.3.1 試驗條件

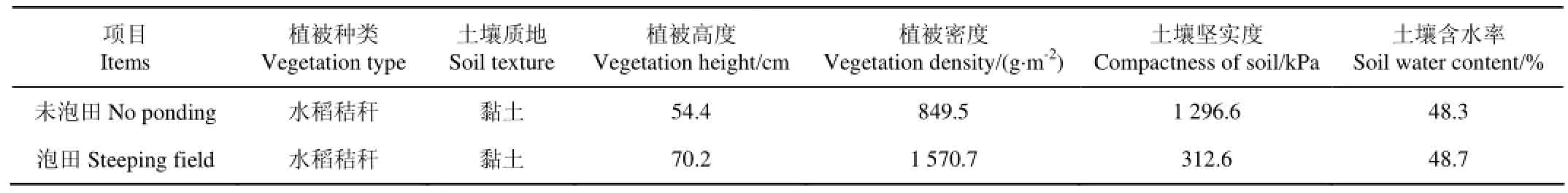

試驗對比刀輥為傳統旱地刀輥、螺旋刀輥及組合刀輥,2015年12月10-12日在華中農業大學水稻核心實驗區選取2塊水稻收獲后閑置的高茬秸稈田塊進行田間作業性能對比試驗,其中田塊1保持水稻收獲后自然閑置狀態,田塊2耕整前放水泡田48 h后將水放掉至田面不見明顯的水,測得試驗條件如表6所示。

鑒于傳統旋耕刀為旱耕刀,其只耕整未泡水田塊,螺旋刀輥和組合刀輥耕整未泡水田和泡水田塊。3種刀輥作業時均為每一前進速度為1個試驗工況,試驗測定3個工況,分別為旋耕常用低1、低2、低3檔[31],具體數值在試驗進行中測定,每個工況測定2個行程,轉速均在260~330 r/min,耕深調整在刀輥作業最大耕深處實測,均由拖拉機LX954驅動。

表6 對比試驗田間試驗條件Table 6 Field conditions during performance test of comparative tests

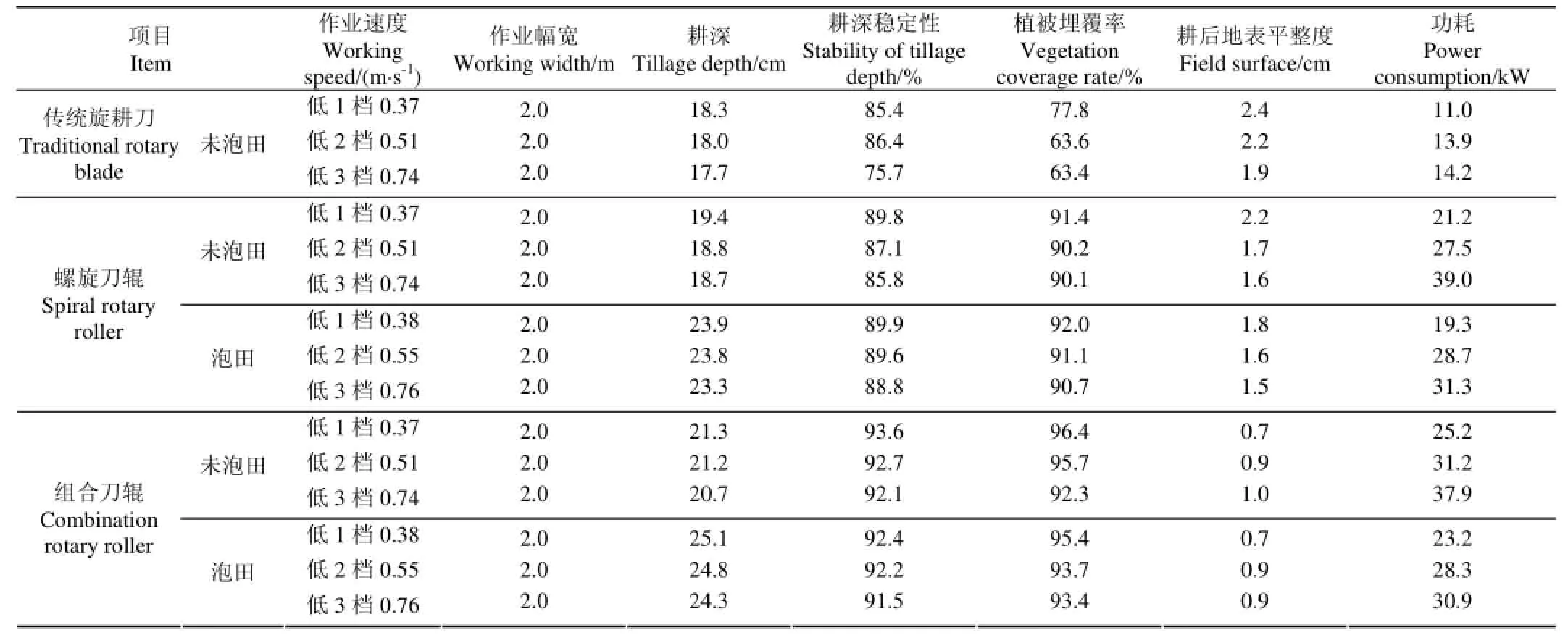

2.3.2 結果與分析

組合刀輥、傳統旋耕刀和螺旋刀輥田間作業對比試驗結果如表7所示,其中測量結果為平均值,耕作效果如圖4所示。

由表7和圖4可知,組合刀輥和螺旋刀輥旋耕后秸稈埋覆率、耕深、耕深穩定性及地表平整度等作業質量指標均高于國標要求,傳統旋耕刀秸稈埋覆率不達標;組合刀輥作業質量最優,但是組合刀輥作業功耗偏高;傳統旋耕刀雖然作業功耗較低,但處理高茬秸稈的能力較差。主要原因有:一、傳統旋耕刀在設計上追求的目標是土壤切削減阻方面以及防止纏草,正切刃的滑切角很大,以及切斷秸稈過程中地面與正切刃之間的夾持角度也很大,會產生“夾不住”秸稈現象,秸稈會在“被夾持”過程中側滑,又由于正切刃刃口比較短,所以秸稈在側滑過程中來不及切斷而滑落,傳統旋耕刀不纏草,不處理秸稈,因而功耗低。螺旋橫刀刃口的滑切角適中,而且螺旋橫刀與地面間的夾角比較小,秸稈在切斷過程中能被地面和螺旋橫刀牢牢地夾持住,即便是夾持不住秸稈而產生側滑,由于螺旋橫刀刃口長而且連續,秸稈在側滑過程中也會被切斷;二、在相同的作業條件下,傳統旋耕刀實際作業最大耕深偏小,作業功耗是隨耕深增加而增大的,通過正交試驗發現秸稈埋覆率也是隨耕深增加而增大。因而對比之下,傳統旋耕刀對秸稈處理能力較差,最大耕深相對較小,功耗相對較低。

組合刀輥結合傳統旋耕刀和螺旋橫刀的優點,具有較高的秸稈埋覆處理和土壤耕整能力,作業性能相對與螺旋刀輥有一定的提高,只是在作業功耗上有待進一步降低。

表7 對比試驗作業性能檢測結果Table 7 Measurement results of the working performance of comparative tests

圖4 對比試驗耕后效果圖Fig.4 Diagram after tillage of comparative tests

3 結論與討論

1)正交試驗結果表明:耕深和前進速度對秸稈埋覆率影響極顯著,刀輥旋轉速度對秸稈埋覆率影響不顯著。組合刀輥最佳作業參數:拖拉機前進速度0.43~0.93 m/s,刀輥旋轉速度330 r/min。

2)性能檢測試驗結果表明:組合刀輥一次作業后,水田耕深達20.8 cm,旱地20.3 cm;水田耕深穩定性達92.3%,旱地90.6%;水田植被埋覆率達94.3%,旱地96.5%;水田耕后地表平整度達0.9 cm,旱地1.2 cm;水田功耗為27.6 kW,旱地31.2 kW,水田和旱地的作業質量和功耗均達到了原設計目標,作業質量滿足GB/T5668-2008規定的性能指標以及后續農藝的要求。

3)性能對比試驗結果表明:傳統旋耕刀雖然作業功耗較低,但作業質量較差,其中植被埋覆率未能達到國標要求;組合刀輥雖然低1及低2檔作業功耗高于其他2種刀輥,但在作業效率較高的低3檔作業時功耗要低于螺旋刀輥,而且作業質量在3種刀輥中是最優的。

組合刀輥能滿足水田和旱地高茬埋覆還田需求,特別能解決水旱輪作區高茬埋覆還田耕作需求問題。針對影響組合刀輥作業質量和功耗的其他因素以及如何達到節能降耗等問題有待于進一步深入研究。

[1] 隋銘明,沈飛,徐愛國,等. 基于北斗衛星導航的秸稈機械化還田作業管理系統[J]. 農業機械學報,2016,47(1):23-28. Sui Mingming,Shen Fei,Xu Aiguo, et al. Precise management system for mechanized straw returning based on BDS[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(1): 23-28. (in Chinese with English abstract)

[2] 余坤,馮浩,李正鵬,等. 秸稈還田對農田土壤水分及冬小麥耗水特征的影響[J]. 農業機械學報,2014,45(10):116-124. Yu Kun, Feng Hao, Li Zhengpeng, et al.Effects of different pretreated straw on soil water content and water consumption characteristics of winter wheat[J].Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(10): 116-124. (in Chinese with English abstract)

[3] 馬欣,周連仁,王曉巍,等. 秸稈對根區土壤酶活性、無機氮及呼吸量的影響[J]. 中國土壤與肥料,2012(4):27-33. Ma Xin, Zhou Lianren, Wang Xiaowei,et al. Effect of straw on enzyme activity, inorganic nitrogen and CO2respiration of root zone soil[J]. Soil and Fertilizer Sciences in China, 2012(4): 27-33. (in Chinese with English abstract)

[4] 胡宏祥,程燕,馬友華,等. 油菜秸稈還田腐解變化特征及其培肥土壤的作用[J]. 中國生態農業學報,2012,20(3):297-302. Hu Hongxiang, Cheng Yan, Ma Youhua, et al. Decomposition characteris-tics of returned rapeseed straw in soil and effects on soil fer-tility[J]. Chinese Journal of Eco-Agriculture, 2012, 20(3): 297-302. (in Chinese with English abstract)

[5] 馮愛青,張民,李成亮,等. 秸稈及秸稈黑炭對小麥養分吸收及棕壤酶活性的影響[J]. 生態學報,2014,35(15):1-12. Feng Aiqing,Zhang Min,Li Chengliang,et al.Effects of straw and straw biochar on wheat nutrient uptake and enzyme activities in brown soil[J].Acta Ecologica Sinica, 2014, 35(15): 1-12. (in Chinese with English abstract)

[6] 陳潔,鄭偉,高浩,等. 多源衛星遙感農作物秸稈焚燒過火區面積估算方法[J]. 農業工程學報,2015,31(3):207-214. Chen Jie, Zhengwei, Gao Hao, et al. Estimation method of straw burned area based on multi-source satellite remote sensing[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(3): 207-214. (in Chinese with English abstract)

[7] 李飛躍,汪建飛. 中國糧食作物秸稈焚燒排碳量及轉化生物炭固碳量的估算[J]. 農業工程學報,2013,29(14):1-7. Li Feiyue, Wang Jianfei. Estimation of carbon emission from burning and carbon sequestration from biochar producing using crop straw in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(14): 1-7. (in Chinese with English abstract)

[8] 趙建寧,張貴龍,楊殿林. 中國糧食作物秸稈焚燒碳釋放量的估算[J]. 農業環境科學學報,2011,30(4):812-816. Zhao Jianning, Zhang Guilong, Yang Dianlin. Estimation of carbon emission from burning of grain cropresidues in China[J]. Journal of Agro-Environment Science, 2011, 30(4): 812-816. (in Chinese with English abstract)

[9] Li Hongyu, Han Zhiwei, Cheng Tiantao, et al. Agricultural fire impacts on the air quality of Shanghai during summer harvesttime[J]. Aerosol and Air Quality Research, 2010, 10(2): 95-101.

[10] 馮偉,張利群,龐中偉,等. 中國秸稈廢棄焚燒與資源化利用的經濟與環境分析[J]. 中國農學通報,2010,27(6):350-354. Feng Wei, Zhang Liqun, Pang Zhongwei, et al. The economic and environmental analysis of crop residues burning and reutilizafion in China[J]. Chinese Agricultural Science Bulletin, 2010, 27(6): 350-354. (in Chinese with English abstract)

[11] 張國忠,許綺川,夏俊芳,等. 1GMC-70型船式旋耕埋草機的設計[J]. 農業機械學報,2008,39(10):214-217. Zhang Guozhong, Xu Qichuan, Xia Junfang, et al. Design of 1GMC-70 ship type rotary tillage buried grass machine[J]. Transactions of the Chinese Society Agricultural Machinery (Transactions of the CSAM), 2008, 39(10): 214-217. (in Chinese)

[12] 余水生. 水田高茬秸稈還田耕整機的研制[D]. 武漢:華中農業大學,2012. Yu Shuisheng. Research and Trial-manufacture of Straw Returning and Tillage Machine for High Stubble Paddy Field[D]. Wuhan: Huazhong Agricultural University, 2012. (in Chinese with English abstract)

[13] 周勇,余水生,夏俊芳. 水田高茬秸稈還田耕整機設計與試驗[J]. 農業機械學報,2012,43(8):46-49,77. Zhou Yong, Yu Shuisheng, Xia Junfang. Design and experiment of cultivator for high straw returning in paddy field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(8): 46-49, 77 (in Chinese with English abstract)

[14] 夏俊芳,賀小偉,余水生,等. 基于ANSYS/LS-DYNA的螺旋刀輥土壤切削有限元模擬[J]. 農業工程學報,2013,29(10):34-41. He Xiaowei, Xia Junfang, Yu Shuisheng, et al. Finite element simulation of soil cutting with rotary knife roller based on ANSYS/LS-DYNA software[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(10): 34-41. (in Chinese with English abstract)

[15] 張居敏,周勇,夏俊芳,等. 旋耕埋草機螺旋橫刀的數學建模與參數分析[J]. 農業工程學報,2013,29(1):18-25. Zhang Jumin, Zhou Yong, Xia Junfang, et al. Mathematical modeling and analysis of helical blade for stubble burying rotary tiller[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(1): 18-25. (in Chinese with English abstract)

[16] 張秀梅,張居敏,夏俊芳,等. 水旱兩用秸稈還田耕整機關鍵部件設計與試驗[J]. 農業工程學報,2015,31(11):10-16. Zhang Xiumei, Zhang Jumin, Xia Junfang, et al. Design and experiment on critical component of cultivator for straw returning in paddy field and dry land[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(11): 10-16. (in Chinese with English abstract)

[17] 張居敏. 水田高茬秸稈旋耕埋覆機理研究[D]. 武漢:華中農業大學,2014. Zhang Jumin. Study on Mechanism of High Stubble Burying Rotary Tiller for Wet Land[D]. Wuhan: Huazhong Agricultural University, 2014. (in Chinese with English abstract)

[18] 龔麗農,高煥文,蔣金琳. 免耕播種機玉米根茬處理裝置作業功耗試驗研究[J]. 農業工程學報,2008,24(7):124-127. Gong Linong, Gao Huanwen, Jiang Jinlin. Experimental study on power dissipation of corn rootstalk treatment device of no-tillage planter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(7): 124-127. (in Chinese with English abstract)

[19] 汲文峰,賈洪雷,佟金. 旋耕-碎茬仿生刀片田間作業性能的試驗研究[J]. 農業工程學報,2012,28(12):24-30. Ji Wenfeng, Jia Honglei, Tong Jin. Experiment on working performance of bionic blade for soil-rototilling and stubble-breaking[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(12): 24-30. (in Chinese with English abstract)

[20] 王志山,夏俊芳,許綺川,等. 船式旋耕埋草機螺旋刀輥作業功耗試驗[J]. 農業機械學報,2010,41(12):44-47. Wang Zhishan, Xia Junfang, Xu Qichuan, et al. Power consumption experiment of rotary tillage and stubble mulch knife roller[J].Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12): 44-47. (in Chinese with English abstract)

[21] 王志山,夏俊芳,許綺川,等. 水田高茬秸稈旋耕埋覆裝置功耗測試方法[J]. 農業工程學報,2011,27(2):119-123. Wang Zhishan, Xia Junfang, Xu Qichuan, et al. Power consumption testing system of high stubble buried device in paddy field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(2): 119-123. (in Chinese with English abstract)

[22] 張居敏,賀小偉,夏俊芳,等.高茬秸稈還田耕整機功耗檢測系統設計與試驗[J]. 農業工程學報,2014,30(18):38-46. Zhang Jumin, He Xiaowei, Xia Junfang, et al. Design and field experiment of power consumption measurement system for high stubble returning and tillage machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(18): 38-46. (in Chinese with English abstract)

[23] 王志山. 基于LabVIEW的船式旋耕埋草機功耗檢測研究[D].武漢:華中農業大學,2010. Wang Zhishan. Research on Power Consumption Detection of Boat-Rotary Tillage and Stubble-mulch Machine Based on LabVIEW[D]. Wuhan: Huazhong Agricultural University, 2010. (in Chinese with English abstract)

[24] 賀小偉. 高茬秸稈旋耕翻埋功耗檢測系統設計與試驗研究[D]. 武漢:華中農業大學,2014. He Xiaowei. Design and Experimental Study of Power Consumption Measurement System for High Stubble Returning and Tillage Machine[D]. Wuhan: Huazhong Agricultural University, 2014. (in Chinese with English abstract)

[25] GB/T 5626—2008. 農業機械試驗條件、測定方法的一般規定[S].

[26] GB/T 5668-2008. 旋耕機[S].

[27] NYT 499-2002. 旋耕機作業質量[S].

[28] DB44/T 367-2006. 南方雙季稻地區水田機械耕整作業技術規程[S].

[29] 李云雁,胡傳榮. 試驗設計與數據處理[M]. 北京:化學工業出版社,2011.

[30] 中國農業機械科學研究院. 農業機械設計手冊[M]. 北京:中國農業科學技術出版社,2007:237-238

[31] 中國一拖集團有限公司. 東方紅—LX954拖拉機使用保養說明書[M]. 洛陽:洛陽大方圖文設計有限公司,2010.

Working performance experiment of combination blade roller for straw returning in paddy field and dry land

Zhang Xiumei, Xia Junfang※, Zhang Jumin, He Xiaowei, Liang Shifang, Zhang Shun, Wu Hao, Wan Song

(College of Engineering, Huazhong Agricultural University, Wuhan 430070)

In transitory and busy farming season, the straw has to be buried in the field whether it’s paddy or dry land. In this study, we designed a straw burying rotary tiller, which can bury crop straw not only in paddy field, but also in dry land. It is suitable for tillage in middle and lower reaches of Yangtze River, where the principal crop rotation is paddy field rice after dry land crop annually. In order to improve the working quality of the cultivating roller for straw returning in paddy field and dry land, the experimental studies have been conducted in the fields. First, L9(34) orthogonal experiment was conducted to research the influence factors of the performance of the cultivator for straw returning. The main influence factors for working quality of rotary tiller were tillage depth, rotary speed and forward speed. The tillage depth of 15.5, 18.5 and 21.5 cm, the rotary speed of 314, 330 and 360 r/min, and the forward speed of 0.43, 0.69 and 0.93 m/s were selected. The results showed that among the above 3 factors the influence order was tillage depth>forward speed>rotary speed. The tillage depth affected straw coverage extremely significantly, the forward speed affected straw coverage extremely significantly, and the rotary speed didn’t affect straw coverage obviously, but it affected soil crushing rate significantly. The better test conditions were shown as below: the forward speed was 0.43-0.93 m/s, the rotary speed was about 330 r/min, and the tillage depth was about 21.5 cm. Based on the better test conditions (the forward speed was selected as 0.43 m/s), the experiments on working performance of cultivator for straw returning in paddy field and dry land were conducted in the fields, and the wireless telemetry technology and the power output shaft torque sensor were used in the study. The results showed that the working qualities of cultivator which met the agro-technical requirement of rice sowing and transplanting were as follows: in paddy field, when the soil texture was clay loam, the soil water content was 42.6%, the height of straw was 78.9 cm, the tillage depth was about 150 mm and the soil compaction value was under 1 244.8 kPa, the vegetation coverage rate reached 94.3%, the tillage depth reached 20.8 cm, the stability of tillage depth was 92.3%, the field surface evenness was 0.9 cm, and the power consumption was 27.6 kW; in dry land, when the soil texture was loam, the soil water content was 25.8%, the height of wormwood was 97.2 cm, the tillage depth was 150 mm and the soil compaction value was under 2 310.5 kPa, the vegetation coverage rate reached 96.5%, the tillage depth reached 20.3 cm, the stability of tillage depth was 90.6%, the field surface evenness was 1.2 cm, and the power consumption was 31.2 kW. At the same time, the comparative tests between the combination blade roller and the spiral blade, the traditional rotary blade were also conducted, in which the new roller was in according with the national standard of the work quality. The results showed that the working quality of the combination blade roller was better than that of the spiral blade and the traditional rotary blade, and the power consumption of the combination blade roller was higher than that of the traditional rotary blade. Based on the above results, further research on the power consumption of the cultivator for straw returning in paddy field and dry land is needed. The results provide the basis for the structure optimization of the cultivator for straw returning and the improvement of its working performance, and also provide a suitable implement to achieve high stubble straw mulching and soil tillage in paddy field and dry land.

agricultural machinery; optimization; experiments; combination blade roller; straw returning; paddy field and dry land; working performance; power consumption

10.11975/j.issn.1002-6819.2016.09.002

S222

A

1002-6819(2016)-09-0009-07

張秀梅,夏俊芳,張居敏,賀小偉,梁世芳,張 順,吳 昊,萬 松. 水旱兩用秸稈還田組合刀輥作業性能試驗[J]. 農業工程學報,2016,32(9):9-15.

10.11975/j.issn.1002-6819.2016.09.002 http://www.tcsae.org

Zhang Xiumei, Xia Junfang, Zhang Jumin, He Xiaowei, Liang Shifang, Zhang Shun, Wu Hao, Wan Song. Working performance experiment of combination blade roller for straw returning in paddy field and dry land[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(9): 9-15. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.09.002 http://www.tcsae.org

2015-08-23

2016-02-23

公益性行業(農業)科研專項經費資助項目(201503136);國家自然科學基金資助項目(51275196);湖北省科技支撐計劃項目資助項目(2015BBA155);湖北省教育廳科學技術研究項目(B2015263)

張秀梅,女,湖北大悟人,博士生,講師,主要從事現代農業裝備設計及測控研究。武漢 華中農業大學工學院,430070。Email:15821588@qq.com

※通信作者:夏俊芳,女,湖北武漢人,教授,博士生導師,主要從事現代農業裝備設計及測控研究。武漢 華中農業大學工學院,430070。Email:xjf@mail.hza.edu.cn