船舶永磁同步推進電動機的基于滑模變結(jié)構(gòu)的SVM—DTC方法

范輝+周志麗+湯天浩

摘要:為解決船舶電力推進系統(tǒng)在螺旋槳負載受到風(fēng)浪干擾時的穩(wěn)定性問題,采用永磁同步電動機(Permanent Magnet Synchronous Motor, PMSM)作為推進電動機,在空間矢量調(diào)制(Space Vector Modulation,SVM)方法和直接轉(zhuǎn)矩控制(Direct Torque Control,DTC)方法的基礎(chǔ)上,提出一種基于滑模變結(jié)構(gòu)的SVMDTC方法.通過

Simulink搭建模型進行船舶工況仿真,對推進電動機的轉(zhuǎn)速和電磁轉(zhuǎn)矩進行分析.仿真結(jié)果表明采用滑模控制的船舶電力推進系統(tǒng)具有很好的靜態(tài)、動態(tài)特性和魯棒性.

關(guān)鍵詞: 船舶電力推進; 永磁同步電動機(PMSM); 空間矢量調(diào)制(SVM); 直接轉(zhuǎn)矩控制(DTC); 滑膜控制

中圖分類號: U665.13

文獻標志碼: A

Abstract: To improve the stability of the ship electric propulsion system when the propeller is suffering wind and wave disturbance, Permanent Magnet Synchronous Motors (PMSMs) are used as propulsion motors, Space Vector Modulation (SVM) method and Direct Torque Control (DTC) method are considered, and the sliding modebased SVMDTC method is proposed. A model is constructed to simulate different working conditions of ships by Simulink, and the rotational speed and the electromagnetic torque of propulsion motors are analyzed. The simulation results prove that the ship electric propulsion system based on sliding mode control is of good static and dynamic characteristics and robustness.

Key words: ship electric propulsion; Permanent Magnet Synchronous Motor (PMSM); Space Vector Modulation (SVM); Direct Torque Control (DTC); sliding mode control

0 引 言

永磁同步電動機(Permanent Magnet Synchronous Motor,PMSM)因其功率密度大和控制簡便等優(yōu)點,逐步取代傳統(tǒng)的電勵磁同步電動機[14],特別是采用永磁材料可以方便地構(gòu)成低速電動機,用作船舶電力推進電動機來驅(qū)動螺旋槳負載[56].隨著大功率變頻器空間矢量調(diào)制(Space Vector Modulation,SVM)技術(shù)和直接轉(zhuǎn)矩控制(Direct Torque Control,DTC)方法的發(fā)展[7],采用SVMDTC技術(shù)能直接控制同步電動機的轉(zhuǎn)矩,具有優(yōu)越的靜、動態(tài)調(diào)速性能[8].然而,船舶航行時會受到風(fēng)浪擾動,也可能遇到螺旋槳受阻或脫落等特殊工況[9],僅采用DTC會因參數(shù)變化和外部擾動加大電動機的轉(zhuǎn)矩脈動,影響系統(tǒng)性能和運行穩(wěn)定.

本文針對上述問題,提出一種基于滑模變結(jié)構(gòu)的SVMDTC方法.引入滑膜控制(Sliding Mode Control,SMC)器來取代DTC中的轉(zhuǎn)速PI調(diào)節(jié)器,構(gòu)成SMC與DTC集成的控制方法,實現(xiàn)船舶PMSM的變頻調(diào)速,并通過建模與仿真,驗證在風(fēng)浪擾動下船舶推進控制的魯棒性.

1 船舶電力推進系統(tǒng)結(jié)構(gòu)與建模

船舶電力推進系統(tǒng)一般由電動機、變流器和螺旋槳負載組成.本文采用PMSM作為推進電動機,通過采用SVM的電壓型逆變器調(diào)速.

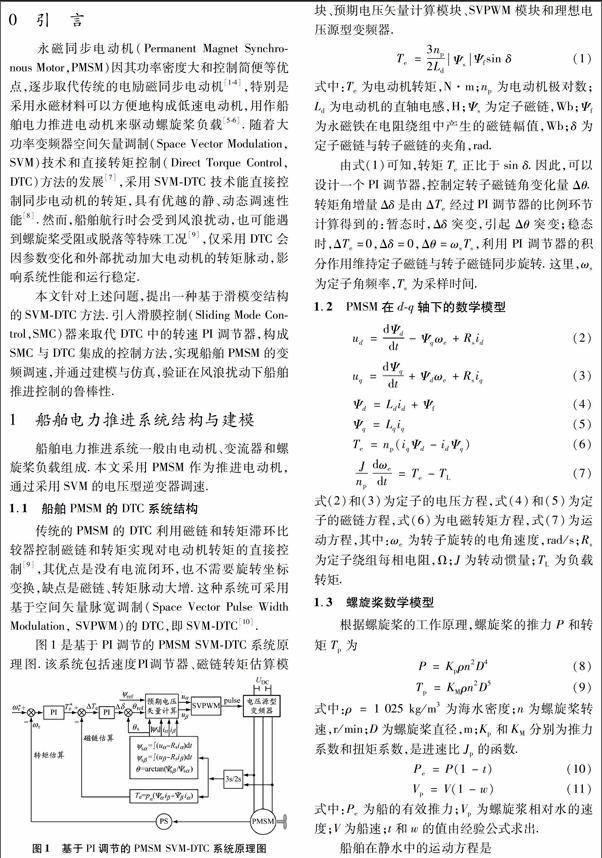

1.1 船舶PMSM的DTC系統(tǒng)結(jié)構(gòu)

傳統(tǒng)的PMSM的DTC利用磁鏈和轉(zhuǎn)矩滯環(huán)比較器控制磁鏈和轉(zhuǎn)矩實現(xiàn)對電動機轉(zhuǎn)矩的直接控制[9],其優(yōu)點是沒有電流閉環(huán),也不需要旋轉(zhuǎn)坐標變換,缺點是磁鏈、轉(zhuǎn)矩脈動大增.這種系統(tǒng)可采用基于空間矢量脈寬調(diào)制(Space Vector Pulse Width Modulation, SVPWM)的DTC,即SVMDTC[10].

由式(22)可知,該速度控制器的輸出為轉(zhuǎn)矩,它的3個分量都經(jīng)過了積分器濾波,這樣可以減弱抖振現(xiàn)象,提高系統(tǒng)的穩(wěn)定性和精確度.

要按照一定的順序設(shè)計SMC器的各參數(shù).首先設(shè)定a和b的值,這是因為從式(22)可以看出a和b是指數(shù),會導(dǎo)致狀態(tài)變量變化迅速.逐漸增大a和b的值直到系統(tǒng)出現(xiàn)抖振,得到a或b的上限值.為防止出現(xiàn)抖振,a和b在這個值的基礎(chǔ)上適當(dāng)減小一點.參數(shù)c作為一個比例系數(shù),會影響系統(tǒng)進入滑模面后的收斂速度.參數(shù) ε和k 分別為變指數(shù)趨近律系數(shù)和變終端吸引趨近律系數(shù),取值不宜過大,否則會增加滑模抖振現(xiàn)象.最后決定參數(shù)p和q的值(與變終端吸引趨近律的收斂時間的關(guān)系比較大).本文選取p=5,q=3,X=x1.

其中c0是常數(shù).由該式可知,因為線性滑模面使x1按指數(shù)趨近于0,所以能夠無超調(diào)地實現(xiàn)速度跟蹤,而當(dāng)系統(tǒng)參數(shù)或者負載發(fā)生變化時,系統(tǒng)運動不會變化,即在SMC下,開關(guān)面參數(shù)可決定系統(tǒng)的品質(zhì),與系統(tǒng)參數(shù)和擾動無關(guān),因此SMC方法具有不可忽略的優(yōu)勢,具有很好的魯棒性和快速性.

綜上,在采用線性滑模面和新型趨近律的SMC下系統(tǒng)能夠?qū)崿F(xiàn)全局穩(wěn)定.

2.3 基于SMCDTC的船舶電力推進系統(tǒng)

圖3是采用SMC器取代PI速度調(diào)節(jié)器的PMSM DTC系統(tǒng)結(jié)構(gòu)框圖,與圖1相比只有轉(zhuǎn)速調(diào)節(jié)器不同,其他模塊都相同.

3 系統(tǒng)建模與仿真

根據(jù)圖3的船舶電力推進控制系統(tǒng),采用Simulink建模,見圖4.船槳模型選取的某實船參數(shù)[5]為:船長為182.6 m,船寬為24.8 m,吃水為5.8 m,方形系數(shù)為0.61,滿載排水量為16 229 t,水線長為168.2 m,螺旋槳直徑為3.6 m.

PMSM的參數(shù)為:定子電阻Rs=0.001 502 Ω;d,q軸電感Ld=Lq=0.476 7 mH;磁鏈Ψa=3.55 Wb;轉(zhuǎn)動慣量J = 550 kg·m2;黏滯摩擦系數(shù)B = 0;極對數(shù)p′=8;額定轉(zhuǎn)速200 r/min,逆變器開關(guān)頻率10 kHz.

SVMDTC的仿真模型如圖5所示,包括坐標變化、磁鏈轉(zhuǎn)矩估算模塊、轉(zhuǎn)速調(diào)節(jié)器、轉(zhuǎn)矩調(diào)節(jié)器、參考電壓生成模塊和SVPWM模塊.轉(zhuǎn)速PI調(diào)節(jié)器比例因數(shù)Kp=40 000,積分因數(shù)KI=20 000,限幅值為195 200×1.5.

基于SMC的轉(zhuǎn)速調(diào)節(jié)器的仿真結(jié)構(gòu)如圖6所示,參數(shù)為a=2.5,b=2.8,c=300,p=3,q=5,X=x1,ε = k=300,限幅值為195 200×1.5.轉(zhuǎn)矩調(diào)節(jié)器的比例因數(shù)Kp=0.01,積分因數(shù)KI=0.01,限幅值為0.1.

仿真試驗的結(jié)果如下:

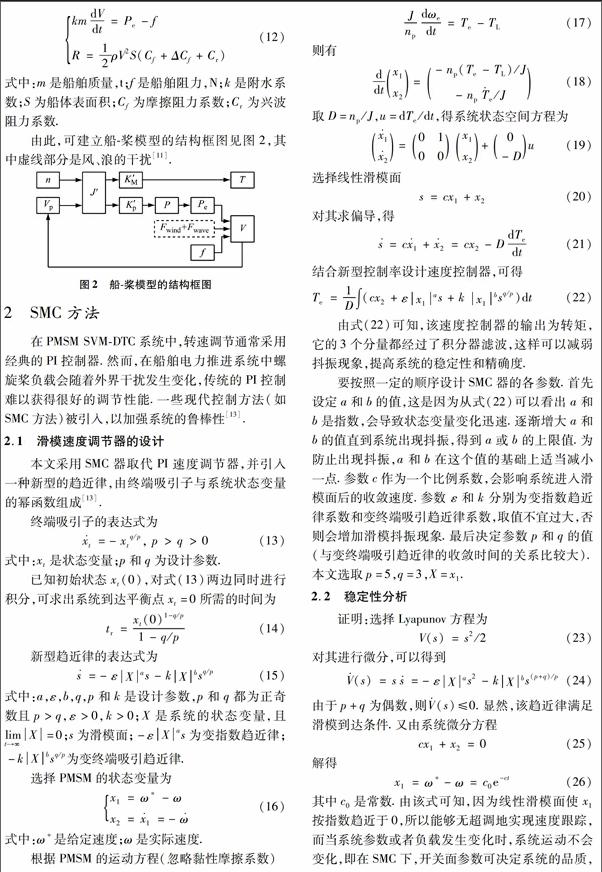

(1)船舶正航,仿真時間設(shè)為10 s, 分三級啟動,給定t=1, 3, 5 s 時轉(zhuǎn)速分別為70, 140, 200 r/min, 仿真波形見圖7.由圖7a)和7b)可以看出,基于SMC的轉(zhuǎn)速響應(yīng)很快,可以準確地跟隨給定轉(zhuǎn)速,且轉(zhuǎn)速最高為200.15 r/min,超調(diào)量較小.然而,在PI控制下,當(dāng)t=5 s時轉(zhuǎn)速為198 r/min,緩慢增至200 r/min.因為螺旋槳負載轉(zhuǎn)矩隨轉(zhuǎn)速變化,采用SMC時,電磁轉(zhuǎn)矩最大值為2.11×105 N·m,比PI調(diào)節(jié)時的最大轉(zhuǎn)矩2.07×105 N·m大,最終都穩(wěn)定在1.92×105 N·m左右,波形放大后發(fā)現(xiàn)采用SMC的轉(zhuǎn)矩脈動小于采用PI調(diào)節(jié)的轉(zhuǎn)矩脈動.

(2)螺旋槳受阻,在t=15,10 s時突加0.5倍的轉(zhuǎn)矩負載,結(jié)果見圖8.

(3)風(fēng)和浪干擾下分級啟動,仿真時間設(shè)為10 s.圖9和10分別為風(fēng)和浪干擾,得到的系統(tǒng)動態(tài)響應(yīng)波形見圖11.

從圖11a)和11b)可以看出:存在風(fēng)浪干擾時,兩種控制下的轉(zhuǎn)速波形都比較穩(wěn)定,說明系統(tǒng)控制效果不錯;PI調(diào)節(jié)器受影響稍大,轉(zhuǎn)速存在比較大的波動,而基于SMC的轉(zhuǎn)速波形比較穩(wěn)定.圖11c)和11d)給出的轉(zhuǎn)矩波形基本一致.

4 結(jié) 論

針對船舶永磁同步電動機(PMSM)在風(fēng)和浪的干擾下驅(qū)動螺旋槳時的轉(zhuǎn)矩波動問題,在空間矢量調(diào)制(SVM)和直接轉(zhuǎn)矩控制(DTC)的基礎(chǔ)上,提出一種基于滑模控制(SMC)的SMCDTC的方法,采用SMC器代替PI轉(zhuǎn)速調(diào)節(jié)器.在SMC中引入新型趨近律設(shè)計SMC器并證明其收斂性.

仿真試驗分析比較了基于SVMDTC和SMCDTC的船舶電力推進系統(tǒng),結(jié)果表明:當(dāng)負載轉(zhuǎn)矩突增或突減時PMSM轉(zhuǎn)速急劇變化;SMC較PI調(diào)節(jié)的轉(zhuǎn)速變化小且調(diào)節(jié)快,轉(zhuǎn)矩脈動也小,動態(tài)性能較好.

由此可知,基于SMC的PMSM SVMDTC系統(tǒng)具有更小的轉(zhuǎn)速超調(diào)和更好的魯棒性,能夠減小轉(zhuǎn)矩脈動,從而提高交流調(diào)速系統(tǒng)的動態(tài)品質(zhì)和船舶電力推進系統(tǒng)的整體性能.

參考文獻:

[1]CHU W Q, ZHU Z Q, CHEN J T. Simplified analytical optimization and comparision of torque densities between electrically excited and permanent magnet machines[J]. IEEE Transactions on Industrial Electronics, 2014, 61(9): 50005011.

[2]ZHU Z Q. Novel permanent magnet machineschallenges and applications[C]//Keynote Speech at International Conference on NdFeB Magnets, Supply Chain, Critical Properties & Applications, March 2014, A03: 110.

[3]HASSANNIA A, DARABI A. Design and performance analysis of superconducting rimdriven synchronous motors for marine propulsion[J]. IEEE Transactions on Applied Superconductivity, 2014, 24(1): 200207.

[4]GAMBLE B, SNITCHLER G, MACDONALD T. Full power test on a 36.5 MW HTS propulsion motor[J]. IEEE Transactions on Applied Superconductivity, 2011, 21(3): 10831088.

[5]馬偉民. 艦船綜合電力系統(tǒng)中的機電能量轉(zhuǎn)換技術(shù)[J]. 電氣工程學(xué)報, 2015, 10(4): 310.

[6]湯天浩. 船舶電力推進系統(tǒng)[M]. 北京: 機械工業(yè)出版社, 2015: 174177.

[7]BERNERT S. Development of high power converters for industry and traction applications[J]. IEEE Transactions on Power Electronics, 2000, 15(6): 11021117.

[8]ZHONG L, RAHMAN M F, HU W Y. Analysis of direct torque control in permanent magnet synchronous motor drivers[J]. IEEE Transactions on Power Electronics, 1997, 12(3): 528535.

[9]LI D, WANG Z, CHI H. Chebyshev fitting way and error analysis for propeller atlas across four quadrants[J]. Journal of Marine Science and Application, 2002, 1(1): 5259.

[10]SWEIERCZYNSKI D, KAZMIERKOWSKI M P. Direct torque control of Permanent Magnet Synchronous Motor (PMSM) using space vector modulation (DTCSVM) simulation and experimental results[C]//28th Annual Conference of the IEEE Industrial Electronics Society, 2002(1): 751755.

[11]HUANG H, SHEN A D, CHU J. Research on propeller dynamic load simulation system of electric propulsion ship[J]. China Ocean Engineering, 2013, 27(2): 255263.

[12]HUNG J Y, GAO W, HUNG J C. Variable structure control: a survey [J]. IEEE Transactions on Industrial Electronics, 1993, 40(1): 222.

[13]KAWAMURA A, ITOH H, SAKAMOTO K. Chattering reduction of disturbance observer based sliding mode control[J]. IEEE Transactions on Industry Applications, 1994, 30(2): 456461.

(編輯 趙勉)